Monitoring trafo temp meanwhile too..

IMG-ac3c4856de88172215abbe7bcf1b0518-V — ImgBB

I'm so grateful for having you all here btw.. leading me on the way when needed.. I wish I could drink that beer with you somewhen..

Crazy times..

IMG-ac3c4856de88172215abbe7bcf1b0518-V — ImgBB

I'm so grateful for having you all here btw.. leading me on the way when needed.. I wish I could drink that beer with you somewhen..

Crazy times..

Last edited:

At 70˚C now. But I'm going to lift them up tomorrow.

Meanwhile thinking of heat-resistant spacers/standoffs which also insulate more or less the heat and don't transfer it that much onto the chassis. (I don't want to use small wooden spacers, they just get loose with time, whereas metal transfers heat).

Meanwhile thinking of heat-resistant spacers/standoffs which also insulate more or less the heat and don't transfer it that much onto the chassis. (I don't want to use small wooden spacers, they just get loose with time, whereas metal transfers heat).

Last edited:

These spacers are not so critical. Just left the space between chassis and sockets couple of mm (for air moving from inside of the chassis to outside). The most of heat to the chassis will be transferred through the heat radiation from the tubes itself. When biased to 200mA the plate (anode) temp will arise to 280-290 deg C. Venting the tubes does not help like vacuum is the best insulator and the only way the heat can leave is radiating...

So, be careful with distances between 6C33 tubes. The minimum is at least 50mm. If you install them closer to each other they will start to overheat each other and this could cause the thermal "runaway". 50mm is safe distance.

So, be careful with distances between 6C33 tubes. The minimum is at least 50mm. If you install them closer to each other they will start to overheat each other and this could cause the thermal "runaway". 50mm is safe distance.

Lift the sockets up. Like insert M4 bolts in mounting holes or something to lift them and grant the air access to the socket bottom. Othervise you can easily overheat the contacts and socket itself as well.

yes....two 4mm nuts, washers and lock nuts is ample spacer...

These spacers are not so critical. Just left the space between chassis and sockets couple of mm (for air moving from inside of the chassis to outside). The most of heat to the chassis will be transferred through the heat radiation from the tubes itself. When biased to 200mA the plate (anode) temp will arise to 280-290 deg C. Venting the tubes does not help like vacuum is the best insulator and the only way the heat can leave is radiating...

So, be careful with distances between 6C33 tubes. The minimum is at least 50mm. If you install them closer to each other they will start to overheat each other and this could cause the thermal "runaway". 50mm is safe distance.

do not skip the 72 hours preconditioning testing for your 6c33 tubes

I didn't. Sockets, etc.. all good.

To everyone: what are the average temps in a tube amp for transformers ? Either OTs or power transformers. I see much more crowded designs than what mine will be and still I'm paying attention to heat and a natural air circulation, so what's considered fully OK for a transformer ? click

Voltages across these pots is not big but RV3 sits at about -400V relative to GND, so keep away from chassis ...

How did you solve this ? Simple hole on the panel and then approaching the pot with a simple precision screwdriver, or what would be a good practice for that ?

- on one hand protecting myself of that potencial difference while missing the pot with the metal tip of the screwdriver which might randomly touch the grounded chassis as well (through the hole)

- on the other hand, ease of adjustment

what are the average temps in a tube amp for transformers ? Either OTs or power transformers[/URL]

wrong question ...

a legitimate question would be: what is the upper temperature limit ...

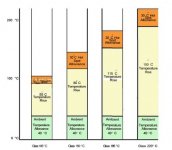

there are standards for the max insulation temp in transformers below 10kVA and which one applies to yours should be printed on the trafo label:

look for something like EN61558 and UL506 / Class 105;

Insulation Temperature Class 105 is the lowest and means that the hottest spot in the windings shall not exceed 105C based on 40C ambient, 55C temp rise, +10C allowance for hottest spot.

Higher classes exist (attached).

Can we measure the rise in temperature inside a transformer winding ?

Yes, we can. Well, at least the average temperature.

The temperature coefficient of copper is a little less than 0.4% per deg C.

This means that a 55 deg rise corresponds to 0.004 x 55 = 0.22.

Thats a 22% increase in DC resistance of the primary and easy to measure.

Attachments

Last edited:

If you can't touch a transformer without it getting painful I'd fit a fan as a precaution. I did this on one of my amps as the chassis was too hot to touch and the toroid tfmr was getting a bit too hot for my piece of mind. smell is a good indicator too;if you can smell scorching/burning, act, you don't want all your hard work going up in smoke or yourself or the house come to that.

I got some fans from here - Quiet Computer Fans for a Virtually Silent PC

Andy.

I got some fans from here - Quiet Computer Fans for a Virtually Silent PC

Andy.

Mine is a custom wound one (all of them), with mandatory CE label and some basic info about primary, secondaries.. (voltage, current).

Additional info I know because I asked for:

- 5% underexcited ? (not sure what's the term in English - it did cost me about 1.5x of normal price. It means the transformer approaches saturation a bit later with excess load while running cooler and more safe on normal load)

- it has a built-in thermal switch, calibrated to 130˚C.

