Wingnut Thought Of The Moment

Has anybody played around with vacuum impregnating balsa wood for an arm ? It seems to me you could end up with the ultimate fiber composite. With a little experimentation you could get a range of masses. I'm thinking urathane, but a whole host of different "binders" could be used.

Just a thought..maybe a dumb one...but a thought

Casey

Has anybody played around with vacuum impregnating balsa wood for an arm ? It seems to me you could end up with the ultimate fiber composite. With a little experimentation you could get a range of masses. I'm thinking urathane, but a whole host of different "binders" could be used.

Just a thought..maybe a dumb one...but a thought

Casey

Here's a unipivot made from old scrap.

Kitchen cabinet hinge clips for stands.

screws for arm rest and pivot (sharpened).

7mm carbon tent pole for arm. (pivot drilled through to top wall).

Grado cartridge clamped to arm.

Washers for counterweight.

2mm wire, thread and screw for anti skate.

Works nicely, but on very warped records, could do with more damping as it rocks a little (azimuth)

Next project using nanooks 'magnetic' azimuth stabiliser.

Kitchen cabinet hinge clips for stands.

screws for arm rest and pivot (sharpened).

7mm carbon tent pole for arm. (pivot drilled through to top wall).

Grado cartridge clamped to arm.

Washers for counterweight.

2mm wire, thread and screw for anti skate.

Works nicely, but on very warped records, could do with more damping as it rocks a little (azimuth)

Next project using nanooks 'magnetic' azimuth stabiliser.

Attachments

Looks good Bob.

Erm, I think you mean maxro's magnetic stabilizer.

Max

bobhayes said:Next project using nanooks 'magnetic' azimuth stabiliser.

Erm, I think you mean maxro's magnetic stabilizer.

Max

Terribly sorry.

Credit where it's due... Maxro's azimuth stabiliser!!!!

Great idea though.

I got a hold of the same size magnets as your suggestion (1/8d x 1/8t)

I've tried a mock up and find the 'washer' needs to be close to the magnets to keep a good axial 'grip'.

I'm mounting the bits in a plastic bottle cap. Any thoughts or advice on the matter? (see pic).

Credit where it's due... Maxro's azimuth stabiliser!!!!

Great idea though.

I got a hold of the same size magnets as your suggestion (1/8d x 1/8t)

I've tried a mock up and find the 'washer' needs to be close to the magnets to keep a good axial 'grip'.

I'm mounting the bits in a plastic bottle cap. Any thoughts or advice on the matter? (see pic).

Attachments

krishu said:

apart from that does anybody have a drawing of a cueing lever (tonearm lift)?

Kind Regards

Christian.

I was thinking of a magnetically damped arm lift a while back. Then, this post came up for a free source for an air damper, and I haven't persued it:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=62599

I got one, but I'm not sure how I'll implement it as it is rather large ~3"long x 1"dia. very large adjusment range though.

Max

tmblack said:Maxro,

thanks but without using magnets do it matter which way it points?

It must be very difficult to balance the tonearm?

Tom

EE

Point up or down, doesn't matter.

You'll need a means of adjusting the counterweight side to side to balance the arm for azimuth.

With magnets you wouldn't need the side-side weight adjustment.

Max

GREAT THREAD!...my thoughts

I'm about to embark on my own tonearm & have some ideas i'd like to share.

ARM TUBE MATERIALS

Bamboo; natures own very strong tube, I seem to recall a bamboo tonearm from many years ago yet a GOOGLE search returns practically nothing! Buy a pack from your gardening centre then look at x-sections of the pieces ‘til you find the right one!

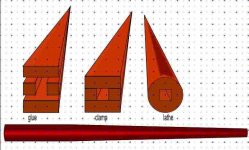

HARDWOOD ARM [ MY NEXT TASK]

Drilling a long centre hole could be difficult so why not prefabricate in strips, When they are glued you will have a square, accurate central ‘tunnel’, which will also serve as centralising hole if you want to lathe it to a round section!

If the middle sections were of contrasting wood [colour] they would also serve as a visual middle location for marking, drilling etc.

See pics.

ALUMINIUM; [ALUMINUM]

If you use aluminium parts you can get cheap polishing kits on ebay & polish the metal to a beautiful mirror finish which will not tarnish.

TONEARM CABLE;

Cheap £2 earphones provide great fine lacquered wire for your arm, I still haven’t mastered ‘tinning’ it very well though. Any tips on this enigma would be greatly appreciated!

I'm about to embark on my own tonearm & have some ideas i'd like to share.

ARM TUBE MATERIALS

Bamboo; natures own very strong tube, I seem to recall a bamboo tonearm from many years ago yet a GOOGLE search returns practically nothing! Buy a pack from your gardening centre then look at x-sections of the pieces ‘til you find the right one!

