The UM18-22 is a Dayton product, made in China, Eminence is made in the USA.

Sorry, don't know what I was thinking.

If you haven't gotten hornresp to kick out a vented alignment you like, the PE site has this:

Recommended sealed volume is 4.2 cubic feet which will provide an F3/F10 of 32 Hz/18 Hz respectively.

Vented is very large and only recommended in home theater applications for ultra low tuning. Vb: 12.1 cubic feet tuned to 15 Hz with an 8" diameter port that is 43.5" long.

Recommended sealed volume is 4.2 cubic feet which will provide an F3/F10 of 32 Hz/18 Hz respectively.

Vented is very large and only recommended in home theater applications for ultra low tuning. Vb: 12.1 cubic feet tuned to 15 Hz with an 8" diameter port that is 43.5" long.

Hi jbell,

Looks like we got the size for the BR and the port just about right. Now it's just a matter of making it fit the cubby hole. Have you ever done any work on jet port as described by JBL? I have simulated them in Hornresp, but don't know what to think.

Have you ever done any work on jet port as described by JBL? I have simulated them in Hornresp, but don't know what to think.

Regards,

Looks like we got the size for the BR and the port just about right. Now it's just a matter of making it fit the cubby hole.

Regards,

Last edited:

Hi,

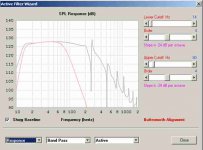

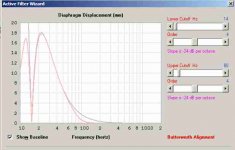

Just thought I'll post the Jet Port BR simulation, sure would be nice to know how far you can take that method without choking the port.

Regards,

Just thought I'll post the Jet Port BR simulation, sure would be nice to know how far you can take that method without choking the port.

Regards,

Attachments

How reliable are the Dayton specs? If this thing really can go to 22mm of xmax you could raise your power level even more. Of course, this is all theoretical without having it built and tested and who knows how much you'll lose from power compression.

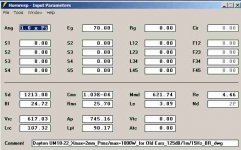

I would build a double driver box on location because getting into the organ chamber is a little narrow. There's plenty of room to build once you get up there. A 4x4x2 box sims really well using a shelf port.

I would build a double driver box on location because getting into the organ chamber is a little narrow. There's plenty of room to build once you get up there. A 4x4x2 box sims really well using a shelf port.

Attachments

Last edited:

Hi Old Ears,

Your drawing from Post #65 looks fine, I have not had the time to put the numbers into a spreadsheet, or into a drawing. I also don't have a drawing for the driver, so I may make one up starting with the SI HT18" that I drew recently. The port length as shown should include the turn around the corner, there should be an inlet/board stiffener that would add to the length of the port,and a center divider that runs the length of the port; this provides at least a little bit of an inlet flare, there should be an outlet flare of some kind (see link: Post #39, Port Flares). You need some bracing/stiffeners on all boards. The front baffle should be build up from at least two layers of material. All this, and the displacement caused by the drivers, has to accounted for, or your initial attempt will not be close enough.

4x4x2' gives you Vgross_external=32ft^3[906L], by the time you subtract all volume losses you should be close. Have you decided on a material? For anything moveable I'd suggest a decent void-free plywood. For a permanent installation 2x4s and MDF should be fine. Don't skimp on the bracing.

Regards,

Your drawing from Post #65 looks fine, I have not had the time to put the numbers into a spreadsheet, or into a drawing. I also don't have a drawing for the driver, so I may make one up starting with the SI HT18" that I drew recently. The port length as shown should include the turn around the corner, there should be an inlet/board stiffener that would add to the length of the port,and a center divider that runs the length of the port; this provides at least a little bit of an inlet flare, there should be an outlet flare of some kind (see link: Post #39, Port Flares). You need some bracing/stiffeners on all boards. The front baffle should be build up from at least two layers of material. All this, and the displacement caused by the drivers, has to accounted for, or your initial attempt will not be close enough.

4x4x2' gives you Vgross_external=32ft^3[906L], by the time you subtract all volume losses you should be close. Have you decided on a material? For anything moveable I'd suggest a decent void-free plywood. For a permanent installation 2x4s and MDF should be fine. Don't skimp on the bracing.

Regards,

Last edited:

Hi,

Just thought I'll post the Jet Port BR simulation, sure would be nice to know how far you can take that method without choking the port.

Regards,

Don't know, my only experience with severe port compression was when I applied the bass reflex rule-of-thumb to a couple of McCauley 6174-8 MLTLs back when this was the Xmax ‘king’ by a wide margin and wound up with the mean area = to Small's 4.5% vent mach minimum.

Dual UMs @ 22 mm = 99.26"^2/640.386 cm^2, but your mean is only [400*800]^0.5 = ~565.685 cm^2, so too small for me.

GM

Don't skimp on the bracing.

As much as I hate working with MDF, this beast will never be seen so that's the way I'll go. I'm also thinking about a double layer for the entire box. The thought that 1 1/2" of MDF could flex is disturbing, but so is the fact that you could wire both speakers in series and just plug it into the wall for some serious 60Hz.

Steve

Well, a 14 Hz sine wave is ~1130 ft/14 Hz = ~80.7 ft in circumference, so your relatively tiny speaker has to do some serious huffing n' puffing to pump it out at ~ 4.0 AW and to keep it from requiring any more electrical power/excursion than necessary, an extremely rigid/massive construction is a good plan.

