Going back a ways to the discussion of magnet types and shorting rings, here's a relevant passage from page 4 of JBL's differential drive technical note, regarding ferrite vs. NdFeB:

The neodymium magnet material used in most Differential Drive transducers is much less prone to flux modulation than ferrite materials. As a result, the flux shorting ring, an essential part of JBL's Symmetrical Field Geometry™, is not usually necessary with neodymium-based structures. Figure 4 shows the demagnetization characteristics for typical NIB and ferrite magnet materials. We can see that a typical operating point for the neodymium magnet is much higher along the B-axis than that of a ferrite magnet. Therefore, for a given change in magnetizing force produced by signal current in the voice coil, the resulting change in induced flux (deltaB/BNIB) will be fairly small. By contrast, the resulting change in induced flux for the ferrite magnet will be deltaB/BF. Since BF is less than BNIB, the total variation in induced flux will be greater with the ferrite magnet. There is about a three-to-one ratio between the amount of flux modulation of the two magnet materials, corresponding to an approximate 10 dB advantage for neodymium over ferrite at any operating level.

Hi Rob,

The 4411 system mentioned was one of my designs.

David S.

I seem to remember a couple of "junior" engineers involved with that design name Don Keele and John Eargle.

I seem to remember a couple of "junior" engineers involved with that design name Don Keele and John Eargle.

Not sure what you are talking about Earl? You might be thinking of the 4430 and 4435 where we co-authored a paper (I was the primary writer). As to the 4411, that was my project and Don was not involved. John Eargle was not in the engineering department and didn't design product, but was a marvelous writer and company spokesman.

I'll let you correct me if I've got any of that wrong.

David

We can see that a typical operating point for the neodymium magnet is much higher along the B-axis than that of a ferrite magnet. Therefore, for a given change in magnetizing force produced by signal current in the voice coil, the resulting change in induced flux (deltaB/BNIB) will be fairly small. By contrast, the resulting change in induced flux for the ferrite magnet will be deltaB/BF. Since BF is less than BNIB, the total variation in induced flux will be greater with the ferrite magnet.

Thanks Bill, that was what I was looking for. A variation in H (sinusoidal applied magnetic force from the voice coil signal input) gives a variation in B (magnetic strength at the operating point). It looks like the B variation is the same in both cases but this makes it much greater in percentage terms for Ferrite.

2nd harmonic is created because the magnet circuit effective strength increases in one direction and decreases in the other i.e. one side of an applied sine wave gets magnified, the other diminished.

By the way, the lesser B of Ferrite is compensated for by using a greater area of material: a bigger diameter magnet.

David S.

This seems to point to an advantage of higher efficiency drivers that I don't see discussed much. They tend to have motors with powerful magnets, high flux density across the gap, and shorter VC winding heights, so it takes comparatively little VC current to reach a given SPL. When you dissect the motor force factor BL(i), you find that the B side is big and beefy, while the role of L(i) is reduced.

Clearly, this gives high-efficiency drivers an advantage WRT the Le(i), flux-modulation distortion mechanism--they require fewer VC amp-turns for a given SPL, so their magnetic operating point is less perturbed, and the steel in the motor stays on a narrower, more linear swath of its BH curve.

Clearly, this gives high-efficiency drivers an advantage WRT the Le(i), flux-modulation distortion mechanism--they require fewer VC amp-turns for a given SPL, so their magnetic operating point is less perturbed, and the steel in the motor stays on a narrower, more linear swath of its BH curve.

Last edited:

This seems to point to an advantage of higher efficiency drivers that I don't see discussed much. They tend to have motors with powerful magnets, high flux density across the gap, and shorter VC winding heights, so it takes comparatively little VC current to reach a given SPL. When you dissect the motor force factor BL(i), you find that the B side is big and beefy, while the role of L(i) is reduced.

Clearly, this gives high-efficiency drivers an advantage WRT the Le(i), flux-modulation distortion mechanism--they require fewer VC amp-turns for a given SPL, so their magnetic operating point is less perturbed, and the steel in the motor stays on a narrower, more linear swath of its BH curve.

Except that efficiency increases when the volume of copper in the gap increases. In general efficiency maxes out when copper weight equals the cone weight.

Not sure why we are back to steel linearity when the reference clearly identifies it as a magnet material issue.

