The paper is 200 gr/m2.

I don't worry about sagging. I thought it was used to center the paper between the magnets. Because they are also at the lower end.

Henjo

Hi Henjo,

It's a nice work. It seems you reach the target : equivalent JANUS50 speaker.

Is it possible to get information for some DIY "begineers" in order to buit themselve a kind of JANUS50 ?

PM

Hi erevan92,

Could you be more specific!

Dimensions, material, assembling sequence?

What do you want to know?

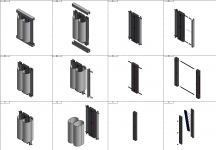

I attached two documents. One pdf (assembly), and one png (assembling sequence).

I also have the assembling sequence in pdf format, but it was too big to upload.

Have fun!

Henjo

Could you be more specific!

Dimensions, material, assembling sequence?

What do you want to know?

I attached two documents. One pdf (assembly), and one png (assembling sequence).

I also have the assembling sequence in pdf format, but it was too big to upload.

Have fun!

Henjo

Attachments

long time ago I promissed a friend we would build the original rubanoide

been too busy with other things

besides that, also a money issue

but now I have some smaller magnets from a 'retired' ribbon project

so I thought it could be fun to build a smaller rubanoide

tho it may need a small series resistor

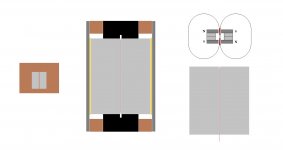

drawings are full size

lenth(height) will be about 4 inches

been too busy with other things

besides that, also a money issue

but now I have some smaller magnets from a 'retired' ribbon project

so I thought it could be fun to build a smaller rubanoide

tho it may need a small series resistor

drawings are full size

lenth(height) will be about 4 inches

Attachments

If you attach the sides so you can insert it in a baffel. It has a potential to be guite broadband...queeston is how you prevent whiplash where the baffel is attached....Like it is there as a quite narrow open baffel dipole unit, the low end performance will be guite weak and you're left with the typical mismatch problems in extending is downwards...

If you attach the sides so you can insert it in a baffel.

it will 'ofcourse' be mounted in some kind of baffle

drawing is only showing principle, and size

lots of construction details still missing

not intended to be a fullrange speaker

'just' BIG tweeter

my major concern is relationship between magnets size/power, and size/weight

I think one of the sweet things about the rubanoide design is that there are no need fore return wires

they are part of the active design

and you can use wire

but no doubt that despite the narrow magnet gap, you probably still need very strong magnets

mine are probably on the weak side

but its experimental

Hi erevan92,

Could you be more specific!

Dimensions, material, assembling sequence?

What do you want to know?

I attached two documents. One pdf (assembly), and one png (assembling sequence).

I also have the assembling sequence in pdf format, but it was too big to upload.

Have fun!

Henjo

Thank you for your reply.

What I need is a detail concerning material, dimensions so all details in order to built myself this kind of speaker.

You can send me if you agree a PM.

Regards

ah, I think you see it running without xo

used down to say 1khz, I dont think it will be moving much at all

anyway, the trick seems to be in how you 'tension/adjust' the outher end/sides

thats wher you adjust allignment in the magnet gap

and besides, the gap probably wont need to be that tight

but your question is indeed valid, and could point at another related possible issue

non controlled ressonance could lead to distortion

maybe eddy current related, or something the like happening inside the magnet system

but less movement, less problems, sure

its surely a clever system, holding more tha meets the eye

maybe the tension of the paper/diaphragm and its curved shape works really well in keeping ressonances controlled

used down to say 1khz, I dont think it will be moving much at all

anyway, the trick seems to be in how you 'tension/adjust' the outher end/sides

thats wher you adjust allignment in the magnet gap

and besides, the gap probably wont need to be that tight

but your question is indeed valid, and could point at another related possible issue

non controlled ressonance could lead to distortion

maybe eddy current related, or something the like happening inside the magnet system

but less movement, less problems, sure

its surely a clever system, holding more tha meets the eye

maybe the tension of the paper/diaphragm and its curved shape works really well in keeping ressonances controlled

Thank you for your reply.

What I need is a detail concerning material, dimensions so all details in order to built myself this kind of speaker.

You can send me if you agree a PM.

Regards

Hi Erevan92,

With the list of materials in this Link, and my previous "pdf", I think you have al the ingredients to build a JanusXX.

Be aware of the strength of the magnets.

Build yourself a rig to assemble the array of magnets.

If the two opposite halves clash together, with your hand or fingers in between. I'm sure al your bones are broken.

Regards,

Henjo

ah, I think you see it running without xo

used down to say 1khz, I dont think it will be moving much at all

anyway, the trick seems to be in how you 'tension/adjust' the outher end/sides

thats wher you adjust allignment in the magnet gap

and besides, the gap probably wont need to be that tight

And a little help of this

Tinitus you're right, the tension and accuracy of the dimensions, of the membrane, and position to the center of the magnets are the most important things.

Another point is the stiffness and flatness of the voicecoil area (width = 50mm). This guarantees a pistonic movement of the membrane in the gap.

I'm using mine from 300 to 16.000 Hz. without noticeable movement.

Henjo

great, thanks

what are the measures regarding allignment accuracy issues

I think of how each 'coil'/winding is placed exact in the middle of magnet gap

not sideways, but front to back

or will it allign itself, once voltage is applied ?

considering no real xmax will be needed, have underhung ever been tried ?

what are the measures regarding allignment accuracy issues

I think of how each 'coil'/winding is placed exact in the middle of magnet gap

not sideways, but front to back

or will it allign itself, once voltage is applied ?

considering no real xmax will be needed, have underhung ever been tried ?

As you can see is my voice coil of the underhung type.

From my own experience, there are still a number of points that I want to mention.

Homogeneity of the membrane material.

As you know, paper has to different sides. (drying, rolling, pressing)

Some people experiences a change in sound, and alignment problems with changing humidity.

The reason for this could be non-mirrored membrane halves. By increasing or decreasing humidity the properties of the paper changing antiparallel.

Any deviation in the z-axis of the mounting sides(direction of motion) is the same derogation off center of the voice coil relative to the magnetic field. Here the earlier mentioned “hen’s foot” can do a good job. Centering the voice coil in the Z en X axis. Adjustment in the Y-axis controls the suspension / resonance frequency.

Fill the space in the core of the coil by a material of the same thickness. And wind the wire tight around it, so the forces can be transferred better to the membrane. Consequently, there is the possibility that the coil is moving in the viscosity of the adhesive connection instead of moving the membrane. I think that is the reason why some people don’t reach the 10kHz.

Henjo

From my own experience, there are still a number of points that I want to mention.

Homogeneity of the membrane material.

As you know, paper has to different sides. (drying, rolling, pressing)

Some people experiences a change in sound, and alignment problems with changing humidity.

The reason for this could be non-mirrored membrane halves. By increasing or decreasing humidity the properties of the paper changing antiparallel.

Any deviation in the z-axis of the mounting sides(direction of motion) is the same derogation off center of the voice coil relative to the magnetic field. Here the earlier mentioned “hen’s foot” can do a good job. Centering the voice coil in the Z en X axis. Adjustment in the Y-axis controls the suspension / resonance frequency.

Fill the space in the core of the coil by a material of the same thickness. And wind the wire tight around it, so the forces can be transferred better to the membrane. Consequently, there is the possibility that the coil is moving in the viscosity of the adhesive connection instead of moving the membrane. I think that is the reason why some people don’t reach the 10kHz.

Henjo

Attachments

I saw the 6 moons report of the rubanoide and was playing since the with the idea of building a small version. This type of design has not much damping except the one inherent to the material (paper). What about resonances? Are there any measurements showing distortion levels and step response?

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind