I also use a 200 Ohm resistor below the current source to drop the voltage a little further before entering the diff pair

while JFet gate is dictating voltage at own source

200R is "just" taking voltage from CCS, JFets source is tracking own gate

sorry...off topic again. D1 is now 10V, R6 is what value? and below Q2 is now a 200R resistor over a jumper?Speaking (off-topic) of the Aleph J...

I have run both of mine on 26.5V power supplies. The original one with store boards has a dual-mono CRCRC fronted by Antek AS-3220 transformers. The Aleph J SS uses a shared CRC store PSU board with synchronous rectifiers and an Antek AS-4220 transformer. I tweak the front end slightly by changing the zener diode to 10V and adjusting the associated resistor to keep the current the same into the diff pair of J74. I also use a 200 Ohm resistor below the current source to drop the voltage a little further before entering the diff pair. So the JFets don't see much higher voltage than they normally would given 24V rails.

Question: are these the right parts of I am tapping my heatsinks? Link

Yes. You also need the correct size of regular drill bits for each tap you will use.

A center punch will also be useful.

Last edited:

I think I have metric drill bits, just missing the tap portion.You also need the correct size of regular drill bits for each tap you will use.

Its worth double checking the tap size/ drill bit chart if you're not certain. For imperial measurements, drill sizes for taps are often given in a 2 digit sizing index used by machinist.

Automatic center punches are super handy. One handed use opens up a bunch of possibilities

Automatic center punches are super handy. One handed use opens up a bunch of possibilities

Last edited:

Cascode is ones friendwhile JFet gate is dictating voltage at own source

200R is "just" taking voltage from CCS, JFets source is tracking own gate

And if you know size of hole, you can buy a two piece set of tap and matching drill bit.Yes. You also need the correct size of regular drill bits for each tap you will use.

A center punch will also be useful.

I don’t really know I thought I read that ums is 3mm but Ive seen other places that says 2mmAnd if you know size of hole, you can buy a two piece set of tap and matching drill bit.

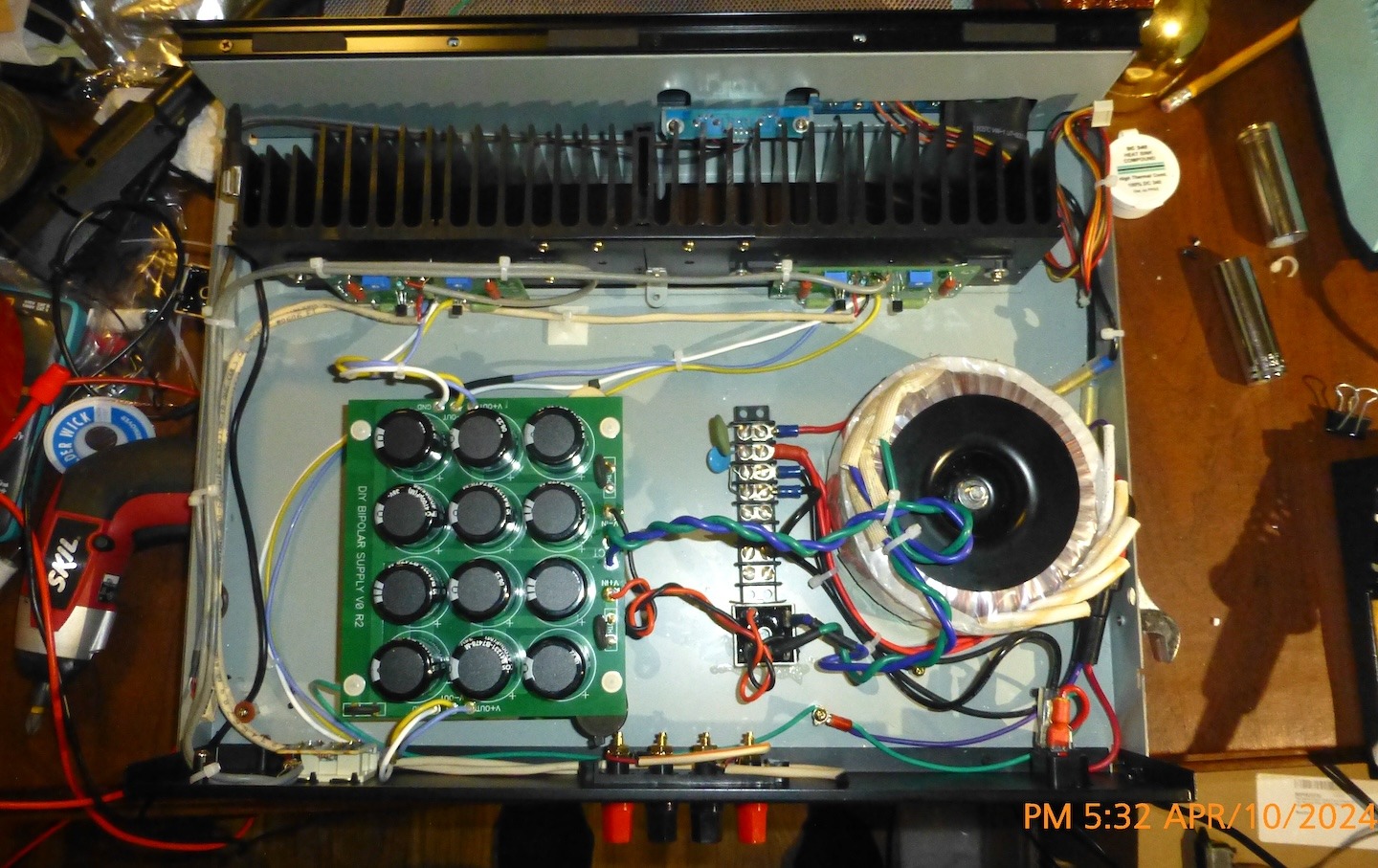

With the benefit of the great advice I’ve received here, I’ve been able to solve the noise issue I had. I have added capacitance to the final C in the CRC filter, and I’ve rotated the PS PCB to an orientation that allows the AC and DC wiring to be more cleanly separated.

I added 2x6800µF to the existing 2x4700µF for V+, and the same for V-, soldering them to the underside of the PS PCB. I used Vishay 6800µF/50V 256 PMG-SI caps that I purchased back in 2016, and have sat unused since. These Vishay are a good match to the ripple rating and ESR of the EPCOS caps from the kit. The PS PCB now stands taller, and I lashed a couple of wine corks to the nylon posts on the opposite side of the PCB so it would sit level. I returned the F5m to the system at this point, but was disappointed to find no discernible change in the buzz. I was thinking I would just remove the extra caps, but I tempered this with the thought that they might need some time to reform, and decided to listen to music while waiting. Well, I played some of my favorite tracks, and despite my disappointed mood, I was more than surprised to find they sounded better than ever; e.g, details like the shimmer in symbols was even more distinct, there was a greater 3D spatial effect. So I cut short the waiting for buzz reduction and went back to the bench to cut wires and reorient the PS PCB.

I rotated the PCB 90° CW, and repositioned the secondaries from the transformer to keep them out of the way of DC wiring, plus a few other minor tweaks. Once fully warmed up, I measured AC on the speaker terminals: 0.12mVAC R, 0.14mVAC L (the latter is closest to the transformer). This is a considerable reduction from the 0.30-0.55mVAC I was getting before. I returned the F5m to the system, and all warmed up, I can’t hear anything from the speakers with my ear against them.

I want to thank again all here who offered suggestions and took on the burden of my ignorance as a first-time chassis builder, especially since I chose a less-than-ideal chassis to work with. I’ve learned a great deal. I want to send a special thanks to Ben Mah and william2001 for suggesting the specific steps which proved so effective.

I added 2x6800µF to the existing 2x4700µF for V+, and the same for V-, soldering them to the underside of the PS PCB. I used Vishay 6800µF/50V 256 PMG-SI caps that I purchased back in 2016, and have sat unused since. These Vishay are a good match to the ripple rating and ESR of the EPCOS caps from the kit. The PS PCB now stands taller, and I lashed a couple of wine corks to the nylon posts on the opposite side of the PCB so it would sit level. I returned the F5m to the system at this point, but was disappointed to find no discernible change in the buzz. I was thinking I would just remove the extra caps, but I tempered this with the thought that they might need some time to reform, and decided to listen to music while waiting. Well, I played some of my favorite tracks, and despite my disappointed mood, I was more than surprised to find they sounded better than ever; e.g, details like the shimmer in symbols was even more distinct, there was a greater 3D spatial effect. So I cut short the waiting for buzz reduction and went back to the bench to cut wires and reorient the PS PCB.

I rotated the PCB 90° CW, and repositioned the secondaries from the transformer to keep them out of the way of DC wiring, plus a few other minor tweaks. Once fully warmed up, I measured AC on the speaker terminals: 0.12mVAC R, 0.14mVAC L (the latter is closest to the transformer). This is a considerable reduction from the 0.30-0.55mVAC I was getting before. I returned the F5m to the system, and all warmed up, I can’t hear anything from the speakers with my ear against them.

I want to thank again all here who offered suggestions and took on the burden of my ignorance as a first-time chassis builder, especially since I chose a less-than-ideal chassis to work with. I’ve learned a great deal. I want to send a special thanks to Ben Mah and william2001 for suggesting the specific steps which proved so effective.

- Home

- Amplifiers

- Pass Labs

- F5m kit