David

Yes, steel is ubiquitous in most loudspeaker motors, and magnet type is the variable we were discussing, but I keep referring to steel's BH curve because steel is primarily what gets modulated in loudspeaker motors when the VC field pushes the B field around. This is mostly because steel is typically the material closest to the VC in the top plate and the pole.

The Linkwitz dicussion of midrange distortion you linked to earlier draws from Klippel's poster "Loudspeaker Nonlinearities - Causes, Parameters, Symptoms." Here's a snip from that poster where Klippel is pretty clear about iron modulation being the primary factor in BL(i) distortion:

The Linkwitz dicussion of midrange distortion you linked to earlier draws from Klippel's poster "Loudspeaker Nonlinearities - Causes, Parameters, Symptoms." Here's a snip from that poster where Klippel is pretty clear about iron modulation being the primary factor in BL(i) distortion:

Attachments

Except that efficiency increases when the volume of copper in the gap increases. In general efficiency maxes out when copper weight equals the cone weight.

Perhaps I didn't set up the scenario comprehensively, but the generality I was trying to express is that, in terms of Le(i) distortion, the fewer VC amp-turns you need to hit a target SPL, the better.

Yes, steel is ubiquitous in most loudspeaker motors, and magnet type is the variable we were discussing, but I keep referring to steel's BH curve because steel is primarily what gets modulated in loudspeaker motors when the VC field pushes the B field around. This is mostly because steel is typically the material closest to the VC in the top plate and the pole.

The Linkwitz dicussion of midrange distortion you linked to earlier draws from Klippel's poster "Loudspeaker Nonlinearities - Causes, Parameters, Symptoms." Here's a snip from that poster where Klippel is pretty clear about iron modulation being the primary factor in BL(i) distortion:

This thread has been about the Faraday ring and why it would be used. The answer is because of the nonlinearity in magnetic material, specifically why Ferrite magnets are inferior to Alnico or Neodymium. Since all structures use steel for core poles and back and top plates, and since Ferrite structures have a problem that Alnico and Neo don't exhibit, then it stands to reason that any nonlinearity in steel is clearly not the dominant issue.

As I stated many posts ago, designers go to great pains to prevent steel saturation so as not to waste magnet potential. That JBL can cut away material in the core pole to create room for the aluminum ring, (hence increasing flux density in the core pole) and still lower distortion, is another indicator that steel nonlinearity is not a major factor.

David S.

I know it might appear that I've been rabbit-chasing with this emphasis on steel's role, but I'm really not. (I do apologize, however, for not being clearer about tying the discussion back to its root in this thread.)

let me try to summarize briefly, and I invite correction from any of the host of magnetics experts out there who are more learned than I:

Steel is at the heart of the discussion in this thread because its variable permeability is the root of the Le(i) distortion mechanism. Klippel, for one, is pretty clear on that point (again, see the wording on the poster). In other words, when steel is subject to varying magnetic fields, its permeability modulates, and distortion results. Yes, the flux through the magnet itself modulates as well, but I believe (again, some guru correct me if I'm wrong) that its BH curve plays less of a role in the Le(i) distortion mechanism than that of the steel return circuit.

So the goal is to stabilize, as far as possible, the B field the magnet projects through its steel return circuit. Shorting rings are one good option (Now we're back on topic!). At frequencies where eddy currents are efficiently induced in shorting rings, they mirror and thus cancel a portion of the alternating VC field, shielding the B field conducted through the steel from modulation.

Another way to stabilize the B-field flux conducted through steel is to choose a "stiffer" magnetic material, such as AlNiCo or NdFeB vs. ferrite. Different approach, but same goal as shorting rings--to minimize the modulation of steel's permeability. (So our magnet discussion isn't so off-topic in a shorting-ring thread.)

Yet a third way to treat the same issue of flux stability through steel is to maximize B and minimize L(i) when you put together a target BL(i), as I mentioned a few posts ago.

A more radical way to treat the steel problem that few (except maybe ATC?) have explored is to minimize the role of steel in the loudspeaker motor.

