Schroeder tonearm magnet

Here is closeup of the tonearm. The magnet is not curved.

Hi there.. thank you for posting but maybe ( I think ) that is not a picture of a genuine FS arm but of a clone?

@directdriver ... its a big optical illusion isn't it?

Is it Einsteinian curved space? Gravity lensing ?...... ?

I am neither Superman with X-ray eyes nor Einstein nor even a scientist. I can only go by my earthly eyeballs. I agree with you that the magnet looks curved to me. I do want to have fish eye vision though.

This is what the designer of the arm says about his bearing........ in post 146 of this long long thread.

My bearing(single or divided string) can be built to have a restoring force(in regard to VTF), to be completely neutral or to exhibit an unstable character.

The determining factor is the size of the magnets and the attachment point of the thread relative to the magnet. On the SQ version of the Reference arm, changes in VTA will not cause changes in VTF, despite the increased stability around the armwand axis. To achieve this, the top magnet's "face" is barrel-segment shaped, the bottom magnet's face is semi-spherical.

Frank

Last edited:

Yes Sorry about that. Looks like a cloned arm.Hi there.. thank you for posting but maybe ( I think ) that is not a picture of a genuine FS arm but of a clone?

Why will not grinding the magnet help ? You can fix the magnet on small rotating platform and with grinding drill bit slowly shape it. Or if proper size concave grinding bit is available it can be used. Like This.

Regards.

Surface working on strong magnets is complex and not recommended for these reasons:

-Magnets are brittle and fragile;

-Heat generation causes the demagnetization;

-Magnet is prone to corrosion;

-Magnet dust is not so healthy.

An alternative for room temperature application is gluing, like hottattoo proposed in post #1343

-Magnets are brittle and fragile;

-Heat generation causes the demagnetization;

-Magnet is prone to corrosion;

-Magnet dust is not so healthy.

An alternative for room temperature application is gluing, like hottattoo proposed in post #1343

Surface working on strong magnets is complex and not recommended for these reasons:

-Magnets are brittle and fragile;

-Heat generation causes the demagnetization;

-Magnet is prone to corrosion;

-Magnet dust is not so healthy.

An alternative for room temperature application is gluing, like hottattoo proposed in post #1343

I suppose that hand filing instead of machine grinding will get around some of those issues ie, no heat generation and care over fragility?

Re-plating then is not a problem here in Sheffield... we still have some industry here that can help. Herr Schroeder stated in one of his posts that some of his magnets are gold plated. I took from that that he re-shaped his magnets and then had to re-plate them to avoid corrosion.

He also said somewhere on here that there were no pieces glued over his magnets..... what you see in pictures are the magnets themselves.

So..... did any clone makers on here re-shape their magnets and ,if so, how and with what results?

Yes Sorry about that. Looks like a cloned arm.

.

Some nice workmanship in that arm though. Some of the implementation is less than optimal if I read Herr Schroeders 'hints' and comments correctly.

The arm wiring looks like it will either interfere with the anti-skate or considerably add to it. The counterweight is very low slung and ( in line with the nature of my present enquiry ) those magnets bother me.

But still... nice machining.

There are a lot of magnets of different size and shape for sell. Assortment is wide and huge, price is affordable. You don't need to shape magnet yourself. As for me- I would use spherical magnet for that purpose. Another option is to use not two magnets, but one together with the iron part instead of the second magnet . In that case you may shape iron part the way you want.

Hi folks,

The arm in the picture is not a clone. I know for sure, because I built that arm and took the picture

The quoted bit about the bottom magnet being semi-spherical and the top magnet having the opposing face ground to a barrel-segment is correct.

Grinding a neodymium magnet is not recommended for anyone who cannot provide cooling and, at least, wear a mask!!!

Attaching a shaped iron pole plate will yield an entirely different fluxline distribution and the fluxline density will be quite a bit lower as a result(= reduced attraction between the magnets/bearing less "stiff")

A great weekend to all!

Frank (Schröder)

The arm in the picture is not a clone. I know for sure, because I built that arm and took the picture

The quoted bit about the bottom magnet being semi-spherical and the top magnet having the opposing face ground to a barrel-segment is correct.

Grinding a neodymium magnet is not recommended for anyone who cannot provide cooling and, at least, wear a mask!!!

Attaching a shaped iron pole plate will yield an entirely different fluxline distribution and the fluxline density will be quite a bit lower as a result(= reduced attraction between the magnets/bearing less "stiff")

A great weekend to all!

Frank (Schröder)

Schroeder tonearm magnet

Here is closeup of the tonearm. The magnet is not curved.

Hi there.. thank you for posting but maybe ( I think ) that is not a picture of a genuine FS arm but of a clone?

Some nice workmanship in that arm though. Some of the implementation is less than optimal if I read Herr Schroeders 'hints' and comments correctly.

.

Hi folks,

The arm in the picture is not a clone. I know for sure, because I built that arm and took the picture

Frank (Schröder)

Whoops ! ... sorry Frank.... no curved magnets threw me off course there.

Is it an early arm?

Could I ask a technical question ? ...I will fully understand if you don't wish to answer...

With the 'shaped' magnets..do you start with cylindrical magnets or are some other shapes like bars?

How about using a magnet ball on the bottom of the bearing?

K&J Magnetics: S8

1/2" is good size, I guess.

In fact, I think two balls may be even better.

K&J Magnetics: S8

1/2" is good size, I guess.

In fact, I think two balls may be even better.

Last edited:

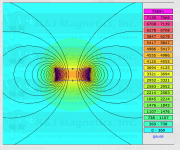

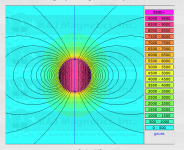

Here are the evidences that ball is better. The magnetic force for a ball is more concentrated at center of the ball. For a magnetic flat disc, its magnetic force is mostly on the edge.

Attachments

super10018, what is the name of program you used for pics above? I want one.

The images are from K&J magnetics web site. However, they do offer an app in apple store. I think it is very useful.

Attachments

How about using a magnet ball on the bottom of the bearing?

K&J Magnetics: S8

1/2" is good size, I guess.

In fact, I think two balls may be even better.

This thread is now too long to search but somewhere in it Frank gives a reason not to use spheres instead of cylinders.

Here are the evidences that ball is better. The magnetic force for a ball is more concentrated at center of the ball. For a magnetic flat disc, its magnetic force is mostly on the edge.

Those images don't show what happens when two attracting magnets are in the field. They just show the isolated field and not the interacting fields. It would be interesting to see such an image.

You need FEM software. femm.info

Beware steep learning curve

Luckily for me it runs on Windows and I only have Apple,

I do start out with cylindrical magnets. If you're using two spheres, you will almost inevitably create too stable a bearing, meaning that the VTF will change A LOT when changing VTA.

Try one sphere and one cylinder... but the key problem with a sphere is always to locate the exact center of the pole when mounting/fixing it.

FEMM is a powerful tool, highly recommended

Have a great weekend,

Frank

Try one sphere and one cylinder... but the key problem with a sphere is always to locate the exact center of the pole when mounting/fixing it.

FEMM is a powerful tool, highly recommended

Have a great weekend,

Frank

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm???