poobah said:If it is a true constant current source... yes.

how long would the other 2 tubes last if the amp was left attended?

say the owner took a nap and forgot to turn off the amp and one of the tubes died during this time.

thanks again

rdf said:So it's a rectification phemonenon! Out of curiousity, do you offset bias your DC filamanents?

No, if voltage between catode and filament is within specified by manufactirer limits, otherwise it is unsafe for the tube.

jarthel said:example:

I have a constant current source DC supply (using a lm317) of 1.5A to supply 3 tubes of the same type. The heaters are connected in parallel.

what will happen if 1 of the tubes goes bad? Will the remaining 2 tubes be consuming 750mA each?

thank you.

one CCS per tube

LM317 is dirt cheap

Problems with my filament limit current circuit

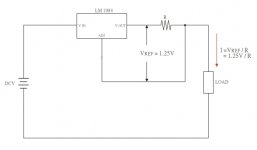

I am using this circuit intended to produce 6.3V constant current at 365mA for my 6DJ8. Input AC is 12.6V but the output is 8.7V with a constant current of 372mA. The R is 3.3 ohme 2W and there is not much heat on it. Can anyone tell me is there anything wrong in this curcuit?

Can I just put a resistor at the DC output to reduce the voltage to 6.3V? Would the consumption of the extra resistor eats up part of the output current that leads to insufficient current going to the filament?

Thank you

I am using this circuit intended to produce 6.3V constant current at 365mA for my 6DJ8. Input AC is 12.6V but the output is 8.7V with a constant current of 372mA. The R is 3.3 ohme 2W and there is not much heat on it. Can anyone tell me is there anything wrong in this curcuit?

Can I just put a resistor at the DC output to reduce the voltage to 6.3V? Would the consumption of the extra resistor eats up part of the output current that leads to insufficient current going to the filament?

Thank you

Attachments

i also know that regulation and constant filament current prolong tube life

How do you know? Have you seen a test that you can refer to?

It is my experience and from what I read is that most tubes doesn't fail due to broken heaters but mostly due to reduced emission which will give too low transconductance etc.

As a heater in itself is a kind of constant current device, (if current goes up the resistance goes which makes the current go down) why would you get longer tube life by using a constant current supply.

What I know is important is to have reasonable constant heater voltage as excessive heater voltage >+10% over nominal could have a negative effect on heater life but you don't need a regulator for this, the mains voltage in most countries is so constant that feeding the heaters from a transformer without regulation is sufficient.

Regards Hans

Personal opinion on this issue.

Either use AC voltage to filaments in parallel, or constant DC current to filaments in series.

Reasons why: if you choose to use dc voltage, it absolutely should be regulated. If not, the ripple present (even if small) will tend to have many more higher order harmonics than straight 60 Hz AC. So those that argue dc is quieter lose the argument with high order harmonics.

To use regualted dc voltage, you still have the limitation of filament variation from tube to tube. So even if each filament has 'perfect' dc across it, unequal current sharing (therefore unequal heat) will be the result.

Finally, voltage is subject to contact resistance. I fail to see the benefit of regulated DC voltage over AC voltage.

Regulated DC current, on the other hand, is a whole different animal.

Heat is an I-squared-R relationship. So while R obviously affects the heat output, I affects it in a square fashion. One gains greater control over the heat output by controlling the current, even if R changes a little.

More so, filaments in series have 'perfectly' identical current through each. While we cannot control the resistance of the filament the manufacturing process produces, we can guarantee each filament sees an identical current.

Constant current is independent of contact resistance / lead length. As long as your regulator has enough headroom, it will compensate for filament aging and contact resistance.

Constant current is independent of mains AC voltage (important).

Constant current, as stated in others' posts, limits inrush, without ANY circuitry specifically designed to 'soft start'. Simpler is better. Why slow start DC voltage when DC current is automatic, and applies rated current immediately? That would seem to be the fastest start possible without affecting filament life.

Constant current does not produce any alternating EMF fields, which will induce stray currents in other circuitry. 1.5A of AC current to EL34's will. Can we hear it? Don't know, but I guarantee it is there. Ask Mr. Lorenz. DC current will NOT induce stray DC currents; it doesn't work that way. DC induction is not a passive phenomenon.

With regards to regulator noise, I simply bypass the entire filament circuit with a polyester capacitor near the regulator output. Given the high impedance of the filament circuit, high frequencies will prefer the capacitor instead of the filaments. Your actual current output will be extremely quiet.

At the end of the day, everyone has their opinion, and possibly any method is just as valid. From a theoretical standpoint, however, I feel DC current blows away all other practical options.

Either use AC voltage to filaments in parallel, or constant DC current to filaments in series.

Reasons why: if you choose to use dc voltage, it absolutely should be regulated. If not, the ripple present (even if small) will tend to have many more higher order harmonics than straight 60 Hz AC. So those that argue dc is quieter lose the argument with high order harmonics.

To use regualted dc voltage, you still have the limitation of filament variation from tube to tube. So even if each filament has 'perfect' dc across it, unequal current sharing (therefore unequal heat) will be the result.

Finally, voltage is subject to contact resistance. I fail to see the benefit of regulated DC voltage over AC voltage.

Regulated DC current, on the other hand, is a whole different animal.

Heat is an I-squared-R relationship. So while R obviously affects the heat output, I affects it in a square fashion. One gains greater control over the heat output by controlling the current, even if R changes a little.

More so, filaments in series have 'perfectly' identical current through each. While we cannot control the resistance of the filament the manufacturing process produces, we can guarantee each filament sees an identical current.

Constant current is independent of contact resistance / lead length. As long as your regulator has enough headroom, it will compensate for filament aging and contact resistance.

Constant current is independent of mains AC voltage (important).

Constant current, as stated in others' posts, limits inrush, without ANY circuitry specifically designed to 'soft start'. Simpler is better. Why slow start DC voltage when DC current is automatic, and applies rated current immediately? That would seem to be the fastest start possible without affecting filament life.

Constant current does not produce any alternating EMF fields, which will induce stray currents in other circuitry. 1.5A of AC current to EL34's will. Can we hear it? Don't know, but I guarantee it is there. Ask Mr. Lorenz. DC current will NOT induce stray DC currents; it doesn't work that way. DC induction is not a passive phenomenon.

With regards to regulator noise, I simply bypass the entire filament circuit with a polyester capacitor near the regulator output. Given the high impedance of the filament circuit, high frequencies will prefer the capacitor instead of the filaments. Your actual current output will be extremely quiet.

At the end of the day, everyone has their opinion, and possibly any method is just as valid. From a theoretical standpoint, however, I feel DC current blows away all other practical options.

however keeping the voltage constant does prolong heater life

I think that is also debatable until someone can provide any proof. I think it is more important not to vastly exceed nominal voltage, if however the voltage varies slightly over time shouldn't matter much.

This is not different then with regulated current as in that case voltage and there also heater power in each tube will vary due to difference in heater resistance.To use regualted dc voltage, you still have the limitation of filament variation from tube to tube. So even if each filament has 'perfect' dc across it, unequal current sharing (therefore unequal heat) will be the result.

Constant current, as stated in others' posts, limits inrush, without ANY circuitry specifically designed to 'soft start'. Simpler is better. Why slow start DC voltage when DC current is automatic, and applies rated current immediately? That would seem to be the fastest start possible without affecting filament life.

I think it is really important to know if there is any need to prolong heater life, if as I believe tubes normally failes due to other reasons there is no need of soft start or un-necessary regulation circuits.

Regards Hans

Definitely, use constant voltage on voltage rated heaters, current on current rated heaters - in other words, voltage for parallel circuits, current for series. Any other way, you run into problems with slightly different tube versions.

With DC heaters, regulation, or at least some form of filtering is a must. The thing that does help with parallel filaments is a soft-start feature on the regulator, either bu a current limit or by generating a voltage ramp.

Do not confuse a current limiter with a current source. Normally, the current would be limited well above the actual requirements. At startup, filaments tend to draw a lot more current as their resistance temperature coefficient is positive. Providing a current limit tends to reduce the 'flashing filament' effect.

Using constant current on series chains provides automatic 'soft start' but you can still get the odd 'flashing filament' depending on the actual heater construction.

Regarding DC bias for filaments, I've had good experience with positive bias. I always thought that since the actual filament is hotter than the cathode, you get a sort of silica-obstructed DHT diode, for which the filament is the cathode, and the actual heater the cathode. Hence, postiively biassing the heater would reverse-bias the diode. TO be honest, I never tried negative bias as a means to stop hum. I'll give it a try while emasuring heater to cathode elakage, should be an interesting experiment.

With DC heaters, regulation, or at least some form of filtering is a must. The thing that does help with parallel filaments is a soft-start feature on the regulator, either bu a current limit or by generating a voltage ramp.

Do not confuse a current limiter with a current source. Normally, the current would be limited well above the actual requirements. At startup, filaments tend to draw a lot more current as their resistance temperature coefficient is positive. Providing a current limit tends to reduce the 'flashing filament' effect.

Using constant current on series chains provides automatic 'soft start' but you can still get the odd 'flashing filament' depending on the actual heater construction.

