Welding is not my forte, soldering is…. I topped my class in soldering 40 years ago…Weld

I heard it said that "you should make the best of what the creator gave you... unless you have a welder. Then make whatever the hell you want".

As a generalist type diy builder, that makes me smile a bit.

It applies every bit as well to the soldering iron though...

I'm looking forward to seeing what you create.

Cheers

As a generalist type diy builder, that makes me smile a bit.

It applies every bit as well to the soldering iron though...

I'm looking forward to seeing what you create.

Cheers

So I was successful in getting another two identical machines, although for a little higher price than the first. Don’t think anyone is buying such antiquated welding machines.

There would be used for as power supply for my Aleph 5 clone mono block.

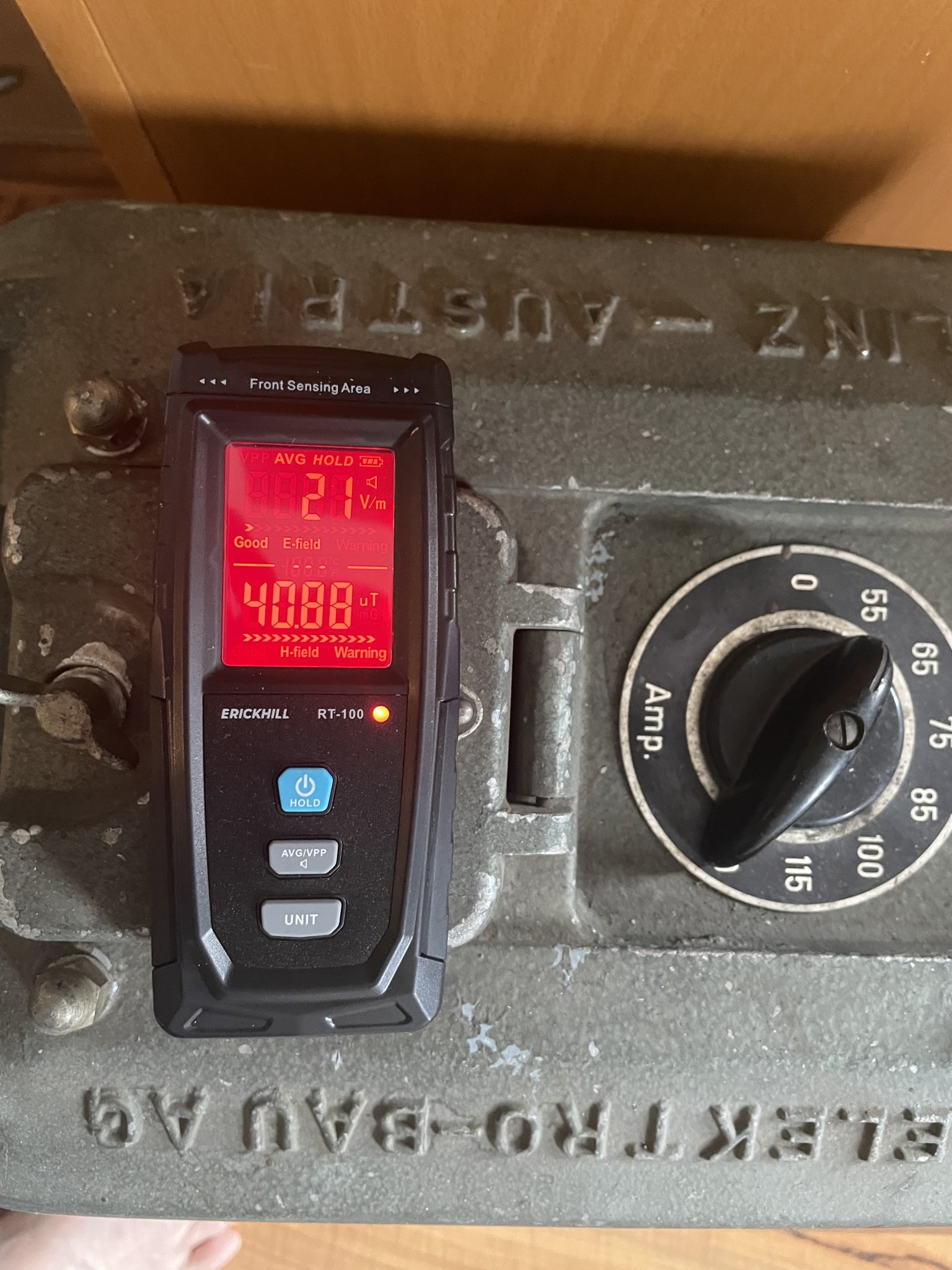

To have a piece of mind that extended exposure to EMF emission, I tested it with a EMF meter, at 1 metre distance, it is 0.05uT, and 40uT when the test meter is placed right next to it, the meter was beeping like crazy, but I read somewhere that the safety limit for emf is 100uT, and for workplace is 500uT, whatever that means, perhaps an expert can chime in.

There would be used for as power supply for my Aleph 5 clone mono block.

To have a piece of mind that extended exposure to EMF emission, I tested it with a EMF meter, at 1 metre distance, it is 0.05uT, and 40uT when the test meter is placed right next to it, the meter was beeping like crazy, but I read somewhere that the safety limit for emf is 100uT, and for workplace is 500uT, whatever that means, perhaps an expert can chime in.

Attachments

I should be using the repurposed Apple Macpower G5 casings got the Aleph 5 clone mono blocks.

I am deliberating between using external huge heat sinks (400X400X50) with natural convection cooling which will make the mono block rather huge, but with fairly empty internals; and forced cooling with heat sinks fitted inside the casings.

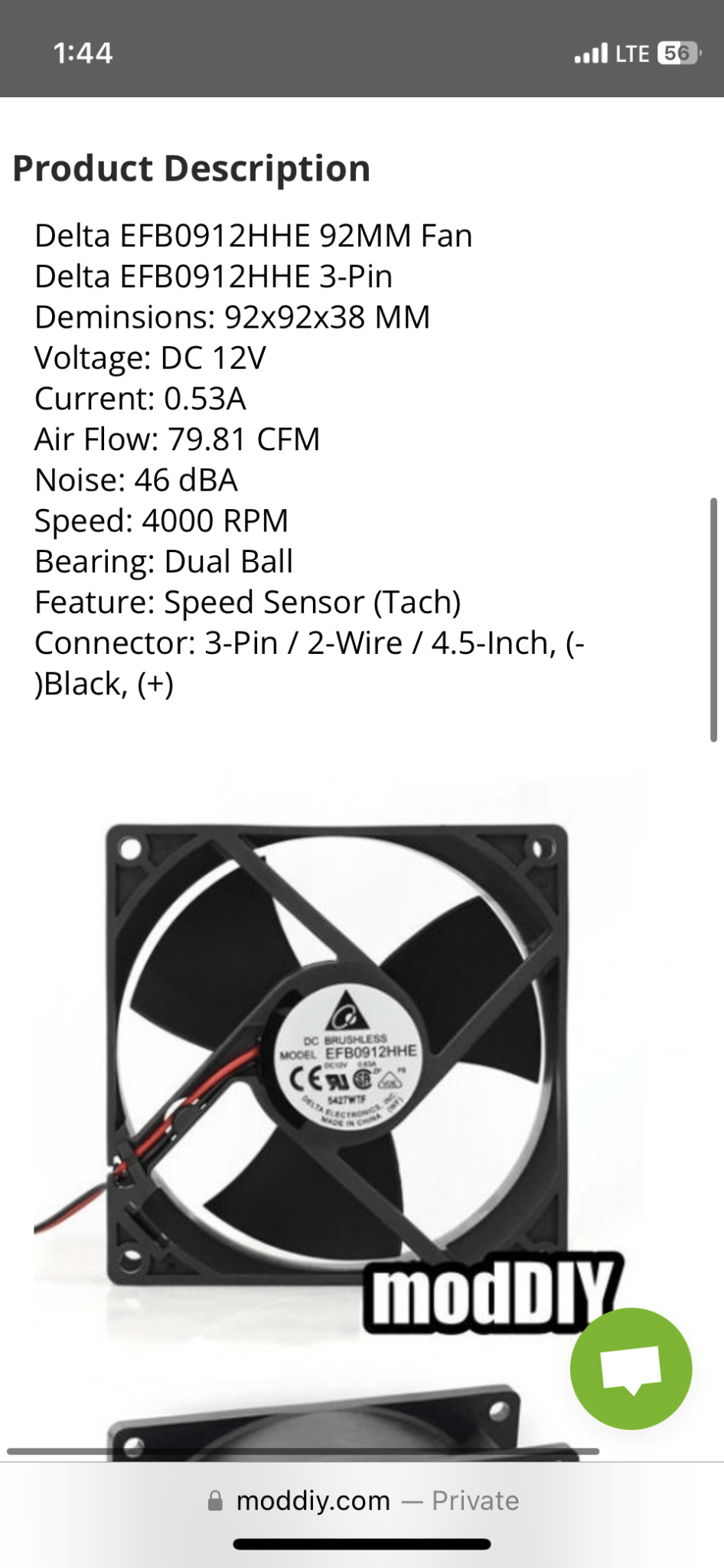

The 4 units of 90mm delta fans came with the original Macpower are loud (46dBA each)! So 4 of these would give me 46+9=54dBA (is that correct way to calculate?)

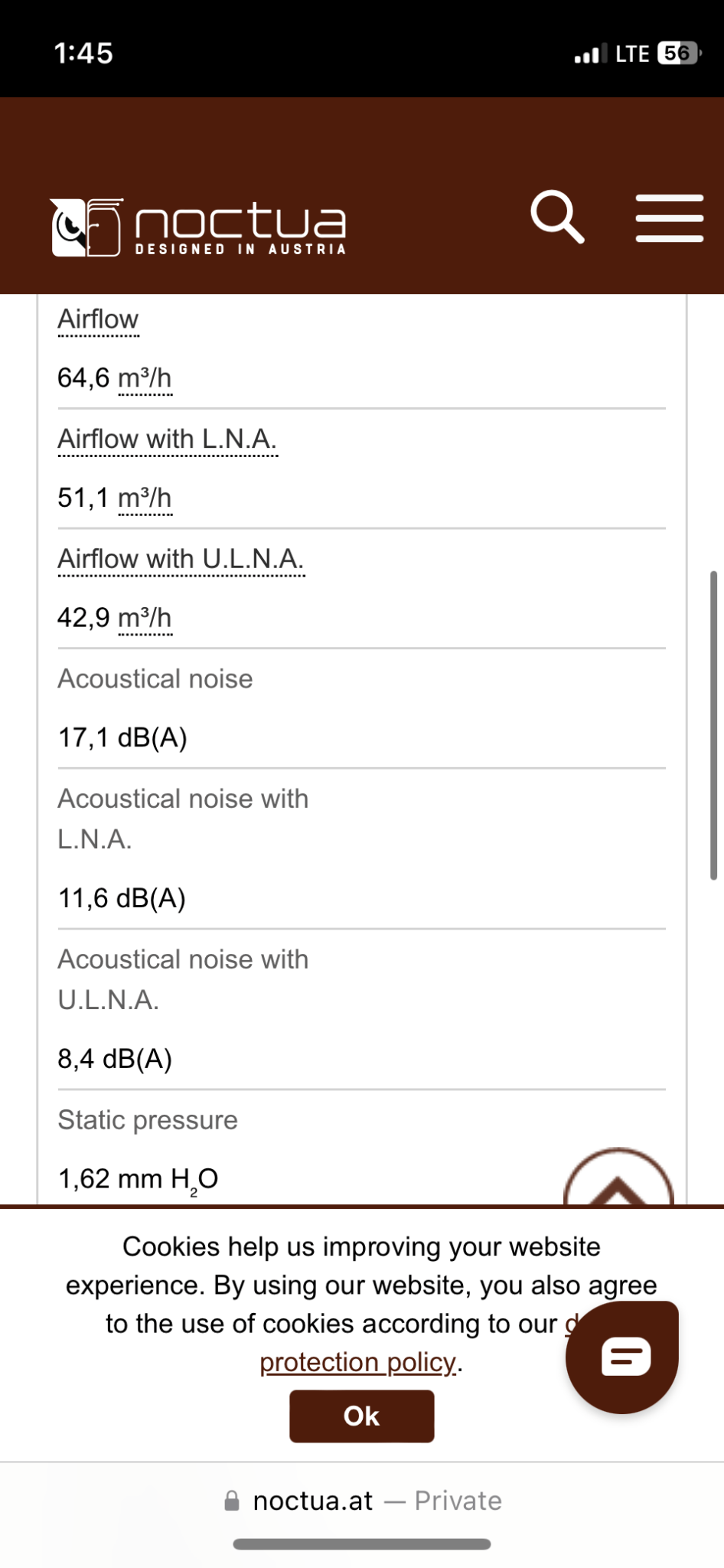

I wonder if anyone have tried the supposedly whispering Noctua NF-A9 FLX fan (17dBA, And 4 of them will be 26dBA?).

how are they like? The volume of air that they move is only about half the amount of air when compared to the Delta fans.

how are they like? The volume of air that they move is only about half the amount of air when compared to the Delta fans.

I am deliberating between using external huge heat sinks (400X400X50) with natural convection cooling which will make the mono block rather huge, but with fairly empty internals; and forced cooling with heat sinks fitted inside the casings.

The 4 units of 90mm delta fans came with the original Macpower are loud (46dBA each)! So 4 of these would give me 46+9=54dBA (is that correct way to calculate?)

I wonder if anyone have tried the supposedly whispering Noctua NF-A9 FLX fan (17dBA, And 4 of them will be 26dBA?).

Creative! What was the outcome?This thread reminds me of when I fed 120VAC into the "output" of 70V audio transformers to use them for an amplifier power supply. 😆

We all knew the P1/P2=V 1/V2 from school, so it should work in reverse too? But the current rating would be different.

The transformer hum quite a bit even after I have disconnected the fan. It is rated as 9.2KVA, and 20V@130A, 3 questions:So I was successful in getting another two identical machines, although for a little higher price than the first. Don’t think anyone is buying such antiquated welding machines.

There would be used for as power supply for my Aleph 5 clone mono block.

To have a piece of mind that extended exposure to EMF emission, I tested it with a EMF meter, at 1 metre distance, it is 0.05uT, and 40uT when the test meter is placed right next to it, the meter was beeping like crazy, but I read somewhere that the safety limit for emf is 100uT, and for workplace is 500uT, whatever that means, perhaps an expert can chime in.

View attachment 1304983 View attachment 1304984

1) if I am using it only for 300W (according to Aleph 5 specs). I am probably using 1/10 (or 1/30) of its capacity, I should be able to get away without the original welding fan?

2) Is there anyway to get rid of transformer hum (mechanical), would adding sound absorption fiber mat helps?

3) 20VX130A = 9.2KVA??? The rest dissipated as heat? So if I am drawing 15A@20V, how much would my hourly electricity consumption be 🤣

It worked quite well actually. IIRC the transformer were rated at 150W. I used two in series to get a bi-polar supply (4x transformers for dual mono). I crudely tested the amp at around 500W into a 4R load. They barely got warm and didn't hum at all. It was a project just for fun. It sat on a shelf for 13 years or so before I disassembled it.Creative! What was the outcome?

You are stuck with the mechanical noise, unless you reduce input voltage. If it ran on 240 normally and you cut it to 120 it would be quiet. it would also put out half voltage, which may not be all that useful to you. Have you measured open circuit voltage yet? Is it close to that 20V or is it quite a bit more?

