Member

Joined 2009

Paid Member

The purpose of the holey brace is not really to brace anything (that is a secondary side effect), but to directly transfer the reactional driver energy to panels that are not the baffle, and to increase the amount of panel (and subsequently the amount of damping) that deals with this energy. Ideally one could bolt the driver to the holey brace to increase the energy transfer.

JRKO gets it.

dave

I'm a bit slow - I don't quite get it yet

the driver is vibrating, some of this transfers to the front baffle since the driver is bolted to it. the holey brace also transfers vibrations from the magnet to other panels. The idea is that more panels to share the vibrations means more mass is being employed to damp away these vibrations. is this right ?

so if you brace the front baffle to the other panels, you can still bring into play the mass of the other panels in damping out the vibrations that are generated by the driver. in this case no brace to the driver magnet, just to the front baffle connecting it to the other panels. is this right ?

I'm not sure why a plumber would be needed for a Karlson install.

it was a comment on the appearance of the Karlson speaker enclosure (perhaps plumbers bum is just a british thing)- I'm not sure I like them.

The idea is that more panels to share the vibrations means more mass is being employed to damp away these vibrations. is this right ?

It isn't the mass that does the damping. In plywood it is the impedance change as you go from one ply to the next. Low mass, high stiffness, high damping good.

so if you brace the front baffle to the other panels, you can still bring into play the mass of the other panels in damping out the vibrations that are generated by the driver. in this case no brace to the driver magnet, just to the front baffle connecting it to the other panels. is this right ?

Not nearly as effective because all the energy has to pass thru the baffle still.

dave

Not nearly as effective because all the energy has to pass thru the baffle still.

dave

This makes sense, just wondering how much further improvement is gained though if the box is braced to buggery (following good design principles)

I find it much easier bracing the box than the driver because getting the dimension right for the driver brace is tricky.

The only way I can think of easily doing it is allowing a gap between the brace and driver and choking it up with a wedge so the driver is in firm contact with the brace. You could then glue the wedge to the brace so it does not come loose with vibration

Last edited:

The only way I can think of easily doing it is allowing a gap between the brace and driver and choking it up with a wedge so the driver is in firm contact with the brace. You could then glue the wedge to the brace so it does not come loose with vibration

It is still direct vrs indirect.

Practise makes perfect... both Chris & Bernie get then pretty much spot on. Using the "wedge" has been oft mentioned

dave

I am not an engineer. Physics, yes, math sort of, but engineering no.

I've been drawing vector diagrams in my head trying to wrap my brain around the holey brace. If I understand you correctly (I hope), assuming that the driver and brace are non-compressible, equal energy will be transmitted to the front and back panels and the panels will then radiate out of phase. The side panels are along for the ride.

I have been using a pair of window braces above and below the driver (actually a panel with a single large hole in it). Energy transmitted to the front panel will be levered into the side panels and then into the back panels. The front and back panels will be in phase and the sides out of phase.

In either case, energy will be absorbed within the plies of the various vibrating panels.

Have I made any sense?

Bob

I've been drawing vector diagrams in my head trying to wrap my brain around the holey brace. If I understand you correctly (I hope), assuming that the driver and brace are non-compressible, equal energy will be transmitted to the front and back panels and the panels will then radiate out of phase. The side panels are along for the ride.

I have been using a pair of window braces above and below the driver (actually a panel with a single large hole in it). Energy transmitted to the front panel will be levered into the side panels and then into the back panels. The front and back panels will be in phase and the sides out of phase.

In either case, energy will be absorbed within the plies of the various vibrating panels.

Have I made any sense?

Bob

If I understand you correctly (I hope), assuming that the driver and brace are non-compressible, equal energy will be transmitted to the front and back panels and the panels will then radiate out of phase.

Big assumption there that is not true if the box is working as it should.

The idea is to spread out the energy sufficiently so that no one panel receives sufficient energy to hit the threshold required to set the panels vibrating. Keep in mind that the energy has to be within the bandwidth of any (potential) resonance for it to excite the resonance.

dave

Member

Joined 2009

Paid Member

Given that the magnet is the heaviest item and is hanging there on the frame, no matter how solid the frame is, it can't but help to include magnet bracing to provide another 'sink' for vibrational energy to the box walls, as Dave suggests. And since this is a doubled walled box, this vibrational energy is hopefully being retained on the 'inside' of the speaker enclosure.

I think it deserves something more sophisticated than having the brace press up against the back of the magnet. And the brace shouldn't present a 'target' for the back wave to reflect off back through the cone.

