Hi nocdplz

Fulcrum "X" is shown between the stylus and the counterweight, which puts the counterweight on the correct side.

Sincerely,

Ralf

the flat Nad has an interesting damped counterweight. On the wrong side?

Fulcrum "X" is shown between the stylus and the counterweight, which puts the counterweight on the correct side.

Sincerely,

Ralf

Dear Ralf, I also believed that it was the fulcrum of a simple gimbal tonearm with a flat shaft, but then, looking at some photos and infos (see attachment) I saw that is instead a DIN plug, and then the "fulcrum" is not an articulation but a fixing point.

Just like in my H arm, but 30 years earlier.

A counterweight in the rear is useful to balance the arm (I've also used, not to stress the bearing), but the damping is needed only in the resonant front section of the shaft.

ciao carlo

link to an old article on 5120, which reached the same conclusions that I got from listening mine.

NAD 5120 - tonearm questions - Vinyl Engine

Just like in my H arm, but 30 years earlier.

A counterweight in the rear is useful to balance the arm (I've also used, not to stress the bearing), but the damping is needed only in the resonant front section of the shaft.

ciao carlo

link to an old article on 5120, which reached the same conclusions that I got from listening mine.

NAD 5120 - tonearm questions - Vinyl Engine

Attachments

horizontal movement

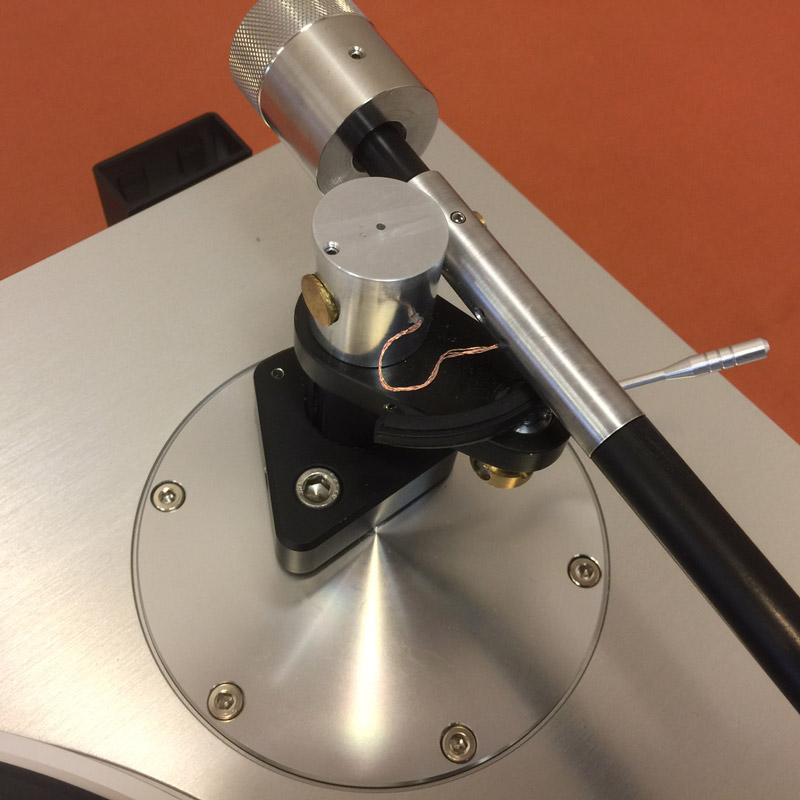

According to Vertere's website, for the vertical and horizontal movements, BOTH use flex bearings. Another thing to add is that the vertical pivot point appears to be at the same plane as the stylus or platter to lessen inertia, which I think is not a bad idea.

No surprise there as the Vertere arm and the Roksan arm are designed by the same man, Touraj Moghaddam. Here's an interview.

Let's begin with the $35k technology:

Horizontal movement: it looks like a normal ball bearing articulation, 23 mm offset.

According to Vertere's website, for the vertical and horizontal movements, BOTH use flex bearings. Another thing to add is that the vertical pivot point appears to be at the same plane as the stylus or platter to lessen inertia, which I think is not a bad idea.

An externally hosted image should be here but it was not working when we last tested it.