- yesterday I put the transformer into its final place in the chassis, although witout top cover.. with its metal base touching the aluminum chassis' bottom panel. I don't plan to separate them tbh. (Tell me pls if I should). It seems it does good for heat spreading because after 4 hours of heating all tubes simultaneously, the maximum I could measure between the transformer chassis and one tube's socket was 39.5˚C (103.1˚F). Temp sensor put onto the top of the transformer, with good contact to the metal surface. Ambient temp was 22.5˚C/72.5˚F.

I might fit 2 fans onto the back of the side panels - just for safety, staying normally always off and switching on if transformer temps approaching hot temps. (Or sockets, or chassis.. I'll monitor their temp too).

Thanks for the link to the fans, we have these brands here too. I'll check them. 2x 70mm one would fit nicely onto the sides. 5V for normal mode and 12V for turbo in the hottest Summers.

Additional info I know because I asked for:

- 5% underexcited ? (not sure what's the term in English - it did cost me about 1.5x of normal price. It means the transformer approaches saturation a bit later with excess load while running cooler and more safe on normal load)

- it has a built-in thermal switch, calibrated to 130˚C.

- yesterday I put the transformer into its final place in the chassis, although witout top cover.. with its metal base touching the aluminum chassis' bottom panel. I don't plan to separate them tbh. (Tell me pls if I should). It seems it does good for heat spreading because after 4 hours of heating all tubes simultaneously, the maximum I could measure between the transformer chassis and one tube's socket was 39.5˚C (103.1˚F). Temp sensor put onto the top of the transformer, with good contact to the metal surface. Ambient temp was 22.5˚C/72.5˚F.

I might fit 2 fans onto the back of the side panels - just for safety, staying normally always off and switching on if transformer temps approaching hot temps. (Or sockets, or chassis.. I'll monitor their temp too).

Thanks for the link to the fans, we have these brands here too. I'll check them. 2x 70mm one would fit nicely onto the sides. 5V for normal mode and 12V for turbo in the hottest Summers.

Sounds like a decent tfmr and should be ok. Most commercial tfmrs are built to a price, if your tfmr is overwound (more turns, thicker gauge wire ) it will run cooler. You can always drill holes in the mounting "washer" to aid cooling.

It's customary to to insulate a toroid from the metal chassis, just in case of insulation breakdown however unlikely and for noise reduction. If yours is without insulation the valve heat could get transferred to the tfmr, though your measurement looks good.

Re the silent fans, the ones I used can't be heard over quiet bits of music but they don't shift no where near as much air as your normal PC type fan. At less than half speed this will be half of b u g g e r all. You might have an issue with it starting too, some of these fans are very touchy.

Lastly I love your amplifier build, it looks absolutely gorgeous, you've done a brilliant job on it, well done mate.

Andy.

It's customary to to insulate a toroid from the metal chassis, just in case of insulation breakdown however unlikely and for noise reduction. If yours is without insulation the valve heat could get transferred to the tfmr, though your measurement looks good.

Re the silent fans, the ones I used can't be heard over quiet bits of music but they don't shift no where near as much air as your normal PC type fan. At less than half speed this will be half of b u g g e r all. You might have an issue with it starting too, some of these fans are very touchy.

Lastly I love your amplifier build, it looks absolutely gorgeous, you've done a brilliant job on it, well done mate.

Andy.

Last edited:

Hi Andy, my build isn't finished yet (see here), maybe you meant your compliment to VintageFart's design. That IS a gorgeous and beautiful one, I agree.

On my pic you can see the toroids too. 2x 400VA for anode voltages (1 transformer per side), 1x250VA for 4x 6S33S-V heating. All in their own metal casing, cast resin type. I intend to put these transformers onto the bottom just so, metal touching metal, so they get a little bit larger surface (namely the chassis itself) to dissipate warmth. Fixing them is from the bottom, a M6 thread goes towards their center, so 1 hole is enough on the chassis.

I'll be curious how warm they will get with top plate mounted and chassis closed - on natural circulating air.

The little toroid for small-signal tubes (non-cast) will be of course isolated from chassis with it's supplied mounting materials (2 metal discs and flat round rubber spacers of the same size).

Now I only have to play around a bit with tube sockets: what to mount where.

On my pic you can see the toroids too. 2x 400VA for anode voltages (1 transformer per side), 1x250VA for 4x 6S33S-V heating. All in their own metal casing, cast resin type. I intend to put these transformers onto the bottom just so, metal touching metal, so they get a little bit larger surface (namely the chassis itself) to dissipate warmth. Fixing them is from the bottom, a M6 thread goes towards their center, so 1 hole is enough on the chassis.

I'll be curious how warm they will get with top plate mounted and chassis closed - on natural circulating air.

The little toroid for small-signal tubes (non-cast) will be of course isolated from chassis with it's supplied mounting materials (2 metal discs and flat round rubber spacers of the same size).

Now I only have to play around a bit with tube sockets: what to mount where.

Last edited:

I`m using this one: AC 85~265V Speaker Protection Board 30A Relay High power for Max 900W Amplifier Board|Amplifier| - AliExpress

It does`nt protect speakers necessarily when the output tube fails but some extra protection in case when output will start to drift. It will actuate at 2Vdc on the output.

Power to this board is provided as the last step in power up sequence.

It does`nt protect speakers necessarily when the output tube fails but some extra protection in case when output will start to drift. It will actuate at 2Vdc on the output.

Power to this board is provided as the last step in power up sequence.

- Home

- Amplifiers

- Tubes / Valves

- OTL designed by Tim Mellow with 4 6C33C?