Yes, what I experienced follows what you identified as the positive effects of adding significantly upping the capacitance in the F5m. I also remember benefiting from your insights on the mods to the ACA when I was building the ACA Redux version.

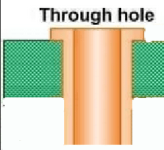

Connecting the caps to the underside of the board - it was a little tricky and does not quite meet the standard of making a solid mechanical connection before soldering. The 6800µF caps I added are snap-ins, just like the existing 4700µF ones, and have the same diameter and pin spacing. I joined them by carefully lining up the pins on the 6800µF ones so they overlapped against the stubs projecting under the board from the 4700µF ones.

Details: The installed 4700µF caps already had a good amount of solder on their pins; I applied some liquid rosin flux to them first (I use Kester 186 and a needle applicator). For the 6800µF pins, I pre-tinned them, and then added some liquid flux to them as well. With the 6800µF cap positioned so its pins overlapped against the stubs from the 4700µF ones, I put a drop of solder on the tip of my iron (this was to ensure rapid heat transfer to the pins) and then slipped the tip into the narrow space between the PCB and the 6800µF caps and applied it to the pins. Giving it a second or so to heat, I then fed in some additional solder to complete the connection. Three hands would have helped, but I got by. I verified a good connection by visual inspection, and also by gently flexing the 6800µF caps in a few directions once the joint cooled off, as a good connection will always be very stiff. Of the 8 solders, I did need to touch up 2 of them to get that stiffness.

Connecting the caps to the underside of the board - it was a little tricky and does not quite meet the standard of making a solid mechanical connection before soldering. The 6800µF caps I added are snap-ins, just like the existing 4700µF ones, and have the same diameter and pin spacing. I joined them by carefully lining up the pins on the 6800µF ones so they overlapped against the stubs projecting under the board from the 4700µF ones.

Details: The installed 4700µF caps already had a good amount of solder on their pins; I applied some liquid rosin flux to them first (I use Kester 186 and a needle applicator). For the 6800µF pins, I pre-tinned them, and then added some liquid flux to them as well. With the 6800µF cap positioned so its pins overlapped against the stubs from the 4700µF ones, I put a drop of solder on the tip of my iron (this was to ensure rapid heat transfer to the pins) and then slipped the tip into the narrow space between the PCB and the 6800µF caps and applied it to the pins. Giving it a second or so to heat, I then fed in some additional solder to complete the connection. Three hands would have helped, but I got by. I verified a good connection by visual inspection, and also by gently flexing the 6800µF caps in a few directions once the joint cooled off, as a good connection will always be very stiff. Of the 8 solders, I did need to touch up 2 of them to get that stiffness.

Last edited:

can be done with little T tubolar to estend ....It is great to see such persistence paying off.

Your improvement to the PSU with the addition of extra capacitance is in line with what I have found with my F5m. I am curious about how you connected those caps to the underside of the board.

Attachments

Why not wait for the P/S boards to become available and use them Dual Mono?Connecting the caps to the underside of the board - it was a little tricky and does not quite meet the standard of making a solid mechanical connection before soldering.

Biasing experiences please. I've built mine into a 2U mini diss chassis (photos to follow). I did my initial biasing this afternoon and left it at c.0.4V and c.10mV for each channel after a couple of hours. I will aim for 0.5V (my planned max) next time but wondered what others have achieved regarding a stable DC offset? Thanks.

I've seen mention of revised PS boards, but no details or timeline. And add in a little impatience, perhaps?Why not wait for the P/S boards to become available and use them Dual Mono?

10mV of dc offset is more than fine. Less than 50mV is fine, no need to be too analytical about thisBiasing experiences please. I've built mine into a 2U mini diss chassis (photos to follow). I did my initial biasing this afternoon and left it at c.0.4V and c.10mV for each channel after a couple of hours. I will aim for 0.5V (my planned max) next time but wondered what others have achieved regarding a stable DC offset? Thanks.

.

.Best,

Anand.

I've posted several of mine in the last several pages here. Given what NP stated in the write up, you should have no issue making 0.50A in that chassis.Biasing experiences please.

My experience with DC offset is that it is pretty stable once you are at temperature, and with some patience on the pots, you should be able to get it under ±5mV. Of course, the slightest adjustment you make to bias will produce a fairly big shift in DC offset, and vice-versa, meaning you will likely be going back a forth several times as you try to hone into a particular bias level and also null out the offset. There is bit of a rolling-the-dice aspect to it, but some patience will pay off. But if I were to build another one of these, I'd probably buy some multi-turn pots.

The only other caveat I can think of is if your ambient (room) temperature varies significantly over time, you will see some shifts in bias and presumably offset as well.

Yes, I brought it up with the store and the reply was they did not think of that but agreed it was possible. They are looking into it afaik in conjunction with getting more F5m kits out.I've seen mention of revised PS boards, but no details or timeline.

I bought a spare board at the marketplace. A few have come up for sale.

NP has not disowned the idea as invalid.

It is up to Jason now and maybe seeding the thread a bit to get it done.

The latest batch of F5m Essentials has shipped to the store. There has been an alteration

to the power supply board that gives minor improvement - they do not have more capacitance

(you could of course buy larger caps that will fit the board) but I have added two thermistors

to the completion kit which allows separate RC filtering for each channel, supporting higher bias

and less supply crosstalk. Documentation to follow shortly.

to the power supply board that gives minor improvement - they do not have more capacitance

(you could of course buy larger caps that will fit the board) but I have added two thermistors

to the completion kit which allows separate RC filtering for each channel, supporting higher bias

and less supply crosstalk. Documentation to follow shortly.

The watch has now begun.The latest batch of F5m Essentials has shipped to the store.

Steel or Aluminum, the difference is only the top, bottom, and rear panels. Front is aluminum, and as Tungsten says, the heatsinks are always aluminum.

Steel is more difficult to drill/cut, and the black finish is paint, not anodization.

I have examples of both and like them all.

Steel is more difficult to drill/cut, and the black finish is paint, not anodization.

I have examples of both and like them all.

An F5m for Lateral Mosfets such as the Hitachi pair you mention is to be published by Nelson, as he mentioned in some earlier posts.Is it possible to use

HITACHI Mosfets

2SK133/ 2SJ48

in the F5/F5M output?

Will it work, or fail?

maybe with the drilling in mind I will choose aluminium. and the anodized aluminium fits with the B1 pre amp.

Steel panels will be more difficult to drill or punch, and the paint tends to flake off near the hole.

Steel or Aluminum, the difference is only the top, bottom, and rear panels

Ok, the back panel is steel? So that does mean it's more work if any drilling or other metal work is needed. I had thought the back panel was still aluminum and only top and bottom are steel if that option is choosen, but the description clearly states rear panel is also steel.

- Home

- Amplifiers

- Pass Labs

- F5m kit