ALW said:

Frank,

Where's the vibration coming from, that you refer to?

The bearing is incredibly precise and is the most expensive single part of an LP12.

The LP12 works on the principle that all energy appears equally within the system and cannot therefore generate a differential signal that can appear at the cartridge.

Attempts to absorb or transform this energy make the situation worse, not better.

------------------------------------------------------------------

This is metaphysics and propaganda without hard science. Bearings cannot be machined to um accuracy without nano-machining techniques which have been developed after Linn made calims for the LP12.

Hi,

The technology was there already but was too expensive to implement in a "mass market" product.

My major quible with it however is the type of bearing used, a 60+ years old design with a surface are so big that any amount of imprecision in the machining is bound to translate itself into spurious noise.

In that respect the Roksan Xerxes is much better executed although it's based around the same idiosyncratic engineering principles.

Take this another step further and you'll arrive at what IMO is the best offering of this type, namely the Well Tempered bearing.

A good bearing should have as small as possible surface area, as independent from the platter as possible and should be as quiet as the proverbial mouse.

Whatever noise is still left should not be allowed to propagate into the main platter but be absorbed and turned into heat as fast as possible.

Cheers,

Bearings cannot be machined to um accuracy without nano-machining techniques which have been developed after Linn made calims for the LP12.

The technology was there already but was too expensive to implement in a "mass market" product.

My major quible with it however is the type of bearing used, a 60+ years old design with a surface are so big that any amount of imprecision in the machining is bound to translate itself into spurious noise.

In that respect the Roksan Xerxes is much better executed although it's based around the same idiosyncratic engineering principles.

Take this another step further and you'll arrive at what IMO is the best offering of this type, namely the Well Tempered bearing.

A good bearing should have as small as possible surface area, as independent from the platter as possible and should be as quiet as the proverbial mouse.

Whatever noise is still left should not be allowed to propagate into the main platter but be absorbed and turned into heat as fast as possible.

Cheers,

"Where's the vibration coming from, that you refer to?"

Also bear in mind that the spindle is probably never 100% vertical in any given set up, and vibration from the motor down the belt into the platter and spindle and noise from the cart and arm interface will certainly cause micro rocking and rubbing in the bearing house thus inducing noise.

Also bear in mind that the spindle is probably never 100% vertical in any given set up, and vibration from the motor down the belt into the platter and spindle and noise from the cart and arm interface will certainly cause micro rocking and rubbing in the bearing house thus inducing noise.

This is metaphysics and propaganda without hard science. Bearings cannot be machined to um accuracy without nano-machining techniques which have been developed after Linn made calims for the LP12.

Email Linn and ask for the tolerance, I cannot remember what it is from the top of my head, but it's a single-point bearing, running in an oil sleeve and always was the single most expensive part of the TT. When they retailed new for 500UKP, the bearing represented some 2/3 of the total cost, simply because of it's precision machining.

The only source of vibration within the bearing is surely from eccentricity in the single-point and Linn have tightened tolerances over the years, through different bearing liners and mods such as the Cirkus.

Under the Linn list of 'Useless, Foolish and Dangerous Modifications to the LP12' no.1 is: -

"Damping material on the subchassis, tonearm, cartridge, or anyplace else. (The idea being to damp resonances.) This totally defeats the design of the Linn Sondek. We want any energy in the system to be present at all points in the-system. This way, any energy that affects the platter is also transmitted to the arm. The arm and cartridge move together, there is no relative movement between the cartridge body and the record, thus the energy has no effect on the output of the system. By damping any part of the turntable you are impeding the flow of energy from one part of the system to other parts of the system. This energy will no longer cancel out and, will show up in the output of the system."

For the same reason, mats that decouple the record from the platter tend to have the same effect, I shall try the suggestions above to see if their effect is similar though.