Horizontal Motion Bearing Assembly & Pillar Sleeve

"As the cartridge tracks the record it also has to move the tonearm, side to side and up and down. It does this in order to position itself, as closely as possible, on the mean line of the groove. Failure to do this accurately will result in loss and distortion of the musical signal the cartridge is to extract. To assist the cartridge in this cumbersome task, the reference tonearm utilises a unique bearing design both in the horizontal and vertical planes. Using metal/polymer film provides silent, ultra‐low friction movement of the arm without any stiction."

Balance: luxury version of a Roksan “intelligent counterweight”

No surprise there as the Vertere arm and the Roksan arm are designed by the same man, Touraj Moghaddam. Here's an interview.

According to Vertere's website, for the vertical and horizontal movements, BOTH use flex bearings.

Really interesting photo: even though I do not understand completely how it works, and how is able to support the weight of the arm without deforming the flex material. But certainly the Roksan designer knows how to do, and therefore this arm is not only made to support the brand image. That's the wrong impression given to me by the brochure, and those still a little vague descriptions

Another thing to add is that the vertical pivot point appears to be at the same plane as the stylus or platter to lessen inertia, which I think is not a bad idea.

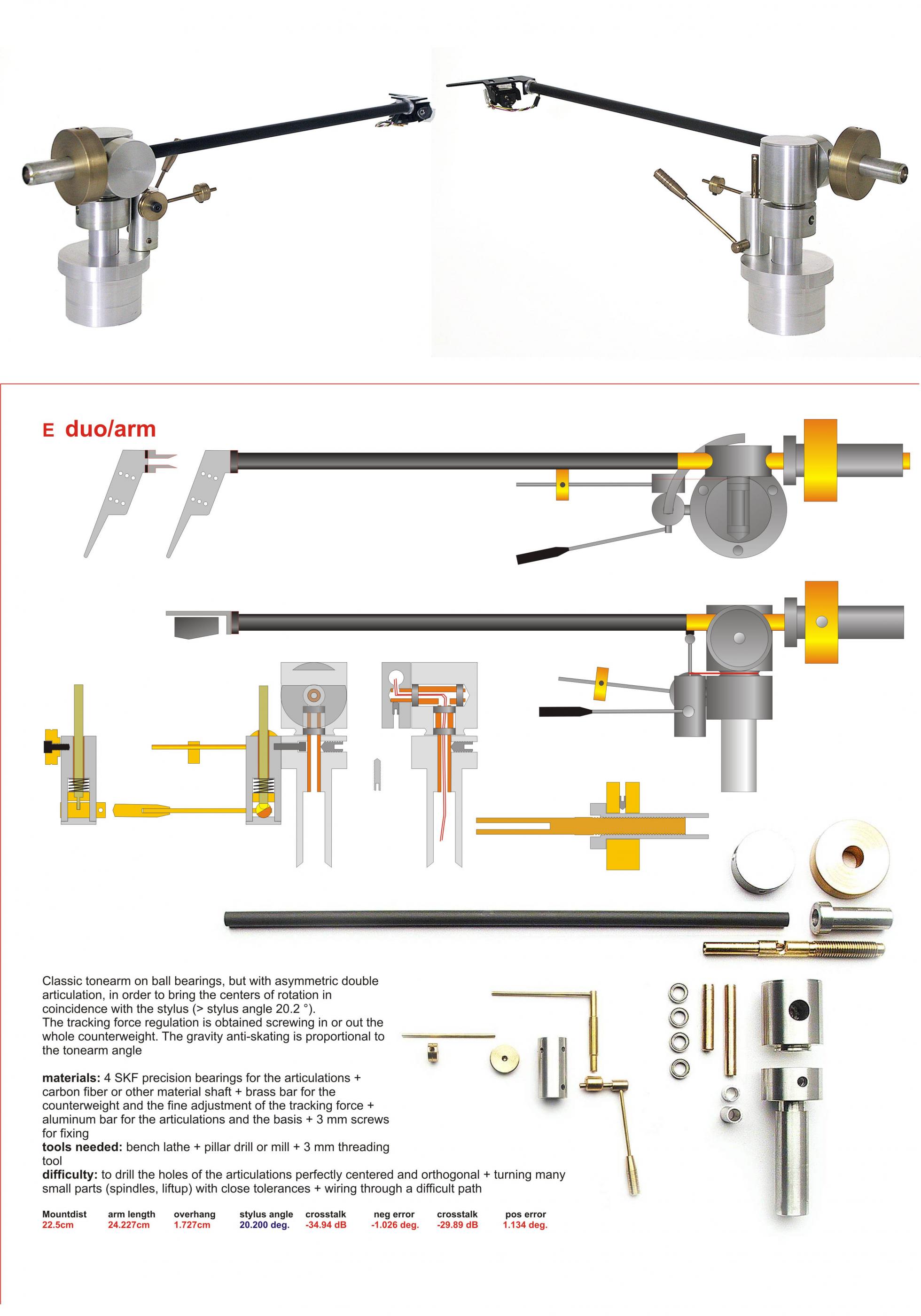

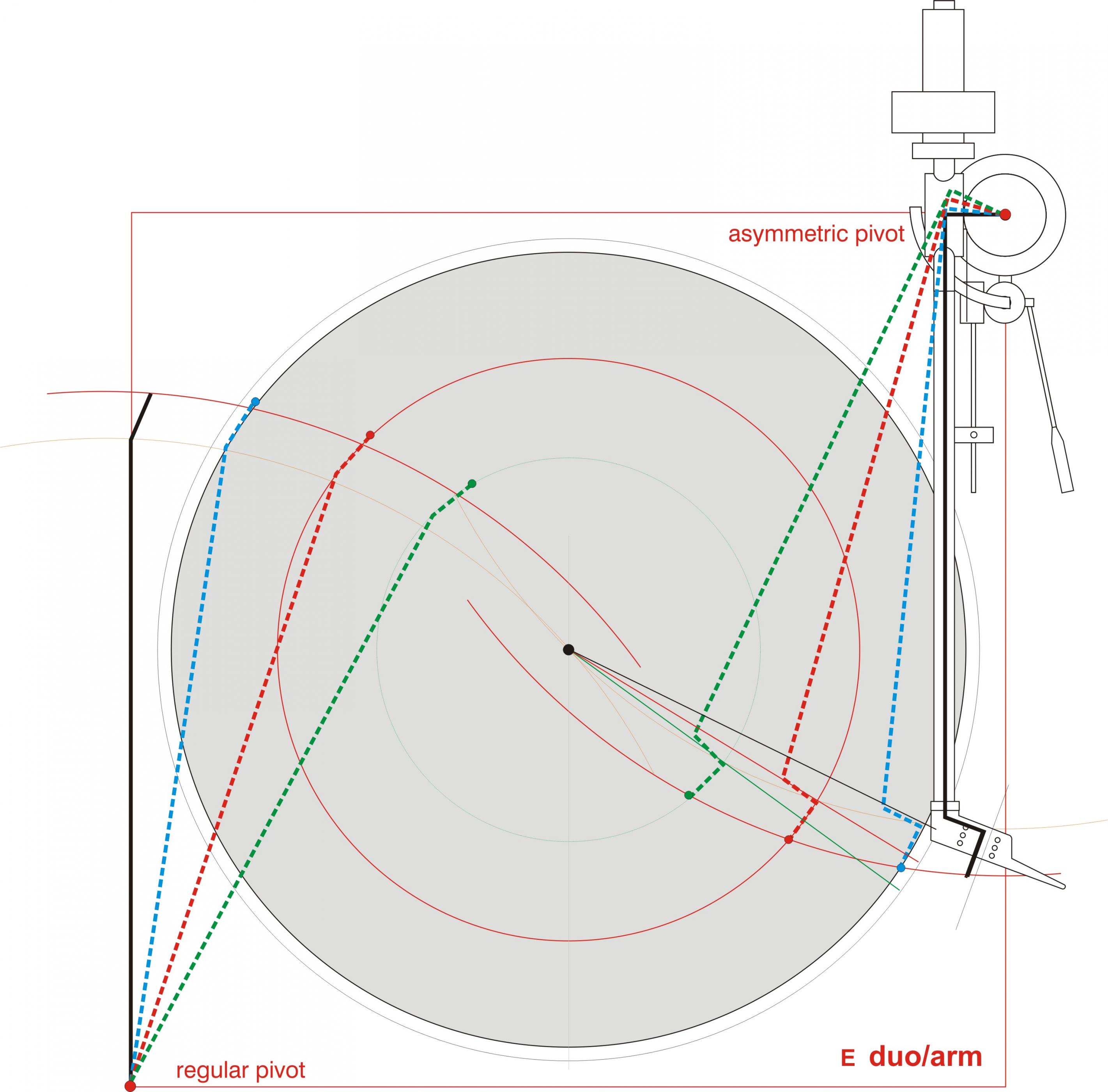

not a bad idea at all: several years ago i made this arm with two asymmetrical axes aligned with the stylus. It allows also to have a constant overhang. However, when properly set, imho the j-arm with the piano wire plays sharper. Sharper not always mean better. There are lots of problems involved with elastic vertical movements (help wanted, forumers). The advantage is that is possible to face one by one, which is difficult with sofisticated solutions.

Carlo

I'm -slowly- reading your super forum "angling for 90°". Great work, a real goldmine!

Really interesting photo: even though I do not understand completely how it works, and how is able to support the weight of the arm without deforming the flex material. But certainly the Roksan designer knows how to do, and therefore this arm is not only made to support the brand image. That's the wrong impression given to me by the brochure, and those still a little vague descriptions

Another thing to add is that the vertical pivot point appears to be at the same plane as the stylus or platter to lessen inertia, which I think is not a bad idea.

not a bad idea at all: several years ago i made this arm with two asymmetrical axes aligned with the stylus. It allows also to have a constant overhang. However, when properly set, imho the j-arm with the piano wire plays sharper. Sharper not always mean better. There are lots of problems involved with elastic vertical movements (help wanted, forumers). The advantage is that is possible to face one by one, which is difficult with sofisticated solutions.

Carlo

I'm -slowly- reading your super forum "angling for 90°". Great work, a real goldmine!

Attachments

several years ago i made this arm with two asymmetrical axes aligned with the stylus. It allows also to have a constant overhang. However, when properly set, imho the j-arm with the piano wire plays sharper. Sharper not always mean better.

Your asymmetrical arm reminds me of Frank Schröder's recent design, The ALTO (Asymmetrical Loading TOpology).

I'm -slowly- reading your super forum "angling for 90°". Great work, a real goldmine!

Have fun!

appearance

Similar but different, unfortunately.

From what I saw on your super forum the Schroeder (a great designer) ALTO is a brilliant answer to the problem of a parallel tracking, maybe based on three axes (2 vertical - 1 horizontal).

My old DUO arm instead is only a standard gimbal arm, but with the two axes decentralized to align to the stylus, for the well known balancing issues.

Idea almost as old as the tonearms. In my little drawing here is the simple geometry of my arm: the offset error is the usual, the bonus is that the overhang remains constant or nearly so.

The sound is almost identical to that of any arm on bearings, strengths and weaknesses included

ciao Carlo

p s - have you understood how works the Vertere flex bearing for hor. movement? there are two parts with screws, probably to fasten the polymer the rest for me is complete darkness

super10018: of which arm?

Similar but different, unfortunately.

From what I saw on your super forum the Schroeder (a great designer) ALTO is a brilliant answer to the problem of a parallel tracking, maybe based on three axes (2 vertical - 1 horizontal).

My old DUO arm instead is only a standard gimbal arm, but with the two axes decentralized to align to the stylus, for the well known balancing issues.

Idea almost as old as the tonearms. In my little drawing here is the simple geometry of my arm: the offset error is the usual, the bonus is that the overhang remains constant or nearly so.

The sound is almost identical to that of any arm on bearings, strengths and weaknesses included

ciao Carlo

p s - have you understood how works the Vertere flex bearing for hor. movement? there are two parts with screws, probably to fasten the polymer the rest for me is complete darkness

super10018: of which arm?

