anatech said:Hi bsgd,

That price is completely unreasonable. It's mostly an AC voltmeter! Surly there must be a competent place where you can get a proper calibration done. I didn't expect this to run you more than $200 on the outside. At $900, you could probably rent a Fluke 5520A multifunction calibrator for a week and make money on the deal! With that, you can calibrate most DVMs, oscilloscopes and all manner of AC voltmeters.

There must be some way you can have your instrument calibrated for reasonable money. You know what? Even an "in cal" HP 34401A plus a sine wave source would get you calibrated, a 3457A even. A newer Fluke might be enough to get the job done, but I'd be buying a nice bench meter with that money instead. I'm sure that with just some basic things, you would be able to set that meter up. In short, I completely agree with you. You can do this work.

I have not yet looked into my manual, and I would have to in order to give you a reasonable answer any further. I do know there are a couple wires near the capacitor that are sensitive to their location. Try not to move any of those wires.

If there is one under rated meter out there, it has to be the Agilent (HP) 34401A. It is extremely accurate, has a number of very useful functions and will average readings over a time period. If you were to buy anything, this one meter will make your life so much easier. If you can swing a new one, try the 34405A(?), 5 1/2 digit bench meter or go for the 34401A. It's still a current product! There are two improved models in the same class, then the 3458A laboratory meter. That one will not suit most audio work, and it costs more than I can wrap my head around.

I have to say that the one purchase I made at list that I never did regret was that HP 34401A. That one meter has saved me so much time, it's silly. I also use it as a calibration standard to set other meters up. It's still bang on with a freshly calibrated 3457A - not too shabby!

Is it at all possible that a "screwdriver jockey" got in there before you received it? I don't know it's history, but it is so unusual to see one way out like that.

-Chris

Well, I did find a few 34401A around here for sale. They run for around $1300 used. Buying it is a far better option that just paying the almost same ammount of money to calibrate my 339A, but still, I cant afford that now.

Oh, I just found a new 34401A here. As you can see, price is around $1900.

You see, Im in Brazil, and things here are much more expensive than anywhere else. We have 100% taxes over anything that gets here from other countries, so, everything is at least double the price. Rafael.luc lives here and Im sure he knows what Im talking about.

If I could get 399As here for $200, Id buy them all and sell them for big $$ !!!

So, the answer is no, I cant get it calibrated buy a professional for a few bucks... I'll try to search a little more, but for now, I just found one place that seems reasonable to do the job, but I wont pay that much... I did find a few 'guys' that would do for little more than $250, but Im not interested in that.

Well, I dont know what happened to this 339A in the past. It is possible someone did mess with it before, but I cant really tell.

IMHO, purveyors of calibration services and agencies who write standards have their own best interests at heart. By sowing FUD (fear, uncertainty & doubt) they make a lot of money. Commercially one has to go down that path, but the hobbyist can make or collect a few inexpensive standards and get every piece of test equipment he/she owns running to factory spec.

I agree, the Agilent 34401A is wonderful and we use them at work, but it's out of my budget for home. I think they're under $1k here, or were during the last sale. Honestly I don't use most of the features and an old HP3455A at home is just as accurate and has a true RMS bandwidth of near 100kHz, if I remember right. They sell for a couple hundred dollars used here. They'll maintain better than ten parts per million for years between calibrations. Unless you're still using tube equipment, the idea of yearly calibration for solid state test equipment is just another money maker for the cal and standards folks. I check my equipment frequently against traceable standards and it would be unusual to have to touch anything more often than every 3-5 years, if at all.

For 99% of audio a good scope and signal generator are far more useful than a meter. There's almost nothing in audio that requires close measurement.

If Digikey ships to Brazil, and I have to believe they do, you should be able to get high precision voltage references and 1% resistors easily. From that you can match resistors and build a divider to far better than 0.1%. From that you can check multiple ranges. If you can find a copy of Fluke's book- Calibration, Philosophy and Practice, it covers the making up of standards and other useful topics.

I agree, the Agilent 34401A is wonderful and we use them at work, but it's out of my budget for home. I think they're under $1k here, or were during the last sale. Honestly I don't use most of the features and an old HP3455A at home is just as accurate and has a true RMS bandwidth of near 100kHz, if I remember right. They sell for a couple hundred dollars used here. They'll maintain better than ten parts per million for years between calibrations. Unless you're still using tube equipment, the idea of yearly calibration for solid state test equipment is just another money maker for the cal and standards folks. I check my equipment frequently against traceable standards and it would be unusual to have to touch anything more often than every 3-5 years, if at all.

For 99% of audio a good scope and signal generator are far more useful than a meter. There's almost nothing in audio that requires close measurement.

If Digikey ships to Brazil, and I have to believe they do, you should be able to get high precision voltage references and 1% resistors easily. From that you can match resistors and build a divider to far better than 0.1%. From that you can check multiple ranges. If you can find a copy of Fluke's book- Calibration, Philosophy and Practice, it covers the making up of standards and other useful topics.

