I'm in (I think...)!!!

I'll jump right in but first mention that I, like others, have had this very project in the back of my head for several years now. I stumbled across an Instructable post today that got me inspired to go DIY a set of these spiral speakers.....so off I go:

1. For the 36" design, does one simply need to blow up Mr. Pitkanen's original layout to accommodate the larger size? Meaning is it the exact design but larger proportionally or does one extrapolate/elongate the curvature further in consideration of the larger footprint?

2. What's considered to be the most "cost effective" driver for this project? I would like to build at least two but possibly four of these spiral speakers to be placed in a friend's design studio (a LARGE area). These would be a gift for his grand opening, FYI, and fit right in with the overall aesthetic of their professional ambitions.

I'll have to ask questions along the way but have gone through a majority of the posts and am ready to dive in. Thank you all for your earnest and detailed posts, they're very inspiring (I realize there are other threads/authors and not just Cal here.....).

thx!

--tli

...I have 20", 27" and 36" and there is a marked difference in each. I can't even listen to the two smaller ones anymore. No, that not an exaggeration...

I'll jump right in but first mention that I, like others, have had this very project in the back of my head for several years now. I stumbled across an Instructable post today that got me inspired to go DIY a set of these spiral speakers.....so off I go:

1. For the 36" design, does one simply need to blow up Mr. Pitkanen's original layout to accommodate the larger size? Meaning is it the exact design but larger proportionally or does one extrapolate/elongate the curvature further in consideration of the larger footprint?

2. What's considered to be the most "cost effective" driver for this project? I would like to build at least two but possibly four of these spiral speakers to be placed in a friend's design studio (a LARGE area). These would be a gift for his grand opening, FYI, and fit right in with the overall aesthetic of their professional ambitions.

I'll have to ask questions along the way but have gone through a majority of the posts and am ready to dive in. Thank you all for your earnest and detailed posts, they're very inspiring (I realize there are other threads/authors and not just Cal here.....).

thx!

--tli

Hi tli,

First off let me welcome you.

Second, I want to say that it really is X who got this going for all of us.

Third, that you will be so much happier if you go for a large 36" unit.

Fourth, the driver is up to you budget but don't go too heavy as this box makes lousy drivers sound better but you may find an expensive driver doesn't benefit as much.

Fifth, that you ask questions before you start and as you go, there's lots of help.

Sixth, that if you use the drawing in the early post and blow it up, it will be fine, BUT... notice the unusual curve where the second horn begins and smooth it out.

Seventh, take the time to read all the tips and do a practice run to get it right.

Eight, you must post pictures of your work as you go. That's mandatory

Nine, you'll have fun if you don't rush or force anything

Ten, you're gonna smile when you hook them up for the first time.

Cheers.

First off let me welcome you.

Second, I want to say that it really is X who got this going for all of us.

Third, that you will be so much happier if you go for a large 36" unit.

Fourth, the driver is up to you budget but don't go too heavy as this box makes lousy drivers sound better but you may find an expensive driver doesn't benefit as much.

Fifth, that you ask questions before you start and as you go, there's lots of help.

Sixth, that if you use the drawing in the early post and blow it up, it will be fine, BUT... notice the unusual curve where the second horn begins and smooth it out.

Seventh, take the time to read all the tips and do a practice run to get it right.

Eight, you must post pictures of your work as you go. That's mandatory

Nine, you'll have fun if you don't rush or force anything

Ten, you're gonna smile when you hook them up for the first time.

Cheers.

I haven't seen one built using the Faital Pro 4FE35 yet but I think it will work really well in a 36in and it is cost effective. It is 91dB sensitive costs $25 and has a very smooth frequency response. The only downside is the looks. You may be able to make a thin supra baffle to flush mount it and cover with a grill. Alternatively, a Faital Pro 4FE32 can work well too as it has a lower Qts and weighs less and is easier to mount. That driver is $37. The Tang Band W4 bamboo cones are also very good candidates and those are $37 ea. other choices include the MA CHR-70 at about same $36 price point. But most cost effective driver for 36in is the 4FE35 in 4 ohms.

If making a 20in the Vifa TC9FD is the winner. Although for $7 more the 3FE25 from Faital Pro is also an excellent choice and can work up to 24in.

If making a 20in the Vifa TC9FD is the winner. Although for $7 more the 3FE25 from Faital Pro is also an excellent choice and can work up to 24in.

Thx folks, this is great. Thus far:

1. I've picked up plenty of glue sticks and foam board from the Dollar Tree - 8 sheets of black (figured the black would have a nicer visual aesthetic assuming I don't wind up finishing with speaker cloth).

2. I couldn't find any front/finish wood I liked over at Home Depot. No rush I guess, will look at a wood store near my office tomorrow.

3. Staples wasn't able to print the exploded picture/template out to 36"x36" so I'll also have to jump on that tomorrow at a different print shop near my office.

I have time to read tonight so, second opinions on the drivers suggested by Mr. XRK971??

I'm off to read some threads in detail, I'm sure I'll have a few questions.

1. I've picked up plenty of glue sticks and foam board from the Dollar Tree - 8 sheets of black (figured the black would have a nicer visual aesthetic assuming I don't wind up finishing with speaker cloth).

2. I couldn't find any front/finish wood I liked over at Home Depot. No rush I guess, will look at a wood store near my office tomorrow.

3. Staples wasn't able to print the exploded picture/template out to 36"x36" so I'll also have to jump on that tomorrow at a different print shop near my office.

I have time to read tonight so, second opinions on the drivers suggested by Mr. XRK971??

I'm off to read some threads in detail, I'm sure I'll have a few questions.

The black is not a good choice for layout work unless you use a white pencil to mark the lines. Also, my experience with the black FC from dollar store is that it is not as good quality as the white. The paper tends to delaminate. Your local store may have a better batch. You can save yourself the printer store job by printing to a "tiled" image in Adobe Acrobat and choose scaling. Good luck!

If you can find RS 40-1354 drivers on eBay those work great too as Cal can tell you.

If you can find RS 40-1354 drivers on eBay those work great too as Cal can tell you.

The black is not a good choice for layout work unless you use a white pencil to mark the lines. Also, my experience with the black FC from dollar store is that it is not as good quality as the white. The paper tends to delaminate.

Well thanks for my first setback.....

I'll run with what I've got - as Cal mentioned, this might just wind up being a trial run anyway.

I'll run with what I've got - as Cal mentioned, this might just wind up being a trial run anyway. Thx for the additional speaker suggestion....in terms of a 36" box, it seems I'm looking for a ~4" or ~5" full range with a Qts <= 0.4. Anything else I should really concentrate on (other than recommendations from those who actually know what they're talking about??)?

--t

Last edited:

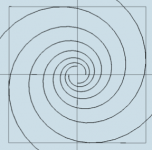

Is there a reason why a more symmetrical spiral isn't used for this layout? I gen'ed this up in Sketchup - is it valid to serve as a template or should I go with the original (after getting it dimensionally correct)? thx....

As a first build I suggest sticking to the real plan for best chance of success. You can experiment with other plans as you have drawn as FC is cheap and the speaker is easy to make. However, your plan, apart from smooth curves leaves out the important feature of a bifurcated double length horns. This helps to smooth response. Your horns appear to be all the same length. It may work it probably won't be as good sounding as the original.

Faital Pro 4FE35's have been ordered and are on the way. Thx again for the suggestions....

1. How tall do my foam board strips need to be for a 36" box?

2. Some pictures of the finished speakers I've seen have double the depth - appearing to have two of the spirals incorporated into one speaker (separated by a single sheet of wood). What's up with that?

3. My goal is to use the two attached images as the speaker "art" - have you guys had success with using an acoustically transparent material on top of the actual speaker itself or should I just have these images be printed and affixed to the front face of the speaker itself? If the latter, the somewhat ugly Faital Pro's will be interrupting these designs.

1. How tall do my foam board strips need to be for a 36" box?

2. Some pictures of the finished speakers I've seen have double the depth - appearing to have two of the spirals incorporated into one speaker (separated by a single sheet of wood). What's up with that?

3. My goal is to use the two attached images as the speaker "art" - have you guys had success with using an acoustically transparent material on top of the actual speaker itself or should I just have these images be printed and affixed to the front face of the speaker itself? If the latter, the somewhat ugly Faital Pro's will be interrupting these designs.

Attachments

I also realize there are quite a few of the inexpensive SS amps being used to power these spiral speakers. Anyone using a relatively inexpensive tube amp for these (?) and if so, please share your thoughts doing the same in a large, open room and whether you feel it'd be adequate.

thx again, looking forward to cutting/gluing/complaining about marrying up that second board. And yes, I'll post pics

thx again, looking forward to cutting/gluing/complaining about marrying up that second board. And yes, I'll post pics

On one side, you have the group that says the amp is big part of the system, the other side says build it so the amp is not a part of the equation. Cornu seems to be adaptable. It is such that you can tune your Cornu quickly no matter the amp. That's what voicing a speaker is all about.inexpensive SS amps being used to power these spiral speakers. Anyone using a relatively inexpensive tube amp for these (?)

