There's a mechanical problem with a long swing arm/short pivot arm Birch variation. The headshell is inherently rests uncomfortably close to the platter, but by splitting the guide into two hinged parts, the headshell can be moved farther away.

There is a small magnet - under all that blue tack - and a small attractor in the wooden part which keep the hinge closed during play.

Following jcarr's lead on the tracking ability of short arms renders this moot, but I just prefer longer arms and it was fun to figure out.

Hi Doug,

Interesting stuff you have been doing. I notice that on the lower lefthand corner of photo 1 (left pic) you have a stylus assembly for an ADC (XLM?). I didn't know you had been using ADC carts. How do you like their performance? I think everyone on this forum has heard me brag about mine.

Regards and Happy Spring

BillG

I've been asked to post this here as it seems connected to what has gone before. I hadn't seen the similar designs previously and thus thought I was ploughing a lone furrow

There is no science involved here, no adherence to geometry, just a suck it and see approach and a trying of different stuff to see what works.

This one sounds good and so I will continue to play with it to see if it can be improved. It is very sensitive to the position of the balance weight which I reckon is necessary to avoid loading the horizontal bearing.

There is no science involved here, no adherence to geometry, just a suck it and see approach and a trying of different stuff to see what works.

This one sounds good and so I will continue to play with it to see if it can be improved. It is very sensitive to the position of the balance weight which I reckon is necessary to avoid loading the horizontal bearing.

I've redone the bearing as there was a slight catch with the original. Also lowered it all so the arm is now parallel with the record surface. Bass is further improved and I have fixed the bearing whereas before, it was just a push fit.

I need to fit a rest and arm lift but that is for later.

I need to fit a rest and arm lift but that is for later.

Geometrically this arm is a conventional arm, but has some drawbacks (higher friction and mass).

Does that mean it will still need some kind of bias correction? I wondered if I need bother as the headshell is straight. It sounds extremely good. The horizontal bearing is, like my other arms, from hard disk motors, extremely free running. It tracks very well indeed. The arm is quite short, just under 8 inches long.

There is no science involved here, no adherence to geometry, just a suck it and see approach and a trying of different stuff to see what works.

Does that mean it will still need some kind of bias correction? I wondered if I need bother as the headshell is straight. It sounds extremely good. The horizontal bearing is, like my other arms, from hard disk motors, extremely free running. It tracks very well indeed. The arm is quite short, just under 8 inches long.

I just want to confirm something. Does the main arm pivot horizontally on that round wood puck? If it doesn't pivot and the only main pivot is the base then it works just like a conventional pivot arm geometrically and dynamically, similar to a Dynavector arm, even if the headshell is straight and has no offset angle.

If your arm has two pivot points and no guiding mechanism, I am curious how it behaves dynamically in motion. Does it swing to one side on a blank disc? I know Dough Tuthill experimented with taking out the guiding mechanism, the hem-joint, and reported exhibiting skating force.

Do you notice any skating force visually, however subtle?

Regardless of where the pivot point or how many pivot points, if the stylus and cantilever to the pivot does not form a straight line, skating force will always exist; it's a matter of degrees.

Your project looks like fun and you're enjoying it and that's what matters. Thanks for chiming in. Please update more info when available.

Last edited:

The only horizontal pivot is the wooden 'puck'. The piece holding the vertical pivot is rigidly coupled. What would happen if I put another pivot under the arm?? With no guiding mechanism, I wonder how it would behave!!I just want to confirm something. Does the main arm pivot horizontally on that round wood puck? If it doesn't pivot and the only main pivot is the base then it works just like a conventional pivot arm geometrically and dynamically, similar to a Dynavector arm, even if the headshell is straight and has no offset angle.

If your arm has two pivot points and no guiding mechanism, I am curious how it behaves dynamically in motion. Does it swing to one side on a blank disc? I know Dough Tuthill experimented with taking out the guiding mechanism, the hem-joint, and reported exhibiting skating force.

Do you notice any skating force visually, however subtle?

Regardless of where the pivot point or how many pivot points, if the stylus and cantilever to the pivot does not form a straight line, skating force will always exist; it's a matter of degrees.

Your project looks like fun and you're enjoying it and that's what matters. Thanks for chiming in. Please update more info when available.

Watching the stylus carefully, it stays dead centred all the way across whereas I can see some small deflection on the more ordinary arms before bias is applied.

As you say, I am enjoying the exercise. The fact that two of my home made arms appear to outperform the commercial product is very satisfying. It might not be science but there is something to be said for just jumping in and having a go.

We had visitors today and their minds boggled a bit. I doubt they had seen so many record players in one room before and they certainly hadn't seen one with two arms on before. If they come back next week, one of them will probably have three on

It is nice to see someone actually did it. I thought the same thing one year ago. Please see the drawing I did a year ago, but I didn’t make it. The reasons not to do it are

1. I think it is not logical to force a pivot arm to do linear movement mechanically.

2. What is the purpose to make tangential pivot arm? Can’t a linear arm perform as good as a pivot arm? The answer is yes. A linear arm can perform as good as and better than a pivot arm. Yes. A linear arm is usually more complicated than pivot arm. It is surely much simpler than a tangential pivot arm.

