As you can see is my voice coil of the underhung type.

From my own experience, there are still a number of points that I want to mention.

Homogeneity of the membrane material.

As you know, paper has to different sides. (drying, rolling, pressing)

Some people experiences a change in sound, and alignment problems with changing humidity.

The reason for this could be non-mirrored membrane halves. By increasing or decreasing humidity the properties of the paper changing antiparallel.

Any deviation in the z-axis of the mounting sides(direction of motion) is the same derogation off center of the voice coil relative to the magnetic field. Here the earlier mentioned “hen’s foot” can do a good job. Centering the voice coil in the Z en X axis. Adjustment in the Y-axis controls the suspension / resonance frequency.

Fill the space in the core of the coil by a material of the same thickness. And wind the wire tight around it, so the forces can be transferred better to the membrane. Consequently, there is the possibility that the coil is moving in the viscosity of the adhesive connection instead of moving the membrane. I think that is the reason why some people don’t reach the 10kHz.

Henjo

Just new to this thread where do I start on this ? could you help, direction please.

i'm trying to get in touch with the guy présentation

to build a pair of "monopole" , if the test is ok , i'll may try the Janus70 quite more expensive.....

to build a pair of "monopole" , if the test is ok , i'll may try the Janus70 quite more expensive.....

Hello Henjo,

wich paper do you have tested, already? Do you have any distortion measurements?

Andre

wich paper do you have tested, already? Do you have any distortion measurements?

Andre

A few pictures of my prototype.

The sound.

At the moment I have no good reference, but they are easy to listen to, a wall of sound, invisible, small sweet spot.

Suspension.

None, just the paper. But it was not easy to adjust.

Next:

- New coils pour into epoxy resin

- Different kinds of paper, starting with "elefantenhaut"

- Neodimium magnets

- Measurements

Henjo

my own Tangent Ribbon !...

Here is my own tangential ribbon...

Sound is immediately loud. It lacks some high frequency range and it haves an uncommon radiation pattern !

Definitely an amazing driver !... It surely deserves more studies and developpment, IMHO !

Here is my own tangential ribbon...

Sound is immediately loud. It lacks some high frequency range and it haves an uncommon radiation pattern !

Definitely an amazing driver !... It surely deserves more studies and developpment, IMHO !

Attachments

Last edited:

Here is my own tangential ribbon...

Sound is immediately loud. It lacks some high frequency range and it haves an uncommon radiation pattern !

Definitely an amazing driver !... It surely deserves more studies and developpment, IMHO !

Hi, good prototype, congratulation.

If you are looking more high freq response, i believe that it is good to understand the technology. I think that this kind of driver is on the Distribuated Mode Loudspeaker (Or DML) group driver technology. You can google it. Rgds

Hi Ondesx,

Congratulations with your model of the JanusXX or Rubanoïde.

"It surely deserves more studies and developpment"

You're right about that.

About the high frequency response, did you read my earlier reply?

Be sure de membrane is glued with high stiffness to the motor.

If I recall, doublesided pcb in your case.

Otherwise the motor is moving into the elasticity/viscosity of the glue.

Do you use anykind of equalising?

Is there a big difference in frequency respons I sent in a earlier PM?

Regards,

Henjo

Congratulations with your model of the JanusXX or Rubanoïde.

"It surely deserves more studies and developpment"

You're right about that.

About the high frequency response, did you read my earlier reply?

Be sure de membrane is glued with high stiffness to the motor.

If I recall, doublesided pcb in your case.

Otherwise the motor is moving into the elasticity/viscosity of the glue.

Do you use anykind of equalising?

Is there a big difference in frequency respons I sent in a earlier PM?

Regards,

Henjo

answers !

@ Kolby : please read the posts from Moray James, he gave the Paul Paddock's list of patents, on which the present prototype is based. The radiation is very narrow vertically and broad horizontally with an amazing sound stage image and a beautiful reproduction of voices... The membranes are made of acetate.

@Abelma : yes this is a sort of DML, but I think there are several points to be discussed... I will be very interested to hear Paul himself do comments on this driver... If somebody knows him please ask him to give his lights on it !

@Henjo :Not sure Henjo that I read your post on high frequency behavior, please let me know where is it... You're right my coil is a double-sided pcb. The coil is "sandwiched" by the 2 membranes. The whole is securely glued by double face tape. The point of this driver is the very small movements of the membranes versus the very high output levels... Probably better than 95 dB/W/m ! I have just measure the frequency response for now... Equalizing will be another step and I prefer use it the less possible. Instead of Janus or Rubanoïde I prefer the term "Tangential Ribbon" or remember the author's of this driver, Paul Paddock, a great guy in audio field !...

If one of you guys, have an idea how to wire rapidly rectangular coils of 50 cm high and 4 cm wide, please let me know your technique !... Thanks.