So, in a nutshell, that's why I keep talking in terms of steel. Because whether you're talking about shorting rings, magnet types, motor strengths, etc, your real goal is to stabilize the flux flowing through steel, to keep it operating on a linear region of its BH curve to minimize Le(i) distortion.

let me try to summarize briefly, and I invite correction from any of the host of magnetics experts out there who are more learned than I:

Steel is at the heart of the discussion in this thread because its variable permeability is the root of the Le(i) distortion mechanism. Klippel, for one, is pretty clear on that point (again, see the wording on the poster). In other words, when steel is subject to varying magnetic fields, its permeability modulates, and distortion results. Yes, the flux through the magnet itself modulates as well, but I believe (again, some guru correct me if I'm wrong) that its BH curve plays less of a role in the Le(i) distortion mechanism than that of the steel return circuit.

So the goal is to stabilize, as far as possible, the B field the magnet projects through its steel return circuit. Shorting rings are one good option (Now we're back on topic!). At frequencies where eddy currents are efficiently induced in shorting rings, they mirror and thus cancel a portion of the alternating VC field, shielding the B field conducted through the steel from modulation.

Another way to stabilize the B-field flux conducted through steel is to choose a "stiffer" magnetic material, such as AlNiCo or NdFeB vs. ferrite. Different approach, but same goal as shorting rings--to minimize the modulation of steel's permeability. (So our magnet discussion isn't so off-topic in a shorting-ring thread.)

Yet a third way to treat the same issue of flux stability through steel is to maximize B and minimize L(i) when you put together a target BL(i), as I mentioned a few posts ago.

A more radical way to treat the steel problem that few (except maybe ATC?) have explored is to minimize the role of steel in the loudspeaker motor.

So, in a nutshell, that's why I keep talking in terms of steel. Because whether you're talking about shorting rings, magnet types, motor strengths, etc, your real goal is to stabilize the flux flowing through steel, to keep it operating on a linear region of its BH curve to minimize Le(i) distortion.

Since all structures use steel for core poles and back and top plates, and since Ferrite structures have a problem that Alnico and Neo don't exhibit, then it stands to reason that any nonlinearity in steel is clearly not the dominant issue.

I fully agree that the variable of magnet type can have a clear impact on measured performance. But I think it's a jump to say that it supersedes the importance of steel's properties. On what is this assertion based? There have been experiments where magnet type is the variable. Have there been any experiments where the return-circuit material is the variable? Since day one, steel has been part of the landscape--it's been a constant, never a variable.

designers go to great pains to prevent steel saturation so as not to waste magnet potential.

This makes sense to me as a cost-cutting calculation, much like it makes sense economically to lower the bias on a class-A amplifier so as not to waste electricity. But what about performance? Just like Class-A amp bias, when you use an orgy of flux to "bias" or push the operating point of steel deep into saturation, its behavior tends toward that of air, which is very linear.

That JBL can cut away material in the core pole to create room for the aluminum ring, (hence increasing flux density in the core pole) and still lower distortion, is another indicator that steel nonlinearity is not a major factor.

Yes! ... I mean, No!

Last edited:

Not sure why we are back to steel linearity when the reference clearly identifies it as a magnet material issue.

David, all parts of the magnetic circuit are in series. Permanent magnet generates the flux, steel parts guide this flux and with the air gap they close the magnetic circuit.

Local modulation of the magnetic flux at any point of this circuit, affects the whole circuit.

http://services.eng.uts.edu.au/cempe/subjects_JGZ/ems/ems_ch7_ppt.pdf

http://services.eng.uts.edu.au/cempe/subjects_JGZ/ems/ems_ch7_nt.pdf

The “ Magnet material issue” may be some sort of ineffective use of said magnet material.

Designing for optimum operating point of selected Permanent Magnet (Load Line) into the specific magnetic circuit, may alleviate the differences of various magnet materials used.

http://www.intemag.com/pdf/MMPAPMG-88.pdf

(Part II and especially page 10)

I hope I am not disturbing the topic's discussion, but I think Bill F. has a good point.

Regards

George

I fully agree that the variable of magnet type can have a clear impact on measured performance. But I think it's a jump to say that it supersedes the importance of steel's properties. On what is this assertion based? There have been experiments where magnet type is the variable. Have there been any experiments where the return-circuit material is the variable? Since day one, steel has been part of the landscape--it's been a constant, never a variable.