Attachments

Vertere & Roksan

You are confusing the ALTO arm with the Schroeder LT arm. ALTO is geometrically conventional and does NOT have an extra pivot! ALTO arm has nothing to do with parallel tracking. None. All you have to do is look at the LT arm's headshell as it has NO offset angle. The ALTO has an offset angle at the headshell.

I failed to see the difference geometrically between your DUO arm and conventional pivot arm. Since your arm has only ONE pivot, the effective length is still measured with a straight line from the pivot point to the stylus tip. Regardless of how you try to angle, curve, change shape, or have different joint, the geometry is still a straight line from pivot point to the stylus. That's why straight, J-shaped, and S-shaped arms are the same thing geometrically; even "split-plane" arm like Dynavector is still the same. Unless you added an extra pivot somewhere in between that straight line then all the conventional geometry is out the window. Care to elaborate on that? Thanks.

The ALTO arm is not about geometry. Based on its name it is about the loading on the bearings asymmetrically as it leans on one side of the horizontal bearing that might lessen chatter. It's analogous to turntable debate that much has been argued about the advantage of belt drive turntable bearing being pulled to one side that effectively preloading the bearing towards one side to create consistency. So far it's all based on observation. Perhaps Frank can chime on on this when he's not busy.

Judging by the picture and description, the cylinder consist of a flex bearing placed horizontally to allow horizontal movement. Since the arm never has to swing laterally more than 45°, it has enough flex to complete a whole record playing time. The only issue I see that agrees with your observation is that the flex bearing has to how the mass of the entire arm assembly. All that weight and down force that assert on the bearing might cause the flex bearing to change shape or sag. It would have to be quite stiff horizontally to withstand the vertical force to not sag. Maybe the arm is just very light and stiff due to the titanium arm but the counterweight seems quite hefty.

For $35K, they better do it right!

PS, I think you should have your own forum thread separately displaying all your designs. You're prolific and inventive. I believe most members here agree that you deserve your own forum thread!

If the Reference arm already has "neutral" balance with the pivot point at platter level, not sure if it's necessary. Perhaps this is a design feature carried over from his Roksan days; to lessen the pendulum effect and inertia and have a more consistent tracking force dynamically. Hey, probably wouldn't hurt... Not sure I like the use of ballbearing for the counterweight pivot in the Vertere. The old Roksan Artemiz counterweight uses a single-point style balance that seems more elegant. But what do I know since I don't design $35K tonearm!

In a unipivot tonearm that has no secondary stabilizing bearing, it might not be a bad thing (It might improve the old Graham unipivot arm with those outrigger side weights). But then again, it adds complexity to the intrinsic simplicity of unipivot. It's that "no free lunch" thing again.

Jim, it might work well in your short air-bearing arms since the pivot point is well above the platter level. No one has tried that before. Go for it!

Similar but different, unfortunately.

From what I saw on your super forum the Schroeder (a great designer) ALTO is a brilliant answer to the problem of a parallel tracking, maybe based on three axes (2 vertical - 1 horizontal).

You are confusing the ALTO arm with the Schroeder LT arm. ALTO is geometrically conventional and does NOT have an extra pivot! ALTO arm has nothing to do with parallel tracking. None. All you have to do is look at the LT arm's headshell as it has NO offset angle. The ALTO has an offset angle at the headshell.

My old DUO arm instead is only a standard gimbal arm, but with the two axes decentralized to align to the stylus, for the well known balancing issues. Idea almost as old as the tonearms. In my little drawing here is the simple geometry of my arm: the offset error is the usual, the bonus is that the overhang remains constant or nearly so.

I failed to see the difference geometrically between your DUO arm and conventional pivot arm. Since your arm has only ONE pivot, the effective length is still measured with a straight line from the pivot point to the stylus tip. Regardless of how you try to angle, curve, change shape, or have different joint, the geometry is still a straight line from pivot point to the stylus. That's why straight, J-shaped, and S-shaped arms are the same thing geometrically; even "split-plane" arm like Dynavector is still the same. Unless you added an extra pivot somewhere in between that straight line then all the conventional geometry is out the window. Care to elaborate on that? Thanks.

