Ok I'll look up that design for the MCM, thanks.

Hmm I dunno about the BL thing. I mean the BL of my 19OV2 is 22, and it works fine.

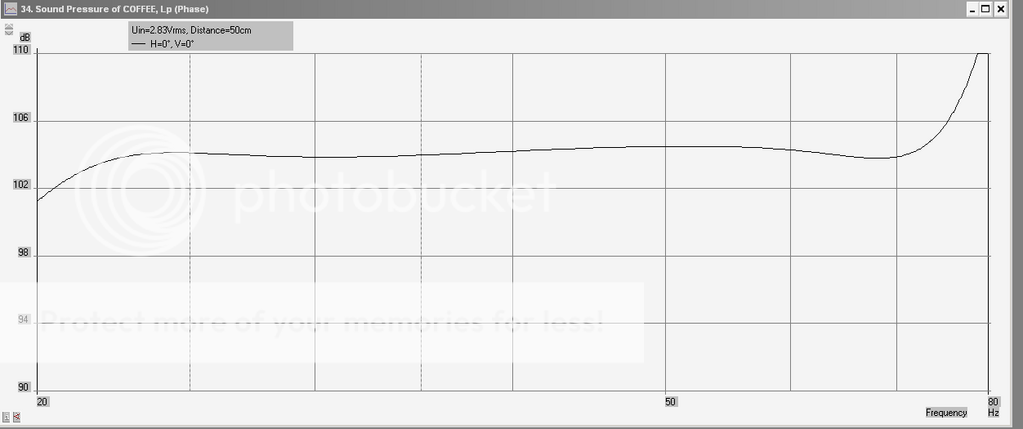

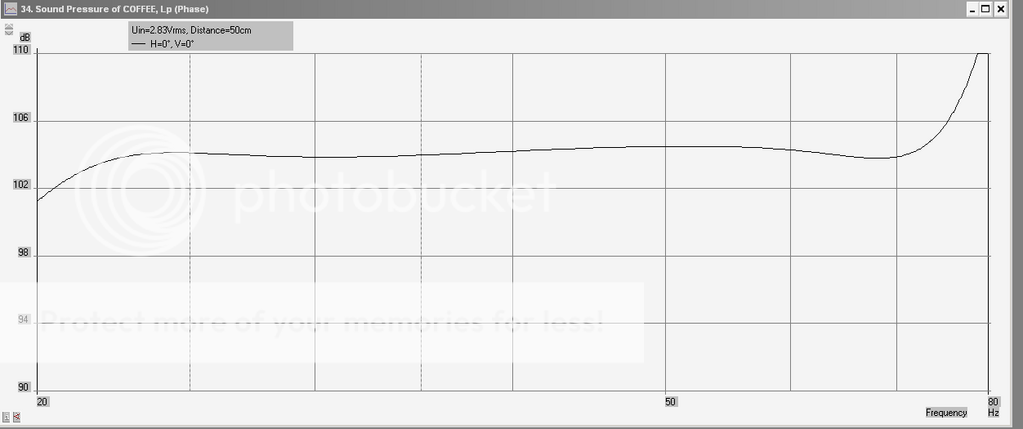

The VAS is pretty high 228L, and the response is very smooth, IMO.

Here is the graph

EDIT: I only use it from 20-70Hz, the 80Hz peak is not a big deal.

Hmm I dunno about the BL thing. I mean the BL of my 19OV2 is 22, and it works fine.

The VAS is pretty high 228L, and the response is very smooth, IMO.

Here is the graph

EDIT: I only use it from 20-70Hz, the 80Hz peak is not a big deal.

djk said:Def_Driver '3015LF'

Sd=881cm2

fs=42Hz

Qes=0.41

Qms=6.82

Vas=160L

Re=5.31ohm

Le=0.92mH

System 'S1'

Driver 'D1' Def='3015LF' Node=1=0=20=21

Waveguide 'W1' Node=20=21

STh=750cm2 SMo=2200cm2

Vf=10L Len=2.5m T=0.9

Horn 'W2' Node=21

STh=2200cm2 SMo=2444cm2

Len=35cm Conical

System 'S3'

Driver 'D1' Def='3015LF' Node=1=0=20=21

Driver 'D2' Def='3015LF' Node=1=0=20=21

Driver 'D3' Def='3015LF' Node=1=0=20=21

Driver 'D4' Def='3015LF' Node=1=0=20=21

Waveguide 'W1' Node=20=21

STh=3000cm2 SMo=8800cm2

Vf=40L Len=2.5m T=0.9

Horn 'W2' Node=21

STh=8800cm2 SMo=.9776m2

Len=35cm Conical

Four in half space (±1dB 32hz~140hz, 113dB/2.83V/1M), bigger throat, smaller mouth, about the same length. Increasing Vf to 15L brings up the 50hz~60hz region a fraction of a dB, but starts killing the response above 100hz.

Thansk djk, for the 3015LF TH simulation. Would it be possible for anyone to just show the box dimensions and other details, as per similation.

I have not worked with Hornresponse or any other speaker design software and don't want to experiment at this point. I am ready with 13 ply 19mm marine ply. In fact, the side panels have already been cut for 2 cabs of Tuba36.

However, the TH looks better and I wouldn't mind changing plans right now.

Thanks everyone,

Is this a new Model?$40 Eminence driver with 10mm x-max

hey DJK - what is 121184's martinsoundpro 4-5 -digit stock number 121184 shows in their search but not directly (??) - got a quick sketch of this pipe to show divider gaps? price even at retail sounds great and got a cutter ready - oops - your model got a real mouth and a lotta size - mass is low for 10mm stroke -

here's one online explanation http://www.geocities.com/f4ier/dvc.htm

re:20-30Hz skinny tapped horn - question for William Cowan and Volvotreter - how in general do they sound with pipe organ, big drums, plucked & bowed bass viola?

re:20-30Hz skinny tapped horn - question for William Cowan and Volvotreter - how in general do they sound with pipe organ, big drums, plucked & bowed bass viola?

"what is 121184's martinsoundpro 4-5 -digit stock number "

1555

"Is this a new Model?"

No, its been available for over 20 years.

"got a quick sketch of this pipe to show divider gaps?"

I just ran it in Hornresponse, I figure you guys are familiar enough with it by now to do the details. You can monkey with the design to see if you can get it better, this was a quickie 5 minute thing.

I picked this driver by its low price and high x-max. With its 27hz resonance it looked like it should be good for a 20hz tapped horn.

http://www.martinsoundpro.com/moreinfo.asp?id=169

I need to find out if Martin will allow me to drop ship to you guys, otherwise they have a high initial order to qualify for dealer pricing.

1555

"Is this a new Model?"

No, its been available for over 20 years.

"got a quick sketch of this pipe to show divider gaps?"

I just ran it in Hornresponse, I figure you guys are familiar enough with it by now to do the details. You can monkey with the design to see if you can get it better, this was a quickie 5 minute thing.

I picked this driver by its low price and high x-max. With its 27hz resonance it looked like it should be good for a 20hz tapped horn.

http://www.martinsoundpro.com/moreinfo.asp?id=169

I need to find out if Martin will allow me to drop ship to you guys, otherwise they have a high initial order to qualify for dealer pricing.

freddi said:

Thanx for the link. Sounds interesting. Another Eminence OEMdjk said:"Is this a new Model?"

No, its been available for over 20 years.

http://www.martinsoundpro.com/moreinfo.asp?id=169

Judging by the looks of it, the diaphragm seems to be more similar to the DELTA 12 (not LF), which is weird since the 121184 has a 2" VC, the dustcab seems a bit bigger, rather than a 2,5". Did you open a broken speaker and got a look at the insides?

So I took Sd from the DELTA 12 Specs and recalculated the rest:

Manufacturer: Eminence

Model: 121184

Filename: 121184.unt

Speaker type: Bass

Manufacturer: Eminence

Model: 121184

Filename: 121184.unt

Speaker type: Bass

Sd: 519.50 cm^2

Vas: 270.14 l

Cms: 7.15e-04 m/N

Cas: 1.93e-06 m^5/N

Mmd: 43.37 g

Mms: 50.07 g

Rms: 1.36 Ns/m

Fs: 26.6 Hz

Bl: 10.78 N/A

Re: 6.80 ohm

Qms: 6.14

Qes: 0.49

Qts: 0.45

Pmax: 250.0 W

HAPPY HOLIDAYS

kinda ot- I have some 15" B&C -how might they do in reflex vs small tapped horn? AJ-horn's simulation of 15trx40 looks "optimistic"?

15trx40 70 liter BR http://img70.imageshack.us/img70/4610/15trx4070lbrqp6.gif

15trx40 70 liter BR http://img70.imageshack.us/img70/4610/15trx4070lbrqp6.gif

Patrick Bateman said:I don't have to change the "mass" parameter do I???

Here's what I used, but it's different than what you posted. The drivers are in series, which raises the BL. It's also a different enclosure - it's basically a seventy two inch long sonotube divided in half.

If you ask me the response is pretty darn good. And anyone could build this in under two hours!

An externally hosted image should be here but it was not working when we last tested it.

###########################################

Def_Driver '55-2421x2'

dD=24.4cm |Piston

fs=30.95Hz Mms=119.58g Qms=12.29

Bl=25.08Tm Re=6.8ohm Le=4.84mH ExpoLe=0.618

Def_Const | all sizes in centimeters

{

| Input Data

DriverSize = 25.4e-2; | The outer driver diameter

Hornlength = 335e-2; | The overall length of the horn including the ducts around the driver

Box_z = 12.7e-2; | The depth of the box (z is constant - x & y get bigger from throat to mouth)

Throat_x = 12.65e-2; | Throat Area = Box_z * Throat_x

Mouth_x =12.75e-2; | Mouth Area = Box_z * Mouth_x

| Experimental Data

Mass = 1.85/(Throat_x+((Mouth_x-Throat_x)/2));

Mass2 = 1.85/Box_z; | I dont know which dimension fits the accoustic mass of the bend. One can try both, "Mass" will be used in the calculation, "Mass2" will be ignored.

}

| Horn Modell

System 'Tapped Horn'

Driver 'D' Node=2=0=100=105 Def='55-2421x2'

Duct 'D1' Node=100 WD={Throat_x} HD={Box_z} Len={Driversize/2}

Duct 'D2' Node=100=101 WD={Throat_x} HD={Box_z} Len={Driversize/2}

Waveguide 'W1' Node=101=102 WTh={Throat_x} HTh={Box_z} WMo={Throat_x+((Mouth_x-Throat_x)/2)} HMo={Box_z} Len={(Hornlength/2)-DriverSize} Conical

AcouMass 'Bend1' Node=102=103 Ma={Mass}

AcouMass 'Bend2' Node=103=104 Ma={Mass}

Waveguide 'W2' Node=104=105 WTh={Throat_x+((Mouth_x-Throat_x)/2)} HTh={Box_z} WMo={Mouth_x} HMo={Box_z} Len={(Hornlength/2)-DriverSize} Conical

Duct 'D3' Node=105=106 WD={Mouth_x} HD={Box_z} Len={DriverSize}

Radiator 'Rad1' Node=106 WD={Mouth_x} HD={Box_z}

A few posts ago someone wondered about a tapped horn using the Tangband Eight.

This is my design for a tapped horn using the MCM 55-2421, which I still believe is one of the best horn drivers available. The fact that it's $25 is a bonus.

The goals of this design were different than what a lot of you guys are going for. This one is optimized to be as small as possible. It's also INCREDIBLY simple to build. It's a six foot tall sonotube, with a plywood divider running down the middle. There isn't even a taper! Because it's efficiency is so low (about 90db) you don't get a lot of ripple.

I think this tapped horn would be great for car stereo too, but you'd have to come up with a novel folding scheme.

So here's how to build it:

1. Get a 6ft tall sonotube that's 8" across

2. Get a piece of plywood, cut it to 8" x 65.5"

3. Cut out two 7.5" holes for the woofers

4. Put the two MCM woofers in the holes, as close as possible together

5. Put the plywood divider right inside the sonotube

6. Cap one end of the sonotube completely. Leave a 5.5" gap between the end cap and your piece of plywood

7. Put a cap on the other end that covers up one HALF of the sonotube

8. That's it!

Here's another design for the MCM 55-2421.

This one is even EASIER to build.

Instead of a subdivided sonotube that's 72" x 8", this one is 48" x 9.5".

This one has some advantages over the previous post:

- it's more efficient

- it's easier to build

And some disadvantages

- The other one isn't as peaky. Because this design has no taper, peaks are inevitable. The other one has fewer peaks because it's less efficient. It's easy to get smooth response with low efficiency.

- The other one plays lower, because it's longer. I made this one shorter to make it easy to build - you don't even need to cut the sonotube!

The top graph is the previous post; bottom graph is this post.

The reason that I went with 9.5" sonotube instead of 10" sonotube is that I'd encourage you to nest two tubes together. Buy a 9.5" tube, and put it INSIDE the 10" tube. Then use something rigid in the gap. The end result is nearly indestructible, but lightweight.

System 'S1'

Def_Driver '55-2421x1'

dD=17.27cm |Piston

fs=30.95Hz Mms=59.79g Qms=12.29

Bl=13.15Tm Re=3.4ohm Le=2.42mH ExpoLe=0.618

Def_Const | all sizes in centimeters

{

| Input Data

DriverSize = 17.27e-2; | The outer driver diameter

Hornlength = 243.84e-2; | The overall length of the horn including the ducts around the driver

Box_z = 15.12e-2; | The depth of the box (z is constant - x & y get bigger from throat to mouth)

Throat_x = 15.02e-2; | Throat Area = Box_z * Throat_x

Mouth_x =15.22e-2; | Mouth Area = Box_z * Mouth_x

| Experimental Data

Mass = 1.85/(Throat_x+((Mouth_x-Throat_x)/2));

Mass2 = 1.85/Box_z; | I dont know which dimension fits the accoustic mass of the bend. One can try both, "Mass" will be used in the calculation, "Mass2" will be ignored.

}

| Horn Modell

System 'Tapped Horn'

Driver 'D' Node=2=0=100=105 Def='55-2421x1'

Duct 'D1' Node=100 WD={Throat_x} HD={Box_z} Len={Driversize/2}

Duct 'D2' Node=100=101 WD={Throat_x} HD={Box_z} Len={Driversize/2}

Waveguide 'W1' Node=101=102 WTh={Throat_x} HTh={Box_z} WMo={Throat_x+((Mouth_x-Throat_x)/2)} HMo={Box_z} Len={(Hornlength/2)-DriverSize} Conical

AcouMass 'Bend1' Node=102=103 Ma={Mass}

AcouMass 'Bend2' Node=103=104 Ma={Mass}

Waveguide 'W2' Node=104=105 WTh={Throat_x+((Mouth_x-Throat_x)/2)} HTh={Box_z} WMo={Mouth_x} HMo={Box_z} Len={(Hornlength/2)-DriverSize} Conical

Duct 'D3' Node=105=106 WD={Mouth_x} HD={Box_z} Len={DriverSize}

Radiator 'Rad1' Node=106 WD={Mouth_x} HD={Box_z}

This one is even EASIER to build.

Instead of a subdivided sonotube that's 72" x 8", this one is 48" x 9.5".

This one has some advantages over the previous post:

- it's more efficient

- it's easier to build

And some disadvantages

- The other one isn't as peaky. Because this design has no taper, peaks are inevitable. The other one has fewer peaks because it's less efficient. It's easy to get smooth response with low efficiency.

- The other one plays lower, because it's longer. I made this one shorter to make it easy to build - you don't even need to cut the sonotube!

