Before you fell in love with them, have you actually heard a pair, or any of Paul's designs? I haven't either, and don't have an opinion of them, other than as to the materials.

I almost exclusively build less ambitious designs than this these days, but would agree with all that suggest 30mm MDF is way overkill - I'd echo the opinion that 18 mm BB ply as thoroughly braced as the conceptual sketches would be quite satisfactory -and a F of a lot easier to manipulate when you get to the finishing stages. But if not available locally, or prohibitively expensive to import, why not consider constrained layers with 1/2" MDF, "rubber- ply" , bituminous padding, etc,

I almost exclusively build less ambitious designs than this these days, but would agree with all that suggest 30mm MDF is way overkill - I'd echo the opinion that 18 mm BB ply as thoroughly braced as the conceptual sketches would be quite satisfactory -and a F of a lot easier to manipulate when you get to the finishing stages. But if not available locally, or prohibitively expensive to import, why not consider constrained layers with 1/2" MDF, "rubber- ply" , bituminous padding, etc,

No biggish speaker plan is ever complete without the 'sheet cut guide'. hehe

also the tweeter height is getting kinda high. Consider a vertical port tube exiting the bottom panel via clever pat pending "vented speaker stands". besides your slot doesn't look like the right dimensions on the sketch.

also the tweeter height is getting kinda high. Consider a vertical port tube exiting the bottom panel via clever pat pending "vented speaker stands". besides your slot doesn't look like the right dimensions on the sketch.

Last edited:

do many DIY folks ever have that luxury esp. on bigger stuff.Before you fell in love with them, have you actually heard a pair, or any of Paul's designs? I haven't either, and don't have an opinion of them, other than as to the materials.

seems lot of them have been built and I haven't heard any negative reports yet.

besides a lot of knowledgeable eyes have looked at it and it seems reasonable to me, IMO could be bit on the boomy bass side w room gain also with a hot tweeter level that may need adjustment. but could be pretty good in a space similar the original room it was designed for. I don't think it's a turkey, like you see on some web sites, or even worse a vendors web site with out the design documents this one has.

materials?

Last edited:

Hi butter,

There is one great downside of the fixed wooden slot,

you can't change its length, unless you have made a

provision for it.

It would really be a good idea to leave the option of

variable port length, no matter how you make one.

Slot is more attractive looking, plastic vent easier to make.

IMO and according to experts( not gurus!) it would make

sense to incorporate bitumen sheets the way BBC used

to make with thinner timber and several layers of these.

Thick mdf with a single thin bitumen is not worth the trouble.

Read this for complete info:

Factors in the design of loudspeaker cabinets. - Publications - BBC R&D

Stuffing midrange box is not an issue. I never buy stuff designated

for audio, acoustic... simply go to a store that keeps supplies

for furniture wadding, very much like what Troels showed.

Egg-crate is unnecessary. First measure the woofer output

and then you will know if and how much standing waves there are.

There is one great downside of the fixed wooden slot,

you can't change its length, unless you have made a

provision for it.

It would really be a good idea to leave the option of

variable port length, no matter how you make one.

Slot is more attractive looking, plastic vent easier to make.

IMO and according to experts( not gurus!) it would make

sense to incorporate bitumen sheets the way BBC used

to make with thinner timber and several layers of these.

Thick mdf with a single thin bitumen is not worth the trouble.

Read this for complete info:

Factors in the design of loudspeaker cabinets. - Publications - BBC R&D

Stuffing midrange box is not an issue. I never buy stuff designated

for audio, acoustic... simply go to a store that keeps supplies

for furniture wadding, very much like what Troels showed.

Egg-crate is unnecessary. First measure the woofer output

and then you will know if and how much standing waves there are.

I'd agree on the above on wall constructions, MDF has higher internal damping and is therefore even better than plywood when used in the thin, heavily damped mid enclosure walls. Plywood just works finer imho.

On the subject cabinet internal damping: use materials with known properties. Mineral fibre wools are unbeaten in acoustic aspects, and application in closed boxes is unproblematic. Polyester and other filling materials are sometimes effective, but mostly not and without expertise you're out in the blind.

On the subject cabinet internal damping: use materials with known properties. Mineral fibre wools are unbeaten in acoustic aspects, and application in closed boxes is unproblematic. Polyester and other filling materials are sometimes effective, but mostly not and without expertise you're out in the blind.

