Hello,

I have thought of building myself a pair of Onken cabinets for my Altec 604E Duplex speakers.

I was wondering if anyone out there has built these cabinets in 25mm or 30mm MDF?

Baltic Birch x-finer is too expensive for me at the moment.

What purpose did the original design have?

- To flex or to be as stiff as possible?

What will I loose by building a Onken cabinet in MDF compared to birch x-finer?

http://www.inner-magazines.com/uploads/images/News/Audio/Enthusiasm/Hiraga Onken.jpg

I have thought of building myself a pair of Onken cabinets for my Altec 604E Duplex speakers.

I was wondering if anyone out there has built these cabinets in 25mm or 30mm MDF?

Baltic Birch x-finer is too expensive for me at the moment.

What purpose did the original design have?

- To flex or to be as stiff as possible?

What will I loose by building a Onken cabinet in MDF compared to birch x-finer?

http://www.inner-magazines.com/uploads/images/News/Audio/Enthusiasm/Hiraga Onken.jpg

FWIW, I've been exposed one way or another to dozens of different sizes of Ultraflex/Onken type cabs over the decades and none have been out of any type of particleboard, though I imagine there's been some small 'Fonken' type MDF cabs, but they don't count when talking about large cab performance, especially when tuned low.

That said, stiffness goes up at the cube of thickness, so based on an average MOE of ~527 k psi for 3/4" MDF Vs 19 mm BB ply's ~1.8 m psi, then ~1-1/8" thick MDF will = the stiffness of the BB, but with superior damping, so in theory the 30 mm MDF is a better choice overall if weight and its toxic sawdust isn't an issue.

So, care to be the 'guinea pig'?

GM

That said, stiffness goes up at the cube of thickness, so based on an average MOE of ~527 k psi for 3/4" MDF Vs 19 mm BB ply's ~1.8 m psi, then ~1-1/8" thick MDF will = the stiffness of the BB, but with superior damping, so in theory the 30 mm MDF is a better choice overall if weight and its toxic sawdust isn't an issue.

So, care to be the 'guinea pig'?

GM

while not literally, but figuratively,those will weigh a ton and be a bear to move

which sufficient bracing, even a lower grade veneer core plywood than Baltic Birch / "Apple" ply can be made stiff enough to suffice, and be of much more manageable a weight

ever dropped a 200+ lb cabinet on your foot? I have - crushed toes ain't no fun

which sufficient bracing, even a lower grade veneer core plywood than Baltic Birch / "Apple" ply can be made stiff enough to suffice, and be of much more manageable a weight

ever dropped a 200+ lb cabinet on your foot? I have - crushed toes ain't no fun

I had a pr of thick MDF Onkens built by a boat builder who was also peripherally in the audio manufacturing business (turntables). He reinforced large panels with glued on tiles of MDF on the inside. Added a few internal braces. solid suckers.

I tried to get him to build them in BB but he wanted to work in MDF. The price was right so I went with it.

They sounded clean and generally awesome. I used them for 15 years. Would have kept them but couldn't fit them onto a moving truck when I shifted half-way cross country..

Yes, they were heavy as hell. They didn't get moved much.

During that move I dropped an 80 lb three arm Japanese Carrard 301 plinth on my toe. Thank god it wasn't an Onken!

I short, go with MDF if that is what you have to do. You will still get rich and satisfying bass. I generally prefer ply cabinets for Altecs, but MDF makes a pretty good bass cabinet. The Japanese and later French aficionados of Onken would probably argue otherwise, but they ain't paying for your wood.

The bigger problem is the crossover for the 604. I can say that I only heard 604s sound really really great one time...Hiraga's 604s at the Munich HighEnd show five or so years back. Maybe they were 605s, not sure. Unfortunately, the room burned up overnight in a fire before I got back to ask him what he did for his magic crossover. Maybe Pano knows?

I tried to get him to build them in BB but he wanted to work in MDF. The price was right so I went with it.

