you probably should swap out the R3 & R4 (rear RCA) and/or the R5 & R6 (front panel 3.5mm) 274R input resistors for 10K (depending on which or both of those ODA inputs you use with the 2Vrms source). Also use the 1K attenuation resistors R31 & R32 if needed to get more volume pot travel with the result. I'll put a set of all those resistors in the mail today so you can try them if you want.

Thanks, I'll swap them out and let you know how it goes

Hey,

After being on now for a few days here are the temps I have measured with a thermocouple:

Front Panel 3.5mm jack: 88 degrees F. Inside about 1/2 inch its 90 deg F

Front Panel RCA Jack: 86 deg F

Front Panel Screw Upper Right Corner: 85 deg F

Top middle case: 87 deg F

Side center/middle case: 85 deg F

Rear Panel Middle Regualtor screw : 89-90 deg F

Front panel 1/4" jack internal about 1" insertion to back of jack : 93 deg F

The entire rear panel is relatively uniform in temp distribution.

Then entire case is relatively uniform in temp distribution as well.

I have no ventilation holes in my build.

I think I will add the holes / slots in the back panel to see how well that goes.

My gut thinks not that much.

I also had a 1/4 headphone plugged into the 1/4 jack all the time except when I measured the internal temp there. So this precluded any air entering that opening.

All in all the case is slightly warm at a 88-89 temp etc.

All the best

Alex

After being on now for a few days here are the temps I have measured with a thermocouple:

Front Panel 3.5mm jack: 88 degrees F. Inside about 1/2 inch its 90 deg F

Front Panel RCA Jack: 86 deg F

Front Panel Screw Upper Right Corner: 85 deg F

Top middle case: 87 deg F

Side center/middle case: 85 deg F

Rear Panel Middle Regualtor screw : 89-90 deg F

Front panel 1/4" jack internal about 1" insertion to back of jack : 93 deg F

The entire rear panel is relatively uniform in temp distribution.

Then entire case is relatively uniform in temp distribution as well.

I have no ventilation holes in my build.

I think I will add the holes / slots in the back panel to see how well that goes.

My gut thinks not that much.

I also had a 1/4 headphone plugged into the 1/4 jack all the time except when I measured the internal temp there. So this precluded any air entering that opening.

All in all the case is slightly warm at a 88-89 temp etc.

All the best

Alex

Hi agdr.

I understand you are striving for the most natural sounding headamp but if I want to change the sonic where do I start? Where should I put in an equalizer to find the curve I like as hearing has had its grand days. What other parts do you think can alter the sonic perception in your version. Well, I'm searching for my headamp which to others might sound as utter crap

/Regards

I understand you are striving for the most natural sounding headamp but if I want to change the sonic where do I start? Where should I put in an equalizer to find the curve I like as hearing has had its grand days. What other parts do you think can alter the sonic perception in your version. Well, I'm searching for my headamp which to others might sound as utter crap

/Regards

I understand you are striving for the most natural sounding headamp but if I want to change the sonic where do I start? Where should I put in an equalizer to find the curve I like as hearing has had its grand days. What other parts do you think can alter the sonic perception in your version.

I'm a believer in equalizers! For exactly the reason you mention. After after a few decades some ears are likely to no longer have a flat frequency response. Most headphones don't on the very low frequency end. Music today has been messed with in the digital recording chain (compression) then there are the Fletcher-Munson curves and A-weighting...

I think it is great for the basic amp to be a neutral as possible, then precede it with an equalizer to makeup for ear / heaphone / compression deficiencies. Because at the end of the day, I believe, what we all want to listen to is what sounds the best to us, which may or may not be perfectly flat frequency response.

The easiest and quickest way to get equalization is really just with the software equalizer in the players. I know there is one in Windows Media Player. Whether implemented as hardware or software, an equalizer probably should be inserted in front of the amp, before the gain stage, or as is the case with the ODA's bass boost actually be part of the gain stage.

The other "mess with the signal" thing I've wanted to try but haven't had time yet is crossfeed. Jan Meier with his old Headwize article and his company are one of the big names there. I believe there are software crossfeed plug-ins too. The goal of crossfeed sounds reasonable, to help eliminate the extreme stereo isolation in headphones vs. speakers by mixing a little bit of the channels together. For that reason it may actually turn out that some crosstalk is a good thing in headphone amps, although "controlled" crosstalk (frequencies) as per crossfeed.