The ALTO arm is not about geometry. Based on its name it is about the loading on the bearings asymmetrically as it leans on one side of the horizontal bearing that might lessen chatter. It's analogous to turntable debate that much has been argued about the advantage of belt drive turntable bearing being pulled to one side that effectively preloading the bearing towards one side to create consistency. So far it's all based on observation. Perhaps Frank can chime on on this when he's not busy.

have you understood how works the Vertere flex bearing for horizontal movement? there are two parts with screws, probably to fasten the polymer the rest for me is complete darkness.

Judging by the picture and description, the cylinder consist of a flex bearing placed horizontally to allow horizontal movement. Since the arm never has to swing laterally more than 45°, it has enough flex to complete a whole record playing time. The only issue I see that agrees with your observation is that the flex bearing has to how the mass of the entire arm assembly. All that weight and down force that assert on the bearing might cause the flex bearing to change shape or sag. It would have to be quite stiff horizontally to withstand the vertical force to not sag. Maybe the arm is just very light and stiff due to the titanium arm but the counterweight seems quite hefty.

For $35K, they better do it right!

PS, I think you should have your own forum thread separately displaying all your designs. You're prolific and inventive. I believe most members here agree that you deserve your own forum thread!

I am wondering if the (Vertere & Roksan) intelligent counterweight is necessary. Otherwise, I am going to steal the idea.

If the Reference arm already has "neutral" balance with the pivot point at platter level, not sure if it's necessary. Perhaps this is a design feature carried over from his Roksan days; to lessen the pendulum effect and inertia and have a more consistent tracking force dynamically. Hey, probably wouldn't hurt... Not sure I like the use of ballbearing for the counterweight pivot in the Vertere. The old Roksan Artemiz counterweight uses a single-point style balance that seems more elegant. But what do I know since I don't design $35K tonearm!

In a unipivot tonearm that has no secondary stabilizing bearing, it might not be a bad thing (It might improve the old Graham unipivot arm with those outrigger side weights). But then again, it adds complexity to the intrinsic simplicity of unipivot. It's that "no free lunch" thing again.

Jim, it might work well in your short air-bearing arms since the pivot point is well above the platter level. No one has tried that before. Go for it!

Last edited:

I am wondering if the (Vertere & Roksan) intelligent counterweight is necessary. Otherwise, I am going to steal the idea.

Here's a YouTube video that the designer explains the counterweight. Segment starts at the 4:59 mark.

What's surprising is that the counterweight shaft is also pivoted horizontally! I wonder if all the extra bearings will add more noise...

Hi guys,

Directdriver is correct. The ALTOs bearing layout primarily pre-loads both bearing sets, lateral and vertical. There are no ball bearings(differing from the drawing nocdplz posted) used for the vertical movement. Even if one chooses such an arrangement, the minute slack of the balls vs their races would allow for relative movement when under a dynamic load(tracing a modulated groove). Not good...

The other advantage of this topology is the utterly simple way to generate a skating compensation force(decreasing towards the center). Move the shaft out of a perpendicular position and the offset mass will tend to find the lowest point. That's why the Alto's base can be"tilted".

And no matter where you put the armwand/bearing point relative to the vertical axis, it can be reduced to a straight line with a headshell featuring an offset angle(as directdriver pointed out above).

All the best,

Frank

Directdriver is correct. The ALTOs bearing layout primarily pre-loads both bearing sets, lateral and vertical. There are no ball bearings(differing from the drawing nocdplz posted) used for the vertical movement. Even if one chooses such an arrangement, the minute slack of the balls vs their races would allow for relative movement when under a dynamic load(tracing a modulated groove). Not good...

The other advantage of this topology is the utterly simple way to generate a skating compensation force(decreasing towards the center). Move the shaft out of a perpendicular position and the offset mass will tend to find the lowest point. That's why the Alto's base can be"tilted".

And no matter where you put the armwand/bearing point relative to the vertical axis, it can be reduced to a straight line with a headshell featuring an offset angle(as directdriver pointed out above).

All the best,

Frank

Ralf,

I watched the video. I understand what the designer was saying. If the counter weight can swing back and forth or left and right, it may compensate the change of counter weight. Counter weight may change very slightly due to up and down action of a cartridge. The purpose of the swing action is to compensate the difference in counter weight.