@ Kolby : please read the posts from Moray James, he gave the Paul Paddock's list of patents, on which the present prototype is based. The radiation is very narrow vertically and broad horizontally with an amazing sound stage image and a beautiful reproduction of voices... The membranes are made of acetate.

@Abelma : yes this is a sort of DML, but I think there are several points to be discussed... I will be very interested to hear Paul himself do comments on this driver... If somebody knows him please ask him to give his lights on it !

@Henjo :Not sure Henjo that I read your post on high frequency behavior, please let me know where is it... You're right my coil is a double-sided pcb. The coil is "sandwiched" by the 2 membranes. The whole is securely glued by double face tape. The point of this driver is the very small movements of the membranes versus the very high output levels... Probably better than 95 dB/W/m ! I have just measure the frequency response for now... Equalizing will be another step and I prefer use it the less possible. Instead of Janus or Rubanoïde I prefer the term "Tangential Ribbon" or remember the author's of this driver, Paul Paddock, a great guy in audio field !...

If one of you guys, have an idea how to wire rapidly rectangular coils of 50 cm high and 4 cm wide, please let me know your technique !... Thanks.

Last edited:

@ Kolby : please read the posts from Moray James, he gave the Paul Paddock's list of patents, on which the present prototype is based. The radiation is very narrow vertically and broad horizontally with an amazing sound stage image and a beautiful reproduction of voices... The membranes are made of acetate.

@Abelma : yes this is a sort of DML, but I think there are several points to be discussed... I will be very interested to hear Paul himself do comments on this driver... If somebody knows him please ask him to give his lights on it !

@Henjo :Not sure Henjo that I read your post on high frequency behavior, please let me know where is it... You're right my coil is a double-sided pcb. The coil is "sandwiched" by the 2 membranes. The whole is securely glued by double face tape. The point of this driver is the very small movements of the membranes versus the very high output levels... Probably better than 95 dB/W/m ! I have just measure the frequency response for now... Equalizing will be another step and I prefer use it the less possible. Instead of Janus or Rubanoïde I prefer the term "Tangential Ribbon" or remember the author's of this driver, Paul Paddock, a great guy in audio field !...

If one of you guys, have an idea how to wire rapidly rectangular coils of 50 cm high and 4 cm wide, please let me know your technique !... Thanks.

Henjo has a good point saying that the interface between the coil and the mebrane has to be rigid to transmit the high frequency. It has the same effect on the DML loudspeaker. Also about the kind of membrane. Exemple, if the membrane is rigid and elastic, means, not plastic deformation, you will have better high freq response. I am not sure if the weight of the membrane has influence on the high freq, because on the DML technology it doesn't. I understandt that for a pistonic loudspeaker, yes, the weight has influence over the HF response.....but not sure at all for this technology. You may try with an aluminium sheet and see what it happens with the HF response, only for test purposes. I hope it helps my humble opinion.....sorry for my bad english!

... I understandt that for a pistonic loudspeaker, yes, the weight has influence over the HF response.....but not sure at all for this technology. You may try with an aluminium sheet and see what it happens with the HF response, only for test purposes. I hope it helps my humble opinion.....sorry for my bad english!

Well not really !... The more weight the less level. But the frequency response of the driver remains unchanged...

I know this is hardly understood, but you can do a very simple test : take a driver, measure the frequency response. Then, put it some weight on the protection dome, why not the same, i. e. you double the mass... Measure again. You have the same curve... But with less level !

Now if we speak of the inductance, it's another story.

Last edited:

Well not really !... The more weight the less level. But the frequency response of the driver remains unchanged...

I know this is hardly understood, but you can do a very simple test : take a driver, measure the frequency response. Then, put it some weight on the protection dome, why not the same, i. e. you double the mass... Measure again. You have the same curve... But with less level !

Now if we speak of the inductance, it's another story.

What kind of driver you use as reference, a pistonic one? The DML drivers do not reproduce the sound as the classic speakers, they do by resonance of the membrane. I am not a expert of the sound technology, just my experience with DML speakers.

I agree that a heavier membrane it will be lower sensibility of the DML speaker, this match my experiences. But the weight do not have a relationship on the HF response in overall. At least after my modest experiences.

Last edited:

What kind of driver you use as reference, a pistonic one?

My remark concerns electrodynamic drivers, obviously... As far as the DML drivers, I'm doing some experiments with exciters and some different types of membranes. Not an easy work indeed. Without the software used by NXT, it isn't easy to "predict" what would going on with the modification of one parameter... It's a very long process of "tries and errors"... But if anyone have the patience and the skills to explain how DML and more precisely this" Tangential Ribbon" work, I will be, and probably some other, definitely interested !...

