Hmmm...

They've gone for a 2-way mechanical XO according to the FE138ESR datasheet - https://www.madisound.com/store/manuals/FE138ES-R-1.pdf

Some correction is in order for that to work out nice.

I suspect the resonances we heard would require a lot more than any electrical correction ( EQ) could remedy - too bad, these are a physically gorgeous driver - incorporating a range of features that I've heard work well in other of the Sigma and even FF series. Is it possible to have too much motor?

I'm guessing that quite a fewlittle woofers will work. We have Silver Flute W14 here so that is where we'll start.

dave

Sounds good Dave, please keep us posted.

Just curious, would the FF85k work in the FH3 or is it too small? I've got a pair in some uFonkens but I'm thinking something larger might suit them better.Very nice build

Over the weekend we garnered a bit of progress wrt FH3.

Turns out FE138eSR works great in the FH3 -- as a bass driver. This is leading us to a FAST based on the FH3. We stuck the FF85wk on top and bi-amped (PLLXO @ 100 Hz as it was handy). This ended up VERY good.

But to fit the FE138eSR in the box necessitated a supraBaffle and the extra room it made for the monster magnet on this driver. SO we ended up with the prototpe of the removable sB version of the baffle that we will be offering with the next batch of FH3 flat-paks.

dave

Just curious, would the FF85k work in the FH3 or is it too small? I've got a pair in some uFonkens but I'm thinking something larger might suit them better.

considering that the original Buschhorn MkI that is in some ways a spiritual grandparent to this design was originally conceived for 3" or so drivers, and with slight modifications to chamber dimensions can be made to work with 4" such as Fostex 103S, 108EZ, 126E....... it couldn't hurt to try

we'd played with the idea of dual 85K in the FH3, but simply haven't gotten around to it yet (it would make a great party trick) - BTW the new 85WK is very very good

Just curious, would the FF85k work in the FH3 or is it too small?

As Chris mentioned, we have considered 2 per FH, as well dual A6P would be a consideration as would 3 A6M (3-eyed monster?)

dave

Both the orginial Buschhorn and FH1 had compression chambers though, while this design does not (not sure if it matters). I've got some FE126eN drivers in the FH1 and was thinking of building these for them to compare both designs...but then I thought my FF85ks could use a new home too! So many designs, so little time.

I've moved my FH1s into my office and they don't sound so hot in there. Previously I was listening to my uFonkens which sound great, but lack bass. The FH1s have more bass, but they just don't sound right in the room. It's a small room with hardwood floors, an 8x11 carpet covering most of the room, and a 60" desk smack dab in the middle.

I've moved my FH1s into my office and they don't sound so hot in there. Previously I was listening to my uFonkens which sound great, but lack bass. The FH1s have more bass, but they just don't sound right in the room. It's a small room with hardwood floors, an 8x11 carpet covering most of the room, and a 60" desk smack dab in the middle.

Both the orginial Buschhorn and FH1 had compression chambers though, while this design does not (not sure if it matters). I've got some FE126eN drivers in the FH1 and was thinking of building these for them to compare both designs...but then I thought my FF85ks could use a new home too! So many designs, so little time.

I've moved my FH1s into my office and they don't sound so hot in there. Previously I was listening to my uFonkens which sound great, but lack bass. The FH1s have more bass, but they just don't sound right in the room. It's a small room with hardwood floors, an 8x11 carpet covering most of the room, and a 60" desk smack dab in the middle.

sounds like a small sealed woofer would be worth considering for the office, unless you're backing away from speaker projects

what am I saying

Both the orginial Buschhorn and FH1 had compression chambers though, while this design does not (not sure if it matters).

In the FH1 documents, the term compression chamber was used incorrectly. In a BLH, the room is the CC & the sir cavity behind the driver is a low-pass filter.

dave

Lock Miter link

Link to Amana Tool's Lock Miter bit.

1) I would only recommend Amana Tool Router bits. Especially complex ones. (see link above)

2) The plans were for someone (me) who already had wood and sheet products on hand and wanted to avoid additional expense of veneer and/or purchasing more wood.

3) If you have limited woodworking experience or lack the patience to master cutting a self aligning and locking 45 degree miter joint, then do it another way. When cut accurately, all the internal parts fell into place and the 45 degree lock miter worked out fairly easily. ( they slip into place and grab each other making assembly easier... for me ) That being said - there is no short cuts in making this horn, either you pay up front in time cutting the hardwood veneer plywood and it falls together easily - or you use easier cutting methods and pay at the end with time finishing and veneering.

This is a tough little cabinet to make. If you are just looking at what a lock miter is, and are not confident that you can be very, very accurate on all your cuts, then you can find the precision required to make it this way a "PIA". There is no forgiveness like with the butt joint/veneer option. If you are not dead on accurate then you will end up with a pile of scrap wood and no Frugal Horn to listen to. You can't just thump on it with a persuader and get it to fit together.

