And finally a Pic of where the transformer's going to go.

i call this my Amp Tower. It will house at the bottom the transformer, there will be a computer fan running at 1 third speed forcing air upwards.

then there will be a Aluminum spacer which will still allow air to pass around it sides on which the bridges for each channel will be mounted.

Above that will be a electro - capacitor bank for each channel and finally about that with be 5 Pre-amp / amplifier channels boards mounted one above each other.

the power transistors will be mounted on the "C" Section Casing and will be covered with Aluminum covers to assist cooling and prevent electric shock form wandering hands. there will be a small gap at the top to allow hot air to escape.

It will be painted black and all input, output power connections will be at the back.

On the front will be the on/off switch and an idicator led for each channel to show that they are powered.

Also Volume, Treble and Bass controls will only be adjustable through cutouts in the back as the volume, treble and bass will be set and forgotten and volume levels will be adjusted from the DVD Player remote.

i call this my Amp Tower. It will house at the bottom the transformer, there will be a computer fan running at 1 third speed forcing air upwards.

then there will be a Aluminum spacer which will still allow air to pass around it sides on which the bridges for each channel will be mounted.

Above that will be a electro - capacitor bank for each channel and finally about that with be 5 Pre-amp / amplifier channels boards mounted one above each other.

the power transistors will be mounted on the "C" Section Casing and will be covered with Aluminum covers to assist cooling and prevent electric shock form wandering hands. there will be a small gap at the top to allow hot air to escape.

It will be painted black and all input, output power connections will be at the back.

On the front will be the on/off switch and an idicator led for each channel to show that they are powered.

Also Volume, Treble and Bass controls will only be adjustable through cutouts in the back as the volume, treble and bass will be set and forgotten and volume levels will be adjusted from the DVD Player remote.

Attachments

well, it doesn't look that bad as what I've thought in the beginning,

since welding arcs that used here are squared toroids, I mean

they do not look like dough nuts, but laminated C cores....

but those you're using still that looks efficient with banked capacitors......

rgds,

hienrich

since welding arcs that used here are squared toroids, I mean

they do not look like dough nuts, but laminated C cores....

but those you're using still that looks efficient with banked capacitors......

rgds,

hienrich

John Biles said:I know my use of an arc welding transformer is not the norm, but the stupid thing works fine with my designs.

and no one should be surprised by that. those transformers are designed to output lower voltage once large current goes through: high voltage helps initiate the arc and once that's done, you don't need as much voltage. to maintain it.

However, for your application where the current draw is much much lower than what those transformers can handle, you shouldn't see much (if any) voltage droop.

Thankyou hienrich and tlf9999 for your comments. So this may not be such a dumb idea after all. More welders might find their transformers missing.

Here are the dc voltages i can get 2 x 28volts with wire size switch set at 0.6mm or 2 x 37volts with the wire size switch set at 0.8mm. or 56volts and 74volts.

Here are the dc voltages i can get 2 x 28volts with wire size switch set at 0.6mm or 2 x 37volts with the wire size switch set at 0.8mm. or 56volts and 74volts.

John Biles said:Hello I am new to this Forum and would like to know if anyone else is using a Arc Welder Transformer to power their projects.

mine is rated at 3000VA and is centre tapped with 28v/28v after rectification om the lower setting or 40v/40v on the higher setting.

i have been using the transformer for 5 months with no problems.

I driven class A's with it and it doesn't get hot only warm even after 8 hours of use.

If that is a 110 volt line voltage thats a 27 amp transformer on a stereo amp LOL I love it!!!

I like creative resourcefullness... way to go!!!

Nice transformer. The damn thing is huge! And I love the huge thick wires that come from the secondary.

Does the transformer get hot? Does it dim the lights in the room when you plug it in.... LOL

Nice setup. Build a few simple 100W amps and run them from it. Heck, being that you have higher, and lower secondary voltages, you could probably make it have a switch to switch between the two voltages depending on 4 or 8 ohm load.

WHERE can I get one of these transformers????

Does the transformer get hot? Does it dim the lights in the room when you plug it in.... LOL

Nice setup. Build a few simple 100W amps and run them from it. Heck, being that you have higher, and lower secondary voltages, you could probably make it have a switch to switch between the two voltages depending on 4 or 8 ohm load.

WHERE can I get one of these transformers????

Hello Eworkshop 1708,

The Welder was made in Italy and i originally brought it for Welding, it's actually called a Gasless Mig Welder and was sold through a Hardware chain of stores in Australia called "Mitre 10".

I brought it about 8 years ago and it was used as a welder for about 5 hours before the wire drive motor melted due to my brother trying to use larger wire in it that it wasn't designed for.

What are brothers for!

I realized that it wasn't going to do the jobs i needed it for and latter brought a proper gas mig welder.

One thing I'd say is that if it was sold in your country, you should be able to find a secondhand one pretty cheaply because as a welder it wasn't very good!

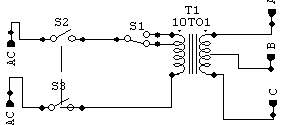

I have quickly made up a drawing of how it is wired.

Because Australia runs on 240VAC this is the voltage on the primarys. As you will see in the diagram if "S1" is in the up position AC is supplied to all of the Primary winding and we get 28volts DC across points "A" + "B" and "B" + "C" after rectification.

If the switch "S1" is moved to the downwards position we are now not using all of the Primary windings changing the ratio between the primary and secondary windings, so the voltage now goes up to 37volts across points "A" + "B" Etc.

So this is how we get a choice to use 28v/28v or 37v/37v or 56v or 74v

Switches S2 and S3 are in the same switch.

The Welder was made in Italy and i originally brought it for Welding, it's actually called a Gasless Mig Welder and was sold through a Hardware chain of stores in Australia called "Mitre 10".

I brought it about 8 years ago and it was used as a welder for about 5 hours before the wire drive motor melted due to my brother trying to use larger wire in it that it wasn't designed for.

What are brothers for!

I realized that it wasn't going to do the jobs i needed it for and latter brought a proper gas mig welder.

One thing I'd say is that if it was sold in your country, you should be able to find a secondhand one pretty cheaply because as a welder it wasn't very good!

I have quickly made up a drawing of how it is wired.

Because Australia runs on 240VAC this is the voltage on the primarys. As you will see in the diagram if "S1" is in the up position AC is supplied to all of the Primary winding and we get 28volts DC across points "A" + "B" and "B" + "C" after rectification.

If the switch "S1" is moved to the downwards position we are now not using all of the Primary windings changing the ratio between the primary and secondary windings, so the voltage now goes up to 37volts across points "A" + "B" Etc.

So this is how we get a choice to use 28v/28v or 37v/37v or 56v or 74v

Switches S2 and S3 are in the same switch.

Attachments

I will keep my eyes open for old or dead arc welders

*Speaking of huge transformers, I have this huge EI transformer that converts 115V to 240 or 220V with lots of other taps. Don't know the current output, but it had no problem running an 800W window AC unit for a while.

It has four large bolts that hold it together, and I'm thinking of trying to disassemble it to wind my own secondary coils to use it for an amplifier trans.........

However, I wish there was an easier way, since this thing is huge.

Primary side: 75,90,115V taps

Secondary: 190,200,210,220,240V taps.

Since there's only 50V difference on 190-240 side, I was wondering if a voltage doubler on the 50V of coil to give me +/- 70V would be safe to do or not.

*Speaking of huge transformers, I have this huge EI transformer that converts 115V to 240 or 220V with lots of other taps. Don't know the current output, but it had no problem running an 800W window AC unit for a while.

It has four large bolts that hold it together, and I'm thinking of trying to disassemble it to wind my own secondary coils to use it for an amplifier trans.........

However, I wish there was an easier way, since this thing is huge.

Primary side: 75,90,115V taps

Secondary: 190,200,210,220,240V taps.

Since there's only 50V difference on 190-240 side, I was wondering if a voltage doubler on the 50V of coil to give me +/- 70V would be safe to do or not.

Hi John Biles,

If you can establish this power supply with stable, optimised +/- supplies they should be able to sustain a number of amp modules e.g. home theatre 6+ as long as they have good PSRR. This way they all share the advantage of an oversize PS rather than needing isolation from each other because PS impedance degrades the sound.

I will be producing a Home Theatre block amp using 6+ modules with very high PSRR all running from a common PS soon.

Just make sure that (EM radiating) transformer is well away from the input stages.

Cheers,

Greg

If you can establish this power supply with stable, optimised +/- supplies they should be able to sustain a number of amp modules e.g. home theatre 6+ as long as they have good PSRR. This way they all share the advantage of an oversize PS rather than needing isolation from each other because PS impedance degrades the sound.

I will be producing a Home Theatre block amp using 6+ modules with very high PSRR all running from a common PS soon.

Just make sure that (EM radiating) transformer is well away from the input stages.

Cheers,

Greg

I've always wondered how I could make use of my 300A 50V Arc welder to do just that for live sound reinforcement to power like a bag of Tripath 5630s. If anyone could suggest the right bridge rectifier and ripple capacitor for 400A, 50V I might just feel like trying. ;-) John how did you go about with the rectifier and filter capacitor and what is the tranny's VA rating?

I am attempting to, sorry for the 20 years late reply 🤣Hello I am new to this Forum and would like to know if anyone else is using a Arc Welder Transformer to power their projects.

mine is rated at 3000VA and is centre tapped with 28v/28v after rectification om the lower setting or 40v/40v on the higher setting.

i have been using the transformer for 5 months with no problems.

I driven class A's with it and it doesn't get hot only warm even after 8 hours of use.

I chanced upon this beautifully made arc welder and wonder if I could do anything with it, and I googled and voila! Your thread showed up 😊

I wondered the progress that you made with yours, please share with us.

Attachments

Weld ...I chanced upon this beautifully made arc welder and wonder if I could do anything with it

- Home

- Amplifiers

- Solid State

- Arc Welder Transformer used to power Amplifier

Thread reopened.

Thread reopened.