They sounded clean and generally awesome. I used them for 15 years. Would have kept them but couldn't fit them onto a moving truck when I shifted half-way cross country..

Yes, they were heavy as hell. They didn't get moved much.

During that move I dropped an 80 lb three arm Japanese Carrard 301 plinth on my toe. Thank god it wasn't an Onken!

I short, go with MDF if that is what you have to do. You will still get rich and satisfying bass. I generally prefer ply cabinets for Altecs, but MDF makes a pretty good bass cabinet. The Japanese and later French aficionados of Onken would probably argue otherwise, but they ain't paying for your wood.

The bigger problem is the crossover for the 604. I can say that I only heard 604s sound really really great one time...Hiraga's 604s at the Munich HighEnd show five or so years back. Maybe they were 605s, not sure. Unfortunately, the room burned up overnight in a fire before I got back to ask him what he did for his magic crossover. Maybe Pano knows?

Waowe..

Thank you all for your inputs

Please fill me in on the problems regarding the crossover :

The thought did strike me when I read about different "optimal" crossover frequency when using the ONKEN cabinet than what the N1500-A crossover does for my Altec 604E.

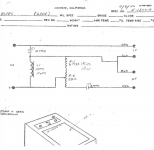

I have today a DIY version of the N1500-A crossover

Schematics attached.

Link to webpage I stumbled upon:

Inner Magazine - My Altec Valencia Iconics

QUOTE:

"... The Onken design allows the use of original dividing network and the driver/horn combination. However, the crossover frequency recommended by Jean Hiraga is around 600Hz with 12db slope... "

I take the challenge GM ! Just give me a bit of time to build...

I will build these MDF monsters !

One last thing , I have no chance in getting into measurements; and all that in designig a suitable crossover for my drivers - anyone out there that have more info about the Jean Hiraga crossover?

Thank you all for your inputs

Please fill me in on the problems regarding the crossover :

The thought did strike me when I read about different "optimal" crossover frequency when using the ONKEN cabinet than what the N1500-A crossover does for my Altec 604E.

I have today a DIY version of the N1500-A crossover

Schematics attached.

Link to webpage I stumbled upon:

Inner Magazine - My Altec Valencia Iconics

QUOTE:

"... The Onken design allows the use of original dividing network and the driver/horn combination. However, the crossover frequency recommended by Jean Hiraga is around 600Hz with 12db slope... "

I take the challenge GM ! Just give me a bit of time to build...

I will build these MDF monsters !

One last thing , I have no chance in getting into measurements; and all that in designig a suitable crossover for my drivers - anyone out there that have more info about the Jean Hiraga crossover?

Attachments

You are facing a totally different scenario with 604s vs. 416s and a midrange horn.

You have to run the bass up to where the horn cuts out, at least 1.5k

N1500 is a decent textbook solution but I recommend looking into advanced thinking on the problem. I believe that Hiraga's xover is derived from the Urei "afttermarket" xover....not sure about that.

I tried lots of experiments with various 604s trying to get them to play as well as a 416 + discrete horn with no success but for the 10 minutes I heard Hiraga's coaxes in Munich I was soundly impressed. Very coherent and a huge dynamic sound.

Basic problem with the 604s in my interpretation is that both the horn and woofer are stretched outside their optimal ranges. Beyond that there are time alignment issues (addressed by various crossover designs over the years) and the constructional facts that the horn is right in the way of the cone and felt is glued to the damn cone behind the horn...making the crossover region even more tricky.

Good luck. I think it can be done.

Maybe I'm being picky because a lot of people love 604s but I'm sketching it out for ya as I see it. Hope the comments are of some use.

Study up. Lots written about 604s.

You have to run the bass up to where the horn cuts out, at least 1.5k

N1500 is a decent textbook solution but I recommend looking into advanced thinking on the problem. I believe that Hiraga's xover is derived from the Urei "afttermarket" xover....not sure about that.