HARDWOOD ARM [ MY NEXT TASK]

Drilling a long centre hole could be difficult so why not prefabricate in strips, When they are glued you will have a square, accurate central ‘tunnel’, which will also serve as centralising hole if you want to lathe it to a round section!

If the middle sections were of contrasting wood [colour] they would also serve as a visual middle location for marking, drilling etc.

See pics.

ALUMINIUM; [ALUMINUM]

If you use aluminium parts you can get cheap polishing kits on ebay & polish the metal to a beautiful mirror finish which will not tarnish.

TONEARM CABLE;

Cheap £2 earphones provide great fine lacquered wire for your arm, I still haven’t mastered ‘tinning’ it very well though. Any tips on this enigma would be greatly appreciated!

Attachments

pioneer pl for a tonearm

This was an ugly seventies PIONEER PL 12D turntable ‘til I got my hands on it! I basically made a new body out of solid maple and did some other tweaks, the spindle bearing seems excellent, and I’ve also made a polycarbonate platter.

The stock tonearm is frankly not very good. I took it apart and fiddled and polished the parts but there’s too much free play in the arm bearings, if I tighten them up then the arm movement gets sticky & heavy, too loose and we have the rattles! so this is the candidate for my new arm project.

I hope this thread picks up again!

This was an ugly seventies PIONEER PL 12D turntable ‘til I got my hands on it! I basically made a new body out of solid maple and did some other tweaks, the spindle bearing seems excellent, and I’ve also made a polycarbonate platter.

The stock tonearm is frankly not very good. I took it apart and fiddled and polished the parts but there’s too much free play in the arm bearings, if I tighten them up then the arm movement gets sticky & heavy, too loose and we have the rattles! so this is the candidate for my new arm project.

I hope this thread picks up again!

Attachments

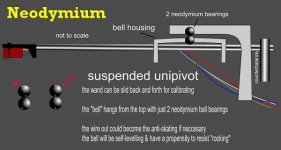

my magnets idea...i think

...Dunno if this is quite the same as the Schroeder philosophy. but I’ve ordered some spherical* neodymium "ball bearing" magnets. clinging together (try pulling them apart!!!) the contact surface area would be miniscule! & so would friction.

this way, the arm can be suspended from above, the magnets have a propensity to "keep straight" pole-to-pole which would have a good damping effect and provide stability in all planes, it would [I think] mean a lighter counterbalance...less mass too.]

The underneath could be kept clear for cable dressing.

BTW BOBHAYES...lovely minimalist arm design, it looks superb, the type of look I'm aiming for!

*another way would be 2 disc magnets which can be bought with holes and countersunk to provide ‘cups.’ Sandwiched each side of a conventional ball bearing.

...Dunno if this is quite the same as the Schroeder philosophy. but I’ve ordered some spherical* neodymium "ball bearing" magnets. clinging together (try pulling them apart!!!) the contact surface area would be miniscule! & so would friction.

this way, the arm can be suspended from above, the magnets have a propensity to "keep straight" pole-to-pole which would have a good damping effect and provide stability in all planes, it would [I think] mean a lighter counterbalance...less mass too.]

The underneath could be kept clear for cable dressing.

BTW BOBHAYES...lovely minimalist arm design, it looks superb, the type of look I'm aiming for!

*another way would be 2 disc magnets which can be bought with holes and countersunk to provide ‘cups.’ Sandwiched each side of a conventional ball bearing.

Attachments

Eggzy,

That looks like a good plan. Forget about the ring magnets with a ball bearing in between though, as you will lose the point contact and the pivot will have too much friction. I would loosely mount the balls, so that the poles can line themselves up. Or, I suppose that you could use one ball magnet and one ball bearing.

One note, the chrome plating chips, or rather, "chunks" off of these magnets very easily because the neodymium is not very hard. So, handle with care as they are your bearing surfaces and they need to stay smooth.

Eventually, I'll get around to building my magnetic tonearm. In the meantime, keep us posted.

Max

That looks like a good plan. Forget about the ring magnets with a ball bearing in between though, as you will lose the point contact and the pivot will have too much friction. I would loosely mount the balls, so that the poles can line themselves up. Or, I suppose that you could use one ball magnet and one ball bearing.

One note, the chrome plating chips, or rather, "chunks" off of these magnets very easily because the neodymium is not very hard. So, handle with care as they are your bearing surfaces and they need to stay smooth.

Eventually, I'll get around to building my magnetic tonearm. In the meantime, keep us posted.

Max

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- a continuation of DIY TT bearing...But now Tonearms!