Because of the way today's music has been compressed in the recording stage I have a copy of Fleetwood Mac's old "Tusk" record recorded digitally straight across that I use as some of my test music. My signal processing professor in college had started a local company way back in the day that did some of the first digital music recording (Thomas Stockham). That album was done on the old equipment before any of the modern digital sound alterations came into play. Lol - the recorder even ran at 50KHz back then, way before the 44.1KHz industry standard was worked out.

Last edited:

ODA in the mail for dScoping!

Well here is some good news. An audio DIYer who has a current model dScope has volunteered to make some of the NwAvGuy measurements on the ODA as time permits on his end. I've sent an ODA out in the mail today. It will be extremely interesting to see the results!

I really appreciate the offer, I know how much time is involved in making those measurements. The person involved will likely makes his own post of the results when the time comes. I'll post a link to it if not here.

Credit goes to Alex for making the introduction!

Well here is some good news. An audio DIYer who has a current model dScope has volunteered to make some of the NwAvGuy measurements on the ODA as time permits on his end. I've sent an ODA out in the mail today. It will be extremely interesting to see the results!

I really appreciate the offer, I know how much time is involved in making those measurements. The person involved will likely makes his own post of the results when the time comes. I'll post a link to it if not here.

Credit goes to Alex for making the introduction!

Hello! A really amazing project you have going on here, I've read through the entire thread (in a few hours, so please forgive me if I missed/forgot a detail). I'd really like to see the ODA become a "no-brainer" choice of amp, so I came up with a few things I'd like to see, though I haven't got enough technical knowledge to say if these are feasible or even make sense, so do shoot me down if I get ahead of myself.

The crossfeed was something I'd been itching to ask for since I saw the iFi iCan, but messing around with the delay, volume difference and the other bits I have no idea would be very time-consuming so I didn't want to. Nevertheless, it'd be a nice add-on.

I'm also a flexibility-lover, so would it be possible to make the voltage switch optional for those who want it (and understand where it should be used)? That said, if even the HE-6 is reaching 113dB I don't know what headphones may need more voltage, so this is probably a redundant option for most people (including me).

As a definitely selfish request, would it be possible to swap out the attenuation resistor for a stepped attenuator, like in the JDS Labs or in Stepped Attenuator & legendary G.E.C CV 2523 tube | Koenig's DIY ? This would serve a two-fold purpose: 1) it'd make all headphones able to use the full (or vast majority) of the front pot, including the really sensitive IEMs, and 2) would allow you to remove attenuation and thus use lower gain settings for the hard-to-drive phones, thus reducing noise added in amplification (I imagine?).

You could also then fine-tune the input voltage to remove clipping (not that I think that's an issue ever as it should be controlled by the gain resistors you choose). Or, and this'll depend on the equations to do with how much noise the op-amps add and how (fixed, proportional, square (root) -ly proportional, etc) placing this after the pot would keep the SnR constant.

And finally, are there no (relatively cheap) log pots capable of matching the linear one you chose? Again I have no idea, but the latter type definitely seems better on the user side for fine-tuning volume.

Although I don't think it was mentioned often, if I remember correctly is the size of the enclosure currently a limiting factor? And the higher-voltage option not the standard as it'd lead to too much heat being dissipated in the ODA/components unless the headphone is high-impedance?

Thanks again for your time,

Moragg

The crossfeed was something I'd been itching to ask for since I saw the iFi iCan, but messing around with the delay, volume difference and the other bits I have no idea would be very time-consuming so I didn't want to. Nevertheless, it'd be a nice add-on.

I'm also a flexibility-lover, so would it be possible to make the voltage switch optional for those who want it (and understand where it should be used)? That said, if even the HE-6 is reaching 113dB I don't know what headphones may need more voltage, so this is probably a redundant option for most people (including me).

As a definitely selfish request, would it be possible to swap out the attenuation resistor for a stepped attenuator, like in the JDS Labs or in Stepped Attenuator & legendary G.E.C CV 2523 tube | Koenig's DIY ? This would serve a two-fold purpose: 1) it'd make all headphones able to use the full (or vast majority) of the front pot, including the really sensitive IEMs, and 2) would allow you to remove attenuation and thus use lower gain settings for the hard-to-drive phones, thus reducing noise added in amplification (I imagine?).