Hi bsgd,

I understand you predicament. It's not unlike what hobbyists go through locally here, although the money amounts are ridiculously high in Brazil it seems. Keep your eyes peeled for any good opportunities.

Keep in mind that my 34401A is now over 15 years old I think. That means that some companies may get rid of them for reasons other than one being serviceable. "Chance favors the prepared mind", from a movie I enjoy.

I'll disagree with Conrad on this one, I think a 34401A will provide you with much higher benefits than you may think. It's both a highly effective instrument with many features that make bench life far easier, and it represents a reliable standard to compare everything else you have to. I've spent enough time calibrating instrumentation - including these and 87's, to understand what an opportunity one of these represents to you. With a 34401A, you are able to depend on the calibration of most of your other test equipment. That means you will know your readings are accurate. This would seem to be a critical thing for you in Brazil, given how much a cal costs. You could very easily correct calibrations for many other meters using the 34401A, certainly anything from an 87 down. Keep in mind that I like the 87, and I wish I had one.

Hi Conrad,

There are several brand new instruments sold that do not meet their published specifications! In fact, there are others that do not hold their calibration well at all. I am not pushing calibration services, but I am trying to educate some as to the importance of knowing what your reading may be compared to the actual values.

I have attempted to calibrate many less expensive meters that were brand new, still in box. It was not possible to "optimize" many of these to comply with their rather loose tolerances. Now, what does that tell you? It tells me that there are several thousand hobbyists using equipment that is either wildly inaccurate, or at least not performing to published limits. I don't know about you, but this worries me. Then we have those meters with tight published accuracies that will not hold a calibration for even one year. Extech come to mind, and their may be several others. Take this information with the knowledge that I have not certified one of these for at least 5 years, they may have corrected that situation.

The only thing that stands any chance of correcting this situation is the process of calibration. This is the only way for someone to actually know what the instrument in question is doing. Some are so bad that they require recertification every 6 months. Since they are specialized products, there is no choice but to continue using these.

In industry, calibration saves millions per year by catching and correcting instrumentation problems before they cause trouble in plant processes. Cheap insurance if you ask me.

For the hobbyist, one very good instrument can be used to correct whatever else is used on the bench. Note that I have not recommended even a two year calibration cycle. My meter is still in tolerance (as close as I can justify) now after 12 years since the last calibration. Not bad. I bought an HP 3457A, calibrated, and performed a cross-check with it. See what I'm saying?

Conrad, I think it is important for any serious hobbyist to have at least one instrument that has been certified, and is of a design that is known to hold that calibration over time and temperature. BTW, certifications are only good for + or - 5 °C from the temperature it was certified at. That information (plus humidity) will be on the certification.

I wonder bsgd, how much would it cost you to send instruments out to the US for certification? I have used "Teletek" before and have found them to be reliable, and fair. Since the same instrument is coming back, the tax situation may allow this as an option for you. Also, you may be able to buy a meter from him at the before calibration price and pay for that separately. Your customs would only see the before cal price is the certification is mailed to you separately, and later on. You may not even need the documentation for your purposes.

Just trying to help here. Conrad, I am not attempting to drum up business for cal labs (I am not associated with any now). But understand that a certification on one piece will allow a hobbyist to transfer that accuracy to many other instruments he or she may own, and extend that to equipment owned by friends.

Remember, a certification is the only way to protect yourself from bad instruments or simply a bad calibration earlier in time. How much bad readings may cost you is something I can't hope to guess at. In my case, I can not afford using things that are out of tolerance. Why even take a reading in a case like that, better to look at the test point and guess maybe.

-Chris

I understand you predicament. It's not unlike what hobbyists go through locally here, although the money amounts are ridiculously high in Brazil it seems. Keep your eyes peeled for any good opportunities.

Keep in mind that my 34401A is now over 15 years old I think. That means that some companies may get rid of them for reasons other than one being serviceable. "Chance favors the prepared mind", from a movie I enjoy.

I'll disagree with Conrad on this one, I think a 34401A will provide you with much higher benefits than you may think. It's both a highly effective instrument with many features that make bench life far easier, and it represents a reliable standard to compare everything else you have to. I've spent enough time calibrating instrumentation - including these and 87's, to understand what an opportunity one of these represents to you. With a 34401A, you are able to depend on the calibration of most of your other test equipment. That means you will know your readings are accurate. This would seem to be a critical thing for you in Brazil, given how much a cal costs. You could very easily correct calibrations for many other meters using the 34401A, certainly anything from an 87 down. Keep in mind that I like the 87, and I wish I had one.

Hi Conrad,

Given that I used to work for Transcat, I can see both sides of your argument. However, your statement as a whole is badly misleading and I must point this out.IMHO, purveyors of calibration services and agencies who write standards have their own best interests at heart.

There are several brand new instruments sold that do not meet their published specifications! In fact, there are others that do not hold their calibration well at all. I am not pushing calibration services, but I am trying to educate some as to the importance of knowing what your reading may be compared to the actual values.

I have attempted to calibrate many less expensive meters that were brand new, still in box. It was not possible to "optimize" many of these to comply with their rather loose tolerances. Now, what does that tell you? It tells me that there are several thousand hobbyists using equipment that is either wildly inaccurate, or at least not performing to published limits. I don't know about you, but this worries me. Then we have those meters with tight published accuracies that will not hold a calibration for even one year. Extech come to mind, and their may be several others. Take this information with the knowledge that I have not certified one of these for at least 5 years, they may have corrected that situation.

The only thing that stands any chance of correcting this situation is the process of calibration. This is the only way for someone to actually know what the instrument in question is doing. Some are so bad that they require recertification every 6 months. Since they are specialized products, there is no choice but to continue using these.

In industry, calibration saves millions per year by catching and correcting instrumentation problems before they cause trouble in plant processes. Cheap insurance if you ask me.

For the hobbyist, one very good instrument can be used to correct whatever else is used on the bench. Note that I have not recommended even a two year calibration cycle. My meter is still in tolerance (as close as I can justify) now after 12 years since the last calibration. Not bad. I bought an HP 3457A, calibrated, and performed a cross-check with it. See what I'm saying?

Maybe yes, maybe no. There is extremely good reason to question the accuracy and reliability of most test equipment. You certainly can not trust the manufacturers or distributors unless they adhere to their own ISO standards and good business practices. I know for a fact that many less expensive options do not.By sowing FUD (fear, uncertainty & doubt) they make a lot of money.

Depends, I agree partially with you here. The 300 KHz bandwidth of the Agilent meters, along with true RMS response, can tell you an amazing amount about what you are working on. Conversely, you can transfer the accuracy of a good meter to an oscilloscope measurement at low to DC frequencies. Now that is useful.For 99% of audio a good scope and signal generator are far more useful than a meter.

We differ on that, but then it depends on what you are doing, and how well you wish to do it.There's almost nothing in audio that requires close measurement.

Yes, I agree with that as long as some cautions are in order. It is very easy to do what you suggest, and still get an incorrect reading.From that you can match resistors and build a divider to far better than 0.1%. From that you can check multiple ranges.

That book is pure gold, and critical to an untrained person attempting a calibration. So we are in complete agreement. I also have a copy of that book. I even read it!If you can find a copy of Fluke's book- Calibration, Philosophy and Practice, it covers the making up of standards and other useful topics.

Conrad, I think it is important for any serious hobbyist to have at least one instrument that has been certified, and is of a design that is known to hold that calibration over time and temperature. BTW, certifications are only good for + or - 5 °C from the temperature it was certified at. That information (plus humidity) will be on the certification.

I wonder bsgd, how much would it cost you to send instruments out to the US for certification? I have used "Teletek" before and have found them to be reliable, and fair. Since the same instrument is coming back, the tax situation may allow this as an option for you. Also, you may be able to buy a meter from him at the before calibration price and pay for that separately. Your customs would only see the before cal price is the certification is mailed to you separately, and later on. You may not even need the documentation for your purposes.

Just trying to help here. Conrad, I am not attempting to drum up business for cal labs (I am not associated with any now). But understand that a certification on one piece will allow a hobbyist to transfer that accuracy to many other instruments he or she may own, and extend that to equipment owned by friends.

Remember, a certification is the only way to protect yourself from bad instruments or simply a bad calibration earlier in time. How much bad readings may cost you is something I can't hope to guess at. In my case, I can not afford using things that are out of tolerance. Why even take a reading in a case like that, better to look at the test point and guess maybe.

-Chris

anatech said:Hi bsgd,

I understand you predicament. It's not unlike what hobbyists go through locally here, although the money amounts are ridiculously high in Brazil it seems. Keep your eyes peeled for any good opportunities.

Keep in mind that my 34401A is now over 15 years old I think. That means that some companies may get rid of them for reasons other than one being serviceable. "Chance favors the prepared mind", from a movie I enjoy.

My eyes are always open, more than 16 hours a day

anatech said:

I wonder bsgd, how much would it cost you to send instruments out to the US for certification? I have used "Teletek" before and have found them to be reliable, and fair. Since the same instrument is coming back, the tax situation may allow this as an option for you. Also, you may be able to buy a meter from him at the before calibration price and pay for that separately. Your customs would only see the before cal price is the certification is mailed to you separately, and later on. You may not even need the documentation for your purposes.

Just trying to help here.

-Chris

That is not an option too. I could send the device to US for around $200... BUT, when it gets back here, I'd have to pay 100% taxes again, including shipping and the declared price of the instrument. So, I basically would have to pay for it again... it would actually be better to just throw this thing on the garbage and get a working one from the US, you see? terrible, but true.

I had that happen to me once when I sent a laptop to US long time ago. When I got it back, I had to pay for it all over again. I started a lawsuit, but no go. They said I had to pay and thats what I did.