I tried lots of experiments with various 604s trying to get them to play as well as a 416 + discrete horn with no success but for the 10 minutes I heard Hiraga's coaxes in Munich I was soundly impressed. Very coherent and a huge dynamic sound.

Basic problem with the 604s in my interpretation is that both the horn and woofer are stretched outside their optimal ranges. Beyond that there are time alignment issues (addressed by various crossover designs over the years) and the constructional facts that the horn is right in the way of the cone and felt is glued to the damn cone behind the horn...making the crossover region even more tricky.

Good luck. I think it can be done.

Maybe I'm being picky because a lot of people love 604s but I'm sketching it out for ya as I see it. Hope the comments are of some use.

Study up. Lots written about 604s.

Thank you all for your inputs

Please fill me in on the problems regarding the crossover :

QUOTE:

"... The Onken design allows the use of original dividing network and the driver/horn combination. However, the crossover frequency recommended by Jean Hiraga is around 600Hz with 12db slope... "

I take the challenge GM ! I will build these MDF monsters !

You're welcome!

No knowledge of JH's XO beyond that he had done one, though it's more likely to be 1600 Hz than 600 Hz...........

Note that Altec XOs in general are optimized for high power apps and studio monitor apps in particular, so a high XO point + loading cap on the HF driver is mandatory, which is intolerable [to mine and some others ears] at the fractional power these normally operate at in a HIFI/HT app.

It's been several decades since I dealt with the 604E, the last model I've any 'hands on' experience with, so with all my notes gone AFAIK that ultimately led me down a far different 'path' than what's considered 'proper', theoretically 'correct', etc., I'm reluctant to offer much in the way of XO advice other than that no 604 thread is complete without reference to Jeff Markwart's website: Jeff Markwart's Corner - Phase Corrected Crossovers and specifically: Altec Compression Driver Rear Loading Caps

Cool! looking forward to your subjective thoughts on its [mid]bass, lower mids, 'tone', perceived transient response, i.e. comparing with/without the HF horn connected.

GM

Last edited:

I should also mention that the much easier to build 620 (big) or 612 (medium) utility cabs are also classic selections for 604s.

see here for Altec box plans out the wazoo

ALTEC PLANS

Personally, I'd do 612s and put them up on stands.

Might be a good path to build easier cabs and see if the 604s are for you before diving into a complex build.

see here for Altec box plans out the wazoo

ALTEC PLANS

Personally, I'd do 612s and put them up on stands.

Might be a good path to build easier cabs and see if the 604s are for you before diving into a complex build.

My picture here at diyaudio shows a 612 utility cabinet I´ve built.

The complex build of the Onken cabinet is no problem as I see it.

Question:

I have a pair of ElectroVoice HP9040 ( midrange horns ) with EV DH1A drivers laying around.

Never hooked them properly up.

Any good idea to use these on top of the Onken cabinet and use a 15" woofer instead of the 604E duplex I got?

If so what 15" woofers should I consider?

Thank you !

The complex build of the Onken cabinet is no problem as I see it.

Question:

I have a pair of ElectroVoice HP9040 ( midrange horns ) with EV DH1A drivers laying around.

Never hooked them properly up.

Any good idea to use these on top of the Onken cabinet and use a 15" woofer instead of the 604E duplex I got?

If so what 15" woofers should I consider?

Thank you !

My picture is El Kabong...that doesn't mean I'm a cartoon character. ;op

I'm not a skilled woodworker so building an Onken is for me a unthinkable task. Good on you if you can whip them out.

A 604 in a good 612 cab should give you an excellent taste of what the 604 is all about.

I would definitely go two way with a big midrange horn with an Onken. That's what the cabinet is intended for. Also, this configuration allows you to sidestep the hellhole of trying to run an Altec 15" above 1000hz.

The EV should be pretty good, although I have no ears-on experience. Again, there are plenty of user reports online.