A few important precisions about this driver. It seems 200 Hz to more than 10 kHz is a reachable target. The improvements of the driver from the first to the second model with circular webs improved several points :

- first the horizontal dispersion is largely improved (from 30° to 180 °)

- secondly the distorsion was reduced,

- thirdly the high frequency is less cancelled by the reflection of the waves on the extremity of the webs.

The quality of the webs is important and PVF is suggested as the best material. Paper and different other solutions suffer of humidity changes.

A damping, at the back of the webs and of their extremities, and a modification of the suspensions (high and low) improved the FR, since they have removed the frequencies lower than 100 Hz and improved the level of the signal above 5 kHz.

- first the horizontal dispersion is largely improved (from 30° to 180 °)

- secondly the distorsion was reduced,

- thirdly the high frequency is less cancelled by the reflection of the waves on the extremity of the webs.

The quality of the webs is important and PVF is suggested as the best material. Paper and different other solutions suffer of humidity changes.

A damping, at the back of the webs and of their extremities, and a modification of the suspensions (high and low) improved the FR, since they have removed the frequencies lower than 100 Hz and improved the level of the signal above 5 kHz.

Hello all,

How about Ruff nTuff papper this comes in large sheets and is resistant to humidity and tearing.

Ruff N Tuff - Real Paper as Strong as Plastic

Also, why not use 1 mm copper foil. This seem much easier and faster to cut and paste then to coil tiny wires for the voice coil.

Copper Foil 1 Mil

With regards to the voice coil. Does it matter if the coil is one large loop. Or can two independent copper strips not connected at the ends work?

With respect to the magnet assembly. Do the magnets have to be in-cased in metal because its part of the magnetic field of the design. Or can the magnets be held in place with hard wood. Its just much easier to work with wood than metal.

Thanks in advanced. Paul.

How about Ruff nTuff papper this comes in large sheets and is resistant to humidity and tearing.

Ruff N Tuff - Real Paper as Strong as Plastic

Also, why not use 1 mm copper foil. This seem much easier and faster to cut and paste then to coil tiny wires for the voice coil.

Copper Foil 1 Mil

With regards to the voice coil. Does it matter if the coil is one large loop. Or can two independent copper strips not connected at the ends work?

With respect to the magnet assembly. Do the magnets have to be in-cased in metal because its part of the magnetic field of the design. Or can the magnets be held in place with hard wood. Its just much easier to work with wood than metal.

Thanks in advanced. Paul.

Hi All,

Vincient Brient and I are the only ones who are posting measurements of this ribbon on the web. Ever tried to find measurements of the commercial variants of this loudspeaker?

You know why? Because they measure miserable.

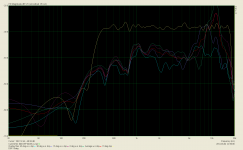

Here is my second measurement publication in this thread.

In this graph are 5 measurements.

0, 15, 30, en 45 degrees. Without DSP.

Calculated average power respons of the 4 mentioned above.

The 15 deg. curve represents approximately the average power respons.

So I tuned the FR at 15deg with DSP, and is represented by the yellow curve.

Measuring distance was 1 meter.

Regards,

Henjo

Vincient Brient and I are the only ones who are posting measurements of this ribbon on the web. Ever tried to find measurements of the commercial variants of this loudspeaker?

You know why? Because they measure miserable.

Here is my second measurement publication in this thread.

In this graph are 5 measurements.

0, 15, 30, en 45 degrees. Without DSP.

Calculated average power respons of the 4 mentioned above.

The 15 deg. curve represents approximately the average power respons.

So I tuned the FR at 15deg with DSP, and is represented by the yellow curve.

Measuring distance was 1 meter.

Regards,

Henjo

Attachments

Last edited:

You are partly right Henjo!Hi All,

Vincient Brient and I are the only ones who are posting measurements of this ribbon on the web. Ever tried to find measurements of the commercial variants of this loudspeaker?

You know why? Because they measure miserable.

Henjo

But before carrying out measures I think we have to improve everything that can be ... For example : centering the coils, damping of membranes and suspensions, the tension of these two parts and the quality of material used for membranes! ...

A tour on the klippel.de site allows to realize the importance of all these parameters on the frequency response and distortion.

I imagine a line source made with these transducer, given its performance and its frequency response ... It must be absolutely fantastic when properly developed!

I'll publish soon some measurements after some improvements...

A very important issue with this driver is the... coil ! An interesting discussion about the size of the coil in the air gap will be found here :

http://www.diyaudio.com/forums/multi-way/54498-how-can-overhung-voice-coil-produce-good-sound-5.html

http://www.diyaudio.com/forums/multi-way/54498-how-can-overhung-voice-coil-produce-good-sound-5.html

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind