Hi Jim,

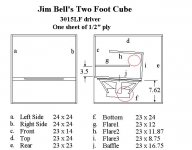

Here's my plan & cut list for the 2' cube.

Changes/corrections?

I'd love to see the calculations you used to come up with those folds, Don. I've been trying to come up with a similar folding scheme for another TH I want to build (S1=258cm^2, S4=1187cm^2, L=241.3cm), but not making much progress...

Hi Brian,

I use an iterative technique that converges at the second or third iteration. It uses a couple of assumptions that seem to cause no harm.

I did a write-up on post 1490 of the big thread.

See: http://www.diyaudio.com/forums/subw...tive-tapped-horn-project-149.html#post1478209

Questions? I'd be glad to help.

I use an iterative technique that converges at the second or third iteration. It uses a couple of assumptions that seem to cause no harm.

I did a write-up on post 1490 of the big thread.

See: http://www.diyaudio.com/forums/subw...tive-tapped-horn-project-149.html#post1478209

Questions? I'd be glad to help.

Last edited:

Hi Brian,

I use an iterative technique that converges at the second or third iteration. It uses a couple of assumptions that seem to cause no harm.

I did a write-up on post 1490 of the big thread.

See: http://www.diyaudio.com/forums/subw...tive-tapped-horn-project-149.html#post1478209

Questions? I'd be glad to help.

Cool - I'll look it up ASAP. Spent too much time tonight tonight trying to reinvent the wheel

Jim

What kind of handles are you going to use for the cube? Also where will you place them?

I got one cube cut out today from a 1/2" sheet of Arruco. Also got the layout drawn onto the wood. The baffle layout is done. Did all the cutting with a skil saw.

If it doesn't rain here tomorrow, I should be able to glue it up. Can't wait to hear it when it's done. 2 of the 3015lf's are coming out of Titan 48's. After the first one gets done, 3 more will follow.

What kind of handles are you going to use for the cube? Also where will you place them?

I got one cube cut out today from a 1/2" sheet of Arruco. Also got the layout drawn onto the wood. The baffle layout is done. Did all the cutting with a skil saw.

If it doesn't rain here tomorrow, I should be able to glue it up. Can't wait to hear it when it's done. 2 of the 3015lf's are coming out of Titan 48's. After the first one gets done, 3 more will follow.

Jim

What kind of handles are you going to use for the cube? Also where will you place them?

I got one cube cut out today from a 1/2" sheet of Arruco. Also got the layout drawn onto the wood. The baffle layout is done. Did all the cutting with a skil saw.

If it doesn't rain here tomorrow, I should be able to glue it up. Can't wait to hear it when it's done. 2 of the 3015lf's are coming out of Titan 48's. After the first one gets done, 3 more will follow.

Dayton PH114 Plastic Pocket Handle 4-Sided | Parts-Express.com

There are a couple options where the 5 3/4" cutout will work without interfering with an interior panel. I don't like spring handles (they vibrate) or strap handles (they are in the way) These seem to be the best idea I've found. With a jasper jig, circle cut outs are a 30 second process.. I've also thought about (but not actually done yet) mounting my jacks in these.

Post pics, and an A-B comparison would be nice.

edit:

shawn -- the big cabinet is big.... as I've said many times, it's a GREAT install cabinet.... portable... not so much.

Last edited:

Thanks Jim... Got the pocket handles ordered. So where are the good locations for them to go? Sure don't want to put them where they will interfere with the output.

It's rained here today, so no work has been done on the cubes yet today. After my daughters band practice finishes in the basement, I will start putting them togather down there. Usually I do it outside. I will take pics and post a A/B comparison.

Thanks Mike

It's rained here today, so no work has been done on the cubes yet today. After my daughters band practice finishes in the basement, I will start putting them togather down there. Usually I do it outside. I will take pics and post a A/B comparison.

Thanks Mike

Cool - I'll look it up ASAP. Spent too much time tonight tonight trying to reinvent the wheel.

Well, I tried, but couldn't make it work. I managed to get a good portion of the calculations into Excel, but the numbers coming back suggested that something still wasn't right.

Instead of TJ'ing any further, I'll post a note about this on my thread.

Jim, I have a trailer with a ramp so size doesn't matter to me. I put 4 casters on each sub and just roll them in place. no big deal. I love my JBell Large TH's.

I just want a set of cubes for the smaller clubs. I just started building 4 more Large JBell TH's for a total of 8. next is a couple cubes to try out.

Thanks,

Shawn

I just want a set of cubes for the smaller clubs. I just started building 4 more Large JBell TH's for a total of 8. next is a couple cubes to try out.

Thanks,

Shawn

shawn:

scott says there is a dj around florida running around with 8 of the big cabinet -- so I guess you are in good company... And wheels are a necessity for that one.

Mike:

I attached a pic of the 2 places I'd put it. Neither place should affect the sound. The good part about the center option, is if you have to notch panel 'j' a little, that's ok, it doesn't create a 'leak' if you do. It should also get at least 3 screws into panels 'h' and 'i' with the slight possibility of getting the 4th into panel 'j' It's close to center of gravity, but not quite. I'm big on handles having something more than 1/2" of wood to connect to. Use the 'mouth' option if you plan on putting stuff on top of the cubes when carting in/out. You have the flexibility there to put them center of gravity. I am going to have to try jacks in these handles, as I think it should provide a nice 'protected' place for them.

scott says there is a dj around florida running around with 8 of the big cabinet -- so I guess you are in good company... And wheels are a necessity for that one.