Thats why I much prefer doing this things myself. I never calibrated an instrument before, but Im willing to learn and fix this thing myself. But I obviously need help as this is not my area of expertise.

Im running a few more tests here and I'll post the results ASAP.

OK, here it goes.

********** TEST 1 **********

On page 3-5 of the manual, section 3-48 there is an Oscillator test. I followed it but my device desnt axactly behave as expected. Step 'J' says the meter should indicate 0dbm and stay that way. But my meter starts to move up as I down-range the level. At 3mV, its about 0.5dbm off. I dont know how accurate this should be, but the manual clearly states it should read exactly 0dbm.

********** TEST 2 **********

At high frequencies (above 10K) my DMMs start to get a reading far off from the voltages indicated by the HP... DMM indicate 6mV, HP indicates 4mV. But then, this *moght* be the DMM's fault.

At 100K, my DMMs always read 3mV (on the 10mV level on the HP), no matter how I turn the level vernier. But, the HP meter does move indicating a change in output.

********** TEST 3 **********

After turning my whole house into a mess, I managed to find a 1K 1% resistor and a 1R 1% resistor (that is the best I have on hand).

I measured them with my Fluke and they seem to be well within their tolerances.

Got a 12V transformer, plugged it in my VARIAC and set the output to exactly 10.10V… this way, I should get 10mV across the 1R resistor.

Now, the readings:

FLUKE $300 DMM: 11.7mV

ANOTHER FLUKE $300 DMM: 10.6mV

MINIPA $60 BRAZILIAN DMM: 10.0mV

Now, time for the analyzer…. And it measure 9.9mV! Not bad…. But then, can I trust it? Not sure.

Obviously this was a 60Hz wave, as I don’t have any means to turn my mains to other frequencies. This Minipa DMM is NOT True RMS and its cheap. The analyzer and my Minipa seem to agree, but I don’t like the fact they don’t match the Fluke readings.

Im starting to realize I was living in a world of illusion.

********** END OF TESTS **********

So, now I need some advice:

1-Does the result of TEST1 indicate I have a big problem?

2-What about TEST 2? Most probably my DMMs can be trusted for high frequencies, right?

3-I dont know what to think about TEST 3. Any opinions are really welcome.

********** TEST 1 **********

On page 3-5 of the manual, section 3-48 there is an Oscillator test. I followed it but my device desnt axactly behave as expected. Step 'J' says the meter should indicate 0dbm and stay that way. But my meter starts to move up as I down-range the level. At 3mV, its about 0.5dbm off. I dont know how accurate this should be, but the manual clearly states it should read exactly 0dbm.

********** TEST 2 **********

At high frequencies (above 10K) my DMMs start to get a reading far off from the voltages indicated by the HP... DMM indicate 6mV, HP indicates 4mV. But then, this *moght* be the DMM's fault.

At 100K, my DMMs always read 3mV (on the 10mV level on the HP), no matter how I turn the level vernier. But, the HP meter does move indicating a change in output.

********** TEST 3 **********

After turning my whole house into a mess, I managed to find a 1K 1% resistor and a 1R 1% resistor (that is the best I have on hand).

I measured them with my Fluke and they seem to be well within their tolerances.

Got a 12V transformer, plugged it in my VARIAC and set the output to exactly 10.10V… this way, I should get 10mV across the 1R resistor.

Now, the readings:

FLUKE $300 DMM: 11.7mV

ANOTHER FLUKE $300 DMM: 10.6mV

MINIPA $60 BRAZILIAN DMM: 10.0mV

Now, time for the analyzer…. And it measure 9.9mV! Not bad…. But then, can I trust it? Not sure.

Obviously this was a 60Hz wave, as I don’t have any means to turn my mains to other frequencies. This Minipa DMM is NOT True RMS and its cheap. The analyzer and my Minipa seem to agree, but I don’t like the fact they don’t match the Fluke readings.

Im starting to realize I was living in a world of illusion.

********** END OF TESTS **********

So, now I need some advice:

1-Does the result of TEST1 indicate I have a big problem?

2-What about TEST 2? Most probably my DMMs can be trusted for high frequencies, right?

3-I dont know what to think about TEST 3. Any opinions are really welcome.

Hi bsgd,

Sorry, just trying to help. It seems your country is stifling education, and that is very, very sad. Their policies are not what I could call reasonable.

Can you approach a university? They will have a calibration department. Some comparisons may save the day for you.

1. -Yes, you have a basic problem there. Make sure there is no static electricity built up on the meter face. It's a long shot, but who knows?

2. -No, you can not assume anything. You can build an oscillator running at 50 KHz or so. If it is outputting a sine wave (check with your 'scope), you can compare the instruments but you will still not know where you are. You will know which meters read high or low from the average.