I would highly recommend the flat packs offered at the Frugal Site for an easy project build. In the end it is not how you put it together, but how it sounds. ...and I am telling you the quality of sound, clarity of individual instruments and crisp reproduction of the slightest variation or pitch just blew me away. It was emotional.

Thank you Frugal-Horn.com!

Link to Amana Tool's Lock Miter bit.

1) I would only recommend Amana Tool Router bits. Especially complex ones. (see link above)

2) The plans were for someone (me) who already had wood and sheet products on hand and wanted to avoid additional expense of veneer and/or purchasing more wood.

3) If you have limited woodworking experience or lack the patience to master cutting a self aligning and locking 45 degree miter joint, then do it another way. When cut accurately, all the internal parts fell into place and the 45 degree lock miter worked out fairly easily. ( they slip into place and grab each other making assembly easier... for me ) That being said - there is no short cuts in making this horn, either you pay up front in time cutting the hardwood veneer plywood and it falls together easily - or you use easier cutting methods and pay at the end with time finishing and veneering.

This is a tough little cabinet to make. If you are just looking at what a lock miter is, and are not confident that you can be very, very accurate on all your cuts, then you can find the precision required to make it this way a "PIA". There is no forgiveness like with the butt joint/veneer option. If you are not dead on accurate then you will end up with a pile of scrap wood and no Frugal Horn to listen to. You can't just thump on it with a persuader and get it to fit together.

I would highly recommend the flat packs offered at the Frugal Site for an easy project build. In the end it is not how you put it together, but how it sounds. ...and I am telling you the quality of sound, clarity of individual instruments and crisp reproduction of the slightest variation or pitch just blew me away. It was emotional.

Thank you Frugal-Horn.com!

Link to Amana Tool's Lock Miter bit.

1) I would only recommend Amana Tool Router bits. Especially complex ones. (see link above)

2) The plans were for someone (me) who already had wood and sheet products on hand and wanted to avoid additional expense of veneer and/or purchasing more wood.

3) If you have limited woodworking experience or lack the patience to master cutting a self aligning and locking 45 degree miter joint, then do it another way. When cut accurately, all the internal parts fell into place and the 45 degree lock miter worked out fairly easily. ( they slip into place and grab each other making assembly easier... for me ) That being said - there is no short cuts in making this horn, either you pay up front in time cutting the hardwood veneer plywood and it falls together easily - or you use easier cutting methods and pay at the end with time finishing and veneering.

This is a tough little cabinet to make. If you are just looking at what a lock miter is, and are not confident that you can be very, very accurate on all your cuts, then you can find the precision required to make it this way a "PIA". There is no forgiveness like with the butt joint/veneer option. If you are not dead on accurate then you will end up with a pile of scrap wood and no Frugal Horn to listen to. You can't just thump on it with a persuader and get it to fit together.

I would highly recommend the flat packs offered at the Frugal Site for an easy project build. In the end it is not how you put it together, but how it sounds. ...and I am telling you the quality of sound, clarity of individual instruments and crisp reproduction of the slightest variation or pitch just blew me away. It was emotional.

Thank you Frugal-Horn.com!

Funny, even before the CNC dadoed flat pack, I didn't find this to be a particularly tough cabinet to make - hand cutting the MDF router template for the curved panels was the hardest part and that took less than 1/2 hour. Now solid bamboo plywood fonkens - that's a fonken challenge.

Of course the first protos were a little rough and ready - all butt joints and brad nailer to the rescue!

Funny, even before the CNC dadoed flat pack, I didn't find this to be a particularly tough cabinet to make - hand cutting the MDF router template for the curved panels was the hardest part and that took less than 1/2 hour. Now solid bamboo plywood fonkens - that's a fonken challenge.

Of course the first protos were a little rough and ready - all butt joints and brad nailer to the rescue!

Your absolutely right - The first two Frugal's I built were helping a friend make his - slab with butt joints - really only need rudimentary woodworking skills... and a "little putty and a little paint makes you the carpenter you ain't. " ( something my high school shop teacher would say )

Some people on the forum indicated they had problems setting up a 45 degree lock miter. ( which is really easy by the way ) Taking that into consideration I think my alternate cabinet construction would be rated "a tough cabinet to make".

All things aside, I think the Frugal Horn should be easy to make, and a different design belongs in another forum. Being new to speaker building and now reading the forums, a construction method of butt joints and veneering seems par for the course. Furniture makers sometime strive for truth in materials and construction. Marquetry and decorating a piece with burl and veneer is a different matter.

...But this is not a woodworking forum - and I was expecting discussions on how the horns I made with Luan 7 ply w/completely different joinery sounded to the Frugal baltic birch/slab w/butt joints that I previously help make.

Your absolutely right - The first two Frugal's I built were helping a friend make his - slab with butt joints - really only need rudimentary woodworking skills... and a "little putty and a little paint makes you the carpenter you ain't. " ( something my high school shop teacher would say )

Some people on the forum indicated they had problems setting up a 45 degree lock miter. ( which is really easy by the way ) Taking that into consideration I think my alternate cabinet construction would be rated "a tough cabinet to make".

All things aside, I think the Frugal Horn should be easy to make, and a different design belongs in another forum. Being new to speaker building and now reading the forums, a construction method of butt joints and veneering seems par for the course. Furniture makers sometime strive for truth in materials and construction. Marquetry and decorating a piece with burl and veneer is a different matter.

...But this is not a woodworking forum - and I was expecting discussions on how the horns I made with Luan 7 ply w/completely different joinery sounded to the Frugal baltic birch/slab w/butt joints that I previously help make.

Well, I've already tasted the difference between MDF and plywood on a different design a few years ago, but would certainly be interested in the impressions of such a comparison. With all due respect to "fine" woodworkers / furniture makers (which I'm not ), I'd suspect that the type of joinery / detailing work you describe would make less of a sonic difference than the design and choice of materials.

and to quote my old man, whose lesson's I'm still unlearning at 60, "carpentry is a sequence of correcting for previous mistakes" (actually he used a shorter anglo-saxon compound word ending in "ups" )

Last edited:

I wouldn't recommend any sort of mitred joints for someone's first project. Butt joints are tough enough if you're not experienced in getting pieces exactly the right size.

BTW, Weeves, I can't get your photos to load anymore.

message me your email and I will get the PDF's and jpgs to you.

Robert

Frankly I think that if the 126s didn't do it for you in the FH3, that in a smaller enclosure they'll underwhelm you even more, unless assisted with woofers. I use the plural because an enclosure qualifying as small (sealed or ported) will be hard pressed to deliver much below 110-120? Hz with this driver. Further, their famous "aggressively forward" presentation isn't to everyone's taste in any enclosure or room and may certainly be ill suited for a bedroom.

While there are other Fostex drivers I prefer overall, I can understand the appeal of the 126 in a BLH.

That said, the Alpair7 is unquestionably a far more refined and elegant driver in any of the 4 or 5 enclosure designs in which I've heard it to date.

Fair enough. Since I have the 126's already, any suggestions on a two way design utilizing them and a woofer?

Thanks

Fair enough. Since I have the 126's already, any suggestions on a two way design utilizing them and a woofer?

Thanks

Well, you could always try a small OB with H-Frame woofer - just not my (wife's) cup of tea aesthetically

Dave keeps promising to sketch a smallish BR for the 126, but even the Fostex recommended box, while far from optimal, would be as good a quick afternoon bash-together project as any.

As for woofers - were you thinking of passive filters/ single amp, or bi-amping. The latter option simplifies selection of drivers, at the expense of needing additional amp(s)

Dave keeps promising to sketch a smallish BR for the 126, but even the Fostex recommended box, while far from optimal, would be as good a quick afternoon bash-together project as any.

Actually, a re-tuned 4.7L mFonken box would be waaaaaaaaaaay better than the Fostex 10.5L BR box. Unless I'm completely OTL, the Fostex box appears to be a cruel joke for the FE126e, unless you can EQ in some upper bass, lower mids.

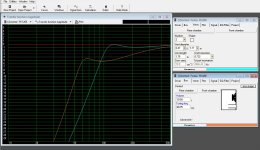

So mFonken vent dims would be approx. .47" x 1.77" x 1.75" long (2 vents). Dave would want to verify (or change) these dims of course. I used WinISD to generate the sim.

jeff

Actually, a re-tuned 4.7L mFonken box would be waaaaaaaaaaay better than the Fostex 10.5L BR box. Unless I'm completely OTL, the Fostex box appears to be a cruel joke for the FE126e, unless you can EQ in some upper bass, lower mids.

So mFonken vent dims would be approx. .47" x 1.77" x 1.75" long (2 vents). Dave would want to verify (or change) these dims of course. I used WinISD to generate the sim.

jeff

the 126's cardboard packing box might sound better than either the oversized BR, or the even stranger hybrid "BLH" which we built a pair of

cruel joke? I'm not sure the Fostex staff is authorized to intentionally attempt that, (or that they actually listen to all the designs?)

yes, provided you're not looking for any upper mid bass on down the little mF enclosure would I guess be as good a starting point as anything

when you get back from yer lunch break, I've have the peach pie with vanilla bean gelato

(Jeff's wife makes excellent pies and pastries - you supply your own toppings )

Last edited:

- Home

- Loudspeakers

- Full Range

- Frugel-Horn Mk3