"Damping material on the subchassis, tonearm, cartridge, or anyplace else. (The idea being to damp resonances.) This totally defeats the design of the Linn Sondek. We want any energy in the system to be present at all points in the-system. This way, any energy that affects the platter is also transmitted to the arm. The arm and cartridge move together, there is no relative movement between the cartridge body and the record, thus the energy has no effect on the output of the system. By damping any part of the turntable you are impeding the flow of energy from one part of the system to other parts of the system. This energy will no longer cancel out and, will show up in the output of the system."

If the LP12 were perfect then this would be right, but its not and energy in the system is not even ,nor can it be.Also what particular set up does this apply too, circus, valhalla , ekos , troika?Each will resonate in a different way due to the design of idividual parts, also the surface it is resting on and the music being played at the time.

Can someone explain how energy can travel between bearing , two piece plater , felt mat record needle arm ,arm bearings arm board and it relvent screws at the same frequancy and time.

Not possible.

Although the ideal is good it doesn't always work in practise.

If the LP12 were perfect then this would be right, but its not and energy in the system is not even ,nor can it be.Also what particular set up does this apply too, circus, valhalla , ekos , troika?Each will resonate in a different way due to the design of idividual parts, also the surface it is resting on and the music being played at the time.

Can someone explain how energy can travel between bearing , two piece plater , felt mat record needle arm ,arm bearings arm board and it relvent screws at the same frequancy and time.

Not possible.

Although the ideal is good it doesn't always work in practise.

Hi,

IOW, we have reflections all over the place and are proud of our stupidity?

Actually it seems pretty obvious they don't even have a clue themselves although I do agree with them when they say you shouldn't add damping materials nilly willylike.

Much better engineering than having "energy present at all points in the system" is to provide the system with a single path of energy drainage, one that doesn't interfere with watever the cartridge is doing and while we're at it it would advisable to have as little energy present as possible in any case.

Does Linn actually claim that?

I sure hope not or they'll prove my point once more...

Why do you think they picked a felt mat in the first place?

To play pool on it?

Anyway, before anyone gets the impression that I think it's a lousy TT (I do) and feel it's terribly outdated (It is) and arrogantly overpriced (That too), I'll be the first to admit that it can appear to play a tune.

But that feat solely depends on speed accuracy....without it any TT is ultimately worthless.

All of which makes me wonder why such "perfect designs" end up with a raft of even more ridiculous mods...

Seems perfection can be improved upon...especially when you're sitting at the other end of the till.

On a more positive note, if you happen to be the proud owner of an LP12 learn how to set it up correctly, it can sound surprisingly good despite it's obvious flaws and the difference between a well setup one and a badly set up unit are simply night and day.

Don't bother to ask any Linn salesman though, they would only look down on you with utter disdain.

Cheers,

"Damping material on the subchassis, tonearm, cartridge, or anyplace else. (The idea being to damp resonances.) This totally defeats the design of the Linn Sondek. We want any energy in the system to be present at all points in the-system.

IOW, we have reflections all over the place and are proud of our stupidity?

Actually it seems pretty obvious they don't even have a clue themselves although I do agree with them when they say you shouldn't add damping materials nilly willylike.

Much better engineering than having "energy present at all points in the system" is to provide the system with a single path of energy drainage, one that doesn't interfere with watever the cartridge is doing and while we're at it it would advisable to have as little energy present as possible in any case.

For the same reason, mats that decouple the record from the platter tend to have the same effect, I shall try the suggestions above to see if their effect is similar though.

Does Linn actually claim that?

I sure hope not or they'll prove my point once more...

Why do you think they picked a felt mat in the first place?

To play pool on it?

Anyway, before anyone gets the impression that I think it's a lousy TT (I do) and feel it's terribly outdated (It is) and arrogantly overpriced (That too), I'll be the first to admit that it can appear to play a tune.

But that feat solely depends on speed accuracy....without it any TT is ultimately worthless.

All of which makes me wonder why such "perfect designs" end up with a raft of even more ridiculous mods...

Seems perfection can be improved upon...especially when you're sitting at the other end of the till.

On a more positive note, if you happen to be the proud owner of an LP12 learn how to set it up correctly, it can sound surprisingly good despite it's obvious flaws and the difference between a well setup one and a badly set up unit are simply night and day.