3. -You may have some problems with very low voltages. The shielding of the meter will come into play, as well as possible stray field pickup. The target for basic calibration on most meters (3 1/2 digit) will be about 1.9 V, or somewhere close to that. You want to be near the top of scale, but far enough down so you are not going above the top limit. Checking points are near bottom scale, mid scale and near top scale at the very minimum. That's to confirm your zero point, midrange for linearity and top for span correction. Some transfer characteristics are not linear.

Take care that your resistors do not self heat, they will change value. That is one reason that standard resistance assets are enormous. The test current should not change the temperature far from ambient.

At this point, try to find a service shop with new Agilent meters, or the service shop in a university. Even a petroleum plant may have their own cal services on site. Time to get creative if you can.

-Chris

Edit: step one and two in any calibration. Clean the terminals with 99% alcohol, and install a fresh battery.

Sorry, just trying to help. It seems your country is stifling education, and that is very, very sad. Their policies are not what I could call reasonable.

Can you approach a university? They will have a calibration department. Some comparisons may save the day for you.

1. -Yes, you have a basic problem there. Make sure there is no static electricity built up on the meter face. It's a long shot, but who knows?

2. -No, you can not assume anything. You can build an oscillator running at 50 KHz or so. If it is outputting a sine wave (check with your 'scope), you can compare the instruments but you will still not know where you are. You will know which meters read high or low from the average.

3. -You may have some problems with very low voltages. The shielding of the meter will come into play, as well as possible stray field pickup. The target for basic calibration on most meters (3 1/2 digit) will be about 1.9 V, or somewhere close to that. You want to be near the top of scale, but far enough down so you are not going above the top limit. Checking points are near bottom scale, mid scale and near top scale at the very minimum. That's to confirm your zero point, midrange for linearity and top for span correction. Some transfer characteristics are not linear.

Take care that your resistors do not self heat, they will change value. That is one reason that standard resistance assets are enormous. The test current should not change the temperature far from ambient.

At this point, try to find a service shop with new Agilent meters, or the service shop in a university. Even a petroleum plant may have their own cal services on site. Time to get creative if you can.

-Chris

Edit: step one and two in any calibration. Clean the terminals with 99% alcohol, and install a fresh battery.

Anatech, we probably disagree less then you think, I'm just coming at things from a hobbyist rather than a commercial perspective. I live in that commercial world too. I'm probably discounting the issue of poorly designed equipment because I only buy good used Fluke, HP/Agilent, Tek and other equipment with a long history of quality and reliability. There's no savings in buying low priced junk as it only misleads one.

It seems the economics of test equipment in Brazil is pretty crazy, but it warms the cockles of my heart to see someone comparing meter readings and really thinking about what they're doing. With a bit of cleverness I think bsgd can sort this out and do his own calibration as well as it would be done commercially. Actually, getting older equipment calibrated often isn't practical anymore because the labor cost to do it right are excessive. In industry, software cal is the only way to go. When I buy an instrument for work these days I have to figure in what the cost of ownership is. It's actually a disincentive to having a well equipped lab.

IMO, bsgd needs something "hang his hat on" in terms of standards. The resistors are a start, though low values will cause grief unless he's using 4-wire techniques. What clever voltage source can you think of? Back in the old days I could get two place accuracy from a 1.35V mercury battery- every one was near identical, but those are long gone, as are saturated and unsaturated cells. I keep coming back to references like the AD588 at 0.01% right out of the box, but I don't know if they can be had in Brazil. There are certainly dozens of 0.1% chips out there. I've also done nice zener references and just had them measured by a local lab, but it sounds like even that might cost more than it's worth.

It seems the economics of test equipment in Brazil is pretty crazy, but it warms the cockles of my heart to see someone comparing meter readings and really thinking about what they're doing. With a bit of cleverness I think bsgd can sort this out and do his own calibration as well as it would be done commercially. Actually, getting older equipment calibrated often isn't practical anymore because the labor cost to do it right are excessive. In industry, software cal is the only way to go. When I buy an instrument for work these days I have to figure in what the cost of ownership is. It's actually a disincentive to having a well equipped lab.

IMO, bsgd needs something "hang his hat on" in terms of standards. The resistors are a start, though low values will cause grief unless he's using 4-wire techniques. What clever voltage source can you think of? Back in the old days I could get two place accuracy from a 1.35V mercury battery- every one was near identical, but those are long gone, as are saturated and unsaturated cells. I keep coming back to references like the AD588 at 0.01% right out of the box, but I don't know if they can be had in Brazil. There are certainly dozens of 0.1% chips out there. I've also done nice zener references and just had them measured by a local lab, but it sounds like even that might cost more than it's worth.

bsgd said:[snip]Got a 12V transformer, plugged it in my VARIAC and set the output to exactly 10.10V… this way, I should get 10mV across the 1R resistor.[snip]

Hi,

Which meter did you use to set that 10.1V? What is that meter's resolution?

Jan Didden

anatech said:Hi bsgd,

Sorry, just trying to help. It seems your country is stifling education, and that is very, very sad. Their policies are not what I could call reasonable.

Hey, I know you're just trying to help! And I really appreciate that. No need for sorry here...

Regarding the country thing, I couldnt agree more. You see, thats why we are the number 1 in taxes numbers collected by the government! Obviously, not something to be proud of.

anatech said:

Can you approach a university? They will have a calibration department. Some comparisons may save the day for you.

Yes, I just graduated and I have access to a University. They certainly dont have a calibration department there, but they certainly have some nice instruments that I could use.

anatech said:

1. -Yes, you have a basic problem there. Make sure there is no static electricity built up on the meter face. It's a long shot, but who knows?

How should I do this?

Anything else that could be causing this drift?

anatech said:

2. -No, you can not assume anything. You can build an oscillator running at 50 KHz or so. If it is outputting a sine wave (check with your 'scope), you can compare the instruments but you will still not know where you are. You will know which meters read high or low from the average.

I'll scope it. I said maybe the DMMs are to blame as the manual only list accuracy up to 20K, so I suppose they not good at all above that range.

anatech said:

3. -You may have some problems with very low voltages. The shielding of the meter will come into play, as well as possible stray field pickup. The target for basic calibration on most meters (3 1/2 digit) will be about 1.9 V, or somewhere close to that. You want to be near the top of scale, but far enough down so you are not going above the top limit. Checking points are near bottom scale, mid scale and near top scale at the very minimum. That's to confirm your zero point, midrange for linearity and top for span correction. Some transfer characteristics are not linear.

I may have problems??? I definitely do

I understand that very low readings are pretty hard to be accomplished, and now I fully understand how hard it is...

anatech said:

Take care that your resistors do not self heat, they will change value. That is one reason that standard resistance assets are enormous. The test current should not change the temperature far from ambient.

Well, I just didnt expect them to drift much, but thats a good point.

anatech said:

Edit: step one and two in any calibration. Clean the terminals with 99% alcohol, and install a fresh battery.

I missed this one! But now I know. Thanks for the advice.

P.S. When you can, could you please check on the manual if my PS readings are fine? I just cant find that info anywhere...

Hi Conrad,

The references you are suggesting are about the only way to go. So I really support that. Of course, the loading and noise must be considered. Running these from a nine volt battery or gel cell is the best plan. Wiring and connections will deserve some thought.

Any standard cells are out of the question. Moving them is one problem, the temperature changes are another. Mercury ... well, they may be available in Brazil. Still, the AD588 makes the most sense, and it will remain accurate. Keeping it isolated from a noisy supply will be the greatest concern. Making sure it isn't loaded down too much, and dividing the output down to approx. 1.9 VDC will be the perfect cal point for most meters. At higher accuracies, some meters may load down the output or drop the voltage in a divider, here a null method might work better to set a higher current source. I'll have to have another peak at the AD588 data sheet.

Like you, I believe that bsgd has what it takes to do this. Some study in calibration procedures will be especially useful.

-Chris

In that case, we really do agree on these things. I do the same thing. However, most hobbyists do not own what is considered reliable or decent quality. The fact that the unit is digital implies an accuracy to most people that has no basis in fact. The fact that bsgd has a pair of Fluke 87s and is attempting to figure out what the real truth is really should be respected. Seldom do I see many people concerned that the measurements are possibly way out. Like you, I feel bsgd certainly deserves assistance.I'm probably discounting the issue of poorly designed equipment because I only buy good used Fluke, HP/Agilent, Tek and other equipment with a long history of quality and reliability. There's no savings in buying low priced junk as it only misleads one.

The references you are suggesting are about the only way to go. So I really support that. Of course, the loading and noise must be considered. Running these from a nine volt battery or gel cell is the best plan. Wiring and connections will deserve some thought.

I'm thinking of getting my 3585A spec analyzer certified. I'm a little frightened of the cost. I may have to try myself. Fluke wants $700 + to certify my Philips 3070 'scope. That is way out of line as the lab I worked in would do the same job between $200 and $300. Fluke has a flat rate (= robbery).Actually, getting older equipment calibrated often isn't practical anymore because the labor cost to do it right are excessive.

Any standard cells are out of the question. Moving them is one problem, the temperature changes are another. Mercury ... well, they may be available in Brazil. Still, the AD588 makes the most sense, and it will remain accurate. Keeping it isolated from a noisy supply will be the greatest concern. Making sure it isn't loaded down too much, and dividing the output down to approx. 1.9 VDC will be the perfect cal point for most meters. At higher accuracies, some meters may load down the output or drop the voltage in a divider, here a null method might work better to set a higher current source. I'll have to have another peak at the AD588 data sheet.

Like you, I believe that bsgd has what it takes to do this. Some study in calibration procedures will be especially useful.

-Chris

Hi bsgd,

-Chris

That's great! Will this allow you access to another university that may have what you need? A professor may be able to introduce you. It seems that a career in metrology might prove to be rewarding for you. Your services are required!Yes, I just graduated and I have access to a University.

