Hi Fran, Sorry i cant be much help, i get very little needle chatter, and cant feel any vibration at all in the gallows.

If the gallows it actually vibrating, i would be surprised if the source of the vibration is the actual needle in the groove, it would require a fair amount of energy to cause the gallows to vibrate, and it would have to travel up the suspension thread.

Is there any vibration from the Turntable motor or main bearing, this woud seem a more likely source for vibration of the Gallows.

Just a thought!

If the gallows it actually vibrating, i would be surprised if the source of the vibration is the actual needle in the groove, it would require a fair amount of energy to cause the gallows to vibrate, and it would have to travel up the suspension thread.

Is there any vibration from the Turntable motor or main bearing, this woud seem a more likely source for vibration of the Gallows.

Just a thought!

Hi guys,

yeah I know - is weird!

OK, so the TT is a lenco in a mass loaded plinth. Absolutely no rumble etc etc. In fact you can tap the plinth with the volume right up and no sound through the speakers. But if you have the volume up, and you rattle the tonearm wiring, I can hear microphonics.

Yes, I know its hard to believe, but that 6mm (ie 1/4") top plate, the one that the arm is actually suspended out of is vibrating!! And it has to be coming from the needle since I can't feel any vibrations say, on the bottom plate, or on the armboard. Its like the arm is resonating (test track is 300Hz BTW) and its draining out through that plate. I know I could maybe make the plate more massive, but surely it would be better to get rid of this earlier in the chain. Oh, and the arm I had in there previously is a roksan tabriz and it showed none of this behaviour.

It actually had me scratching my head for ages yesterday because I thought it was an alignment issue, so I aligned the thing about 5 times yesterday with lofgren, then baerwald etc etc. It sounds exactly like mistracking, but it seems it this resonance. Luckily I felt this vibration or I'd be still looking at alignment.

Any help greatly appreciated!! I'll post up some photos later.

Fran

yeah I know - is weird!

OK, so the TT is a lenco in a mass loaded plinth. Absolutely no rumble etc etc. In fact you can tap the plinth with the volume right up and no sound through the speakers. But if you have the volume up, and you rattle the tonearm wiring, I can hear microphonics.

Yes, I know its hard to believe, but that 6mm (ie 1/4") top plate, the one that the arm is actually suspended out of is vibrating!! And it has to be coming from the needle since I can't feel any vibrations say, on the bottom plate, or on the armboard. Its like the arm is resonating (test track is 300Hz BTW) and its draining out through that plate. I know I could maybe make the plate more massive, but surely it would be better to get rid of this earlier in the chain. Oh, and the arm I had in there previously is a roksan tabriz and it showed none of this behaviour.

It actually had me scratching my head for ages yesterday because I thought it was an alignment issue, so I aligned the thing about 5 times yesterday with lofgren, then baerwald etc etc. It sounds exactly like mistracking, but it seems it this resonance. Luckily I felt this vibration or I'd be still looking at alignment.

Any help greatly appreciated!! I'll post up some photos later.

Fran

Hi Fran,

Your pics, as nice as they are, don't show the thread attachment/exit point on the armwand. It kinda looks as if the thread comes out on the very top of the wand. The magnets are rather small it appears and the counterweight has a waaay low cog.

All of this amounts to a tremendous restoring force which will lead to large VTF differences depending upon the record thickness, warps and, possibly important in this case, misleading readings on your tracking force gauge. If you don't want to change the general layout for now, first make sure to measure VTF EXACTLY on record level(like,150gr. pressings). If you use a Shure gauge or any other gauge where the measuring level is above record level, you will end up with too low a VTF "in action".

Can you make out any rotational(around the armwand axis) movement while mistracking occurs?

Don't worry, we'll straighten you out !

!

Cheers,

Frank

Your pics, as nice as they are, don't show the thread attachment/exit point on the armwand. It kinda looks as if the thread comes out on the very top of the wand. The magnets are rather small it appears and the counterweight has a waaay low cog.