Don't bother to ask any Linn salesman though, they would only look down on you with utter disdain.

Cheers,

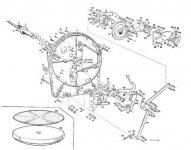

Ah, that's what it is. Thanks foir the pic Frank. I've been using this mat in the car, under the radar detector. And 30 minutes later i am the happy owner of an Extreme phono clone-mat. Almost as ugly cut as the original. But it beats the felt accross the board.

Attachments

------------------------------------------------------------------------fmak said:IME that's the felt mat you're hearing.

Another artefact due to it is absorption of fine detail and dynamics.

Cheers,

It's not as simple as that. As you say later, it's the system. Every bit seesm to count.

The Garrard 301, when suspended on it's original springs sound excellent, despite a massive motor and idler wheel!

[/B][/QUOTE]

[/B][/QUOTE]The idler wheel has a better 'micro inertial' effect, or continuity of drive that DD or belt cannot match, in some ways. This preserves micro/macrodynamic transient information as the rotation of the platter is not microscopically 'slowed' by the lateral motion of the stylus under hard record transisents.... slowed as it can be in other TT's. Record clamps achieve a similar effect at the expense of adding resonant mass charateristics which screw up the sound.

To each their own. The proper sort of damping situation for the bearing on the LP12 may improve it dramatically.....

Hi,

It also comes with a minimalist number of parts...No room for aftermarket tweeking there...

Just kidding guys,

The Garrard 301, when suspended on it's original springs sound excellent, despite a massive motor and idler wheel!

It also comes with a minimalist number of parts...No room for aftermarket tweeking there...

Just kidding guys,

Attachments

Hi,

Somehow I don't think you expect anyone to congratulate you on that particular audio purchase....

Fifteen seconds of just listening to that CDP and you had yourself a valid excuse not to make love to the wife that night.

Better bring it back to the US of A, it can still beat a frightening number of CDPs to bits ( analogue bits, mind you).

Ciao,

I haven't used since I bought the first philips cd player

Somehow I don't think you expect anyone to congratulate you on that particular audio purchase....

Fifteen seconds of just listening to that CDP and you had yourself a valid excuse not to make love to the wife that night.

Better bring it back to the US of A, it can still beat a frightening number of CDPs to bits ( analogue bits, mind you).

Ciao,

Yep, CDs do suck, and reliability-wise the first philips CD reader (that got rave reviews on many mags at the time) was a pretty piece of crap too.

I was almost kidding when I sais to Magura I don't like listening all that much anymore, I suspect that has alot to do with the CDs.

As I recall from 18 years ago the rubber disk had gotten a little hard and I somehow misplaced the shell for the SME tonearm, the cartridge got lost with it too.

The whole thing would have to be restored at this point.

Sorry for the threadjacking.

I was almost kidding when I sais to Magura I don't like listening all that much anymore, I suspect that has alot to do with the CDs.

As I recall from 18 years ago the rubber disk had gotten a little hard and I somehow misplaced the shell for the SME tonearm, the cartridge got lost with it too.

The whole thing would have to be restored at this point.

Sorry for the threadjacking.

The technology was there already but was too expensive to implement in a "mass market" product.

----------------------------------------------------------------------------------

Nano machining was not available in the late 1960s when the claims were originally made!

-------------------------------

Under the Linn list of 'Useless, Foolish and Dangerous Modifications to the LP12' no.1 is: -

"Damping material on the subchassis, tonearm, cartridge, or anyplace else. (The idea being to damp resonances.) This totally defeats the design of the Linn Sondek. We want any energy in the system to be present at all points in the-system. This way, any energy that affects the platter is also transmitted to the arm. The arm and cartridge move together, there is no relative movement between the cartridge body and the record, thus the energy has no effect on the output of the system. By damping any part of the turntable you are impeding the flow of energy from one part of the system to other parts of the system. This energy will no longer cancel out and, will show up in the output of the system."

