serengetiplains said:My goal is to make a capacitor with a dielectric constant <1.9.

So you're basically just chasing after numbers?

For low voltage use, perhaps a dielectric like a loose-weave silk or cotton would work well? Anyone think why not?

Size for one thing. Unless you're only wanting to make picofarad caps. Second, neither cotton nor silk have dielectric constants as low as you want to go.

The claims made for cotton's dielectric constant of 1.4 are misleading as it only applies to cotton in its raw form, i.e. cotton balls, due to the vast amount of air that makes up the total volume. In textile form, dielectric constant is higher, and higher than the sub-1.9 figure you're chasing after.

se

Steve Eddy said:

So you're basically just chasing after numbers?

Yup. Numbers is it.

I can understand that pinholes would become a concern at higher voltages, but for coupling purposes in low voltage situations, perhaps the bigger the pinhole the better?

I'm currently having a capacitor manufacturer experiment with a paper-in-Fluorinert (1.86 dielectric k) construction. No word yet on whether it might succeed.

I'm currently having a capacitor manufacturer experiment with a paper-in-Fluorinert (1.86 dielectric k) construction. No word yet on whether it might succeed.

serengetiplains said:Yup. Numbers is it.

Well, this is a society that largely worships the quantitative over the qualitative so I guess I can't blame you.

Enjoy the chase.

se

serengetiplains said:My goal is to make a capacitor with a dielectric constant <1.9.]

amorphous FEP teflon by dupont is said to be either 1.92 or 1.93... I forget which.

"regular" FEP teflon is close to 2.0 or 2.2... forget exactly... you can look these materials up on dupont's website.

Mike

Thanks, Mike. Fluorinert comes in at 1.75-1.91, depending on the variety, but it's liquid, so requires a suspending solid to hold it in place. The particular variety of Fluorinert I'm testing is FC-84, which has a DC of 1.86. Porous teflon is 1.5 and higher, depending on the pore size, and porous polypropylene should be about the same. One possibility is to wind a capacitor with two layers of dielectric, one layer of foam ptfe/pp, the other solid ptfe/pp, the solid layer to prevent arcing or electrostatic whatever (I have no idea).

If teflon capacitors at 2.1 DC sound better than polypropylene at 2.2, can you imagine what a 1.8-1.5 DC capacitor would sound like?

If teflon capacitors at 2.1 DC sound better than polypropylene at 2.2, can you imagine what a 1.8-1.5 DC capacitor would sound like?

serengetiplains said:The hunch I'm chasing follows the observation that evil dielectric absorption largely correlates with dielectric constant such that the lower the DC the lower the DA the higher the signal transfer fidelity.

What exactly makes dielectric absorption so evil? What exactly is its effect on signal transfer fidelity? I can see how it would be a problem with something like a sample and hold circiut, but for an analogue signal?

se

water, water everywhere...

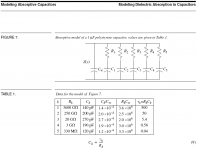

http://www.designers-guide.org/Modeling/da.pdf

also

http://www.national.com/rap/Application/0,1570,28,00.html

point out that dielectric adsorption has a very successful linear model that doesn’t affect audio signals (sub ppm linear freq response variations vs the "pure C" model in most continuous filter applications)

no good theory linking da with distortion - do you have the ability to measure even polystyrene distortions?

a big issue is water, water is polar, has huge dielectric constant and everything absorbs water, papers/fabrics of organic fibers adsorb multiple percent - water even diffuses through oil impregnants - you'll need to vacuum bake to dry and then hermetically seal any of your experiments to avoid absorbed water dominating the dielectric effects as you try to go lower

even with < 0.1% equilibrium water absorption polystyrene has measurable dielectric changes - I recall seeing a report of 10X increase of 1KHz dielectric loss for polystyrene with absorbed water

http://www.designers-guide.org/Modeling/da.pdf

also

http://www.national.com/rap/Application/0,1570,28,00.html

point out that dielectric adsorption has a very successful linear model that doesn’t affect audio signals (sub ppm linear freq response variations vs the "pure C" model in most continuous filter applications)

no good theory linking da with distortion - do you have the ability to measure even polystyrene distortions?

a big issue is water, water is polar, has huge dielectric constant and everything absorbs water, papers/fabrics of organic fibers adsorb multiple percent - water even diffuses through oil impregnants - you'll need to vacuum bake to dry and then hermetically seal any of your experiments to avoid absorbed water dominating the dielectric effects as you try to go lower

even with < 0.1% equilibrium water absorption polystyrene has measurable dielectric changes - I recall seeing a report of 10X increase of 1KHz dielectric loss for polystyrene with absorbed water

Attachments

Re: water, water everywhere...

Right. DA has been made into a huge Bogey Man, and it is in certain applications such as sample and hold circuits. But I haven't seen anyone demonstrate that it affects analogue audio signals in any appreciable way.

I'm beginning to think it's the case of the Bogey Man that wasn't there.

se

jcx said:http://www.designers-guide.org/Modeling/da.pdf

also

http://www.national.com/rap/Application/0,1570,28,00.html

point out that dielectric adsorption has a very successful linear model that doesn’t affect audio signals (sub ppm linear freq response variations vs the "pure C" model in most continuous filter applications)

no good theory linking da with distortion - do you have the ability to measure even polystyrene distortions?

Right. DA has been made into a huge Bogey Man, and it is in certain applications such as sample and hold circuits. But I haven't seen anyone demonstrate that it affects analogue audio signals in any appreciable way.

I'm beginning to think it's the case of the Bogey Man that wasn't there.

se

JCX,

The National article by Bob Pease does in fact say the soakage (DA) can be a detriment to AC coupled amplifiers.

Steve Bench also has some convincing tests on his website... with REAL data. Paper in oil showed the best results... hmmmmm.

I agree that much more "non-ear" testing needs to be done; but this looks real.

The National article by Bob Pease does in fact say the soakage (DA) can be a detriment to AC coupled amplifiers.

Steve Bench also has some convincing tests on his website... with REAL data. Paper in oil showed the best results... hmmmmm.

I agree that much more "non-ear" testing needs to be done; but this looks real.

Based on polarization/dielectric constant considerations for minimization of dielectric absorption, the best films for audio applications are teflon and polypropylene. Runners up would be polyethylene and polystyrene, based on these considerations alone. Throughout this discussion, I have assumed that dielectric absorption and the dielectric constant are directly correlated.

Apparently, when polarizability factors predominate, the time constant for relaxation of the field induced dipole is critical. Otherwise, one would expect polypropylene to have a lower dielectric absorption than polystyrene, which is not the observed result. This can be reasoned by re-examining what is being polarized by the field in each. In the case of the polystyrene, the pi-electrons in the aromatic rings (which have been modeled, in the past, as a "free electron gas") can orient electronically, with less mechanical change in the polymer structure. Hence, it can relax faster. In contrast, the polarization of polypropylene involves more mechanical change of the structure, and hence a slower relaxation rate.

From Anatech's first link in thread. Discussing PS vs PP in particular.

poobah said:Steve Bench also has some convincing tests on his website... with REAL data. Paper in oil showed the best results... hmmmmm.

Which is interesting given that paper in oil caps are far far worse than film caps when it comes to DA.

se

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Dielectric Constant of Kraft Paper