If you ran a 15 amp load on it and it’s voltage was at 20V, you would only draw 300 watts. Probably twice that many volt-amps, or perhaps even more. A very large 9.2 kVA trafo will have a very small conduction angle with a 300W rectifier load and could draw 600, 900 VA. That extra is NOT power draw and doesn’t directly cause heat. But the wires in the trafo and wires leading to it heat up as if it were drawing 600 to 900 watts of AC load. That’s still a light load for that trafo and will not cause excessive heating. Your electric outlet will heat up like you’ve got a 900 watt space heater plugged into it, but the meter would only accumulate 300 watt hours in an hour.

If you ran a 15 amp load on it and it’s voltage was at 20V, you would only draw 300 watts. Probably twice that many volt-amps, or perhaps even more. A very large 9.2 kVA trafo will have a very small conduction angle with a 300W rectifier load and could draw 600, 900 VA. That extra is NOT power draw and doesn’t directly cause heat. But the wires in the trafo and wires leading to it heat up as if it were drawing 600 to 900 watts of AC load. That’s still a light load for that trafo and will not cause excessive heating. Your electric outlet will heat up like you’ve got a 900 watt space heater plugged into it, but the meter would only accumulate 300 watt hours in an hour.

So were you trying to use it as a step up transformer?It worked quite well actually. IIRC the transformer were rated at 150W. I used two in series to get a bi-polar supply (4x transformers for dual mono). I crudely tested the amp at around 500W into a 4R load. They barely got warm and didn't hum at all. It was a project just for fun. It sat on a shelf for 13 years or so before I disassembled it.

Which is not as stupid as it sounds. A big one like that will probably have magnetic headroom. Run it on one of the lower wattage taps and you can put even more on it. So can the little 10-15W multi-tap ones. Use the largest or 2nd largest wattage tap as the CT, and go down by a factor of 4 from there and it makes a serviceable tube output trafo. Those voltages can be higher. If a 15W tap can take 70V, than a 3.75W tap can take 140.This thread reminds me of when I fed 120VAC into the "output" of 70V audio transformers to use them for an amplifier power supply. 😆

You just have to be mindful of the current being drawn. Fortunately, most manufacturers are lazy and use the same gauge wire for the lower watt taps.

The arc welder is a 3-phase 380V (Europe), but only uses 2-phase with no neutral.You are stuck with the mechanical noise, unless you reduce input voltage. If it ran on 240 normally and you cut it to 120 it would be quiet. it would also put out half voltage, which may not be all that useful to you. Have you measured open circuit voltage yet? Is it close to that 20V or is it quite a bit more?

If you ran a 15 amp load on it and its voltage was at 20V, you would only draw 300 watts. Probably twice that many volt-amps, or perhaps even more. A very large 9.2 kVA trafo will have a very small conduction angle with a 300W rectifier load and could draw 600, 900 VA. That extra is NOT power draw and doesn’t directly cause heat. But the wires in the trafo and wires leading to it heat up as if it were drawing 600 to 900 watts of AC load. That’s still a light load for that trafo and will not cause excessive heating. Your electric outlet will heat up like you’ve got a 900 watt space heater plugged into it, but the meter would only accumulate 300 watt hours in an hour.

I reconnected it to a single phase and neutral so the input is 230Vac single phase now. Output is 40Vac with no load (O/C). I have zero knowledge with arc-welding machine so I have no idea how the 20V, 130A came about, presumably at short circuit, high current drawn , it is still able to maintain 20V.

I am waiting for the power resistors that I bought to be deliver to me and I intend to test it with one Ohm load and check the voltage with it. If the voltage can be maintained at 40V then it will be 1600W then.

I cannot comprehend what you mentioned about the 900W space heater but with meter only shows 300W, I suppose this is something to do with power factor? But whatever it is I like what you said, especially during winter!

Have you hooked up a rectifier and cap yet, and see how well it maintains 56VDC? That is the $64k question - it would be useful if it didn’t drop like a stone at say 10A DC. If it puts out 40 at 230 in, it would be 66 at no load, nominal. Dropping to 20V at 130A of course. A practical amplifier load will be somewhere in between. 5 or 6 amps per channel (for class A, staying in A at 4 ohms) I’m guessing.