3. The arm like the one in my drawing requires very precise machined parts. I don’t have the access to such facility.

4. I do think there is skating force for this kind of arm.

1. I think it is not logical to force a pivot arm to do linear movement mechanically.

2. What is the purpose to make tangential pivot arm? Can’t a linear arm perform as good as a pivot arm? The answer is yes. A linear arm can perform as good as and better than a pivot arm. Yes. A linear arm is usually more complicated than pivot arm. It is surely much simpler than a tangential pivot arm.

3. The arm like the one in my drawing requires very precise machined parts. I don’t have the access to such facility.

4. I do think there is skating force for this kind of arm.

Attachments

The only horizontal pivot is the wooden 'puck'. The piece holding the vertical pivot is rigidly coupled. What would happen if I put another pivot under the arm?? With no guiding mechanism, I wonder how it would behave!!

If you only have ONE pivot at the base, then it is geometrically conventional just like any other pivot arm, instead of the offset angle at the headshell, it's now placed at the vertical pivot point -- imagine the main arm being a very looong headshell. If you add another pivot at the second wood puck, it will probably behave like what Doug did to his arm, going out of tangency and probably swinging inward towards the label by the skating force. You can always try it and report back and then can always add a guiding mechanism a la Schroeder LT.

Watching the stylus carefully, it stays dead centered all the way across whereas I can see some small deflection on the more ordinary arms before bias is applied.

I believe there's skating force however subtle. I'm curious how you set the overhang or underhang a la RS Labs arm. How did you determine the offset angle at the vertical pivot point?

--------------------------------------------------------------------

http://www.diyaudio.com/forums/atta...ing-90-tangential-pivot-tonearms-img_0619.jpg

Please see the drawing I did a year ago, but I didn’t make it. The reasons not to do it are

1. I think it is not logical to force a pivot arm to do linear movement mechanically.

To achieve tangency an arm does not have to have linear "movement" so linear bearing (air or roller) is not required. So the attempt is not really a forced effort.

2. What is the purpose to make tangential pivot arm? Can’t a linear arm perform as good as a pivot arm? The answer is yes. A linear arm can perform as good as and better than a pivot arm. Yes. A linear arm is usually more complicated than pivot arm. It is surely much simpler than a tangential pivot arm.

For me, to dispense the airpump was the main goal at the beginning. (I absolutely hate airpumps.) As the concept evolved, I think there's much to like in this genre, especially for those skeptical about the horizontal mass in parallel arms... It is possible for someone with less tools to come up with a modern Garrard Zero 100 style arm or Thales Simplicity or Easy arm and the Birch concept provides another option. I don't think they are mechanically that much more complicated than many linear arms. Yes, some can look rather Rube Goldberg-ish but the more evolved ones can be rather elegant (Schroeder LT). They operate closer to a conventional arm which is a plus for us creatures of habit.

Of course, there's absolutely nothing wrong with using a parallel arm and if it suits you sonically and mechanically, by all means enjoy it! Not to mention your DIY airbearing arm is quite impressive.

DIY audio is not about sonic perfection for me, it's just there for entertainment and edification. Nothing too serious.

3. The arm like the one in my drawing requires very precise machined parts. I don’t have the access to such facility.

I have seen the admirable work on your air-bearing arm so I believe you are capable of making a quasi-Birch or Schroeder LT style arm; see DTUT's project. It's just a conventional pivot arm with an extra horizontal pivot point whether at the headshell or at the vertical pivot point, similar to your drawing. One can even re-purpose a used conventional tonearm, like a Rega, to save time and for those on a budget. The geometry can be aligned like the Birch or LT, the key is in devising a guiding mechanism. Ultimately the fun is in using your creativity on this feature.

Don't forget there's also Tom Bloem's fluid bearing arm in another thread to try or check out his video.

4. I do think there is skating force for this kind of arm.

Yes, it will exhibit skating force as there appears to have no guiding mechanism and bias or compensating feature in your drawing. As I said, Doug Tuthill tried it and it loses tangency as it does not behave in a self correcting way. The Schroeder LT uses magnet for guiding and minimizing bias. Based on some of the videos I saw with it in action, it seems to work elegantly.

I believe there's skating force however subtle. I'm curious how you set the overhang or underhang a la RS Labs arm. How did you determine the offset angle at the vertical pivot point?

I didn't really!! As I had an old scrap Dual TT, I just cut the arm mount off and glued that to the wood. In my other arms there is no angle as I just drilled straight through the arm tube to set the bearings. It doesn't appear to have any sonic or physical result. I'm not sure of the logic behind the offset!!