The so-called intelligent counter weight has three design aspects.

1. Don’t use excess weight, so no excess inertia.

2. Central gravity is below the level of stylus.

3. Swings left and right, back and forth to compensate the changing weight.

Actually, on my tonearm, I use lead shots as counter weight. So, the counter weight is exact the weight as a particular cartridge's VTF requires. If there is no excess weight, there is no excess inertia. In my opinion, it is very important for linear tracking arm. It may not be so critical for a pivot arm.

The central gravity of my counter weight is at same level as the stylus. I believe that will reduce the inertia as well.

The above two aspects of my counter weight are similar to the Vertere & Roksan intelligent counterweight.

Vertere’s counter weight can pivot horizontally. I think it is because its pivot bearing allows the arm has wobble, i.e. arm can swing from left to right.

My arm has no wobble at all. So, I don’t need the counter weight swings from side ways. I may add a mechanism to allow the counter weight swings back and forth. However, even I may do it, I still suspect if it is necessary because the changing in counter weight is so small.

Jim

I watched the video. I understand what the designer was saying. If the counter weight can swing back and forth or left and right, it may compensate the change of counter weight. Counter weight may change very slightly due to up and down action of a cartridge. The purpose of the swing action is to compensate the difference in counter weight.

The so-called intelligent counter weight has three design aspects.

1. Don’t use excess weight, so no excess inertia.

2. Central gravity is below the level of stylus.

3. Swings left and right, back and forth to compensate the changing weight.

Actually, on my tonearm, I use lead shots as counter weight. So, the counter weight is exact the weight as a particular cartridge's VTF requires. If there is no excess weight, there is no excess inertia. In my opinion, it is very important for linear tracking arm. It may not be so critical for a pivot arm.

The central gravity of my counter weight is at same level as the stylus. I believe that will reduce the inertia as well.

The above two aspects of my counter weight are similar to the Vertere & Roksan intelligent counterweight.

Vertere’s counter weight can pivot horizontally. I think it is because its pivot bearing allows the arm has wobble, i.e. arm can swing from left to right.

My arm has no wobble at all. So, I don’t need the counter weight swings from side ways. I may add a mechanism to allow the counter weight swings back and forth. However, even I may do it, I still suspect if it is necessary because the changing in counter weight is so small.

Jim

Last edited:

Ralf,

Just for the record. I am NOT Ralf. Ralf is member Straight Tracker, a very knowledgeable tonearm designer specializes in linear tracking. You can refer to me as directdriver or DD.

As for the comments on the Roksan intelligent counterweight, very well observed as always. Have fun experimenting, Jim!

Why there is a need to have dynamic counter weight ? Shoudn't tracking force be same from outer grooves to inner grooves ? If it is required, would a hollow counter weight filled with proper viscosity liquid serve the dual purpose of sinking vibrations and also behaves as dynamic weight ? Taking care that center of gravity is not affected we can hang it on tiny thread so that it self adjusts itself.

Regards

Hi,

#72

What do You mean by excess weight and excess inertia?

If we assume that You call excess weight the difference between counterweight and pickup mass, that would indicate that for equilibrum the centres of weight need to be of equal mass if they are equally distanced from the pivot.

If we assume now the counterweight to be heavier than the pickup, then the distance-to-pivot of the counterweight must be shorter.

As inertia increases proportional to the square of distance, it follows that the heavier but closer distanced counterweight has less inertia than the lighter but more distanced one.

So, what is excess inertia then?

jauu

Calvin

#72

I don't understand that.If there is no excess weight, there is no excess inertia.

What do You mean by excess weight and excess inertia?

If we assume that You call excess weight the difference between counterweight and pickup mass, that would indicate that for equilibrum the centres of weight need to be of equal mass if they are equally distanced from the pivot.

If we assume now the counterweight to be heavier than the pickup, then the distance-to-pivot of the counterweight must be shorter.

As inertia increases proportional to the square of distance, it follows that the heavier but closer distanced counterweight has less inertia than the lighter but more distanced one.