Hmmm...i have a hard time explaining so i will post a link instead to troels site;

As mentioned earlier, separating the woofer cabinet and the mid/tweeter is a good idea because they can then benefit from being constructed differently. A woofer cabinet that is stiff and not too heavy can shift the lowest frequency cabinet resonance above the woofer passband where they will not get driven if the mid/tweeter cabinet is isolated from the woofer cabinet. Such cabinets do not need or benefit from wall damping material although they may benefit for damping material in the air enclosure.

The midrange/tweeter cabinet could do the opposite in shifting the lowest resonances below the passband of the midrange and using strong damping. The BBC paper discusses this design approach but not stiff woofer cabinet approach.

However, MDF is a lot less stiff than plywood and I am not sure the stiff but not too heavy cabinet approach is going to be viable. Anyone? Would make a nice design exercise.

if the mid/tweeter cabinet is isolated from the woofer cabinet. Such cabinets do not need or benefit from wall damping material although they may benefit for damping material in the air enclosure.

And how would you perform the isolation procedure ?

The objective is to get the resonant frequency of the mid/tweeter cabinet sitting on top of the isolating spring as low as possible and with little damping in order to increase the effectiveness of the isolation. Given the mid/tweeter cabinet is going to be fairly heavy and with a large flat surface underneath then a large range of things are likely to work fairly well such as lumps of something soft and rubbery.And how would you perform the isolation procedure ?

hello guys! thanks for all the interesting input

chris-b - i agree in all you are saying. but i cant go to the states to check the speakers out it would add a few 1000 euro too much to the budget

it would add a few 1000 euro too much to the budget  also unfortunatelly using multiple layers gets more expensive than using only one.

also unfortunatelly using multiple layers gets more expensive than using only one.

infinia - you are right - i can give a shot to try to hide the vent even more. the vent proportions are a bit above the recommended ones. this one is 1:7 - i need to keep the opening small enough for my cats to not go inside

- you are right - i can give a shot to try to hide the vent even more. the vent proportions are a bit above the recommended ones. this one is 1:7 - i need to keep the opening small enough for my cats to not go inside  but i could definitely change the proportions a bit. 1:4 or 1:5 would be good.

but i could definitely change the proportions a bit. 1:4 or 1:5 would be good.

lojzek - yes it has crossed my mind. i have been thinking of a system for adjustable length of the port but i havent said anything about it yet. i need to think it through and check my mechanics in real life to see how it would work.. ill get back to that later.

i will check that link out.. also ill have a look for a suppliers of materials for furniture. i know already my local fabric store does not store anything suitable last time i checked - but it was in 2006

still even if i have to use mdf because of my budget for all of the enclosure, i still am thinking of either veneering or covering the sides with hardwood. choice will depend on price of the materials.

markbakk - about the materials for stuffing - mineral/glass wool is too annoying to work with. but i will have a look for local supplies.

here in spain most small businesses do not have proper web pages and its not as easy to find stuff. i have a huge industrial complex just a few km away where almost anything is available, but most of the time its impossible to know its there.

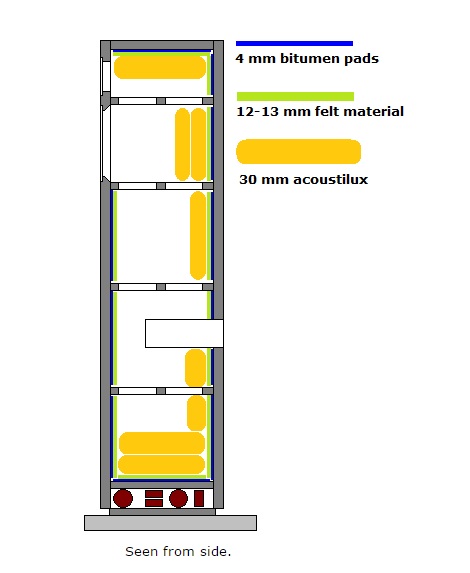

andy im not sure i understand your post. the tarkus im building has the tm box separate from the woofer enclosure (2 piece design). also i will most likely use de-coupling pads if i find the right size for it, if not - i will use other de-coupling methods. the speaker on the image i shared that you are quoting is an image i took from troels site to show the plan i had for damping and should not be taken for reference on the speaker design i am going to build. sorry if i confused the issue even more

im not sure i understand your post. the tarkus im building has the tm box separate from the woofer enclosure (2 piece design). also i will most likely use de-coupling pads if i find the right size for it, if not - i will use other de-coupling methods. the speaker on the image i shared that you are quoting is an image i took from troels site to show the plan i had for damping and should not be taken for reference on the speaker design i am going to build. sorry if i confused the issue even more