GM

GM

So wait, you could hear directly how clean your mains supply is?

Cool.

If this does become reality I will be SO tempted to do this. I've just got to be sure to use a long extension cord as standing right next to the cabinet might be a little frightening (ear protection doesn't help much with bone conductance).

Years ago I did have one of the large power supply filter caps in an old Peavey CS-400 amplifier internally short out causing the amp to go full power at 60hz. Luckily the amp was slightly underrated for the speakers, so no damage was done. It was powering 4 Peavey SP-1s at the time. Sure was loud.

Steve

Hi,

On the updates again, I've updated to most version from V8.4 on to now, and had no problems. You can always rename your old Hornresp folder, and have the update create a new one, then copy the old .dat file(s) into the new folder. That way you have a backup.

Regards,

On the updates again, I've updated to most version from V8.4 on to now, and had no problems. You can always rename your old Hornresp folder, and have the update create a new one, then copy the old .dat file(s) into the new folder. That way you have a backup.

Regards,

Last edited:

Speaking of isobaric, double the drivers and power for the same output...Speaking of box volume: isobaric.

Hi Y'all,

Well, it's the international day of labor, so I took some of my sitting around time to take a stab at a 2D drawing of the Dayton UM 18-22, and at a BR enclosure using Old Ears' outside dimensions.

Looking at it for a little while, I arrived at a more symmetrical layout w/ the port inbetween the drivers, this should also split up, and support the large side panels.

At the port inlet (inside) I added 2x4s (1.5"x3.5") to help support the edges of the port, there are two port divider braces running the length of the port, and all the way against the rear panel.

Additional 2x2 (1.5"x1.5") braces help to support the large panels. The drivers are mounted on a three board thick baffle that is set back to provide room for the diaphragm to move to its forward excursion limit.

From my experience I lean towards panel bracing and cross-bracing over additional wall thickness. If additional wall thickness is desired it may be a good idea to go w/ void-free plywood instead of MDF. MDF adds a lot of weight to a given panel, but its stiffness increase is not as high as that of plywood (which is also lighter); so doubled MDF panels will not raise the panel resonance as much as doubled plywood would; others have suggested using plywood inside, and MDF outside (North Creek?).

The nominal cutout diameter is 17", this needs to be checked on the real thing, as it looks like a smaller cutout circle might work for mounting from the front.

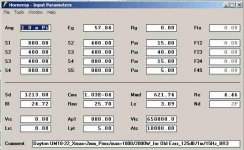

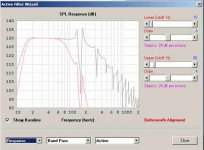

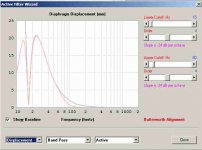

I subtracted all volume losses caused by drivers, port and braces to get the attached Hornresp simulation.

IF this driver actually becomes available, and IF the T/S parameters are as presently stated (or close) this Dual Driver BR should get to the target of 125dB/1m/15Hz/1xPi. In 2xPi it clocks in @ 122.94dB/16Hz - taking 4dB off for power compression and losses we get 118.94dB/16Hz.

That would put it into an exclusive club, even the best systems on data-bass.com do not get higher, the Gjallarhorn comes close @ 118.3dB/16Hz, the DTS-10 LMS-R falls of another 2.3dB. Naturally, these are actual measurements in a 2xPi environment.

Hope somebody gets to build this.

Regards,

Well, it's the international day of labor, so I took some of my sitting around time to take a stab at a 2D drawing of the Dayton UM 18-22, and at a BR enclosure using Old Ears' outside dimensions.

Looking at it for a little while, I arrived at a more symmetrical layout w/ the port inbetween the drivers, this should also split up, and support the large side panels.

At the port inlet (inside) I added 2x4s (1.5"x3.5") to help support the edges of the port, there are two port divider braces running the length of the port, and all the way against the rear panel.

Additional 2x2 (1.5"x1.5") braces help to support the large panels. The drivers are mounted on a three board thick baffle that is set back to provide room for the diaphragm to move to its forward excursion limit.

From my experience I lean towards panel bracing and cross-bracing over additional wall thickness. If additional wall thickness is desired it may be a good idea to go w/ void-free plywood instead of MDF. MDF adds a lot of weight to a given panel, but its stiffness increase is not as high as that of plywood (which is also lighter); so doubled MDF panels will not raise the panel resonance as much as doubled plywood would; others have suggested using plywood inside, and MDF outside (North Creek?).

The nominal cutout diameter is 17", this needs to be checked on the real thing, as it looks like a smaller cutout circle might work for mounting from the front.

I subtracted all volume losses caused by drivers, port and braces to get the attached Hornresp simulation.

IF this driver actually becomes available, and IF the T/S parameters are as presently stated (or close) this Dual Driver BR should get to the target of 125dB/1m/15Hz/1xPi. In 2xPi it clocks in @ 122.94dB/16Hz - taking 4dB off for power compression and losses we get 118.94dB/16Hz.

That would put it into an exclusive club, even the best systems on data-bass.com do not get higher, the Gjallarhorn comes close @ 118.3dB/16Hz, the DTS-10 LMS-R falls of another 2.3dB. Naturally, these are actual measurements in a 2xPi environment.

Hope somebody gets to build this.

Regards,

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Reproducing a 16Hz pipe organ note