You could also then fine-tune the input voltage to remove clipping (not that I think that's an issue ever as it should be controlled by the gain resistors you choose). Or, and this'll depend on the equations to do with how much noise the op-amps add and how (fixed, proportional, square (root) -ly proportional, etc) placing this after the pot would keep the SnR constant.

And finally, are there no (relatively cheap) log pots capable of matching the linear one you chose? Again I have no idea, but the latter type definitely seems better on the user side for fine-tuning volume.

Although I don't think it was mentioned often, if I remember correctly is the size of the enclosure currently a limiting factor? And the higher-voltage option not the standard as it'd lead to too much heat being dissipated in the ODA/components unless the headphone is high-impedance?

Thanks again for your time,

Moragg

I came up with a few things I'd like to see, though I haven't got enough technical knowledge to say if these are feasible or even make sense, so do shoot me down if I get ahead of myself.

Comments and suggestions are always welcome! Good timing too since I'm about to post a first draft of the new V2.1 that I will probably send out for fabrication in a couple of weeks.

The crossfeed was something I'd been itching to ask for since I saw the iFi iCan, but messing around with the delay, volume difference and the other bits I have no idea would be very time-consuming so I didn't want to. Nevertheless, it'd be a nice add-on.

I agree, I would really like to add an (optional) crossfeed circuit. I think it is one of those "messing with the signal" things that could add some listening enjoyment. Unfortunately there isn't any room left on the board for the circuit or for the front panel switches/pots required. I wish Box Enclosures made a bigger case! The B4 case here is their largest, taking a 160mm by 100mm board.

But I may whip up an top-slot add-on board at some point in the distant future. I've left places on the ODA PC board where the signal path could be taken off, fed to a top slot board, then fed back to the ODA board. Parametric bass boost is another thing I may add to a board like that.

In the meantime I've read that there are a couple of software crossfeed plug-ins for the various music players out there. Seems that I read one of them was for-pay but pretty good.

I'm also a flexibility-lover, so would it be possible to make the voltage switch optional for those who want it (and understand where it should be used)?

I actually had that on the back in the earlier versions of the ODA, but I think it wound up confusing folks as to when the different voltages should be used. Luckily there is an easy workaround here. If you put the ODA in a larger case you can run wires from the voltage setting resistor pads on the ODA board to an external switch with resistors. That way you could make a 2 position voltage select, or many position if a rotary switch is used. The resistors on the LT LDO regulators are the only ones that need to be changed, the pre-regulators can stay at a fixed voltage.

There is one trick here though that I used in that earlier ODA version with the volt select switch. It is best to leave one set of voltage setting resistors soldered to the ODA board, then just put your other resistors on the external switch in parallel with those to alter the voltage. And chose a "shorting" switch. That way the voltage regulator setting resistor won't go "open circuit" between switch contact flips.

would it be possible to swap out the attenuation resistor for a stepped attenuator

Yes it is! Just leave off the two attentuation resistor and instead run wires from those 4 holes to the externally mounted stepped attenuator. This would require mounting the ODA in a larger case again though. I've added holes on the board corners (thanks to dace for that suggestion!) to mount the board on standoffs in a larger case.

And finally, are there no (relatively cheap) log pots capable of matching the linear one you chose?

Unfortunately none that I have found. The power dissipation is an issue. With the attenuation resistors jumpered a 1K pot will dissipate 50mW at the maximum 7.25Vrms swing, and that is exactly what the 1K linear Boarns 9mm is rated at. Their log 1K is only rated at half, 25mW. I've looked around for some panel mounted larger 1K pots and haven't come up with much there either. Looks like 1K is an harder to find value.

Although I don't think it was mentioned often, if I remember correctly is the size of the enclosure currently a limiting factor? And the higher-voltage option not the standard as it'd lead to too much heat being dissipated in the ODA/components unless the headphone is high-impedance?