The preferred Onken woof is the Altec 416. I know for sure that woofer works great in the Onken box. That could have been a lifetime setup for me, if I were able to keep it.

In my mind, a large scale two way Onken system is a step beyond the 604 generally. Since you have Onken on the brain and the skills to build a pair, plus you already have the mid horns, go for it!

I'm not a skilled woodworker so building an Onken is for me a unthinkable task. Good on you if you can whip them out.

A 604 in a good 612 cab should give you an excellent taste of what the 604 is all about.

I would definitely go two way with a big midrange horn with an Onken. That's what the cabinet is intended for. Also, this configuration allows you to sidestep the hellhole of trying to run an Altec 15" above 1000hz.

The EV should be pretty good, although I have no ears-on experience. Again, there are plenty of user reports online.

The preferred Onken woof is the Altec 416. I know for sure that woofer works great in the Onken box. That could have been a lifetime setup for me, if I were able to keep it.

In my mind, a large scale two way Onken system is a step beyond the 604 generally. Since you have Onken on the brain and the skills to build a pair, plus you already have the mid horns, go for it!

Personally, I'd do 612s and put them up on stands.

To me, using a tower design makes more sense if stand mounting is an option and since we're straying from the thread, my choice would be a MLTL of ~the same alignment as the Onken, which gives all the [mid]bass performance [and maybe then some] except with an easy to tune vent vs only being able to either damp the vents individually or use some form of digital EQ.

The potential downside is that it won't have the Onken vent system's [excessive] lower mids harmonic distortion, euphonic though it is to many folks.

GM

I have a pair of ElectroVoice HP9040 ( midrange horns ) with EV DH1A drivers laying around.

Any good idea to use these on top of the Onken cabinet and use a 15" woofer instead of the 604E duplex I got?

If so what 15" woofers should I consider?

No experience with the EV, but there's a bit of a following for it.

Historically, multi-cell or the 300 series large format [1.4"] horns combined with the 416A or B was the goal, but really needs a super tweeter, so using either a 604 [515 series woofer] or 605 [416 series woofer] with its HF horn used only as a super tweeter is a good plan for a vintage SOTA speaker system, budget willing.

Nowadays though, modern, reasonably priced round or radial WG, tractrix/whatever mid range horns to perch on top [some having proper mounting flanges] are aplenty, so can choose much more by budget than traditionally. The main thing is to have the woofer at the extreme top of the cab or as close as practical to the horn if inside.

I much prefer radial WGs since they have the least [throat] distortion, but the trade-off is they are much larger for a given BW than the others. Historically, 500, 5000 Hz XOs are used, so 1.4" or 2" exit drivers preferred.

Best IME would be a DSL Synergy concept horn down to around 80 Hz, then a plethora of woofer options and usable reproduction to near Dc becomes viable.

GM

Best IME would be a DSL Synergy concept horn down to around 80 Hz, then a plethora of woofer options and usable reproduction to near Dc becomes viable.

Are you saying that I could hear them all the way to DC? Let me know when they are on and I'll open my windows!:D

I agree that there are a lot of cool DIY parts around these days, but 1505 multicells on Onkens works pretty good. And EQ in the crossover can get you to ~12k with a 288C.

288/1505 sounds quite rich at the lower end of its range, so the Onken matched up rather well. I tried many tweeters but I could always hear them as separate appliances and ultimately ended up with the EQed horn and no tweeter.

I forget the details but I stuffed a port (1/6 of total port area) on mine with foam. At first I used a phone book. And I used a cellulose curtain (KimPak aka VersaPak today) over the ports to damp the huffing and puffing. A lot of sound comes out of the side ports if untreated.

I didn't have the facilities to measure speaker distortion back in the 80s but these measures tightened up the lower mids some.

Some classics live up to their reputation and some not, but the Onken with 1505s holds up in my experience. I'd do it all again but I have other irons in the fire these days, but I'm using older designs not newer ones!