Please explain the overhang/underhang comment. You are talking to a complete amateur here, I have zero technical knowledge. I just do what feels the thing to do at the time

The angle either side of the pivot is just 90 degrees for simplicity. The balance weight can be turned to adjust the weight. I'm not sure if it makes a great deal of difference but it seemed sensible to even the load across the bearing as much as possible.

Hello gus 3049

The head shell is not straight. It may look straight but it is not.

That arm skates and it needs an anti skate device.

Just lower the arm onto an LP without grooves and you'll see.

Sincerely,

Ralf

Does that mean it will still need some kind of bias correction? I wondered if I need bother as the headshell is straight.

The head shell is not straight. It may look straight but it is not.

That arm skates and it needs an anti skate device.

Just lower the arm onto an LP without grooves and you'll see.

Sincerely,

Ralf

Hi Ralf

If a conventional tonearm is used or the length of a tonearm doesn’t satisfy the requirement of Thales’ theorem, a guiding mechanism is necessary. Otherwise, it is not needed. I highly doubt about the tracking ability of Thales tonearm, but admire the elegance of Schroeder LT arm.

A conventional anti-skating device can be added on very easily.

If a conventional tonearm is used or the length of a tonearm doesn’t satisfy the requirement of Thales’ theorem, a guiding mechanism is necessary. Otherwise, it is not needed. I highly doubt about the tracking ability of Thales tonearm, but admire the elegance of Schroeder LT arm.

A conventional anti-skating device can be added on very easily.

Hi Gus,

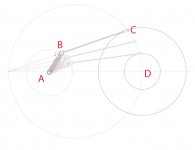

Your idea is correct, but it seems to me that the geometry is not correct. Let’s compare your photo and my drawing. The distance AB in your photo must be equal to the distance AB in my drawing. BC must be equal to my BC. AD must be equal to my AD. Therefore, it meets the requirements of Thales’ Theorem. In theory, the needle is tangent to groove and there are no tracking errors.

Your idea is correct, but it seems to me that the geometry is not correct. Let’s compare your photo and my drawing. The distance AB in your photo must be equal to the distance AB in my drawing. BC must be equal to my BC. AD must be equal to my AD. Therefore, it meets the requirements of Thales’ Theorem. In theory, the needle is tangent to groove and there are no tracking errors.

Attachments

Hi Gus,

Your idea is correct, but it seems to me that the geometry is not correct. Let’s compare your photo and my drawing. The distance AB in your photo must be equal to the distance AB in my drawing. BC must be equal to my BC. AD must be equal to my AD. Therefore, it meets the requirements of Thales’ Theorem. In theory, the needle is tangent to groove and there are no tracking errors.

Interesting. I had no idea that this idea had been thought of before (although I'm certainly not surprised) and I did it just to see how it would work because I am in the middle of a tonearm building session (six so far)

Adjusting the arm to meet your measurements would be simple enough if I knew what they are. Can you tell me what they are or at least the relationship between them? Geometry is not a strong point of mine

As it is, the cartridge appears pretty close to the right position across the record although it obviously isn't perfect

Super10018, based on Gus' information, his arm does NOT have a pivot nor able to rotate horizontally at point B. It's at a fixed angle, much like the offset angle of a headshell. His arm is just a variation of the Dynavector split-plane design. Had I known about this fact earlier, I wouldn't try to compare it to the Birch or Schroeder LT design. But I'm glad Gus is intrigued by the idea.

Super10018, based on Gus' information, his arm does NOT have a pivot nor able to rotate horizontally at point B. It's at a fixed angle, much like the offset angle of a headshell. His arm is just a variation of the Dynavector split-plane design. Had I known about this fact earlier, I wouldn't try to compare it to the Birch or Schroeder LT design. But I'm glad Gus is intrigued by the idea.

In that case, where is offset angle? It looks like 90 degree to me.

In that case, where is offset angle? It looks like 90 degree to me.

It is 90 degrees. What that means in terms of geometry, I have no idea

Hi Gus,

If you want to make your own tonearm, you need to follow the basic rules. You need to understand the underlying geometry. Here is a nice article to outline these basic tonearm geometry.

Tone Arm Geometry 101 | Analog Planet

Offset angle should not be 90 degree for a pivot arm.

If you want to make your own tonearm, you need to follow the basic rules. You need to understand the underlying geometry. Here is a nice article to outline these basic tonearm geometry.

Tone Arm Geometry 101 | Analog Planet

Offset angle should not be 90 degree for a pivot arm.

Hi Gus,

If you want to make your own tonearm, you need to follow the basic rules. You need to understand the underlying geometry. Here is a nice article to outline these basic tonearm geometry.

Tone Arm Geometry 101 | Analog Planet

Offset angle should not be 90 degree for a pivot arm.

Great, thanks for that. In spite of a bit of rule breaking, this arm sounds terrific - I wonder why??

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms