After lots of listening and tweaks, I have decided that the F6CC is not for my listening taste. The problem with the F6CC and the F6 appears to be the low damping factor and my B&W CDM1 speakers. Those amplifiers might do better with open baffle designs, but cause lots of low frequency resonance issues with my speakers.

I just finished an F4 build and think that it will be my preferred, everyday amplifier. I am currently listening to it driven by a Buffalo-IIISE DAC modded to deliver about 7 volts peak single-ended. That peak output is a bit low so I will add a BA-3 front end to the F4. The F4 really sounds great.

I just finished an F4 build and think that it will be my preferred, everyday amplifier. I am currently listening to it driven by a Buffalo-IIISE DAC modded to deliver about 7 volts peak single-ended. That peak output is a bit low so I will add a BA-3 front end to the F4. The F4 really sounds great.

After lots of listening and tweaks, I have decided that the F6CC is not for my listening taste. The problem with the F6CC and the F6 appears to be the low damping factor and my B&W CDM1 speakers. Those amplifiers might do better with open baffle designs, but cause lots of low frequency resonance issues with my speakers. ............

First Lhquam, thanks for your profound analyses and modifications of the F6, you really tried hard to get the sound you wanted out of this amp.

Second, low frequency issues....

By chance I changed the last days from my open baffles to a "boom"y Tannoy in a real case. Amp driving was a M2 clone with double mono PSU.

First thing I noticed was a boomy bass, of course I thought that the position in the room caused this.

Later I cut off the autoformer and set the BA-3 Frontend in front of the output stage, no boomy bass any more! Without changing room position.

I friend of mine just makes his first experience with F6 compared to his XA60.5 and besides the good sides of F6 he spoke of less bass control.

When you look at the distortion over frequency diagrams on the First Watt homepage concerning M2 and F6, the F6 looks still much better than the M2 on the low frequency area.

Would be interesting to hear more peoples experience with F6 and "heavy" speakers and bass controll in closed or vented area solutions.

And we all know that the First Watt line is a special line not for "heavy speakers"

Any comments?

Of course I forgot that F5 behaves much better for these kind of speakers....or Burning Amps or F5 turbo and all these things Nelson did for us....!

Last edited:

BTW, I found that putting F6 on a big heatsink did not help much. With only two JFETs I found that heat transfer from the fet to the sink is a bottle neck. There is not a big difference in output device temperature when they mounted on the either on heatsinks with 0.2c/w or 0.14c/w. I tried many different insulators too.

BTW, I found that putting F6 on a big heatsink did not help much. With only two JFETs I found that heat transfer from the fet to the sink is a bottle neck. There is not a big difference in output device temperature when they mounted on the either on heatsinks with 0.2c/w or 0.14c/w. I tried many different insulators too.

I wonder if you could mount the FET directly on a copper heat spreader which is 3-4 times the size of the FET with some grease or keratherm but no insulator then mount that on a heatsink with an insulator.

Better yet, use ArcticSilver to mount the FET to the copper spreader, and mica and grease to insulate the spreader from the heatsink.I wonder if you could mount the FET directly on a copper heat spreader which is 3-4 times the size of the FET with some grease or keratherm but no insulator then mount that on a heatsink with an insulator.

BTW: The transconductance will only increase by approximately the square-root of the increase in bias current. The MOSFET equation gives Gm=sqrt(2*Ibias*Kp)

I don't know why I suggested Keratherm. That's an insulator. A thin layer of Thermalcote or Arctic Silver would do.

I haven't found a large difference between Arctic Silver and Thermalcote. Without an insulator and a thin layer of grease, I suspect the difference is small too. And original Thermalcote has a higher temperature rating if that matters.

I haven't found a large difference between Arctic Silver and Thermalcote. Without an insulator and a thin layer of grease, I suspect the difference is small too. And original Thermalcote has a higher temperature rating if that matters.

With grease, what holds the FET to the spreader? I guess you could use a clamping bar for the whole works: FET - grease - speader - grease - mica (or other insulator) grease - heatsink.I don't know why I suggested Keratherm. That's an insulator. A thin layer of Thermalcote or Arctic Silver would do.

I haven't found a large difference between Arctic Silver and Thermalcote. Without an insulator and a thin layer of grease, I suspect the difference is small too. And original Thermalcote has a higher temperature rating if that matters.

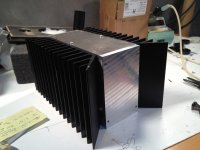

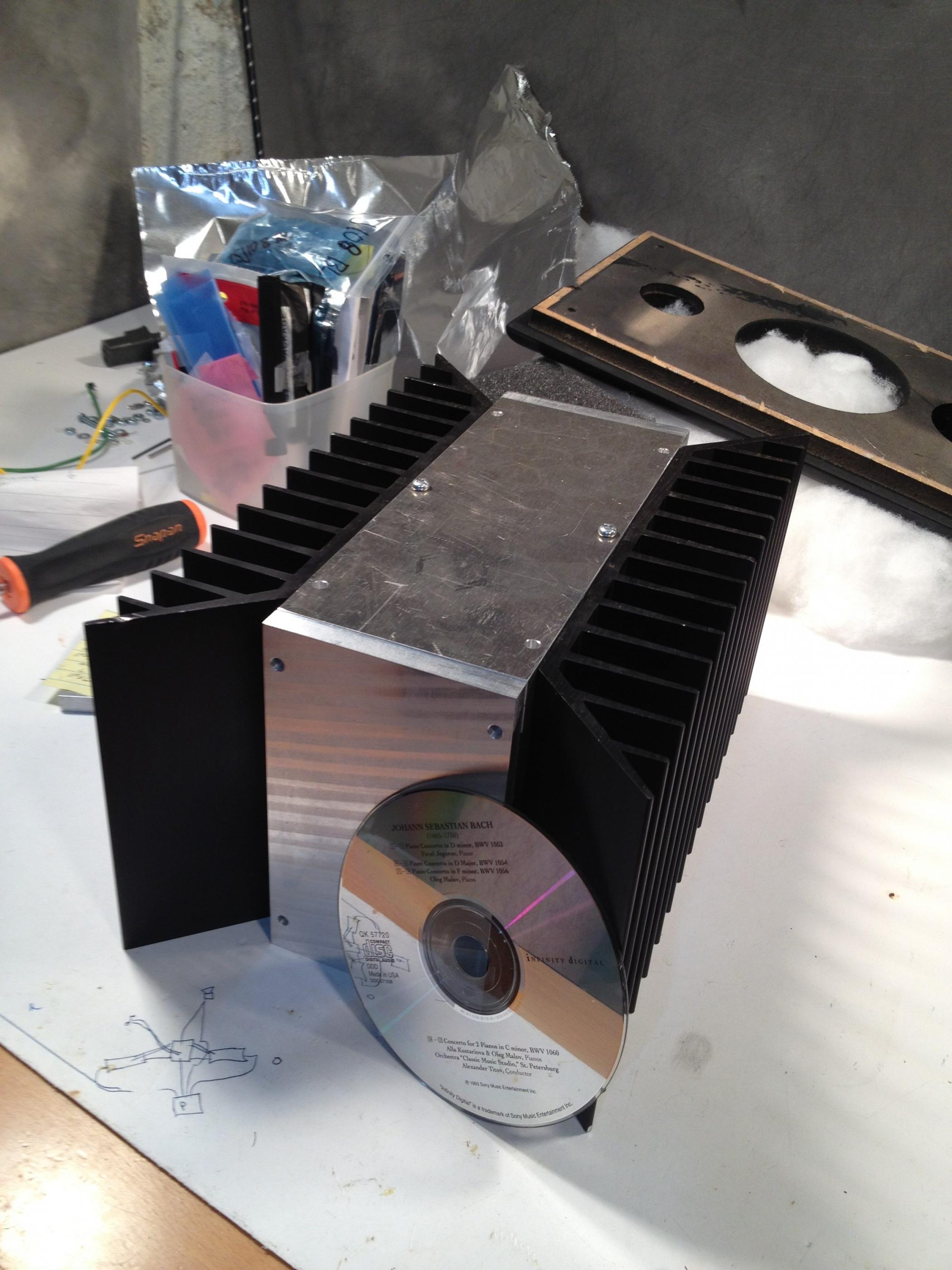

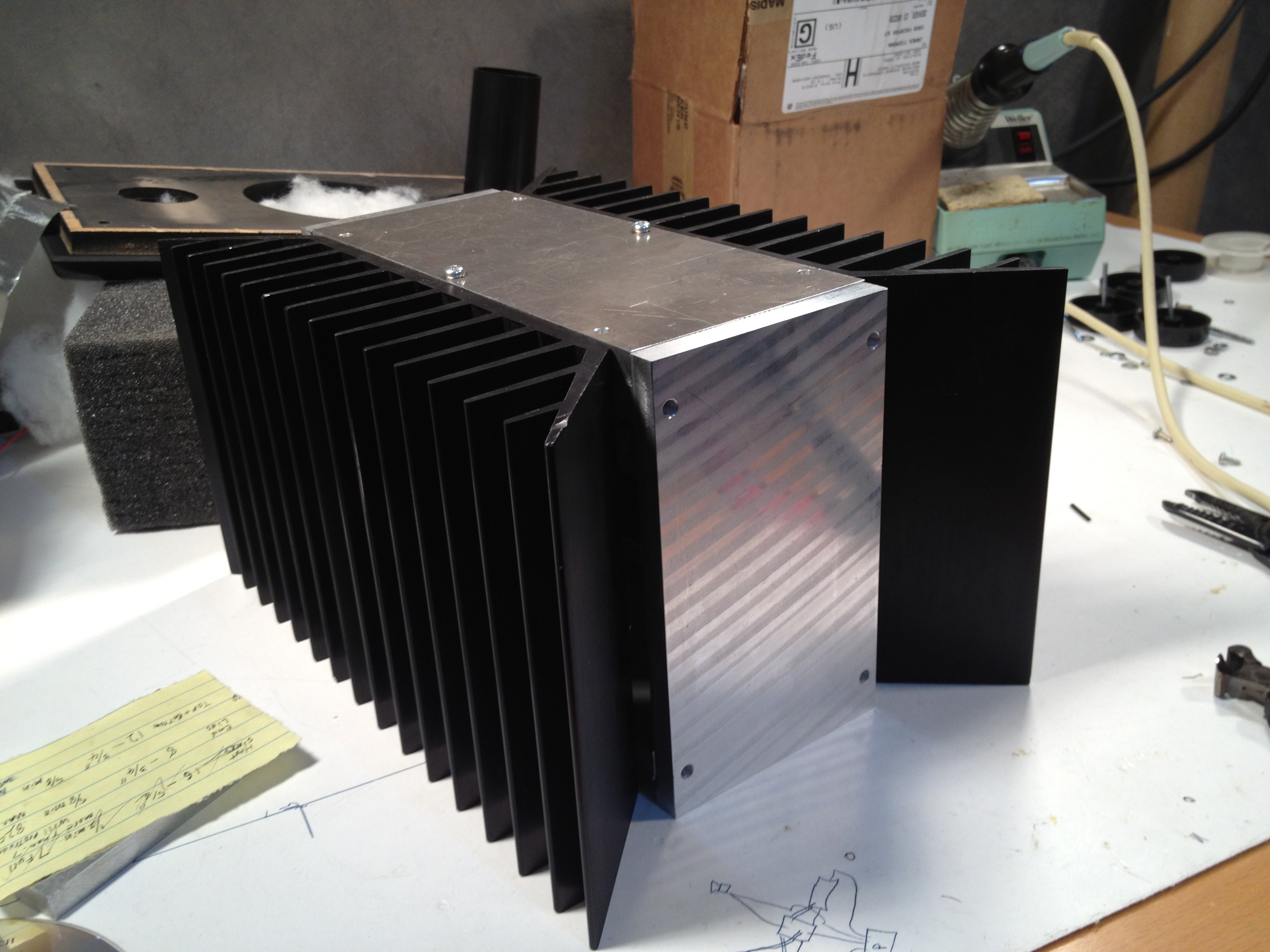

I finally got my F6 chassis from the machinist...

I'm not sure what finish I will have for the bare metal bits, I can polish it to very shiny, bead blast it and go for a clear anodize, or anodize black. The hardware will be black oxide.

Yes, the PSU will be separate. I haven't done that yet. It will likely be a small chassis from the store or something from Par-Metal.

I'm not sure what finish I will have for the bare metal bits, I can polish it to very shiny, bead blast it and go for a clear anodize, or anodize black. The hardware will be black oxide.

Yes, the PSU will be separate. I haven't done that yet. It will likely be a small chassis from the store or something from Par-Metal.

Attachments

Last edited:

Awesome.I finally got my F6 chassis from the machinist...

I'm not sure what finish I will have for the bare metal bits, I can polish it to very shiny, bead blast it and go for a clear anodize, or anodize black. The hardware will be black oxide.

- Home

- Amplifiers

- Pass Labs

- F6 Amplifier