--

i will now take some time and do new sketches of the speaker cabinets. this time i will use 19mm mdf.

ill try to think of a new vent placement for the woofer section.

chris-b - i agree in all you are saying. but i cant go to the states to check the speakers out

infinia

lojzek - yes it has crossed my mind. i have been thinking of a system for adjustable length of the port but i havent said anything about it yet. i need to think it through and check my mechanics in real life to see how it would work.. ill get back to that later.

i will check that link out.. also ill have a look for a suppliers of materials for furniture. i know already my local fabric store does not store anything suitable last time i checked - but it was in 2006

still even if i have to use mdf because of my budget for all of the enclosure, i still am thinking of either veneering or covering the sides with hardwood. choice will depend on price of the materials.

markbakk - about the materials for stuffing - mineral/glass wool is too annoying to work with. but i will have a look for local supplies.

here in spain most small businesses do not have proper web pages and its not as easy to find stuff. i have a huge industrial complex just a few km away where almost anything is available, but most of the time its impossible to know its there.

andy

--

i will now take some time and do new sketches of the speaker cabinets. this time i will use 19mm mdf.

ill try to think of a new vent placement for the woofer section.

The objective is to get the resonant frequency of the mid/tweeter cabinet sitting on top of the isolating spring as low as possible and with little damping in order to increase the effectiveness of the isolation. Given the mid/tweeter cabinet is going to be fairly heavy and with a large flat surface underneath then a large range of things are likely to work fairly well such as lumps of something soft and rubbery.

ok now i see what you mean - yeah i was thinking in the same line...

i use decoupling foam pads for my studio monitors in my production studio. it works very well and i wanted to apply this.

also i take my studio monitors as an example for how i want my speaker build. the monitors are built out of 19mm mdf with rectangular slot vent

lojzek - yes it has crossed my mind. i have been thinking of a

system for adjustable length of the port, also ill have a look for

a suppliers of materials for furniture. i know already my local

fabric store does not store anything suitable last time i checked

- but it was in 2006

78 lit, Fb=30 Hz, vent diameter 4", length 10,5". Slot opening

should be 81 cm^2. Make it variable in length, won't regret it.

This is the stuffing I get for myself. It suppresses standing waves

succesfully. They store 150,250 and 350 gramm types.

Attachments

andyim not sure i understand your post. the tarkus im building has the tm box separate from the woofer enclosure (2 piece design). also i will most likely use de-coupling pads if i find the right size for it, if not - i will use other de-coupling methods. the speaker on the image i shared that you are quoting is an image i took from troels site to show the plan i had for damping and should not be taken for reference on the speaker design i am going to build.

My post was prompted by the wall damping pads shown in the figure. If you were to construct the woofer cabinet the ideal way (i.e. very stiff and not too heavy) there would be no need for damping the walls in the same way as there is no need to damp the walls of a typical subwoofer cabinet. However, the choice of MDF probably (I am not in a position to do the sums) means the first few energetic woofer cabinet resonances are going to fall within the passband of the woofer and you will therefore want a significant amount of wall damping.

78 lit, Fb=30 Hz, vent diameter 4", length 10,5". Slot opening

should be 81 cm^2. Make it variable in length, won't regret it.

This is the stuffing I get for myself. It suppresses standing waves

succesfully. They store 150,250 and 350 gramm types.

what is the most usual scenario in port adjusting? adding or removing length? the later option is easier to design

i will do my best to think out a method to have an adjustable port length -BUT using slotted port

i recognise that material in the picture - im originally from a cold nordic country, and that there is what my mom used when she made winter clothes for people. its like fluffy polyester fibre or similar.

andy19191 - yes - i read MDF has resonances in the same area as this woofer will be playing (woofer plays from 400ish Hz downwards - mdf has most of its resonances below 500Hz.. this is why i thought of extensive bracing + the foam. i would also add some fluffy filling material - BUT i do not want to use BITUMEN

---

ok... back to sketchup

one question more - flared ends or not? - what complications do they add to vent length? i read only one part of the curved part will count as port. about 1/3rd or so?