Just an inference from the measurements of JBL and McIntosh. They were happy with woofer distortion levels when Alnico was used, but found that Ferrite structures were 15 to 20dB worse. Their modified ferrite structures got performance back to where it had been previously and they were again satisfied.

If steel were the greater culprit then you might not even see a difference between Ferrite and Alnico. It would certainly diminish the difference. Clearly not the case.

Also the inference from their narrative. They did not say that "Although nonlinearity of steel is a significant problem we chose to pursue the lesser issue of magnet nonlinearity." (Sounds kind of silly when you say it that way.)

I agree that heavy steel saturation has been used as a method of decresing inductance effects, but this does not seem to be a factor (give an improvement) in traditional nonlinearity.

David S.

I hope I am not disturbing the topic's discussion, but I think Bill F. has a good point.

Regards

George

You are not disturbing the topic's discussion and thanks for the good reference material. It seems like a good overview on the subject.

The question remains whether nonlinearity of steel equates to nonlinear speaker output. The practical answer (not necessarily the theoretical answer) is no, steel nonlinearity is not a major factor.

David S.

Just an inference from the measurements of JBL and McIntosh. They were happy with woofer distortion levels when Alnico was used, but found that Ferrite structures were 15 to 20dB worse. Their modified ferrite structures got performance back to where it had been previously and they were again satisfied.

Dave, I think perhaps we're arguing the same point from from two slightly different starting points. We are both referring to Le(i) distortion, right? We both agree that a historical ferrite-magnet motor initially lagged behind the performance of a similarly designed AlNiCo-magnet motor.

WHY seems to be where we split. If I hear you correctly, you are suggesting that the Le(i) distortion in the ferrite-mag motor arose primarily from from within the magnet itself as its operating point on its BL curve was perturbed.

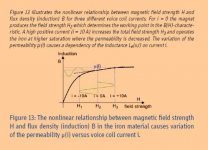

For my part, I defer to Klippel (from the attachment to post 89): "The nonlinear relationship between magnetic field strength H and flux density (induction) B in the iron [read: steel return circuit] material causes variation of the permeability u(i) versus voice coil current i."

So, yes, the magnet's operating point was perturbed as its flux was modulated by the VC field, but it was in the varying permeability of the steel in the motor that birthed the Le(i) distortion.

This is independent of the established fact that some magnet types are measurably better than others, all else being equal.

The question remains whether nonlinearity of steel equates to nonlinear speaker output. The practical answer (not necessarily the theoretical answer) is no, steel nonlinearity is not a major factor.

One idea for an interesting experiment regarding the nonlinearity impact of steel:

Position an immobilized voice coil in the gap of a field-coil loudspeaker motor. (The use of a field coil removes the magnet-material variable and any competing BH curve.) Energize the field coil to create a desired flux density in the motor steel. You've basically created a magnetically biased steel-core inductor. Now test the distortion spectrum induced into the voice coil at a range of frequencies and power levels.

How does this spectrum compare to that of an equivalent air-core inductor? The presence of steel should account for the difference.

However, to put it all in perspective, the practical truth is that Earl Geddes has demonstrated that average people have a hard time detecting even high levels of 2nd harmonic distortion, and they're only a little better at detecting 3rd harmonic. So all this running away from distortion may be nothing more than vanity, a chasing after the wind.

Last edited:

Sorry but I am not talking about Le(i) variation. The shorting (Faraday) ring of the original question is a solution to the inferior performance of the magnetic material Ferrite. The JBL paper showed Delta B over B difference of 3 to 1 in Neodymium vs. Ferrite. The measurements showed a 3 to 1 ratio in second harmonic (10dB reduction). The fact that the final distortion varies by the full amount of the magnet material's factor proves that the magnet material is the dominant nonlinearity, therefore iron nonlinearity is not a factor.

I don't know how to say it any clearer than that.

David S.

I don't know how to say it any clearer than that.

David S.

The speaker/headphone has other issues that mask this, so unless we can split out all the effecting factors and quantify them, the limit is not proven to be in the human hearing capability....

However, to put it all in perspective, the practical truth is that Earl Geddes has demonstrated that average people have a hard time detecting even high levels of 2nd harmonic distortion, and they're only a little better at detecting 3rd harmonic. So all this running away from distortion may be nothing more than vanity, a chasing after the wind.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Faraday ring in louspeaker driver, what is it?