---------------------------------------------------------------------------------

Linn and others simply cannot quantify performance in terms of displacement, velocity and acceleration contributing to energy storage and release. I guess that it can be done using FE analysis.

Hence all this talk about energy flows which seems to be aimed at convincing buyers. There is no reason why damping should not be applied beneficially in any part of the system. However, people seem to prefer to believe that screws make more difference!!!

If we must talk scince, let's talk science and none of this airy fairy stuff.

----------------------------------------------------------------------------------

Nano machining was not available in the late 1960s when the claims were originally made!

-------------------------------

Under the Linn list of 'Useless, Foolish and Dangerous Modifications to the LP12' no.1 is: -

"Damping material on the subchassis, tonearm, cartridge, or anyplace else. (The idea being to damp resonances.) This totally defeats the design of the Linn Sondek. We want any energy in the system to be present at all points in the-system. This way, any energy that affects the platter is also transmitted to the arm. The arm and cartridge move together, there is no relative movement between the cartridge body and the record, thus the energy has no effect on the output of the system. By damping any part of the turntable you are impeding the flow of energy from one part of the system to other parts of the system. This energy will no longer cancel out and, will show up in the output of the system."

---------------------------------------------------------------------------------

Linn and others simply cannot quantify performance in terms of displacement, velocity and acceleration contributing to energy storage and release. I guess that it can be done using FE analysis.

Hence all this talk about energy flows which seems to be aimed at convincing buyers. There is no reason why damping should not be applied beneficially in any part of the system. However, people seem to prefer to believe that screws make more difference!!!

If we must talk scince, let's talk science and none of this airy fairy stuff.

-------------------------------------------------------------------------------sleepy said:"Damping material on the subchassis, tonearm, cartridge, or anyplace else. (The idea being to damp resonances.) This totally defeats the design of the Linn Sondek. We want any energy in the system to be present at all points in the-system. This way, any energy that affects the platter is also transmitted to the arm. The arm and cartridge move together, there is no relative movement between the cartridge body and the record, thus the energy has no effect on the output of the system. By damping any part of the turntable you are impeding the flow of energy from one part of the system to other parts of the system. This energy will no longer cancel out and, will show up in the output of the system."

If the LP12 were perfect then this would be right, but its not and energy in the system is not even ,nor can it be.Also what particular set up does this apply too, circus, valhalla , ekos , troika?Each will resonate in a different way due to the design of idividual parts, also the surface it is resting on and the music being played at the time.

Can someone explain how energy can travel between bearing , two piece plater , felt mat record needle arm ,arm bearings arm board and it relvent screws at the same frequancy and time.

Not possible.

Although the ideal is good it doesn't always work in practise.

This is not based on science but postulations.

Will take you up on that paul if you don't want it, but..

From the looks of the mat its quite a bit thicker than a felt mat did you adjust your VTA to compensate?

If not your arm might be too low resulting in a deader sound.Also if it helps the arm track better(less distortion)maybe the tracking weight could be set a little lower than with the felt mat.

Just some ideas.I find that often if you change one thing you need to adjust others to fit in line with the change and only then can you tell if the change is positive.

From the looks of the mat its quite a bit thicker than a felt mat did you adjust your VTA to compensate?

If not your arm might be too low resulting in a deader sound.Also if it helps the arm track better(less distortion)maybe the tracking weight could be set a little lower than with the felt mat.

Just some ideas.I find that often if you change one thing you need to adjust others to fit in line with the change and only then can you tell if the change is positive.

I finally found the non slip mat, 3 Euro for a 420x420mm sheet  in the car section of a standard supermarket.

in the car section of a standard supermarket.

As soon as I try it, I'll report.

Analog_sa,

What does "But it beats the felt accross the board" mean? You know I'm not british native, and don't get the meaning of this sentence. Is that is much better than the felt?

BTW, nice arm

As soon as I try it, I'll report.

Analog_sa,

What does "But it beats the felt accross the board" mean? You know I'm not british native, and don't get the meaning of this sentence. Is that is much better than the felt?

BTW, nice arm

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Linn LP12 first mod?