Hi Xoc1,

There also seems to be still some debate about mounting the driver to the horn with a mounting plate, providing the full cone diameter in the mounting plate, and a reduced entry into the horn. ScreamerUSA did this in his Furybox. This would create a small coupling chamber between driver and horn, which again may be beneficial, but only measurements could tell the difference at high power.

Regards,

Oliver how would the coupling chamber benefit the driver and horn.

I think that the horn throat is critical to the design of high power TH speakers. Especially as highlighted by PASC in the TH18 thread.

As you mentioned ScreamerUSA has done some work on this.

I think that if a ramp is used in the horn throat then it should extend for the full length of the speaker, not stopping at the S2 point. To stop at S2 just makes me think that this point is being used just because it is easier to sim the change in Hornresp!

I am also beginning to wonder if the S2 compression ratio shown in Hornresp has any real validity. After all at the S2 point half of the speaker driver is past that point in the horn.

I am going to try to understand this area of TH design a bit better.

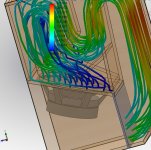

I am trying some flow analysis with my speaker models, and some good old fashioned thinking!

My current thoughts are to encourage a linear velocity in all parts of the throat.

Regards

Martin (Xoc1)

As you mentioned ScreamerUSA has done some work on this.

I think that if a ramp is used in the horn throat then it should extend for the full length of the speaker, not stopping at the S2 point. To stop at S2 just makes me think that this point is being used just because it is easier to sim the change in Hornresp!

I am also beginning to wonder if the S2 compression ratio shown in Hornresp has any real validity. After all at the S2 point half of the speaker driver is past that point in the horn.

I am going to try to understand this area of TH design a bit better.

I am trying some flow analysis with my speaker models, and some good old fashioned thinking!

My current thoughts are to encourage a linear velocity in all parts of the throat.

Regards

Martin (Xoc1)

Attachments

Hi kornnylike and Xoc1,

First a small correction it's "screamersusa" not "ScreamerUSA" as I wrongly wrote in Post #140 (that can mess up searches).

I got the general idea from his thread:

http://www.diyaudio.com/forums/subwoofers/131852-live-sound-specific-tapped-horn-thread.html

It has also been quoted in different places, e.g.: the single sheet thread

http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge.html.

It has also been used by PASC, cannot find the quote.

Hopefully Xoc1 comes up with something.

Regards,

First a small correction it's "screamersusa" not "ScreamerUSA" as I wrongly wrote in Post #140 (that can mess up searches).

I got the general idea from his thread:

http://www.diyaudio.com/forums/subwoofers/131852-live-sound-specific-tapped-horn-thread.html

It has also been quoted in different places, e.g.: the single sheet thread

http://www.diyaudio.com/forums/subwoofers/170771-single-sheet-th-challenge.html.

It has also been used by PASC, cannot find the quote.

Hopefully Xoc1 comes up with something.

Regards,

Hi,

Here is the link to PASC's use of a "circular restriction", Post #400:

http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-40.html#post2844264

This type of coupling chamber may help in leveling the pressure across the cone area (see Xoc1's FEA picture above).

Regards,

Here is the link to PASC's use of a "circular restriction", Post #400:

http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-40.html#post2844264

This type of coupling chamber may help in leveling the pressure across the cone area (see Xoc1's FEA picture above).

Regards,

Last edited:

Hi,

Here is the link to PASC's use of a "circular restriction", Post #400:

http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-40.html#post2844264

This type of coupling chamber may help in leveling the pressure across the cone area (see Xoc1's FEA picture above).

Regards,

Oliver

Thanks for the above link to PASC's post. I am excited to see what improvement Xoc1 come up with for a better cone control.

Last edited:

Any progress, kornylike?

I will be starting a new thread for Xco1 6 folded tapped horn. I have everything ready to start building just waiting to see if Xco1 or tb46 come up with any improvement for the 6 folded horn throat.

Last edited:

Hi kornnylike,

Please, dont let me hold you back, I don't have anything to add to Posts #140/143/144.

Josh Rici has a similar throat in his Othorn, maybe he can add something from his experience; or maybe Xoc1 has done more FEA work on the subject. Maybe, take another look at http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-49.html, particularly Posts #488, there may be another morsel of thruth there.

If it were mine, I would follow screamersusa's method.

Regards,

Please, dont let me hold you back, I don't have anything to add to Posts #140/143/144.

Josh Rici has a similar throat in his Othorn, maybe he can add something from his experience; or maybe Xoc1 has done more FEA work on the subject. Maybe, take another look at http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-49.html, particularly Posts #488, there may be another morsel of thruth there.

If it were mine, I would follow screamersusa's method.

Regards,

Hi kornnylike,

Take another look at http://www.diyaudio.com/forums/subwoofers/190635-th-18-flat-35hz-xoc1s-design-49.html, particularly Posts #488, there may be another morsel of thruth there.

If it were mine, I would follow screamersusa's method.

Regards,

I would like to use screamersusa method but I do not know how to apply it to Xco1 6 folded

Last edited:

I am going to try to understand this area of TH design a bit better.

I am trying some flow analysis with my speaker models, and some good old fashioned thinking!

My current thoughts are to encourage a linear velocity in all parts of the throat.

Regards

Martin (Xoc1)

I also wonder if the 2:1 compression plate helps in other ways besides just providing an 'air shock' to help prevent overexcursion, as it reduces the area that is exposed to the horn path.

Subjectively, It does appear to sound 'cleaner' with the plate vs without.... at high power levels.

It might be difficult but it is certainly possible to retrofit such a compression plate to the horn throat. The plate should be small enough to fit though the baffle cut out and place in position.

With the 18TBX100 driver a clearance of approx 25mm would be needed. This requires a thicker baffle board or packing. If packing is used then it might be best fitted on the driver side of the baffle. Maybe a 1/4" thick packing ring for the driver?

Crescendo, if you are going to build a prototype I could try to draw up a part that fits, for you to try out.

If you are going to use the revised plans it might be better to cut the shape into the baffle board and use a 25mm thick spacer.

Regards Martin (Xoc1)

With the 18TBX100 driver a clearance of approx 25mm would be needed. This requires a thicker baffle board or packing. If packing is used then it might be best fitted on the driver side of the baffle. Maybe a 1/4" thick packing ring for the driver?

Crescendo, if you are going to build a prototype I could try to draw up a part that fits, for you to try out.

If you are going to use the revised plans it might be better to cut the shape into the baffle board and use a 25mm thick spacer.

Regards Martin (Xoc1)

Last edited:

Hi kornnylike,

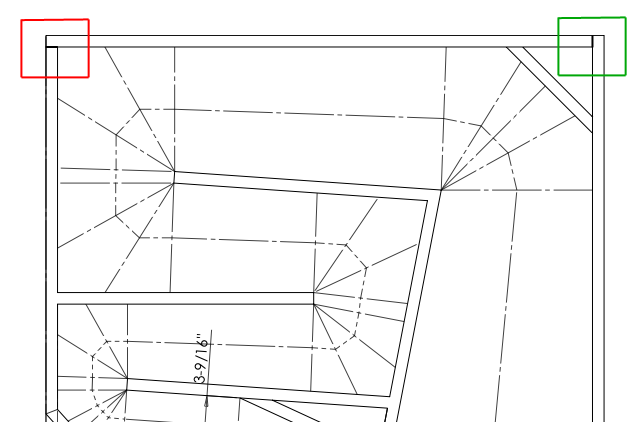

Just a sketch as to the alternate mounting/throat:

Regards,

Oliver,

Thank you for the drawing.

Post #156

Hi kornnylike,

This same question was asked and answered in this thread: http://www.diyaudio.com/forums/subwoofers/178029-c-e-x-pa-flat-30-ft30-pa-th-awesomeness-60.html; Posts #599 and 608.

Regards,

Hi kornnylike,

This same question was asked and answered in this thread: http://www.diyaudio.com/forums/subwoofers/178029-c-e-x-pa-flat-30-ft30-pa-th-awesomeness-60.html; Posts #599 and 608.

Regards,

Baffle Cutout and Spacer

Hi All.

Firstly I would like to point out that I am unsure about the depth required for the driver spacer - if it requires more than 25mm clearance then please make the spacer depth adequate for the X-Mech of the driver!!!!

Cut out Dimensions (the thought process)

I made the overall radius of the cut out, the equivalent of the SD of the 18TBX100 driver (1210 cm sq). The curves were them adjusted until the area of the cut out was half of the SD figure. This should mean that the average of the curved edge should be bang on the S2 point of the horn, and the compression ratio 2:1.

The spacer board is designed to be reasonably simple to setout and cut.

The overall dimension is to fit the smallest dimension of the baffle board.

The orientation of the speaker mount holes in the baffle is important, if you want any chance of fitting theT nuts

Regards Martin

Hi All.

Firstly I would like to point out that I am unsure about the depth required for the driver spacer - if it requires more than 25mm clearance then please make the spacer depth adequate for the X-Mech of the driver!!!!

Cut out Dimensions (the thought process)

I made the overall radius of the cut out, the equivalent of the SD of the 18TBX100 driver (1210 cm sq). The curves were them adjusted until the area of the cut out was half of the SD figure. This should mean that the average of the curved edge should be bang on the S2 point of the horn, and the compression ratio 2:1.

The spacer board is designed to be reasonably simple to setout and cut.

The overall dimension is to fit the smallest dimension of the baffle board.

The orientation of the speaker mount holes in the baffle is important, if you want any chance of fitting theT nuts

Regards Martin

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 18TBX100 vs 2lab12

very nice indeed!

very nice indeed!