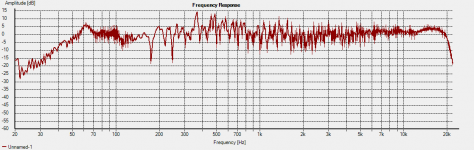

One more with a flatter W shape Planar. Measured fullrange 1 meter

nice dude! so you made the ribbon wider by unfolding it a bit ? its a pretty good result i must add.!!!. tobad i dont have magnets that could be used in such way or i would make one right away

oh one thing could you make a distortion measurement up closer? without dsp, i want to se how low it can dip without involing the room to much and compare it to some esl designs i made.

greetings Joppe

nice dude! so you made the ribbon wider by unfolding it a bit ? its a pretty good result i must add.!!!. tobad i dont have magnets that could be used in such way or i would make one right awayreally like you build! well done and not seen before !!

oh one thing could you make a distortion measurement up closer? without dsp, i want to se how low it can dip without involing the room to much and compare it to some esl designs i made.

greetings Joppe

I haven´t used DSP. Just some smoothing. Maybe sunday I will find time and space to make a nerfield measurement

Raw respons

Attachments

@ABJensen,

Pretty impressive Sir. What sound pressure can reach for the range you want to use it?

Thank you. I dont now how loud. The test I have done says pretty loud with 300 hz 24 db crossover

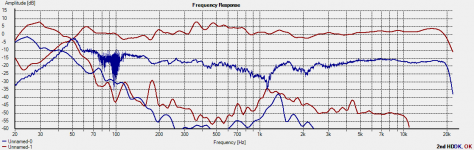

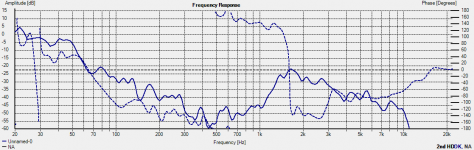

Red curve distance 1 meter. Blue curve distance 1 cm raw respons.

Distortion goes up at 1300 hz ???.

that looks really good to be honest. the increase is due to phase cacelations , thats why you see the dip, when the ouput lowers the distortion goes up. can you scale a bit down ? since half of the disortion plot falls of the chart

but looking really promising dude!

a complete wave at 1300 Hz is 26 cm when one wave is reflected half a wavelength in extra travel time it creates a dip.

there should be a problem with a distance of around 13 cm anything measuring 13 cm ? in you construction ?

try to have 1 2 3 harmonic to be in one plot

you can hunt down this problem by using REW put the generator at 1300Hz, then use the scope thing where you can read disortion live, and play around with covering edged of magnets for instance, or it might be the grill itself or the slots.

there should be a problem with a distance of around 13 cm anything measuring 13 cm ? in you construction ?

try to have 1 2 3 harmonic to be in one plot

you can hunt down this problem by using REW put the generator at 1300Hz, then use the scope thing where you can read disortion live, and play around with covering edged of magnets for instance, or it might be the grill itself or the slots.

Last edited:

a complete wave at 1300 Hz is 26 cm when one wave is reflected half a wavelength in extra travel time it creates a dip.

there should be a problem with a distance of around 13 cm anything measuring 13 cm ? in you construction ?

try to have 1 2 3 harmonic to be in one plot

you can hunt down this problem by using REW put the generator at 1300Hz, then use the scope thing where you can read disortion live, and play around with covering edged of magnets for instance, or it might be the grill itself or the slots.

This isn´t my own speaker. But one I sold years ago I just chanced the planar to the W. And I think your right it is proberply the grill for protection of the ribbon. The next version for my self will be without the grill. I can make I a new planar in case

I will try that REW. Holm only one distortion in one plot.

Last edited:

Hi ABjensen, i made this tiny contraption. i used doublesided aluminium foil. the stuff is coated with a laquer witch i had to remove prior to printing and etching. the trick to not let the paper saturate and etch the traces underneith the wax from the printer was verry agressive etching. so it does not get the change to penetrate the paper. i did not know how thick the alu was so i made a several trace setup. but i will amke a new one with only one 9 mm trace, so i dont have as much alu outside the gap. and make less deep pleats, (i used 15mm now) so to increase the high end a bit. the youtube is playing fullrange with soem added highs since i miss them a bit. and lowered low end to not overload the fragile coil. the field is way to weak i used 4 x 40x20x5 mm magnets on 10 mm steel bar. gap is way to big to 60mm. next setup ill decrease pleat depth and magnet gap bij 20mm or so. i like the design, it is funny i once played with normal ribbons and i though by myself why they where horizontal corrugated since i corrugated a piece of alu foil vertically and it was way more stable. thank god you made these pair so it reinspired me. yours looks awesome. next is hunting down the left over resonances.

btw how wide are your fold ?

small video, it is the max i can put out of this small thing i guess.

https://www.youtube.com/watch?v=idTl7nnGGx8&feature=youtu.be

oh and i did not remove the wax from the etching, nexct time i will since it adds weight, be it a little but i want to reach 20k to

btw how wide are your fold ?

small video, it is the max i can put out of this small thing i guess.

https://www.youtube.com/watch?v=idTl7nnGGx8&feature=youtu.be

oh and i did not remove the wax from the etching, nexct time i will since it adds weight, be it a little but i want to reach 20k to

Last edited:

oooh wauw 17 mm wide, 22 total length so one fold is, 22 /6 ? 3.6 ?

then im quite off to your design by 12 mm haha

to your design by 12 mm haha

i just made a version with 10mm folds so toal 10x6 60 mm wide menbrame in a 40 mm gap, i gues my membrane is to wide for the 40 mm gap.. maybe have to shrink it a bit

then im quite off

i just made a version with 10mm folds so toal 10x6 60 mm wide menbrame in a 40 mm gap, i gues my membrane is to wide for the 40 mm gap.. maybe have to shrink it a bit

oooh wauw 17 mm wide, 22 total length so one fold is, 22 /6 ? 3.6 ?

then im quite offto your design by 12 mm haha

i just made a version with 10mm folds so toal 10x6 60 mm wide menbrame in a 40 mm gap, i gues my membrane is to wide for the 40 mm gap.. maybe have to shrink it a bit

I take a picture when I get home from work of and unfolded ribbon. So there are no misunderstandings

I take a picture when I get home from work of and unfolded ribbon. So there are no misunderstandings

thanks, the paper is a good idea, i noticed from hing to hing is going to bend indeed. i could either go paper over it or use the backside aluminum. but that would mean i have to print both sides and perfectly align.. not seeing that happening any time soon. or i should leave the backside aluminium, but i guess its gone be rather heavy then. and stiff

very nice dude!thanks for the photo, how did you manage to layout the 4 micron alu so nice. you cut it from bigger roll on wetted glass?

this cap paper is this the verry well damped stuff, tha paper that not make noise on its own if you know what i mean when you wrinkle it.

so i see might need to scale down big time to see what it does. your paper is lighter i recon wich should help as well in efficciency since mine is pretty poor (and small of course)

this cap paper is this the verry well damped stuff, tha paper that not make noise on its own if you know what i mean when you wrinkle it.

so i see might need to scale down big time to see what it does. your paper is lighter i recon wich should help as well in efficciency since mine is pretty poor (and small of course)

very nice dude!thanks for the photo, how did you manage to layout the 4 micron alu so nice. you cut it from bigger roll on wetted glass?

this cap paper is this the verry well damped stuff, tha paper that not make noise on its own if you know what i mean when you wrinkle it.

so i see might need to scale down big time to see what it does. your paper is lighter i recon wich should help as well in efficciency since mine is pretty poor (and small of course)

I tighten it up with tape on a bent MDF plate, then I line it up before I glue it. I don´t think that paper that thin and soft, damped with contakt glue and alu will make noise, but I am not sure

PS use the soft toilet paper ;-)

Last edited:

sorry im not really clear in what i write. i ment. you paper is the sort of paper that does not make sound when wrinkled (indeed as toilet paper as well but thats to sloppy to hold any shape?)

i see i made one dumb mistake. i though of 6 folds and only 4 with coil on it. so the outer ones work like a hinge only. but ill try the normal 4 tomorrow that would make it more easy to get it in a small gap without the 2 i used extra

that would make it more easy to get it in a small gap without the 2 i used extra

i might give toilet paper a go although i dont have such thin foil on a roll.

although i dont have such thin foil on a roll.  i have to etch my designs, and it needs to be on a substrate that can handle water , toilet paper wont survive the bath

i have to etch my designs, and it needs to be on a substrate that can handle water , toilet paper wont survive the bath

i see i made one dumb mistake. i though of 6 folds and only 4 with coil on it. so the outer ones work like a hinge only. but ill try the normal 4 tomorrow

i might give toilet paper a go

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Magnetic paper ribbon