Cheers

Faital Pro 4FE35's have been ordered and are on the way. Thx again for the suggestions....

1. How tall do my foam board strips need to be for a 36" box?

2. Some pictures of the finished speakers I've seen have double the depth - appearing to have two of the spirals incorporated into one speaker (separated by a single sheet of wood). What's up with that?

3. My goal is to use the two attached images as the speaker "art" - have you guys had success with using an acoustically transparent material on top of the actual speaker itself or should I just have these images be printed and affixed to the front face of the speaker itself? If the latter, the somewhat ugly Faital Pro's will be interrupting these designs.

1. 4in deep for 36in box should work. You could go as thin as 3.5in.

2. Double layer is needed if building traditional way where middle layer has slot cut in it to hold wood strips. The FC method with hot glue doesn't need middle layer. If making a very thick Cornu, make two FC ones and glue together with big driver camber hole.

2. I think white porous fabric can work well.

After you build it, glue some thin wood strips around the front edge to hold the fabric up off the driver. Print your pattern on porous material, then stretch it around the whole speaker and glue it on the back. Same sort of construction as canvas painting panels...

Thx Don, that's what I had envisioned, will do!

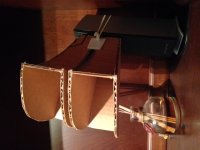

Faitals are here, I'm breaking them in now. I've never done this - they're hooked up to an older AIWA stereo (20 W), drivers are on a Futon underneath a blanket and pillows so as not to disrupt the house. Volume level is 3/10, is this the right way to do this?

Foam strips are cut, still don't have any wood faces yet so can't start the official spirals. Might do a test run of something "small" this morning, pics to follow.

thx guys....

Just to document a little progress, and an excuse to post a pic or two:

1. Initial foam cuts, I was doing this with a scrap piece of particle board as my guide and am using a typical thick-bodied utility knife. So, I wasn't able to be as consistent with the angle of the blade and all of my cuts and I knew it. First pic sort of shows the variability of my results - quality control fail #1.

2. Another trip to HD and I picked up a monster aluminum adjustable t-square. It can rotate and lock at 90-degrees and it's big enough to accommodate anything I'll ever do (I do a lot of projects and have needed something bigger anyway over the years - why I waited this long is a mystery). Once I got that home and did some more cuts, much better results (and a lot faster to use as well). Still nowhere near mechanical consistency in nature (a planar would be nice to have to knock 1/8" off what I've got for true accuracy) but I'm satisfied and know I can make these work.

3. Still being without facing boards I'm happy with, I took a different tact and switched priorities. My youngest daughter and I built some Barbie houses with the inventory of pieces from my initial cuts....she's happy and we had a good time.

O yeah, the black foam board I've got - the black paper is really not an issue at all. I played with bending the bejezezus out of several pieces and that paper isn't coming up/off/anything. Should be fine for my needs, phew!

Spirals ASAP, can't wait to get the hot glue gun going (been years since I've used one). Last time I did a speaker project with hot glue, I built horns for my PC speakers and they're still in use (love 'em!).

Have a good one....

1. Initial foam cuts, I was doing this with a scrap piece of particle board as my guide and am using a typical thick-bodied utility knife. So, I wasn't able to be as consistent with the angle of the blade and all of my cuts and I knew it. First pic sort of shows the variability of my results - quality control fail #1.

2. Another trip to HD and I picked up a monster aluminum adjustable t-square. It can rotate and lock at 90-degrees and it's big enough to accommodate anything I'll ever do (I do a lot of projects and have needed something bigger anyway over the years - why I waited this long is a mystery). Once I got that home and did some more cuts, much better results (and a lot faster to use as well). Still nowhere near mechanical consistency in nature (a planar would be nice to have to knock 1/8" off what I've got for true accuracy) but I'm satisfied and know I can make these work.

3. Still being without facing boards I'm happy with, I took a different tact and switched priorities. My youngest daughter and I built some Barbie houses with the inventory of pieces from my initial cuts....she's happy and we had a good time.

O yeah, the black foam board I've got - the black paper is really not an issue at all. I played with bending the bejezezus out of several pieces and that paper isn't coming up/off/anything. Should be fine for my needs, phew!

Spirals ASAP, can't wait to get the hot glue gun going (been years since I've used one). Last time I did a speaker project with hot glue, I built horns for my PC speakers and they're still in use (love 'em!).

Have a good one....

Attachments

- Home

- Loudspeakers

- Full Range

- Ever think of building a Cornu Spiral horn? Now you can!