Breathe on the glass. The moisture in your breath will dissipate any static charges. If you are in a high humidity environment, static should not be an issue. I am hoping the meter is not damaged.How should I do this?

Most analog oscilloscopes are not accurate for voltage measurements. They will tell you what the test points "look like". You can then correct your readings.I'll scope it. I said maybe the DMMs are to blame as the manual only list accuracy up to 20K, so I suppose they not good at all above that range.

You have now won that battle. Knowing a problem exists will allow you to solve that issue.now I fully understand how hard it is...

I will try. It may take some time as I'm not moving around too quickly these days.When you can, could you please check on the manual if my PS readings are fine?

-Chris

bsgd said:[

So, now I need some advice:

1-Does the result of TEST1 indicate I have a big problem?

2-What about TEST 2? Most probably my DMMs can be trusted for high frequencies, right?

3-I dont know what to think about TEST 3. Any opinions are really welcome. [/B]

This gives much more to help understand the problem.

The Fluke is good at 20-20K AC but not much beyond. They made a few instruments that were extended, the 8920-8922 series and the 8506A have extended AC accuracy. I would not get stuck on the issue.

In sequence, the first issue is an attenuator tracking issues. It could be the source or the meter. The usual HP attenuator scheme has a two stage method for the meter (what I would suspect first) and may have an adjustment on the 300 mV or 1V step. The generator attenuator should be completely passive. You can check for noise in the meter (a real possibility) by connecting the monitor output to a scope. The level on the scope should track the meter as you scale down. If the noise increases substantially at the lowest level that would be the issue. Do you have the low pass filter on or off? I would check with it on to reduce the noise.

Accurately checking HF response requires a good source or metering device. You will go in circles otherwise. A decent scope should have much better bandwidth than the 339 so I would carefully check the compensation of the scope probe and monitor the output of the generator to its highest frequency. It should not change perceptibly.

You will go in circles that get larger and larger if you try to fix/adjust both halves of the instrument at the same time. I would start with the generator and your scope to get a reference. Once the generator is reasonably right you can work with the analyzer. The fluke meter should be fine at 1KHz and at 60 Hz. And it should give accurate info on the output attenuator.

Another tool that can be very useful and not too expensive is a good decade attenuator. GR and HP have both made them as have a few other companies. Usually less than $100 for a good one. Nothing much to age or fall out of cal ever, just precision resistors and switches. If you are really crazy (like me) you would get a ratio transformer, with even more AC accuracy. I used it once to calibrate my AC calibrator.

Once you have a good known source you can start sorting out the meter.

Looking through the manual carefully finally I would suggest the following (should have looked first, oh well) :

1) test the generator with a proper 600 Ohm load. The attenuator won't work right without it.

2) There aren't many adjustments so it should not be too far out of adjustment. The ST1700's have lots more adjustments.

3) I think you noted fairly high ripple on the supplies earlier. They should probably be 1 mV or less. At its age replacing primary filter caps would not be unusual. Looking at the monitor output would reveal presence of excess hum at low input settings.

1) test the generator with a proper 600 Ohm load. The attenuator won't work right without it.

2) There aren't many adjustments so it should not be too far out of adjustment. The ST1700's have lots more adjustments.

3) I think you noted fairly high ripple on the supplies earlier. They should probably be 1 mV or less. At its age replacing primary filter caps would not be unusual. Looking at the monitor output would reveal presence of excess hum at low input settings.

Conrad Hoffman said:Anatech, we probably disagree less then you think, I'm just coming at things from a hobbyist rather than a commercial perspective. I live in that commercial world too. I'm probably discounting the issue of poorly designed equipment because I only buy good used Fluke, HP/Agilent, Tek and other equipment with a long history of quality and reliability. There's no savings in buying low priced junk as it only misleads one.

It seems the economics of test equipment in Brazil is pretty crazy, but it warms the cockles of my heart to see someone comparing meter readings and really thinking about what they're doing. With a bit of cleverness I think bsgd can sort this out and do his own calibration as well as it would be done commercially. Actually, getting older equipment calibrated often isn't practical anymore because the labor cost to do it right are excessive. In industry, software cal is the only way to go. When I buy an instrument for work these days I have to figure in what the cost of ownership is. It's actually a disincentive to having a well equipped lab.

IMO, bsgd needs something "hang his hat on" in terms of standards. The resistors are a start, though low values will cause grief unless he's using 4-wire techniques. What clever voltage source can you think of? Back in the old days I could get two place accuracy from a 1.35V mercury battery- every one was near identical, but those are long gone, as are saturated and unsaturated cells. I keep coming back to references like the AD588 at 0.01% right out of the box, but I don't know if they can be had in Brazil. There are certainly dozens of 0.1% chips out there. I've also done nice zener references and just had them measured by a local lab, but it sounds like even that might cost more than it's worth.

Hi Conrad

The Farnell has subsidiary in Brazil, sells a variety of components and use the stock of their country, components of accuracy can be found here.

instruments, the two manufacturers in my country, but not produce distortion analyzers, only common instruments.(oscilloscope digital and analog, DMM, generator)

For a new product imported sophisticated is expensive here ( 3, 4 times the cost price in your country) only companies can buy.

equipment used , is relative, can be expensive or not, depends on the equipment, in general costs less what equipment manufactured here (which has a year warranty). HP and Tek are models coveted, they may cost more.

Demian,

Im not home right now, but tonight I'll try to check everyhting you suggested. I did test it with a 680Ohm load as far as I remember (a single 680R resistor accross the output).

I'll connect my Scope to the Monitor out and see what I get. Btw, there is a 62mA fuse in series with this output, and mine is blown.. could I replace it with 100mA? I know I shouldnt but thats the lowest I can get here. If something ever goes wrong, will 100mA damage the HP?

Regarding the Supply caps. Should I replace them or not? I dont wanna make things worse. If so, what should I replace them with?? Panasonic FCs or FMs?? I have some that I got from US, though I have to check their ratings.

Or should I use anything better? I laso have a few big ELNA Cerafines.

Also, should I keep their capacitance? Or replace with something higher?

Should I replace all electrolytic caps or just the big ones?

I really appreciate your help guys. Thank you.

Im not home right now, but tonight I'll try to check everyhting you suggested. I did test it with a 680Ohm load as far as I remember (a single 680R resistor accross the output).

I'll connect my Scope to the Monitor out and see what I get. Btw, there is a 62mA fuse in series with this output, and mine is blown.. could I replace it with 100mA? I know I shouldnt but thats the lowest I can get here. If something ever goes wrong, will 100mA damage the HP?

Regarding the Supply caps. Should I replace them or not? I dont wanna make things worse. If so, what should I replace them with?? Panasonic FCs or FMs?? I have some that I got from US, though I have to check their ratings.

Or should I use anything better? I laso have a few big ELNA Cerafines.

Also, should I keep their capacitance? Or replace with something higher?

Should I replace all electrolytic caps or just the big ones?

I really appreciate your help guys. Thank you.

If you are careful 100 mA should be fine. its unususal to even have a fuse on the monitor output.

Don't get silly with the supply caps. It will never show on the meter or a scope. Check the existing ones, but at the age of the unit is possible that the esr is high. Fresh quality caps (I would use 105C caps) should be fine. Same value or a little larger in the same footprint.

Good luck!

Don't get silly with the supply caps. It will never show on the meter or a scope. Check the existing ones, but at the age of the unit is possible that the esr is high. Fresh quality caps (I would use 105C caps) should be fine. Same value or a little larger in the same footprint.

Good luck!

1audio said:

Don't get silly with the supply caps. It will never show on the meter or a scope. Check the existing ones, but at the age of the unit is possible that the esr is high. Fresh quality caps (I would use 105C caps) should be fine. Same value or a little larger in the same footprint.

Good luck!

Well, the thing is, I cant really check mine, as I have no way of measuring ESR. All I can check is capacitance... so, if capacitance is fine, I still dont know whether to replace them or not. I'll check which values I have by the way, cause if I dont have any high quality caps, I'd rather just keep the originals.

anatech said:At $900, you could probably rent a Fluke 5520A multifunction calibrator for a week and make money on the deal! With that, you can calibrate most DVMs, oscilloscopes and all manner of AC voltmeters.

I have a Fluke 5205A Amplifier which I am willing to give away to anyone who will pay the shipping (or pick up). I think it fell on its head, however. Uses a pair of 120V lines.

It takes 2 healthy guys to carry it!

jackinnj,

Too bad Im not in the US, or I'd carry it home by myself if needed

Demian,

I tried to scope the monitor output of my HP, but, set to the OSCILLATOR LEVEL function, the output is disabled. So, I just connect the oscillator output to the distortion input and set the HP to INPUT LEVEL. This way the monitor out gets enabled.

But, I have a question.. how can I determine the noise, since its an AC wave we have here??

Here are two scope shots.

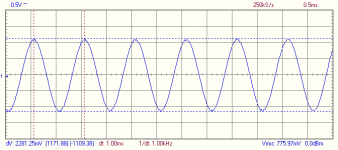

SCOPE OUTPUT NUMBER 1

Here is the output with the oscillator set to 3V and 1kHz. The HP meter was set to 0dbm exactly.

Too bad Im not in the US, or I'd carry it home by myself if needed

Demian,

I tried to scope the monitor output of my HP, but, set to the OSCILLATOR LEVEL function, the output is disabled. So, I just connect the oscillator output to the distortion input and set the HP to INPUT LEVEL. This way the monitor out gets enabled.

But, I have a question.. how can I determine the noise, since its an AC wave we have here??

Here are two scope shots.

SCOPE OUTPUT NUMBER 1

Here is the output with the oscillator set to 3V and 1kHz. The HP meter was set to 0dbm exactly.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- Improving older test equipment