Yeah, dual 515B/tar filled 1803 driven with a MC275 is best 'Onken' [actually a Jensen Ultraflex] system I've auditioned, but this was back in the '60s when my 'frame of reference' was an early '30s full size mono WE system in a local electrical engineer's barn/loft 'man cave', so overall wasn't much impressed at the time other than it was the best overall 'home stereo' system. For sure, it 'sunk the hook' to want tar filled 803s, but by the time some became available I could no longer afford them at such inflated prices.

Yeah, I'm always amazed that so many folks like all that vent generated pipe harmonics comb filtering out of phase with the driver's output. All it shows me is how poor our hearing acuity is in general even up into the lower mids.

GM

Yeah, I'm always amazed that so many folks like all that vent generated pipe harmonics comb filtering out of phase with the driver's output. All it shows me is how poor our hearing acuity is in general even up into the lower mids.

GM

I am blessed with the ability to listen to things in a big picture way. Nothing is perfect and everything is subject to further refinement. If the flavor is right and the presentation is emotionally compelling with my music, I'm happy. Over time, some imperfections may begin to get on my nerves and I'll fix them if I can.

I tried the tar filled 1505s but preferred the sheet metal ones with the Onken because the added resonance worked with the system. The tar filled seemed to ring even though they were heavy and in a painful way.

For all of its faults, I think I'd pick that vintage Onken setup I had over 99% of modern attempts. Hearing or rather music listening is a funny thing. Scientific and engineering logic does not map the world of musical aesthetics very well.

I get to play with most of the complete factory WE theater systems frequently thanks to my work and, you know, I don't really want to own any of that stuff, even though it can be absolutely fabulous. For one thing, who has the space? I am ever thankful that I have those sounds in my mental catalog though.

I think the WE Mirrophonic Model 2 is the best of the 2 way theater horn genre and also the first, which is something that is hard to reconcile. Perhaps some work can be done on the crossovers for better coherence between the bass cabs and the 24A horn, but the ancient 594A driver is in a class of its own. That system is a monster though. It is just too big for domestic use unless you live in a factory loft.

All told, based on long experience, I remain an Onken/416 + big midrange horn fan. Maybe one can do better in the same moderate scale but I'd have to hear it before I agree that it is better. I have heard a lot worse.

I tried the tar filled 1505s but preferred the sheet metal ones with the Onken because the added resonance worked with the system. The tar filled seemed to ring even though they were heavy and in a painful way.

For all of its faults, I think I'd pick that vintage Onken setup I had over 99% of modern attempts. Hearing or rather music listening is a funny thing. Scientific and engineering logic does not map the world of musical aesthetics very well.

I get to play with most of the complete factory WE theater systems frequently thanks to my work and, you know, I don't really want to own any of that stuff, even though it can be absolutely fabulous. For one thing, who has the space? I am ever thankful that I have those sounds in my mental catalog though.

I think the WE Mirrophonic Model 2 is the best of the 2 way theater horn genre and also the first, which is something that is hard to reconcile. Perhaps some work can be done on the crossovers for better coherence between the bass cabs and the 24A horn, but the ancient 594A driver is in a class of its own. That system is a monster though. It is just too big for domestic use unless you live in a factory loft.

All told, based on long experience, I remain an Onken/416 + big midrange horn fan. Maybe one can do better in the same moderate scale but I'd have to hear it before I agree that it is better. I have heard a lot worse.

I built my Onkens out of 1" baltic birch. To my mind, there is no substitute! Here in Canada I ordered four 5'x5' sheets at $100 a peice to make them. I had to adjust an inch here and there to get the panels to fit on the sheets.

#1. It's a ton of work and careful alignment to make an onken. If you're going to spend the time, start with the right material.

#2. Resale value. I've had offers on my onkens for $2000. You won't get that with mdf.

#3. With that size enclosure the 1" BB really does solidify the whole thing. The knuckle knock test sounds like a well constructed bookshelf speaker...just bigger! My A7's are made of 3/4" mdf and the are very resonatey.