All of this amounts to a tremendous restoring force which will lead to large VTF differences depending upon the record thickness, warps and, possibly important in this case, misleading readings on your tracking force gauge. If you don't want to change the general layout for now, first make sure to measure VTF EXACTLY on record level(like,150gr. pressings). If you use a Shure gauge or any other gauge where the measuring level is above record level, you will end up with too low a VTF "in action".

Can you make out any rotational(around the armwand axis) movement while mistracking occurs?

Don't worry, we'll straighten you out

Cheers,

Frank

Hi guys,

yeah I know - is weird!

OK, so the TT is a lenco in a mass loaded plinth. Absolutely no rumble etc etc. In fact you can tap the plinth with the volume right up and no sound through the speakers. But if you have the volume up, and you rattle the tonearm wiring, I can hear microphonics.

Yes, I know its hard to believe, but that 6mm (ie 1/4") top plate, the one that the arm is actually suspended out of is vibrating!! And it has to be coming from the needle since I can't feel any vibrations say, on the bottom plate, or on the armboard. Its like the arm is resonating (test track is 300Hz BTW) and its draining out through that plate. I know I could maybe make the plate more massive, but surely it would be better to get rid of this earlier in the chain. Oh, and the arm I had in there previously is a roksan tabriz and it showed none of this behaviour.

It actually had me scratching my head for ages yesterday because I thought it was an alignment issue, so I aligned the thing about 5 times yesterday with lofgren, then baerwald etc etc. It sounds exactly like mistracking, but it seems it this resonance. Luckily I felt this vibration or I'd be still looking at alignment.

Any help greatly appreciated!! I'll post up some photos later.

Fran

Hi Fran, First I must compliment you on a very nice job building this arm, beautiful. Next I suggest that "we" of this thread do some rethinking of the previously held belief that energy won't drain out through the suspension thread. Your problem and my experience seems to say otherwise.

Next, for some easy and quick trouble shooting hints: take the cartridge mounting screws out and hold the cartridge on with some double sided sticky tape, several layers, and see if that makes any difference.

As for the microphonics when rattling the tone arm wires, grab the wires firmly with several fingers at a point between the arm and where you apply the rattle. Should damp out any microphonics there. This will most likely generate some hum though. If there is no change, there is something different to consider.

Do you have any damping inside the arm wand? If not try some black electrical tape, a few layers and maybe wrap it with sewing thread on the outside. This worked well for me on an experimental linear tracking arm.

Lastly I suggest getting some modeling clay and see what can be done with damping areas of the gallows assembly. I found damping the bottom plate most effective. None of these parts are going to self resonate. The arm wand will have a resonant signature, but so what if you are not coupling energy into it. I believe the best approach is keeping the energy out (isolating) rather than trying to drain it out once it is there. This of course is begging the issue of what to do with that energy if it is still locked up in the cartridge. I think the modifications to cartridges such as fancy wooden shells and special gluing to selected areas inside the cartridge are attempts to deal with this energy at the point of origin.

Lotsaluck,

BillG

WTF,.....Wood Turner Fran...... coincidence? LOL

I seem to recall that Mr. Davidson had similar issues with his counter weight he had at first. Remember that really cool looking one that was under-slung on both sides? It gave him trouble(s) and he went a different route, more mass centered on the longitudinal axis of the arm wand.

His Uberness, Frank, mentions this as a possible point of trouble as well.

Imagine the point where the string exits the top of it's connection inside the arm wand as the axis point for micro-rotational wobble. The arm wand is a pendulum and that attachment point is the fulcrum, it can wobble in 3 planes, X,Y,Z.

Try removing your counterweight and wrapping some lead / heavy solder around the arm tube in lieu of the counterweight.

I could be completely off track (no pun intended) but it's easy to try and worth a shot to see if it helps.

An awesome looking build, and I'm jealous of everyone who's completed theirs, working or not.

As always, Big Thank You to Frank (Mr. Schroder) for helping us with his expertise and background. Bless you.

Bgruhn, any photos you could share with us?

