Magura said:1 very good W can be fabricated somewhat more elegant.

....especially with an inductor load.

Magura

I can get more wattage if I lower the resistance of the choke and increase the voltage swing. But every extra volt vastly increases the current and adds a tremendous burden to the power supply and everything else down the line.

This amp doesn't swing a lot of voltage. I think of it as a current amp. You can see what I'm up to on my web site: www.inlowsound.com

I love opinions...

jkeny said:Careful Carpenter, or you might end up with a herniated Discman

Good one.....

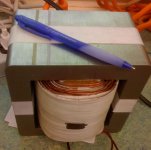

The choke in that picture weighs about 35lb.

I loaded my amp with 0.5 ohm resistors (after removing the inductor) as an experiment to evaluate the difference in the sonic qualities between a choke loaded amplifier and a resistor loaded version.

The resistor loaded amp sounded very smooth, lush--safe. The inductor loaded version had a bit more grain in the top end, but that's a compromise I'm more than willing to accept in trade for the liveliness it adds to the music. Every note sounds as if it has bounce, like they're spring loaded. Just amazing fun...

The powdered iron core helps reduce wire length requirements to get the mH necessary for this amp. The E core I use has a permeability of 66. It's my understanding that this is far less than an E I stack of standard iron.

I loaded my amp with 0.5 ohm resistors (after removing the inductor) as an experiment to evaluate the difference in the sonic qualities between a choke loaded amplifier and a resistor loaded version.

The resistor loaded amp sounded very smooth, lush--safe. The inductor loaded version had a bit more grain in the top end, but that's a compromise I'm more than willing to accept in trade for the liveliness it adds to the music. Every note sounds as if it has bounce, like they're spring loaded. Just amazing fun...

The powdered iron core helps reduce wire length requirements to get the mH necessary for this amp. The E core I use has a permeability of 66. It's my understanding that this is far less than an E I stack of standard iron.

Magura said:If you had made a form to wind on, it would have made your life easier, and the result better. Such you sure are able to make left handed.

Magura

Actually, I used a form. Two strands of #11 wire, together, are rather difficult to lay flat and tight by hand.

That should change in the future when my winder arrives.

carpenter said:

Actually, I used a form. Two strands of #11 wire, together, are rather difficult to lay flat and tight by hand.

That should change in the future when my winder arrives.

Well, I meant a form with ends.

Your winding machine is not going to make it much easier to lay two strands well, that is still just a matter of practice.

What it will do for you, is making the counting of turns, making it easier to keep the windings tight, and so forth, but that's it.

Magura

Magura said:

Well, I meant a form with ends.

Your winding machine is not going to make it much easier to lay two strands well, that is still just a matter of practice.

What it will do for you, is making the counting of turns, making it easier to keep the windings tight, and so forth, but that's it.

Magura

My form had ends. The wire is a bit springy. Any lose wires will be taped tight before the unit is dipped in resin.

Choke cooling!

John,

you could easily include a solid centre connected to a heatsink to remove much of the heat from the choke before you pot the finished product - Ali/copper won't effect the field if that's a concern or use a heat conducting glue to the "centre slug" if required. This is used on welders and such and in a lot of marine solutions.

Did you get the house finished and is your shoulder okay? Perhaps you'd better install a lift!

John,

you could easily include a solid centre connected to a heatsink to remove much of the heat from the choke before you pot the finished product - Ali/copper won't effect the field if that's a concern or use a heat conducting glue to the "centre slug" if required. This is used on welders and such and in a lot of marine solutions.

Did you get the house finished and is your shoulder okay? Perhaps you'd better install a lift!

Well, the house is nearly finished, but you know how it is... there's always something else that requires attention. This summer I want to pour a slab under my office and erect some walls and make a storage room for all the stuff in my garage. Why you ask? Not that you did... But, I'll tell you why--I need to make room for more stuff.

I just found out today that the winder I bought weighs 1100 lbs. I better be able to wind some nice chokes at that rate, or the wife's gonna kill me...

Shoulder's fine, thanks for asking. Health in general seems good. I'm taking my exam to get my contractor's license this coming Monday. My brain is practically mush from all the studying I've been doing. Gotta make some money to pay for my other favorite business: Inlow Sound.

Isn't it funny how money comes from what you're good at, rather than what you love... I enjoy being a carpenter, mind you, but my heart truly belongs to audio.

And thanks, Nelson, for the added reminder that this IS art! I do take it seriously...

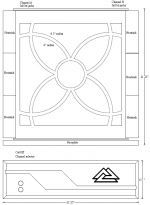

The heat sink idea seems great, though I'm not certain how to slip it into a double E stack. I'll be strapping the choke down to the bottom of the amp chassis with aluminum banding. Perhaps there's the chance to add heat sinks. Trouble is, this amp is big as it is. Where am I going to find room for internal heat sinks?

I'll work it out.

I just found out today that the winder I bought weighs 1100 lbs. I better be able to wind some nice chokes at that rate, or the wife's gonna kill me...

Shoulder's fine, thanks for asking. Health in general seems good. I'm taking my exam to get my contractor's license this coming Monday. My brain is practically mush from all the studying I've been doing. Gotta make some money to pay for my other favorite business: Inlow Sound.

Isn't it funny how money comes from what you're good at, rather than what you love... I enjoy being a carpenter, mind you, but my heart truly belongs to audio.

And thanks, Nelson, for the added reminder that this IS art! I do take it seriously...

The heat sink idea seems great, though I'm not certain how to slip it into a double E stack. I'll be strapping the choke down to the bottom of the amp chassis with aluminum banding. Perhaps there's the chance to add heat sinks. Trouble is, this amp is big as it is. Where am I going to find room for internal heat sinks?

I'll work it out.

carpenter said:I want to take a moment to thank Magura for starting this thread. I appologize for taking so much space.

Just don't forget to copy the item in post #1

Magura

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- No more aching back