On a side note, make sure you drape a thick wool blanket between the woofer and the ports as per the onken specs. A large downe filled pillow works too. All my walls are covered in 1" dense mattress foam. Helped a lot. Its now deep and tuneful.

#1. It's a ton of work and careful alignment to make an onken. If you're going to spend the time, start with the right material.

#2. Resale value. I've had offers on my onkens for $2000. You won't get that with mdf.

#3. With that size enclosure the 1" BB really does solidify the whole thing. The knuckle knock test sounds like a well constructed bookshelf speaker...just bigger! My A7's are made of 3/4" mdf and the are very resonatey.

On a side note, make sure you drape a thick wool blanket between the woofer and the ports as per the onken specs. A large downe filled pillow works too. All my walls are covered in 1" dense mattress foam. Helped a lot. Its now deep and tuneful.

#1. It's a ton of work and careful alignment to make an onken. If you're going to spend the time, start with the right material.

I definetly understand; and agree to what you`re saying.

25mm ( 2.54mm=1inch ) birch plywood costs twice the amount where I live per sheet ( 1220x2440mm )

I have a bit of a crazy idea. I´m definitely driftin from the original post here...

- But since I got your attension I would like to ask:

1. WOODEN HORNS - DIY: if built correctly - will they preform well / really well ?

Link to site with details about wooden horns: Wood Horn

3. If I was to choose a horn out of these on this site : which one should I consider for a Onken setup?

"I guess I`m a sucker for wood/woodworking....

Just to back up my statement:

I do not in any way feel like a Renaissance Man... !

I´ve tried building electronics - I can do kits - sure... still: this is field is an enigma for me... I just love building things in wood !

Wood horns of that genre are super popular in Japan. The company who started it all back in the 80s is named Yamamoto.

YAMAMOTO HIGH EFFICIENCY LOUDSPEAKERS

I have heard a number of such horns and they are pretty good, but I can't say that they are fundamentally superior to non-wood horns. However, if you are excited about building a pair and have the skills. this would be a great project.

The wood horn I have heard the most is made by GIP Laboratory for the WE 594A. Despite the use of natural organic material, it sounds a bit harder (some would say crisper) than a WE multicell. Very good horn overall.

These wood horns are super expensive in Japan and have a very high perceived value. Japanese sometimes go for some odd stain colors and finishes, especially weird orange teak-like tones, but obviously a wood horn can be made very pleasing to the eye...well beyond an EV9040!

YAMAMOTO HIGH EFFICIENCY LOUDSPEAKERS

I have heard a number of such horns and they are pretty good, but I can't say that they are fundamentally superior to non-wood horns. However, if you are excited about building a pair and have the skills. this would be a great project.

The wood horn I have heard the most is made by GIP Laboratory for the WE 594A. Despite the use of natural organic material, it sounds a bit harder (some would say crisper) than a WE multicell. Very good horn overall.

These wood horns are super expensive in Japan and have a very high perceived value. Japanese sometimes go for some odd stain colors and finishes, especially weird orange teak-like tones, but obviously a wood horn can be made very pleasing to the eye...well beyond an EV9040!

1. WOODEN HORNS - DIY: if built correctly - will they preform well / really well ?

I guess you'll have to define 'really well' since they all tend to an Fs well into the their pass-band, so resonate out of tune with their output to a greater or less degree depending on the material and the horn's intended BW, so MDF or better, particle board is preferred from an acoustical POV, though the hardwoods typically used are a good match with the resonant Onken if not well damped; otherwise the horn needs to literally be 'sandbagged' to sufficiently mass load [damp] it: https://www.youtube.com/watch?v=4P12CQT00SE

GM

Wood at its finest, a RCA Ubangi system: https://www.youtube.com/watch?v=l3BmSG85p_A

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- MDF? - Onken Cabinet for Altec Duplex 604E