Regarding DC bias for filaments, I've had good experience with positive bias. I always thought that since the actual filament is hotter than the cathode, you get a sort of silica-obstructed DHT diode, for which the filament is the cathode, and the actual heater the cathode. Hence, postiively biassing the heater would reverse-bias the diode. TO be honest, I never tried negative bias as a means to stop hum. I'll give it a try while emasuring heater to cathode elakage, should be an interesting experiment.

Here is my thoughts about constant current and filaments. When do most incandescent light bulbs burn out? During initial turn on. Then again almost every old radio I've bought had either a shorted or very weak output tube as the cause of failure. Rarely did a tube have an open filament. So I guess it can't hurt to use CCS filament supplies but its not often the main cause of failure. For rare or expensive tubes I would say sure why not use CCS.

Something get into my mind

Regulated DC filament supply will induce high current when started and I measured a peak current of 900 mA for my 300 mA tube. Constant current supply also post some sort of problem when dealing with tubes of different manufacturers. What about an alternative in between?

Can we use a regulated PSU with limited current supply? In my example of 6DJ8, it has various models ranging from 300 mA to 400 mA. What about we limit the current to 400mA therefore the worse damage to the 300mA is only 100mA. Even more, if we limit our choice to 6DJ8 of 365 mA, we can limit the PSU to 365 mA that reduces the at-most over-current to 65mA?

Would like to hear more comments for you all.

Regulated DC filament supply will induce high current when started and I measured a peak current of 900 mA for my 300 mA tube. Constant current supply also post some sort of problem when dealing with tubes of different manufacturers. What about an alternative in between?

Can we use a regulated PSU with limited current supply? In my example of 6DJ8, it has various models ranging from 300 mA to 400 mA. What about we limit the current to 400mA therefore the worse damage to the 300mA is only 100mA. Even more, if we limit our choice to 6DJ8 of 365 mA, we can limit the PSU to 365 mA that reduces the at-most over-current to 65mA?

Would like to hear more comments for you all.

Quote

Then again almost every old radio I've bought had either a shorted or very weak output tube as the cause of failure. Rarely did a tube have an open filament.

Unquote

In most cases when a filament is burnt, people will change it because the tube is not glowng. Whereas they sell the machine when they heard the sound is not good without knowing its the tube is approaching end-of-life. Does this logic work?

Then again almost every old radio I've bought had either a shorted or very weak output tube as the cause of failure. Rarely did a tube have an open filament.

Unquote

In most cases when a filament is burnt, people will change it because the tube is not glowng. Whereas they sell the machine when they heard the sound is not good without knowing its the tube is approaching end-of-life. Does this logic work?

Sunsun22,

It seems to me that you are convinced that constant current will extend tube life as you seem to believe that burned out filaments is a major fault effect. I understand that it is easy to think like that as one can see a resemblance between the filament in a tube and the filament in a light bulb and light bulb of course always have a broken filament as the major fault effect.

However a light bulb filament and a filament in a tube are quite different things and it pays to study all the efforts that was made by tube manufacturers in the beginning to develop better type of filaments. The earliest tubes had indeed a filament that burned at approximately the same temperature as a light bulb, (brigth emitter filements) but soon it was possible to make filaments that gave much higher emissivity at much lower temperature and the filament life was extended many times compared to the early light bulb type.

GEC In England describe the development of filaments and heaters in their valve manual but similar descriptions can also be found elsewhere.

Instead of assuming this and that I think it is a much more efficient to do some reserach and in the area of tube reliability there are literally tons of books available. In the books I have read on this subject I have never seen burned out heaters as the most common fault instead it is often mentioned low emission or shorted electrodes

Or you can do a poll here on DIYaudio.com and ask people how many have experienced a burnt out filament of all the tubes they have replaced.

Regards Hans

It seems to me that you are convinced that constant current will extend tube life as you seem to believe that burned out filaments is a major fault effect. I understand that it is easy to think like that as one can see a resemblance between the filament in a tube and the filament in a light bulb and light bulb of course always have a broken filament as the major fault effect.

However a light bulb filament and a filament in a tube are quite different things and it pays to study all the efforts that was made by tube manufacturers in the beginning to develop better type of filaments. The earliest tubes had indeed a filament that burned at approximately the same temperature as a light bulb, (brigth emitter filements) but soon it was possible to make filaments that gave much higher emissivity at much lower temperature and the filament life was extended many times compared to the early light bulb type.

GEC In England describe the development of filaments and heaters in their valve manual but similar descriptions can also be found elsewhere.

Instead of assuming this and that I think it is a much more efficient to do some reserach and in the area of tube reliability there are literally tons of books available. In the books I have read on this subject I have never seen burned out heaters as the most common fault instead it is often mentioned low emission or shorted electrodes

Or you can do a poll here on DIYaudio.com and ask people how many have experienced a burnt out filament of all the tubes they have replaced.

Regards Hans

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Is constant filament current better way to build amps?