Mike:

I attached a pic of the 2 places I'd put it. Neither place should affect the sound. The good part about the center option, is if you have to notch panel 'j' a little, that's ok, it doesn't create a 'leak' if you do. It should also get at least 3 screws into panels 'h' and 'i' with the slight possibility of getting the 4th into panel 'j' It's close to center of gravity, but not quite. I'm big on handles having something more than 1/2" of wood to connect to. Use the 'mouth' option if you plan on putting stuff on top of the cubes when carting in/out. You have the flexibility there to put them center of gravity. I am going to have to try jacks in these handles, as I think it should provide a nice 'protected' place for them.

Attachments

Here's a set of eight 24" cubes at 63v each in 2pi that is safe xmax wise to 35hz, that I'm starting a run of. Each cube can be made from a single 42lb sheet of 1/2" ply. (quite the contrast to 2 sheets of 72lb ply each.) Yea it takes more power/drivers to get there, but my back will like me better the next day.

Just a quick one - what's the measured Fc of your new TH?

Just a quick one - what's the measured Fc of your new TH?

Funny you ask, and also funny that I'm not sure exactly how to answer...

There are lies, darn lies, and then there are specs....

Is measured Fc the point where efficiency starts to decline? or is it measured as lowest freq of a +-3db response ?

42hz is where the efficiency really starts to drop, but 40hz is still well within a +-3db of 100db overall efficiency. Hornresp says 40hz is the excursion null. I guess you could in theory use either number.

Here's what I posted earlier as the every 10hz responses...

30hz 87

40hz 98

50hz 100.5

60hz 100.5

70hz 99.5

80hz 98.5

90hz 99

100hz 100

110hz 102

120hz 103

130hz 102.5

140hz 101

150hz 98.5

160hz 93

170hz 83

Funny you ask, and also funny that I'm not sure exactly how to answer...

There are lies, darn lies, and then there are specs....

Is measured Fc the point where efficiency starts to decline? or is it measured as lowest freq of a +-3db response ?

42hz is where the efficiency really starts to drop, but 40hz is still well within a +-3db of 100db overall efficiency. Hornresp says 40hz is the excursion null. I guess you could in theory use either number.

That would be the design Fc. The measured impedance response of the the TH is probably the best way to identify the actual Fc - it's at the first impedance mininum. A WT3 will measure the response in a few seconds. If you don't have access to a WT3, there are other ways to find this impedance minimum.

so it measures a bit better then hornresp predicts ?

Looks so. I'll bet that mounting the driver backside out has resulted in the mouth being shaded a bit, which in turn perhaps has resulted in Fc being shifted downwards (similar to what happens if you partially block the port of a vented box). The smaller the mouth, or the larger the driver, the greater the effect. This is not necessarily a bad thing, and perhaps even preferable

Cubic inches:

4 Big uns:

4 x 36 x 46 x 24 = 158 976

8 Little uns:

8 x 24 x 24 x 24 = 110 592

Wood:

4 Big uns:

8 Sheets 0.75 inch plywood

8 Little uns:

8 sheets 0.50 inch plywood

Drivers:

4 Big uns:

4 Kappalite 3015lf

8 Little uns:

8 Kappalite 3015lf

What does it cost us? I'm guessing the US guys have cheaper plywood, so you are happy to build big high efficiency boxes.

In my case the wood makes costs almost as much as the driver on the big boxes.

Regards, Ben

Hi Ben. Have you shopped around thoroughly for MPX (plywood) prices? The price differences from store to store are very significant here in Munich. I recently bought 3/4 birch ply for 48€ per square meter, and then later found it in a different store for 28€ per square meter:

An externally hosted image should be here but it was not working when we last tested it.

At those prices, a pair of the little ones would cost 100€ in wood, and 330€ in drivers, so 430€ total per pair. An eightpack could be had for 1720€ then, which is not bad.

Anyways, jbell, these small cubes look quite good - I'd definitely build a pair if I had any use for them

so it measures a bit better then hornresp predicts ?

I wouldn't say 'better' just different. When you fold a TH, the reflectors close to the driver play a big part in the response. I can sacrifice 40hz for more 80hz, and vice versa depending. I chose to use no reflectors and achieved more 40hz than hornresp predicted, at the expense of a larger dip in the 80hz range. If you go look at what screamersusa did on his, the 12degree reflectors and non parallel walls close to the driver show how he achieved a better 80hz-100hz range. A solid rear brace reduced his 40hz by a few db. Even my triangle braces reduced 40hz by a full db. So braces and reflectors play a big part in the overall response.

So, a TH is like a soup, yes hornresp gets you the main ingredients of a good TH, but then you have to season to taste.....

I wouldn't say 'better' just different. When you fold a TH, the reflectors close to the driver play a big part in the response. I can sacrifice 40hz for more 80hz, and vice versa depending. I chose to use no reflectors and achieved more 40hz than hornresp predicted, at the expense of a larger dip in the 80hz range. If you go look at what screamersusa did on his, the 12degree reflectors and non parallel walls close to the driver show how he achieved a better 80hz-100hz range. A solid rear brace reduced his 40hz by a few db. Even my triangle braces reduced 40hz by a full db. So braces and reflectors play a big part in the overall response.

So, a TH is like a soup, yes hornresp gets you the main ingredients of a good TH, but then you have to season to taste.....

Did you try to account for the effect of those reflectors and braces in HornResp? They will all reduce Sd at points in the horn, which will in turn may affect the predictions if you try to account for them in the design.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- jbell's set of four tapped horns