So, what is excess inertia then?

jauu

Calvin

Last edited:

off topic

"You are confusing the ALTO arm with the Schroeder LT"

You are completely right Direct driver.

Yesterday I looked better on the net finding the article of the manufacturer and understood to have taken a topical. The two arms are similar in appearance, but the new Schroeder arm has innovative contents (pre loaded bearings), while my duoarm was built only to test the ball bearings articulation (on the basis of that experience, I have gotten the same idea expressed by Frank).

The geometry, imho, is a little different from the classical one since the fulcrum of the vertical movement moves back and forth: the sound, however, does not improve so it is useless, if not dangerous. I posted that old arm just because you talked about the axis alignement in the Vertere, but this quickly led off the subject.

PS, I think you should have your own forum thread

The "elastic" arms were posted simply to discuss with people more experienced than me the real role of the vertical movement of the shaft (not of the stylus) to trace a groove which - in theory - should fit on a plane.

This in the spirit of the first post of Nanook.

"I only ask that the posts are :

1) Friendly

2) Non-judgemental

3) Creative criticism and references to other articles and posts (and other sites if need be)

4) Personal experiences only---please no "I read in S'file" or "TAbS "or whatever."

and also of his beautiful, essential constructions.

ciao to all - carlo

"You are confusing the ALTO arm with the Schroeder LT"

You are completely right Direct driver.

Yesterday I looked better on the net finding the article of the manufacturer and understood to have taken a topical. The two arms are similar in appearance, but the new Schroeder arm has innovative contents (pre loaded bearings), while my duoarm was built only to test the ball bearings articulation (on the basis of that experience, I have gotten the same idea expressed by Frank).

The geometry, imho, is a little different from the classical one since the fulcrum of the vertical movement moves back and forth: the sound, however, does not improve so it is useless, if not dangerous. I posted that old arm just because you talked about the axis alignement in the Vertere, but this quickly led off the subject.

PS, I think you should have your own forum thread

The "elastic" arms were posted simply to discuss with people more experienced than me the real role of the vertical movement of the shaft (not of the stylus) to trace a groove which - in theory - should fit on a plane.

This in the spirit of the first post of Nanook.

"I only ask that the posts are :

1) Friendly

2) Non-judgemental

3) Creative criticism and references to other articles and posts (and other sites if need be)

4) Personal experiences only---please no "I read in S'file" or "TAbS "or whatever."

and also of his beautiful, essential constructions.

ciao to all - carlo

Forgive me. I add some word for DD and Frank, to be clearer (my bad english does not help me).

Of course the shape of the shaft is irrelevant, if the two axis meet in one point.

But if the horizontal axis is shifted laterally from the vertical one ,the thing changes: not for the offset error, but for the hoverhang.

Am i wrong? carlo

carlo

may be wrong - carlo

Of course the shape of the shaft is irrelevant, if the two axis meet in one point.

But if the horizontal axis is shifted laterally from the vertical one ,the thing changes: not for the offset error, but for the hoverhang.

Am i wrong? carlo

carlo

may be wrong - carlo

Sorry again - too many years from that project.

I was tryng to explain this (see attachment): It was an experiment to test the influence of a variable position of the vertical movement fulcrum and the 2 axis in line with the stylus. Of results was just talked enough

carlo

I was tryng to explain this (see attachment): It was an experiment to test the influence of a variable position of the vertical movement fulcrum and the 2 axis in line with the stylus. Of results was just talked enough

carlo

Attachments

Calvin,

Perhaps, I used the word, inertia too liberally. It may cause confusion. What I actually meant was if you add more weight to the counterweight, you need more force to move it, especially for a mechanical linear arm. Once the counterweight moves with the carriage, heavier counterweight can generate more inertia. So, it will also need stronger force to stop the movement of a heavier counterweight.

Jim

Perhaps, I used the word, inertia too liberally. It may cause confusion. What I actually meant was if you add more weight to the counterweight, you need more force to move it, especially for a mechanical linear arm. Once the counterweight moves with the carriage, heavier counterweight can generate more inertia. So, it will also need stronger force to stop the movement of a heavier counterweight.

Jim

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- a continuation of DIY TT bearing...But now Tonearms!