I think it deserves something more sophisticated than having the brace press up against the back of the magnet. And the brace shouldn't present a 'target' for the back wave to reflect off back through the cone.

Last edited:

Keep in mind that the energy has to be within the bandwidth of any (potential) resonance for it to excite the resonance.

If you look at the shelf brace vrs the vertical brace, based on this research (and example data) there is about ~150%* less energy available to excite the panel with the vertical brace. * (if i got the ratio calculated correctly -- (100^2-160^2)/100^2)

I aim for much higher panel frequencies in my boxes.

dave

I reckon if your front baffle is 1.5" of birch ply and you have properly braced the hell out of it, I am still not sure how much extra audible improvement you will get by bracing the driver but I am willing to try it out.

I do think it is a very good idea in principle though

I do think it is a very good idea in principle though

Last edited:

Member

Joined 2009

Paid Member

I think it deserves something more sophisticated than having the brace press up against the back of the magnet. And the brace shouldn't present a 'target' for the back wave to reflect off back through the cone.

As i have lamented in the past, it would be nice to have drivers you could bolt the back of the frame to the brace as you can with the PEARL PR2 woofer (i have a pair of this unique creatures). PEARL PR-2 Woofer

Here you can see a scheme i came up with to maximize coupling between a pair. toobz woofer

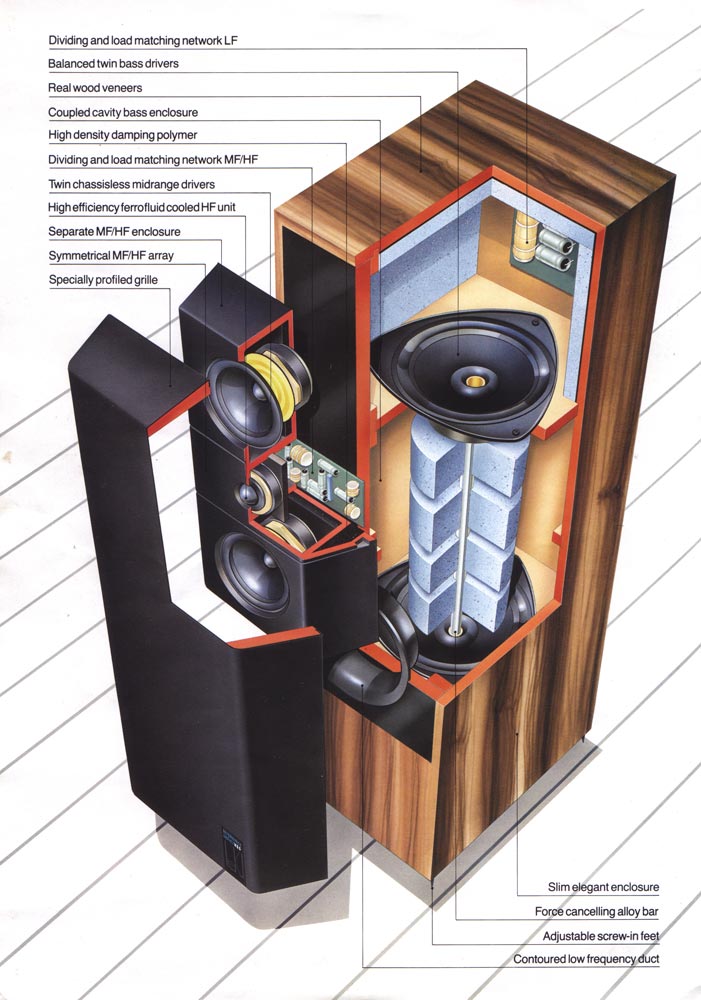

You could also do it like KEF did (there was/is an american speaker manufacturer that does something similar)

I have also seen speakers from Focal & B&W that brace the driver to the back panel, so i have good company (and am not the 1st)

dave

for reasons of simplicity -- is only SE, it is only effective when the driver is pushing against it (ie when the cone is moving outwards)

dave

Dave oi

It doesn't necessarily need to be that way. If you know what the actual push pull force is of the driver (just a rough guess) you can exceed that by choking it up with a wedge (or use shims) and apply a compressive load high enough so that it never sees zero load.

Eg If you chok it up with 200N of compressive force with a wedge then if the speaker is applying a maximum of +/- 50N then the brace will cycle between 250N and 150N of compressive force and never go to 0 N load. The driver will always be braced with load

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- A Big'un - the Audio Nirvana Super 15