The case size is definitely the big limiting factor. There are several things I would do with the board if there was more space available. I have considered moving the power supply parts off the board entirely on to a separate PC board to free up space on the signal board.. Then the ODA would become a 2-board amplifier, with the power supply PC board in the rear and the signal circuit board in the front, with wires connecting the two (or a molex connector if I can line things up right at the card edges). Both boards would fit end-to-end in the same slot in the longer B4-160 case (twice as long so it can hold 2 boards end to end). One problem with this idea though is no additional front panel space. Whatever additional circuit was added couldn't require any more front panel controls.

You are right about the +/-15Vdc option, the problem is power dissipation in the output chips. With the higher voltage +/-15Vdc rails the ODA will be OK with any volume position for headphones 300R and up. Below 300R is would work for some (less than maximum) volume pot positions, but of course that wouldn't work from a usability standpoint.

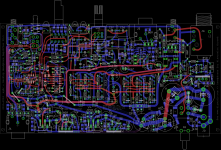

ODA V2.1 preview!

There are several folks on the "next board run" board waiting list now out at the project's Google Drive link. This board will be V2.1 with some minor changes. I've had some questions about what the changes are going to be. I've summarized the whole thing up in the PDF file below.

This isn't the final product yet. I'll likely mess with a few more things before sending it out to fabrication. No changes have been made to the schematic, other than the part values in the BOM have changed in a couple of places, as noted in the PDF. All the changes are layout related.

dace - I haven't forgotten about your good suggestion of the molex spacing at the rear RCA jack. That is one of the things I haven't got to yet.

If anyone wants to be added to the next board run list just PM me. It will all be at-cost again and I'll post the Gerbers again at the Google Drive link if anyone wants to fabricate their own boards. I just realized in working on V2.1 here that I pulled the V2.0 Gerbers a week or so ago to make a text change and forgot to repost them. I'll do that tomorrow.

There are several folks on the "next board run" board waiting list now out at the project's Google Drive link. This board will be V2.1 with some minor changes. I've had some questions about what the changes are going to be. I've summarized the whole thing up in the PDF file below.

This isn't the final product yet. I'll likely mess with a few more things before sending it out to fabrication. No changes have been made to the schematic, other than the part values in the BOM have changed in a couple of places, as noted in the PDF. All the changes are layout related.

dace - I haven't forgotten about your good suggestion of the molex spacing at the rear RCA jack. That is one of the things I haven't got to yet.

If anyone wants to be added to the next board run list just PM me. It will all be at-cost again and I'll post the Gerbers again at the Google Drive link if anyone wants to fabricate their own boards. I just realized in working on V2.1 here that I pulled the V2.0 Gerbers a week or so ago to make a text change and forgot to repost them. I'll do that tomorrow.

Attachments

Last edited:

Thanks for the quick reply!

Perhaps it would be an idea to split the "final" version into a "Core" and "Extended" module. That way people could use the B4-080 (and it's quite convenient size) or move to a bigger case if they want the "mess-with-the-signal" stuff. I imagine the electronics are modular enough for this to be doable.

I wish we could get cases like the Sennheiser HDVD800's (though smaller, it's such a nice design) - what would you say is the ideal size? I can take a look around and see if I can find anything in Europe that might be usable. I'm not sure how tall components are, but what would you say would be the minimum to have two PCBs on top of each other?

If I understood correctly from this thread, are the attenuation resistors before or after the opamps? If the former, since you said noise added is only proportional to the sqrt of voltage, wouldn't it make sense to feed the largest voltage to reduce SnR, and then attenuate afterwards?

Do the 1K pots have lower noise than the alternatives?

For the stepped attenuator, wouldn't it also be a good idea to use the shorting method to prevent a surge of current while switching?

Perhaps it would be an idea to split the "final" version into a "Core" and "Extended" module. That way people could use the B4-080 (and it's quite convenient size) or move to a bigger case if they want the "mess-with-the-signal" stuff. I imagine the electronics are modular enough for this to be doable.

I wish we could get cases like the Sennheiser HDVD800's (though smaller, it's such a nice design) - what would you say is the ideal size? I can take a look around and see if I can find anything in Europe that might be usable. I'm not sure how tall components are, but what would you say would be the minimum to have two PCBs on top of each other?

If I understood correctly from this thread, are the attenuation resistors before or after the opamps? If the former, since you said noise added is only proportional to the sqrt of voltage, wouldn't it make sense to feed the largest voltage to reduce SnR, and then attenuate afterwards?

Do the 1K pots have lower noise than the alternatives?

