I was first zipped by 220 when I was 6 or 7, high voltages still scare me at a very basic level.

Since I was around 6 or 7 I liked to touch an ****** just for the sensation feeling, and later for the "waked up" feeling. It's probably a good discussion topic for Physicists or EEs, but it could probably be a prohibited topic.

Anyone with suggestions for offensive 6-letter words, please PM me.

Or better yet, just turn off that insipid nanny filter.

se

My physics teacher at school had very high skin resistance and could hold a 240v live without any sensation. I once saw him lick his fingers before touching something so he could sense if it was live.

You must be kidding! I'm the opposite. I'm zipped almost everytime I plug my metal thumb drive into a PC at work. Even when touching my laptop when opening the lid. And I have to disconnect the VGA cable before touching my CPU casing. Shoes, newspaper or even plastic under my foot didn't prevent this from happening.

This is I don't understand. I assume that VGA cable has low voltage and when I touch the VGA pins nothing happened, so why when it is connected to a CPU the CPU casing becomes "alive" (must be the switching supply)?

Last edited:

Jay,

I am one of those who have very dry skin, so dry that I have problems with touch screens and anything that relies on inductive pickup. I've shown my kids many times that though they can swipe something and have no problems I can do the same over and over and get no response. How the moisture level in the skin changes all that I am not sure as I assure you I do have good blood supply to my extremities. You may just be the opposite and have very high moisture levels at the skin surface. Perhaps it is actually you that is carrying the surface charge and the equipment you are touching is grounding out your surface charge or it is the clothes you wear. I don't know but others may have those types of answers. The environmental conditions also have a lot to do with surface charge.

I am one of those who have very dry skin, so dry that I have problems with touch screens and anything that relies on inductive pickup. I've shown my kids many times that though they can swipe something and have no problems I can do the same over and over and get no response. How the moisture level in the skin changes all that I am not sure as I assure you I do have good blood supply to my extremities. You may just be the opposite and have very high moisture levels at the skin surface. Perhaps it is actually you that is carrying the surface charge and the equipment you are touching is grounding out your surface charge or it is the clothes you wear. I don't know but others may have those types of answers. The environmental conditions also have a lot to do with surface charge.

Jay,

I am one of those who have very dry skin,

So it is about moisture? Still a mystery to me how the sensation work. But I know about "funny" bone, just below your elbow. If you "hit" the spot with your finger nail you will feel the same sensation as being zipped by 220V. It is said that this spot has the closest distance to a "neuron" or sensor in the brain.

I have problems with touch screens

Interesting. There is a stone that is popular around this year, due to it being used by the president (in a ring) and also the same stone being given to Barack Obama. Here it is called "bacan" stone. What I don't understand is that this stone can be used to move object in touch screen.

You may just be the opposite and have very high moisture levels at the skin surface. Perhaps it is actually you that is carrying the surface charge and the equipment you are touching is grounding out your surface charge or it is the clothes you wear.

It is probably the high electrostatic charge in my body. Cannot be the clothes because I have many clothes

The environmental conditions also have a lot to do with surface charge.

Yes, the moisture level is relatively high here, but the phenomenon doesn't happen with everyone else.

My cousin can almost zap you unconscious with the touch of a finger.

That's unbelievable!

If there is audible 1KHz from cart vibrating mechanically this is clearly not true, also if this was true the arm in general would make no difference rattling bearings and all. I'm assuming here you are referring to the usual mass/spring effective mass model where the spring is rigidly attached to a mechanical "ground".

Scott

I am aware of what you say. In the past I had tried again on this topic (and even that approach is simplistic).

http://www.diyaudio.com/forums/analogue-source/100408-results-m97xe-mod-9.html#post1211741

But one has to start from somewhere. The proposed simple test will give a few numbers. Let's look into them ( in ~ a month I will be able to do the test)

BTW another point by this argument the output at 23.5K load should drop by 3dB, right, or at least enough to keep the 80% from going over 100%?

When the resistance of the electrical load becomes smaller and smaller, I would expect that the voltage output of the generator with a finite internal impedance (~1kOhm for a MM) will start to drop. Demian has hinted on the magnetics too

Also, if you model a cartridge as a voltage source in series with the internal magnetics it should be clear that as you lower the impedance (of the load) the magnetics will interact with the current.

George

When the resistance of the electrical load becomes smaller and smaller, I would expect that the voltage output of the generator with a finite internal impedance (~1kOhm for a MM) will start to drop.

Only at LF. As the frequency rises, the impedance does as well, exacerbating the effect of the load resistance on output.

Only at LF. As the frequency rises, the impedance does as well, exacerbating the effect of the load resistance on output.

If I understand you well, you mean that as freq increases, the inductive impedance of the coils increases, thus the cartridge's internal impedance goes up, which has the effect of further increasing the voltage drop in the process of deliberate lowering the resistance of the cartridge load ( frequency dependence of the series leg of the voltage divider),yes?

George

Applaud the effort, George - however the mechanical impedance does not arise from inertia or mass equivalent of the stylus. I hope I can explain..........Kinetic energy entering the cartridge

KE=0.5*m*v^2 (m for mass, v for velocity)

For

v=5cm/s (modulation velocity)

m=0.5mg (effective mass)

KE=6.25E-10 Joule

So the mechanical power entering the cartridge in 1s is 6E-10 W

A 1mV/1cm/s MM cartridge when reading a 5cm/s modulation supplies to a 47k load a P(el)=5E-10W

The mechanical to electrical efficiency seems to be ~ 80%, a very high number for such a small generator

Let's put aside effective tip mass for a moment.

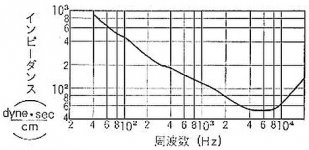

In the bigger picture, if it were not for mechanical impedance to motion of the stylus, there would be no need for downforce to keep it tracking groove motion. Then, it is possible to determine mechanical impedance versus frequency from measuring the limit of trackability velocity versus frequency, and this is what was done by manufacturers back in the day. There were published mechanical impedance curves for some cartridges, I've attached an example for a Denon DL103.

By reading the mechanical impedance curve, one can readily obtain mechanical power required to move the stylus at any given velocity and frequency. This is the best way to evaluate mechanical power involved in stylus movement. When we do this, we find it works out perhaps a few mW typ at 5 cm/s 1kHz.

Returning to effective tip mass, in principle it is what determines mechanical impedance at high acceleration, ie high frequency, the right hand part of the impedance curve. HOWEVER, the method typically used by manufacturers to determine effective tip mass is seriously flawed and does not correlate well - it assumes vinyl is springy and then determine e-mass from the mechanical resonant frequency always observed in the cartridge frequency response. Whereas this resonance can be that of cantilever self flex, not related to vinyl spring-tip e-mass system at all. Poor correlation obtains from using published tip mass as a figure of merit then, other than to locate the frequency of the mechanical resonance - it is useless for evaluating mechanical impedance and power for example.

Best to use the published mechanical impedance curves then, eg in the example below. So, for MM, typical power conversion ratio when loaded at 47k works out about -45dB or about 0.002% (NB that is a power ratio).

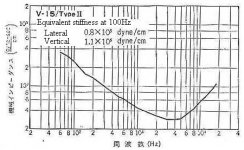

Edit: also added a published Shure V15 cartridge mech impedance chart

Attachments

Last edited:

Where have reviewers like this gone?

This seems to agree with the above ~40 mechanical Ohms in the critical band. Is that right?

This seems to agree with the above ~40 mechanical Ohms in the critical band. Is that right?

Stanley Kelly writing in Gramophone in 1966 reviewing the Ortofon S15T:

The flexible mounting carries a damping block and is arranged to prevent fore and aft movement, thus preventing a rather nasty form of distortion in which the wave is frequency modulated by itself. It does not, however, completely stop torsional movement, and it is believed that the resonance occurring at 8 Kc/s is due to the torsional resonance of the system. The ratio of cantilever length to coil dimension is 7:1, giving a mechanical impedance ratio of 50:1, and it is this feature which results in an extremely low mechanical impedance at the stylus tip. The static compliance is 17 by 10-6 cm/dyne, which is within commercial tolerance of the claimed 20 by 10-6 cm/dyne. Because of the damping mentioned above, the resistive component becomes predominant in the important frequency band of 1 Kc/s to 3 Kc/s, and approximates to 40 mechanical Ohms. The claimed tip mass is 0.9 milligrammes, but because the method of measurement is not specified it is difficult to Verify. In terms of mechanical impedance it approximates to 2.37 mg at 5 Kc/s, 2.7 mg at 8 Kc/s, 2.3 mg at 10 Kc/s, 2.6 mg at 12 Kc/s, and 1.29 mg at 20 Kc/s. The stylus resonance is at 26 Kc/s with the STR 100 test record speeded up to 45 rpm, and is at 24 KO when measured on a specially cut disc moving at 334 rpm; this gives a calculated resonating mass of 1.24 mg.

This dissertation is to illustrate the difficulties in assessing the euphemistic quality known as 'stylus mass' or 'equivalent mass referred to stylus tip'. Because there are inevitably a number of resonances in the upper frequency regions, it is not possible, except in very simple structures, to give one value for tip mass which is meaningful! But what is important is the impedance presented to the record.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II