Last edited:

78 lit, Fb=30 Hz, vent diameter 4", length 10,5". Slot opening

should be 81 cm^2. Make it variable in length, won't regret it.

im using 92cm^2 port area

with slotted vent the resonances are different - to keep it above crossover point i need to increase the cross area.

also if i reduce the port area i get an airspeed in the vent like in Pauls design (about 19 m/s) - i thought lowering the airspeed will reduce possibility of noise in the vent so i went for a somewhat lower airspeed (17m/s). but i wanted even lower, but the port resonance goes down too into audible range.

using a slotted port its easier to adjust the values to lower the airspeed... when im plotting round tubes - the diameter is very limiting.

Depends on where you put the speakers. I have found

out lower tuning frequencies work better for me.

That's why it's smart to leave room for that mod.

You never know what it feels like unless you try.

Secondly, tarkus is very practical in sense that you could

take the upper box anywhere and use it as a sealed 2 way.

It would call for a separate and different filter to be installed

in TM box with a switch to bypass when in 3 way configuration.

I have never had any problems with vent noise. Increasing the

slot (vent) area you know you have to increase the length too

for the same tuning frequency.

out lower tuning frequencies work better for me.

That's why it's smart to leave room for that mod.

You never know what it feels like unless you try.

Secondly, tarkus is very practical in sense that you could

take the upper box anywhere and use it as a sealed 2 way.

It would call for a separate and different filter to be installed

in TM box with a switch to bypass when in 3 way configuration.

I have never had any problems with vent noise. Increasing the

slot (vent) area you know you have to increase the length too

for the same tuning frequency.

Last edited:

lowering the tuning would be a question of adding length to the vent - in my new design i can add an extension on the inlet or on the outlet. it was faster to solve than i thought and didnt need any complicated mechanics as i first planned. ill show pics later.

yes - my thought was to make a few of the TM box in the future to extend the system to surround. i just hope they will keep making the drivers that long! yes i suppose it would need a mod to the filter. maybe removing the low pass and adding a highpass to cut some of the lower end if its not clean. i will let the future decide.

yes i suppose it would need a mod to the filter. maybe removing the low pass and adding a highpass to cut some of the lower end if its not clean. i will let the future decide.

yes i know the length increases when the cross-area increases. i use Winisd - its a great program and its easy to see how changes relate to each other. very logical user interface.

yes - my thought was to make a few of the TM box in the future to extend the system to surround. i just hope they will keep making the drivers that long!

yes i know the length increases when the cross-area increases. i use Winisd - its a great program and its easy to see how changes relate to each other. very logical user interface.

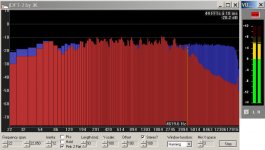

it is not that frequency of 400Hz that will trouble your plans. that driver is not easy to tame as i said already.

it has nasty hump between 70 and 100Hz and right afterwards huge trench.

here is the graph without Xover and with some attempts with test Xover (3.3mH+68uF+5E6, then 2.2mH+150uF+3E9)

didn't have larger coils for more tests

box was approx. the same size as Carmody's

second pic is the first one, sorry

it has nasty hump between 70 and 100Hz and right afterwards huge trench.

here is the graph without Xover and with some attempts with test Xover (3.3mH+68uF+5E6, then 2.2mH+150uF+3E9)

didn't have larger coils for more tests

box was approx. the same size as Carmody's

second pic is the first one, sorry

Attachments

Last edited:

it is not that frequency of 400Hz that will trouble your plans. that driver is not easy to tame as i said already.

it has nasty hump between 70 and 100Hz and right afterwards huge trench.

ground bounce effect?

change distance to ground ( flip sub upside down ) plus perhaps measure closer

gated measurements can help

mic, driver and box were aligned on some 3 or 4ft above floor.

830866 driver is the cheap crappy one. Carmody cut it with 6mH coil if I remember well.

I doubt 400Hz is the happy road for this driver. one can trust it to play below 150 or even less Hz. It means few lbs of copper in coil for air winded coils.

The latest Gates of HiFi, Mr Lampizator, has some points right. And one is 'listen your driver naked...if you like it naked you will like it on the baffle or in the box'

830866 driver is the cheap crappy one. Carmody cut it with 6mH coil if I remember well.

I doubt 400Hz is the happy road for this driver. one can trust it to play below 150 or even less Hz. It means few lbs of copper in coil for air winded coils.

The latest Gates of HiFi, Mr Lampizator, has some points right. And one is 'listen your driver naked...if you like it naked you will like it on the baffle or in the box'

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- building the TARKUS