For the stepped attenuator, wouldn't it also be a good idea to use the shorting method to prevent a surge of current while switching?

what would you say is the ideal size?

For starters it would be great to find a box that can take a 100mm x 200mm board instead of the 100mm x 160mm for the B4 series. When getting the boards fabricated at Seeed Studio the choices are a 10cm x 15cm price and a 10cm by 20cm price. I have to used the 10cm x 20cm, even though the width is 16cm, and that last 4 cm goes wasted. That would also be 4cm more of front panel space for no additional board cost.

Past that, wider and deeper would both be good, although I would have to go somewhere else for the boards since Seeed only goes up to 20cm. Or maybe not - I see they have a special order section now that does 6 layers, 2oz copper and some other stuff.

If I understood correctly from this thread, are the attenuation resistors before or after the opamps? If the former, since you said noise added is only proportional to the sqrt of voltage, wouldn't it make sense to feed the largest voltage to reduce SnR, and then attenuate afterwards?

The attentuation resistors are after the op amps. The main purpose of those resistors is to provide more travel (rotation) for the volume pot when using 2Vrms or higher sources (which most of mine are). At 2Vrms in, even with a gain of 1x, you only get 1/3 rotation out of the pot with the fairly sensitive headphone I have. The attenuation resistors cut the op amp output in half, essentially giving you a total gain of 1/2X if the lowest gain switch position is otherwise 1X, to cut the incoming signal voltage in half. Then you are up to 2/3 rotation on the pot.

Which brings up an interesting point. If a person knew for certain that ALL their sources were 2Vrms or higher, why even have a gain stage? Why not feed the pot directly and just use the output stage? Well that is actually one of the modifications I posted in the O2 mod thread for the O2 headamp. But in this case the gain stage does still buy something. With the pot at 1K to reduce noise the gain stage acts as a "pot driver" to drive that relatively low impedance load. 1K would be too low for many sources. The LME49990 are rated for 600R and even have THD graphs in the data sheet at 600R (the 1K pot in parallel with the 1.5K feedback resistor). Without the gain stage a person would be back to a minimum of 10K pot if it were on the signal input. I know what Sergey888 and some other folks would point out here though. It is trading off lower Johnson noise in the 1K pot for additional voltage and current noise by adding the gain stage (Vs. just feeding the 10K pot directly).

Which brings up yet another interesting thing.

Do the 1K pots have lower noise than the alternatives?

They do, at least Johnson noise, since that is dependent solely on resistor value and temperature. The 1K would have lower Johnson noise than a 10K for a given temperature. Then it isn't just the pot - the ground return resistor for the output stage on the pot wiper also shrinks and has lower Johnson noise. In the O2 headamp those are 40.2K resistors but in the ODA they are 4.99K.

For the stepped attenuator, wouldn't it also be a good idea to use the shorting method to prevent a surge of current while switching?

Good point. Shorting would prevent pops in the headphone output.

Last edited:

Ah, that's good. I'll get a stepped potentiometer with lots of steps in that case - would the higher levels (e.g. -30dB) require heatsinking?

If there are equations for them, surely it's possible to use calculus to minimise noise? You could even add in an "audiability factor" depending on the type of noise.

As for enclosures, Electronic Enclosures - Lincoln Binns might be able to do us something. Custom Aluminium Electronic Enclosure - U-Case 1 Data - Lincoln Binns would let you use components up to ~28mm in height (could be a problem) but they sell boxes for 200x80 and 200x120 PCBs so the middle option should be easy to find. PCB would need to be 1.6mm thick at the most.

If you could get quotes for the Seeed Fusion Premium PCB (and they turn out not to be too much more expensive) we might be able to get easier-to-use PCB sizes.

I've already spoken to LincolnBinns and I've got an email address to send details to - I can correspond with them if you let me know exactly what you want enclosure-wise, or I can PM you the email if you'd prefer to do it yourself.

They also do panels, but I don't know how good they are compared to what's currently being used.

I'll keep searching for other options this side of the pond.

If there are equations for them, surely it's possible to use calculus to minimise noise? You could even add in an "audiability factor" depending on the type of noise.

As for enclosures, Electronic Enclosures - Lincoln Binns might be able to do us something. Custom Aluminium Electronic Enclosure - U-Case 1 Data - Lincoln Binns would let you use components up to ~28mm in height (could be a problem) but they sell boxes for 200x80 and 200x120 PCBs so the middle option should be easy to find. PCB would need to be 1.6mm thick at the most.

If you could get quotes for the Seeed Fusion Premium PCB (and they turn out not to be too much more expensive) we might be able to get easier-to-use PCB sizes.

I've already spoken to LincolnBinns and I've got an email address to send details to - I can correspond with them if you let me know exactly what you want enclosure-wise, or I can PM you the email if you'd prefer to do it yourself.

They also do panels, but I don't know how good they are compared to what's currently being used.

I'll keep searching for other options this side of the pond.

Also, have you seen the iFi iDSD micro (not nano)? They've got a description on their site here: Micro – iDSD - it seems to be along the lines of what the ODA is trying to become. The amp section has bass-boost, crossfeed and a selector for the sensitivity of the headphones (the stepped attenuator I wanted).

Ah, that's good. I'll get a stepped potentiometer with lots of steps in that case - would the higher levels (e.g. -30dB) require heatsinking?

You should be OK there. Any value of attenuation resistor (including shorting them) won't require any more heatsinking for the amp.

If there are equations for them, surely it's possible to use calculus to minimise noise? You could even add in an "audiability factor" depending on the type of noise.

It probably is! Maybe solving a matrix of simultaneous equations if two ore more of the noise types could be expressed in terms of the same two (or more) variables. Now there is something to try over the weekend for any engineering students out there.

As for enclosures, Electronic Enclosures - Lincoln Binns might be able to do us something. Custom Aluminium Electronic Enclosure - U-Case 1 Data - Lincoln Binns would let you use components up to ~28mm in height (could be a problem) but they sell boxes for 200x80 and 200x120 PCBs so the middle option should be easy to find. PCB would need to be 1.6mm thick at the most.

If you could get quotes for the Seeed Fusion Premium PCB (and they turn out not to be too much more expensive) we might be able to get easier-to-use PCB sizes.

I've already spoken to LincolnBinns and I've got an email address to send details to - I can correspond with them if you let me know exactly what you want enclosure-wise, or I can PM you the email if you'd prefer to do it yourself.

They also do panels, but I don't know how good they are compared to what's currently being used.

I'll keep searching for other options this side of the pond.

Now that is an interesting find! I hadn't heard of Lincoln Binns. I just compared their Case "D" mechanical drawing to the B4 drawing from Box Enclosures and they are virtually identical. By all means, please see if they can produce either an extruded case or those flat pack cases for a 10cm x 20cm PC board, or for a 15cm x 20cm PB board. The first one would give 4cm of front panel space with no additional board cost. The second 15 x 20 would allow more circuitry to be added in addition. With a 15 x 20 I could probably go back to the CLC filter I originally had in the ODA rather than the CRC.

Also, have you seen the iFi iDSD micro (not nano)? They've got a description on their site here: Micro – iDSD - it seems to be along the lines of what the ODA is trying to become. The amp section has bass-boost, crossfeed and a selector for the sensitivity of the headphones (the stepped attenuator I wanted).

I haven't heard about that headamp before. Sure enough, they are changing the system voltage same as the previous ODA version. Looks like 2Vrms, 4Vrms, and 8Vrms output voltage swings. The ODA with the voltage select switch had +/-7Vdc rails and +/-16Vdc, so output swings were around 2Vrms and 10.5Vrms.

Sounds like they are using hardware for the bass and their "3D audio" too, rather than software.

If you can express noise in terms of any variables it becomes an optimisation problem, at which point Excel's Solver would probably do the trick. Heck, even if you can't model it as long as I got a lookup table for the noise-variable curve for the relevant opamps it should be doable.

Over the phone they said making bigger sizes of the solid boxes isn't doable, but the U-Case 1 has a "standard" option for 220x160 PCBs so 200x150 shouldn't be a problem - that's just a case of cutting things shorter, though it would add to the cost (mildly I hope). And we'd have to factor in the cost of shipping overseas too... it could come to quite a bit per case - I'd expect $50 each at the very least.

The spec says 32mm as max component height, is that enough or would you like more?

Over the phone they said making bigger sizes of the solid boxes isn't doable, but the U-Case 1 has a "standard" option for 220x160 PCBs so 200x150 shouldn't be a problem - that's just a case of cutting things shorter, though it would add to the cost (mildly I hope). And we'd have to factor in the cost of shipping overseas too... it could come to quite a bit per case - I'd expect $50 each at the very least.

The spec says 32mm as max component height, is that enough or would you like more?

Over the phone they said making bigger sizes of the solid boxes isn't doable, but the U-Case 1 has a "standard" option for 220x160 PCBs so 200x150 shouldn't be a problem - that's just a case of cutting things shorter, though it would add to the cost (mildly I hope). And we'd have to factor in the cost of shipping overseas too... it could come to quite a bit per case - I'd expect $50 each at the very least.

Yeah I think the extra cost of the case and shipping probably wouldn't be worth it, plus the cost of the PC board would increase exponentially. But thank you for checking into those cases! I will keep those in mind for the future.

The best solution for a bigger box in the future might be giving up on the card-edge cases and just mounting the boards on standoffs in a much larger case. That way several 160 x 100 boards could be used, lined up edge to edge across the front panel. One card could be input / gain stage / gain switch - plus stepped attenuator!. Then the card next to it could be crossfeed and parametric bass boost. Then the card next to that could be volume control, coupling caps, and DC output offset null. Then in the back a power supply card and an output stage card, both heatsinked to the rear panel.

Well, I'll send them an email anyway. No harm in getting a quote.

Bigger box and standoffs is exactly what I was looking for at first. I like the 4 boards idea too, modularity could let people skip the bass/crossfeed bit if they want. Hopefully there's room for an ODAC too, that'd be nice.

Bigger box and standoffs is exactly what I was looking for at first. I like the 4 boards idea too, modularity could let people skip the bass/crossfeed bit if they want. Hopefully there's room for an ODAC too, that'd be nice.

Well, I'll send them an email anyway. No harm in getting a quote.

That would be interesting to hear the quote! In going from the 220 x 160 to 200 x 150 case, would they do the cutting in both directions or would the user have to do the cutting? Maybe the shipping cost isn't that big of a deal in the overall scheme of things if more board value results. On the other hand I should look into other services like OSH Park. Maybe someone else out there can just make a 160 x 220 board.

Bigger box and standoffs is exactly what I was looking for at first. I like the 4 boards idea too, modularity could let people skip the bass/crossfeed bit if they want. Hopefully there's room for an ODAC too, that'd be nice.

Yeah modular would be handy. Folks could just uses the pieces they wanted.

C11 & C12 change to 25mm tall in September

Here is some good news for the project. On September 15th the BOM part specfication for C11 & C12 will change to a new cap Mouser is getting in, Mouser #661-EGPD500E821MK25H. The cap is the new GPD series from UCC, which is the downsized version of the existing GPA cap used for C11 & C12. It is 820uF, 50V, and 12.5mm diameter just like the existing cap, but 5mm shorter to match the 25mm height of C7 & C8. The new cap has a similar low ESR, a higher ripple current rating, and is also an automotive cap rated for 125 - 135C.

Right now C11 & C12 are the tallest things on the board. They just barely miss a board inserted in the top slot. With the change C7, C8, C11, & C12 will all be the same height and give a good 5mm spacing to a top slot board.

Here is some good news for the project. On September 15th the BOM part specfication for C11 & C12 will change to a new cap Mouser is getting in, Mouser #661-EGPD500E821MK25H. The cap is the new GPD series from UCC, which is the downsized version of the existing GPA cap used for C11 & C12. It is 820uF, 50V, and 12.5mm diameter just like the existing cap, but 5mm shorter to match the 25mm height of C7 & C8. The new cap has a similar low ESR, a higher ripple current rating, and is also an automotive cap rated for 125 - 135C.

Right now C11 & C12 are the tallest things on the board. They just barely miss a board inserted in the top slot. With the change C7, C8, C11, & C12 will all be the same height and give a good 5mm spacing to a top slot board.

Last edited:

Got a package today. Thanks a lot agdr.

How much do I owe you for these?

Nothing! All on me.

If you haven't ordered parts yet then you have less to buy, and if you have ordered parts you won't be out any $$ on the changes.

- Home

- Amplifiers

- Headphone Systems

- A version of an O2 Desktop Amp (ODA)