Update on sound: after letting my new drivers break in for 40 hours, these speakers are sounding fantastic! I am again getting that non-stop grin  when I listen to them and just want to try more and more CD's. The imaging, sound stage, and clarity are superb. With the 3.5 in Vifa, of course you cannot expect deep bass, but I think I am hearing stuff reach down to 50 to 60 Hz and it is wide - since it radiates from the back and reflects off the wall. The bass that is there is very clear, well-balanced with the mids and highs, and has punch, it is not boomy. The speakers work really well with jazz, vocals, chamber classical, and pop.

when I listen to them and just want to try more and more CD's. The imaging, sound stage, and clarity are superb. With the 3.5 in Vifa, of course you cannot expect deep bass, but I think I am hearing stuff reach down to 50 to 60 Hz and it is wide - since it radiates from the back and reflects off the wall. The bass that is there is very clear, well-balanced with the mids and highs, and has punch, it is not boomy. The speakers work really well with jazz, vocals, chamber classical, and pop.

After hearing how good they sound driven by a Lepai 2020+, I decided to hook them up to my old Yamaha power amp (45 W/ch at 8 ohms). WOW is all I have to say, the bass extension is now remarkable! I am only running the amp with the volume knob at the 10 'o clock position and the sound is amazing. I can really feel the bass much more now. The Lepai in stock form with its puny power capacitor just doesn't have enough oomph to drive the Vifa's to an excursion that can produce the nice bass in this enclosure.

Anyhow, I am very happy and can't wait to get back to listen to them again.

After hearing how good they sound driven by a Lepai 2020+, I decided to hook them up to my old Yamaha power amp (45 W/ch at 8 ohms). WOW is all I have to say, the bass extension is now remarkable! I am only running the amp with the volume knob at the 10 'o clock position and the sound is amazing. I can really feel the bass much more now. The Lepai in stock form with its puny power capacitor just doesn't have enough oomph to drive the Vifa's to an excursion that can produce the nice bass in this enclosure.

Anyhow, I am very happy and can't wait to get back to listen to them again.

Prezden,

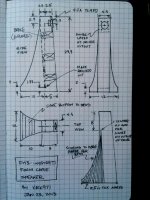

Let me know if you need more details on the plans, that was what I was able to send you while on the road armed with nothing more than my notebook and a cell phone camera. Refer to the photos to get clarification on the bracing, etc. Looking forward to seeing your build.

Good luck!

Xrk971

Let me know if you need more details on the plans, that was what I was able to send you while on the road armed with nothing more than my notebook and a cell phone camera. Refer to the photos to get clarification on the bracing, etc. Looking forward to seeing your build.

Good luck!

Xrk971

I've used foam insulation board for mock ups (Audio Express, 9- 2011 issue.) but never tried it in a live enclosure. Foam enclosures would save money and reduce dust in the shop. You could use 1/2 inch wood strips as corner blocks to reduce resonance. I'm going to get a few sheets and give it a try.

That is my biggest advantage in using foam core is no dust as I currently do not have a shop so all speaker builds are indoors in the kitchen or rec room. No power tools needed either - just a razor. Are you considering the foam core FH3-inspired speaker or something else? A folded MLTL, a TABAQ for example, is a great way to get started that sounds really nice and is simple to make.

I am thinking about a quarter wave with a Dayton ND 105 4 inch driver.I also have couple of the Audience 3 inch drivers they use intheir line array system. I want to experiment with the 1/2" Johns Mansville insulation foam board I used on my mock up on the Castle Speakers. Its denser than the smaller craft board, yet still ultra light weight compared with MFD or plywood. Can be glued with craft glue or the special caulking they make for installing it.

I am thinking of trying this design at a larger scale with a 4 inch budget driver. The Visaton FR10 that Ken turned me onto looks very promising for a larger design, I am actually thinking of going with the 4 ohm variant to get more power from my T-amp delivered to the driver, The driver is $12 at MCM Visaton 4 Inch 20W 4 Ohm Full Range Dual Cone Speaker | FR10 2020 | Visaton

http://www.visaton.com/en/industrie/breitband/fr10_4.html

Specs:

Rated power 30 W

Maximum power 50 W

Nominal impedance Z 4 Ohm

Frequency response 80–20000 Hz

Mean sound pressure level 86 dB (1 W/1 m)

+/−4 mm Excursion limit

Resonance frequency fs 92 Hz

D.C. resistance Rdc 3,2 Ohm

Mechanical Q factor Qms 2,29

Electrical Q factor Qes 0,7

0,54 Total Q factor Qts

Equivalent volume Vas 2,3 l

Effective piston area Sd 50 cm²

Dynamically moved mass Mms 5,7 g

Force factor Bxl 4,6 T m

Inductance of the voice coil L 0,2 m

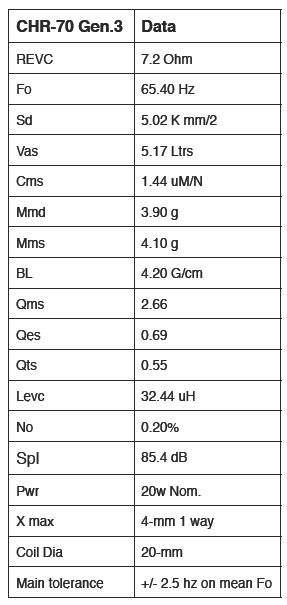

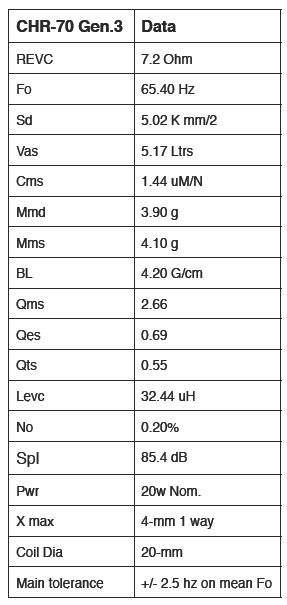

Note that the specs of this driver is very close to the MA CHR70: except for Vas

http://www.visaton.com/en/industrie/breitband/fr10_4.html

An externally hosted image should be here but it was not working when we last tested it.