Ron

I seem to recall that Mr. Davidson had similar issues with his counter weight he had at first. Remember that really cool looking one that was under-slung on both sides? It gave him trouble(s) and he went a different route, more mass centered on the longitudinal axis of the arm wand.

His Uberness, Frank, mentions this as a possible point of trouble as well.

Imagine the point where the string exits the top of it's connection inside the arm wand as the axis point for micro-rotational wobble. The arm wand is a pendulum and that attachment point is the fulcrum, it can wobble in 3 planes, X,Y,Z.

Try removing your counterweight and wrapping some lead / heavy solder around the arm tube in lieu of the counterweight.

I could be completely off track (no pun intended) but it's easy to try and worth a shot to see if it helps.

An awesome looking build, and I'm jealous of everyone who's completed theirs, working or not.

As always, Big Thank You to Frank (Mr. Schroder) for helping us with his expertise and background. Bless you.

Bgruhn, any photos you could share with us?

Ron

First of all, I want to say thanks so much to all of you for your help so far.

Frank, I read your post earlier today and have been thinking ever since!! I'm going to modify the arm as you suggest. I am measuring VTF at above record height, and I'll bet it is making a hell of a difference. The second thing you mention about the COG of the counterweight being too low - I have another counterweight that I think will slide right on to try out. Lastly, what you mention about the magnet size. I bought 8mm (dia) x 5mm magnets from ebay. They certainly feel very strong, and I think were what was used by another member here - IIRC I asked what were people using.... although its a while ago now.

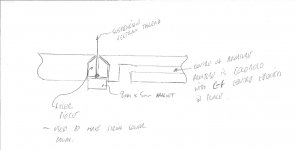

If you remember a few pages back, I mentioned that I though the arm was quite "stiff" in vertical movement. You advised me to move the bottom suspension point down to lower in the arm. Well, I did that - see the drawing below gives you an idea of what I did. Essentially, I made a filler piece to take the position of the bottom knot lower.

Now as I looked at what I've drawn, it seems to me that the string passes through that narrow "chimney" and I wonder if that's effectively making the pivot point higher (by binding on the thread). Although when I did this, it certainly "felt" better that it did.

I can't see any movement around the axis when the mistracking happens.

Pic:

Frank, I read your post earlier today and have been thinking ever since!! I'm going to modify the arm as you suggest. I am measuring VTF at above record height, and I'll bet it is making a hell of a difference. The second thing you mention about the COG of the counterweight being too low - I have another counterweight that I think will slide right on to try out. Lastly, what you mention about the magnet size. I bought 8mm (dia) x 5mm magnets from ebay. They certainly feel very strong, and I think were what was used by another member here - IIRC I asked what were people using.... although its a while ago now.

If you remember a few pages back, I mentioned that I though the arm was quite "stiff" in vertical movement. You advised me to move the bottom suspension point down to lower in the arm. Well, I did that - see the drawing below gives you an idea of what I did. Essentially, I made a filler piece to take the position of the bottom knot lower.

Now as I looked at what I've drawn, it seems to me that the string passes through that narrow "chimney" and I wonder if that's effectively making the pivot point higher (by binding on the thread). Although when I did this, it certainly "felt" better that it did.

I can't see any movement around the axis when the mistracking happens.

Pic:

Attachments

Hi Fran,

"2. Drill the filler piece shown above out bigger so that string only moves on lowest pivot point"

Absolutely! For the magnet dimensions you've chosen, the pivot point needs to be very close to or on the "surface" of the magnet. While your drawing implies that the "pivot point" is near the magnet, the thread seems to be touching the walls of the exit hole and the edge above if the armwand is raised or lowered too far. Find a way to give it room for unimpeded movement...

Your counterweight doesn't seem to feature any decoupling from the armwand, correct?

I must admit that I still find it amazing that a mechanical resonance exited by a diminuitive excursion should be able to cause the upper base plate to vibrate noticably(unless the bearing is "too stiff" in the vertical plane). Even if you were to damp the vibration using clay, blue tack or whatever, it's far better to deal with vibrations generated by the cartridge during playback WITHIN the suspended part of the entire tonearm. The CF core of your armwand may be doing you a disservice. Additionally, you could reduce the size of top and bottom base plate.

More to come if this doesn't help...

Cheers,

Frank

"2. Drill the filler piece shown above out bigger so that string only moves on lowest pivot point"

Absolutely! For the magnet dimensions you've chosen, the pivot point needs to be very close to or on the "surface" of the magnet. While your drawing implies that the "pivot point" is near the magnet, the thread seems to be touching the walls of the exit hole and the edge above if the armwand is raised or lowered too far. Find a way to give it room for unimpeded movement...

Your counterweight doesn't seem to feature any decoupling from the armwand, correct?

I must admit that I still find it amazing that a mechanical resonance exited by a diminuitive excursion should be able to cause the upper base plate to vibrate noticably(unless the bearing is "too stiff" in the vertical plane). Even if you were to damp the vibration using clay, blue tack or whatever, it's far better to deal with vibrations generated by the cartridge during playback WITHIN the suspended part of the entire tonearm. The CF core of your armwand may be doing you a disservice. Additionally, you could reduce the size of top and bottom base plate.

More to come if this doesn't help...

Cheers,

Frank

Counterweight is not decoupled - bolt holds it tight in place.

Frank, would you recommend bigger magnets? If so, what is a good size?

The way this is set up, the knot touches the upper side of the magnet in the tonearm. Apart from drilling a hole in the magnet, this is as close as I can get really. Of course, as I have done it, the string undoubtedly does touch the walls which negates this completely!

I might take a precaution and drill out a new armwand from cocobolo and have it coming along just in case. No CF in it!!

Fran

Frank, would you recommend bigger magnets? If so, what is a good size?

The way this is set up, the knot touches the upper side of the magnet in the tonearm. Apart from drilling a hole in the magnet, this is as close as I can get really. Of course, as I have done it, the string undoubtedly does touch the walls which negates this completely!

I might take a precaution and drill out a new armwand from cocobolo and have it coming along just in case. No CF in it!!

Fran

WTF,.....Wood Turner Fran...... coincidence? LOL

I seem to recall that Mr. Davidson had similar issues with his counter weight he had at first. Remember that really cool looking one that was under-slung on both sides? It gave him trouble(s) and he went a different route, more mass centered on the longitudinal axis of the arm wand.

His Uberness, Frank, mentions this as a possible point of trouble as well.

Imagine the point where the string exits the top of it's connection inside the arm wand as the axis point for micro-rotational wobble. The arm wand is a pendulum and that attachment point is the fulcrum, it can wobble in 3 planes, X,Y,Z.

Try removing your counterweight and wrapping some lead / heavy solder around the arm tube in lieu of the counterweight.

I could be completely off track (no pun intended) but it's easy to try and worth a shot to see if it helps.

An awesome looking build, and I'm jealous of everyone who's completed theirs, working or not.

As always, Big Thank You to Frank (Mr. Schroder) for helping us with his expertise and background. Bless you.

Bgruhn, any photos you could share with us?

Ron

Hi Ron,

Here are a few pics of my arm and TT. Pics are strictly hurry up, flash on the camera and I didn't even clean up the dust and debris. So pardon is begged of you all and thanks for asking. Left pic shows counterweight and cartridge with prototype isolator. Right pic shows TT and tone arm. Pardon the leftover arm rest. That has to go! Center pic shows gallows assembly with the wad of clay.

BillG

BillG

Attachments

Last edited:

BillG,

Thanks for sharing those photos with us, I really like the wood look for the upper tower. The arm looks good too. You have a wooden cart attachment point too. Did the wood coupling to the cart make a difference over metal? ie; aluminum / brass?

WTF, Keep us posted!

Ron

Thanks for sharing those photos with us, I really like the wood look for the upper tower. The arm looks good too. You have a wooden cart attachment point too. Did the wood coupling to the cart make a difference over metal? ie; aluminum / brass?

WTF, Keep us posted!

Ron

BillG,

Thanks for sharing those photos with us, I really like the wood look for the upper tower. The arm looks good too. You have a wooden cart attachment point too. Did the wood coupling to the cart make a difference over metal? ie; aluminum / brass?

WTF, Keep us posted!

Ron

Ron,

Go to "DIY headshell with energy sink" for a detailed description of its evolution. When I get some more time I am going to replace the balsa wood center section with something more isolating. There is lots of info in the other thread.

Bill

Well tonight I went and experimented a bit.

I drilled out a much bigger hole (4mm) where the thread comes up through the armtube. I made a small disc of brass (hardened) with a 1mm hole and then "dished" it so that the knot sat down into it. Then I glued that plate into the bottom of the arm. Then went and added in the magnet - so that the knot is now right at the top surface of the magnet. That's as close as I can get it.

Then I took off my existing counterweight and just used a old rega one instead.

I reassembled the arm and mounted it on the TT. I listened quickly with the test tracks and now there is definitely less mistracking - and only in the left channel, right channel is pretty ok. Also, the vibration at the top plate is much reduced - I can barely feel it now.

Now heres the interesting part. I took some VTF measurements at different heights.

I set the cart for 2g at exactly surface level. I moved over to the edge of the platter and took a measurement about 1-2mm lower. Only 1g VTF now. But if I used the grub screw to raise the arm (i.e. move the magnets further apart) then I got 2g.

So it seems that its not yet OK. Now I need to go back and fine tune fitting the magnet to the arm. When I glued it in, I obviously didn't set it perfectly and I can see that the gap between the 2 magnets is not perfectly even.

Progress of a sort - but not there yet. Frank has mentioned a few times that the magnets I have are a bit small. So I might try getting bigger diameter ones.

Fran

I drilled out a much bigger hole (4mm) where the thread comes up through the armtube. I made a small disc of brass (hardened) with a 1mm hole and then "dished" it so that the knot sat down into it. Then I glued that plate into the bottom of the arm. Then went and added in the magnet - so that the knot is now right at the top surface of the magnet. That's as close as I can get it.

Then I took off my existing counterweight and just used a old rega one instead.

I reassembled the arm and mounted it on the TT. I listened quickly with the test tracks and now there is definitely less mistracking - and only in the left channel, right channel is pretty ok. Also, the vibration at the top plate is much reduced - I can barely feel it now.

Now heres the interesting part. I took some VTF measurements at different heights.

I set the cart for 2g at exactly surface level. I moved over to the edge of the platter and took a measurement about 1-2mm lower. Only 1g VTF now. But if I used the grub screw to raise the arm (i.e. move the magnets further apart) then I got 2g.

So it seems that its not yet OK. Now I need to go back and fine tune fitting the magnet to the arm. When I glued it in, I obviously didn't set it perfectly and I can see that the gap between the 2 magnets is not perfectly even.

Progress of a sort - but not there yet. Frank has mentioned a few times that the magnets I have are a bit small. So I might try getting bigger diameter ones.

Fran

Last edited:

The new magnets arrived today - very quick shipping from seller "emovendo" on ebay. So I had already bored out a piece of macassar ebony for the armwand. I'm not completely confident of it, so I think I may go back and do one in cocobolo. On the outside of the square blank there was a little bit of a split - it didn't show up when I rough turned it down, but I think it likely it will open up over time. ho hum.

I made a new stub for the magnet and am much happier with my effort this time. I achieved much greater precision in the machining, so I'm really hopeful that this one will work out better. I need to let the timber stabilise now for a week or 2 - even though it has been air dried for several years, I like to give it another little while inside in the final environment it will live in.

Fran

I made a new stub for the magnet and am much happier with my effort this time. I achieved much greater precision in the machining, so I'm really hopeful that this one will work out better. I need to let the timber stabilise now for a week or 2 - even though it has been air dried for several years, I like to give it another little while inside in the final environment it will live in.

Fran

- Home

- Source & Line

- Analogue Source

- DIY Schroeder Tonearm???