The top graph is the previous post; bottom graph is this post.

The reason that I went with 9.5" sonotube instead of 10" sonotube is that I'd encourage you to nest two tubes together. Buy a 9.5" tube, and put it INSIDE the 10" tube. Then use something rigid in the gap. The end result is nearly indestructible, but lightweight.

System 'S1'

Def_Driver '55-2421x1'

dD=17.27cm |Piston

fs=30.95Hz Mms=59.79g Qms=12.29

Bl=13.15Tm Re=3.4ohm Le=2.42mH ExpoLe=0.618

Def_Const | all sizes in centimeters

{

| Input Data

DriverSize = 17.27e-2; | The outer driver diameter

Hornlength = 243.84e-2; | The overall length of the horn including the ducts around the driver

Box_z = 15.12e-2; | The depth of the box (z is constant - x & y get bigger from throat to mouth)

Throat_x = 15.02e-2; | Throat Area = Box_z * Throat_x

Mouth_x =15.22e-2; | Mouth Area = Box_z * Mouth_x

| Experimental Data

Mass = 1.85/(Throat_x+((Mouth_x-Throat_x)/2));

Mass2 = 1.85/Box_z; | I dont know which dimension fits the accoustic mass of the bend. One can try both, "Mass" will be used in the calculation, "Mass2" will be ignored.

}

| Horn Modell

System 'Tapped Horn'

Driver 'D' Node=2=0=100=105 Def='55-2421x1'

Duct 'D1' Node=100 WD={Throat_x} HD={Box_z} Len={Driversize/2}

Duct 'D2' Node=100=101 WD={Throat_x} HD={Box_z} Len={Driversize/2}

Waveguide 'W1' Node=101=102 WTh={Throat_x} HTh={Box_z} WMo={Throat_x+((Mouth_x-Throat_x)/2)} HMo={Box_z} Len={(Hornlength/2)-DriverSize} Conical

AcouMass 'Bend1' Node=102=103 Ma={Mass}

AcouMass 'Bend2' Node=103=104 Ma={Mass}

Waveguide 'W2' Node=104=105 WTh={Throat_x+((Mouth_x-Throat_x)/2)} HTh={Box_z} WMo={Mouth_x} HMo={Box_z} Len={(Hornlength/2)-DriverSize} Conical

Duct 'D3' Node=105=106 WD={Mouth_x} HD={Box_z} Len={DriverSize}

Radiator 'Rad1' Node=106 WD={Mouth_x} HD={Box_z}

Sabbelbacke said:

So I took Sd from the DELTA 12 Specs and recalculated the rest:

Sd: 519.50 cm^2

Vas: 270.14 l

Cms: 7.15e-04 m/N

Cas: 1.93e-06 m^5/N

Mmd: 43.37 g

Mms: 50.07 g

Rms: 1.36 Ns/m

Fs: 26.6 Hz

Bl: 10.78 N/A

Re: 6.80 ohm

Qms: 6.14

Qes: 0.49

Qts: 0.45

Pmax: 250.0 W

Greets!

Hmm, when I use this Sd, etc., specs I don't get the same calc'd specs in Hornresp:

Cms = 7.02e-04

Mmd = 44.17

BL = 10.88

Rms = 1.39

Anyway, while DJK's design gain BW is impressive, its ~991 L net is a bit much even for me, so not needing this much in any typical HIFI/HT app I chose a simple folded straight pipe of 'only' ~383.12 L net:

GM

Attachments

pinkmouse said:Anyone fancy knocking up a sim for the Kef B139s?

Greets!

What did you have in mind? With only 3.5 mm Xmax and relatively low Fs/high mass corner, a wide BW alignment will be quite large and typical 20-80 Hz will be under-damped, though this straight pipe doesn't look too bad, is small at ~136.4 L, but doesn't play very loud either with only a ~5 W Xmax limit down low if the room doesn't boost it:

GM

Attachments

- Home

- Loudspeakers

- Subwoofers

- Collaborative Tapped horn project