Specs:

Rated power 30 W

Maximum power 50 W

Nominal impedance Z 4 Ohm

Frequency response 80–20000 Hz

Mean sound pressure level 86 dB (1 W/1 m)

+/−4 mm Excursion limit

Resonance frequency fs 92 Hz

D.C. resistance Rdc 3,2 Ohm

Mechanical Q factor Qms 2,29

Electrical Q factor Qes 0,7

0,54 Total Q factor Qts

Equivalent volume Vas 2,3 l

Effective piston area Sd 50 cm²

Dynamically moved mass Mms 5,7 g

Force factor Bxl 4,6 T m

Inductance of the voice coil L 0,2 m

Note that the specs of this driver is very close to the MA CHR70: except for Vas

Last edited:

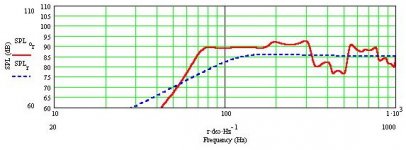

I have begun building the FH3 inspired foam core speakers to give the Vifa TC9FD a try. Just for fun I ran a simulation in MJK's MathCAD worksheets. Modeled as an MLTL (similar to a Metronome, just folded and with a rear firing port instead of down firing).

The stuffing/lining should improve the suck-out in the 400-500 Hz (I hope).

Cheers, Jim

The stuffing/lining should improve the suck-out in the 400-500 Hz (I hope).

Cheers, Jim

Attachments

Hi xrk,

I used your dimensions for the enclosure minus the 'horn' behind the port. The MLTL worksheet has no provision for dealing with that. (I also didn't bother with the later parts of the worksheet where you enter further details of the enclosure, etc.)

To better simulate, you would have to use the BLH-sections worksheet; being lazy, I didn't bother going there, as it would mean learning how to deal with that sheet. Maybe someday.... or maybe not...

BTW: I am simplifying your design by making the 'horn' behind the port a straight (as opposed to curved) expansion. Yea, lazy, lazy, lazy.

Cheers, Jim

I used your dimensions for the enclosure minus the 'horn' behind the port. The MLTL worksheet has no provision for dealing with that. (I also didn't bother with the later parts of the worksheet where you enter further details of the enclosure, etc.)

To better simulate, you would have to use the BLH-sections worksheet; being lazy, I didn't bother going there, as it would mean learning how to deal with that sheet. Maybe someday.... or maybe not...

BTW: I am simplifying your design by making the 'horn' behind the port a straight (as opposed to curved) expansion. Yea, lazy, lazy, lazy.

Cheers, Jim

Jim,

The curved sides are easy and their difficulty to execute shouldn't be over-estimated. It takes 15 minutes to score the lines on the side to allow curving before you glue it on. Make the base curved with the flare out. You have built cornu before so know how easy it is to bend, hold, tack with hot melt and you are done. It looks and sounds better with curve - gives you 3x gain on horn expansion and adds stability to base. Trust me on this

One other thing, since you have benefit of sim, try reducing terminus gap from 1.33 in to something a tad smaller. It should pull bass extension down lower if that is what you want.

The curved sides are easy and their difficulty to execute shouldn't be over-estimated. It takes 15 minutes to score the lines on the side to allow curving before you glue it on. Make the base curved with the flare out. You have built cornu before so know how easy it is to bend, hold, tack with hot melt and you are done. It looks and sounds better with curve - gives you 3x gain on horn expansion and adds stability to base. Trust me on this

One other thing, since you have benefit of sim, try reducing terminus gap from 1.33 in to something a tad smaller. It should pull bass extension down lower if that is what you want.

Last edited:

I have begun building the FH3 inspired foam core speakers to give the Vifa TC9FD a try. Just for fun I ran a simulation in MJK's MathCAD worksheets. Modeled as an MLTL (similar to a Metronome, just folded and with a rear firing port instead of down firing).

The stuffing/lining should improve the suck-out in the 400-500 Hz (I hope).

Cheers, Jim

Jim,

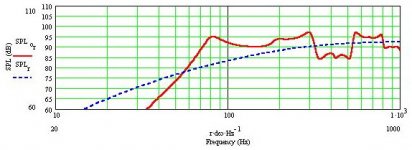

It's actually kind of surprising how good the sim is given the crude scaling I did which shouldn't have worked given the feedback I got on how nothing depends on Sd. Lucky

I guess? If you can do me a favor and run the sim with the params for the FR10 driver I have above - keep dims the same. I am wondering what a swap would do.

Thanks,

X

Jim,

It's actually kind of surprising how good the sim is given the crude scaling I did which shouldn't have worked given the feedback I got on how nothing depends on Sd. Lucky

I guess? If you can do me a favor and run the sim with the params for the FR10 driver I have above - keep dims the same. I am wondering what a swap would do.

Thanks,

X

Guess you got lucky. And the reason I decided to proceed.

Using your original dimensions, the FR10 doesn't look nearly as nice. An expert like Scottmoose could probably adjust it in a jiffy to get a good alignment. I expect I would need to fiddle for two or three weeks to fix it.

Cheers, Jim

Attachments

- Home

- Loudspeakers

- Full Range

- FH3-inspired Foam Core Mini Build