If you’ve got a little hum at 230V now, it must be one of those things that you can hear going “errrrrrrrnnnnnggggg” from the end of the block when fed with 380.

If you’ve got a little hum at 230V now, it must be one of those things that you can hear going “errrrrrrrnnnnnggggg” from the end of the block when fed with 380.

Couldn’t remember where I read I think someone suggested putting the power resistors in a bucket of water to aid cooling during testing, I supposed it is no harm with such low voltage?The arc welder is a 3-phase 380V (Europe), but only uses 2-phase with no neutral.

I reconnected it to a single phase and neutral so the input is 230Vac single phase now. Output is 40Vac with no load (O/C). I have zero knowledge with arc-welding machine so I have no idea how the 20V, 130A came about, presumably at short circuit, high current drawn , it is still able to maintain 20V.

I am waiting for the power resistors that I bought to be deliver to me and I intend to test it with one Ohm load and check the voltage with it. If the voltage can be maintained at 40V then it will be 1600W then.

I cannot comprehend what you mentioned about the 900W space heater but with meter only shows 300W, I suppose this is something to do with power factor? But whatever it is I like what you said, especially during winter!

I haven’t tested the transformer under load.Have you hooked up a rectifier and cap yet, and see how well it maintains 56VDC? That is the $64k question - it would be useful if it didn’t drop like a stone at say 10A DC. If it puts out 40 at 230 in, it would be 66 at no load, nominal. Dropping to 20V at 130A of course. A practical amplifier load will be somewhere in between. 5 or 6 amps per channel (for class A, staying in A at 4 ohms) I’m guessing.

If you’ve got a little hum at 230V now, it must be one of those things that you can hear going “errrrrrrrnnnnnggggg” from the end of the block when fed with 380.

I think it shouldn’t have any problem to cope with such light load, nonetheless I am going to test it as soon as I receive my power resistors.

Yeah, it is the annoying mechanical humming noise. I am not sure if there would be any electrical humming noise. In any case, I am going to give it a shot, if it is too annoying then I would just salvage the vintage looking case, swop it for an audio grade toroidal transformer. It is just fun experimenting.

Power resistors? I would probably be hanging incandescent lights, toasters, or whatever off of it and gathering SOME data in the meantime. As long as you can measure volts and amps, and draw a curve.

Yeah, you do have to wait for the right resistors to check a 600V B+.

Yeah, you do have to wait for the right resistors to check a 600V B+.

thanks John, treasure her and you will be happy for life.....will keep you well fed....Salamat, Tony from the Philipines, i like you transformer, you shouldn't run out of current with that one.

It's Good to hear from someone fron the Philipines as my wife was born in Manilla and i have found Filipino people to be some of the friendliest people around and that's why i married my wife.

As will most woman she doesn't care much for my electronics hobby.

i have an even bigger PTX made.... weighed in at around 28kg..

Attachments

You can weld SMD parts with this. Even silicon die vaporizes in an arc.Welding is not my forte, soldering is…. I topped my class in soldering 40 years ago…

One thing with welding transformers are that they are not very good at transients, due to their crappy V-I curve due to the lekage shunt.

But on the other hand , transients needs to be in the kW range or the transformer will just se the amp as idle load...

But yes, they spew magnetic field.

I actually have a amplifier transformer I turned into an arc welder. It was a 1400VA toroid from a PA amp that was more or less burned to ashes due to a faulty cap or something which I rewound with some pretty thick secondary and connecting to a couple of carbon rods used normally for gouging.

I guess you can pound a tack down with a drop forge, I 'spoze.Hello I am new to this Forum and would like to know if anyone else is using a Arc Welder Transformer to power their projects.

mine is rated at 3000VA and is centre tapped with 28v/28v after rectification om the lower setting or 40v/40v on the higher setting.

i have been using the transformer for 5 months with no problems.

I driven class A's with it and it doesn't get hot only warm even after 8 hours of use.

- Home

- Amplifiers

- Solid State

- Arc Welder Transformer used to power Amplifier