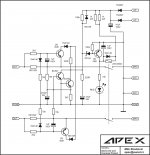

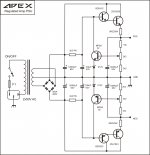

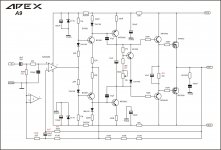

Is this circuit (on post 1) adaptable to be powered by -85V, 0V, +85V power supply? I think, I should be able to replace its input stage with a Complementary Feedback Pair and replace some transistors with others that are rated for higher voltages.

Why are there TWO grounds one for signal and one for power? Are these electrically isolated?

Why are there TWO grounds one for signal and one for power? Are these electrically isolated?

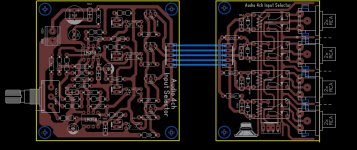

I im searching for this pcb in this thread and could not find post who made this nice pcb of input selector...could someone find what post is this so that i can contact author for gerbers or lay6 file.

View attachment APEX Audio input Selector.zip

I im searching for this pcb in this thread and could not find post who made this nice pcb of input selector...could someone find what post is this so that i can contact author for gerbers or lay6 file.

Attachments

My A9 singing

Hi to All

Finally my A9 working.

I used my old Sony TA-F261RI and I replaced PSU, protector and STK 4182 with two A9.

It remains to build the fan controller, at the low volume of the amplifier, the fan is noisy.

I usually use the Sony TA-FE330 and compared to A9, the sound of A9 is better. For almost the same sound, Sony use bass and treble to maximum, to A9 is not needed. Sony has a flat sound compared to A9 in all frequencies: low, medium and high. A9 also has a better voice stamp and stereo effects have higher amplitude. The comparison is made with the same speakers and signal source.

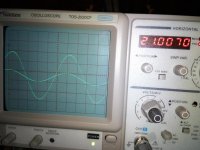

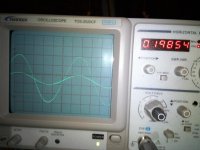

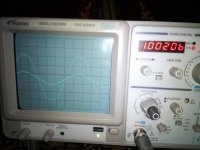

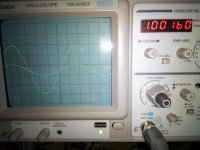

Rail is +/- 35.6 V dc stabilized, offset 1.3 mV, 48 mA bias. I'm attaching a couple of photos during the tests. On the oscilloscope the signal source is directly connected to the A9 input. For input I have 0.5 V pp (0.5 V / division) and output about 50 V pp (10 V / division) and perfect sinus forms at 1 kHz, 20 Hz and 21 kHz.

Thanks to Mr. Miles for this great amplifier. Now I'm listening to my favorite music on the Sony A9 which offers a higher quality audition than the other Sony. The sound space and the stereo effects are excellent.

which offers a higher quality audition than the other Sony. The sound space and the stereo effects are excellent.

Regards

Cornel

Hi to All

Finally my A9 working.

I used my old Sony TA-F261RI and I replaced PSU, protector and STK 4182 with two A9.

It remains to build the fan controller, at the low volume of the amplifier, the fan is noisy.

I usually use the Sony TA-FE330 and compared to A9, the sound of A9 is better. For almost the same sound, Sony use bass and treble to maximum, to A9 is not needed. Sony has a flat sound compared to A9 in all frequencies: low, medium and high. A9 also has a better voice stamp and stereo effects have higher amplitude. The comparison is made with the same speakers and signal source.

Rail is +/- 35.6 V dc stabilized, offset 1.3 mV, 48 mA bias. I'm attaching a couple of photos during the tests. On the oscilloscope the signal source is directly connected to the A9 input. For input I have 0.5 V pp (0.5 V / division) and output about 50 V pp (10 V / division) and perfect sinus forms at 1 kHz, 20 Hz and 21 kHz.

Thanks to Mr. Miles for this great amplifier. Now I'm listening to my favorite music on the Sony A9

Regards

Cornel

Attachments

-

pf_1530806856.jpg120.8 KB · Views: 457

pf_1530806856.jpg120.8 KB · Views: 457 -

pf_1530806643.jpg50.6 KB · Views: 332

pf_1530806643.jpg50.6 KB · Views: 332 -

pf_1530806530.jpg89.3 KB · Views: 314

pf_1530806530.jpg89.3 KB · Views: 314 -

pf_1530806153.jpg88.7 KB · Views: 210

pf_1530806153.jpg88.7 KB · Views: 210 -

pf_1530806064.jpg71.2 KB · Views: 221

pf_1530806064.jpg71.2 KB · Views: 221 -

pf_1530805916.jpg72 KB · Views: 226

pf_1530805916.jpg72 KB · Views: 226 -

pf_1530805785.jpg81.3 KB · Views: 1,074

pf_1530805785.jpg81.3 KB · Views: 1,074 -

APEX Stereo DC and OL protect.JPG244 KB · Views: 1,140

APEX Stereo DC and OL protect.JPG244 KB · Views: 1,140 -

APEX Regulated PSU.jpg239.4 KB · Views: 1,209

APEX Regulated PSU.jpg239.4 KB · Views: 1,209 -

APEX AA9sch.JPG396.8 KB · Views: 1,262

APEX AA9sch.JPG396.8 KB · Views: 1,262

Hello Cornel,

Congratulations on the success and that you were able to solve the problem and enjoying the sound.

So which one you used finally irf540 or irfp240?

For the fan noise, you could use an appropriate value power resistor to slow it down to the desired level so that there is enough cooling at the same time lower noise.

regards

Prasi

Congratulations on the success and that you were able to solve the problem and enjoying the sound.

So which one you used finally irf540 or irfp240?

For the fan noise, you could use an appropriate value power resistor to slow it down to the desired level so that there is enough cooling at the same time lower noise.

regards

Prasi

Last edited:

Hello Cornel,

Congratulations on the success and that you were able to solve the problem and enjoying the sound.

So which one you used finally irf540 or irfp240?

For the fan noise, you could use an appropriate value power resistor to slow it down to the desired level so that there is enough cooling at the same time lower noise.

regards

Prasi

Hi Prasi,

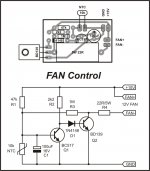

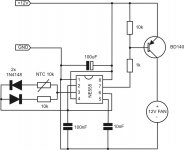

I used irf 540/9540. For fan control I will use Mr. Mile's schematic. The fan start up to 50 degrees and to this temperature the power of amp will be large enough to cover the fan noise.

The second time I replaced the IRF's, I built the regulated PSU because I thought I had too much rail, I set biass close to 50 mA, and I connected the signal source because I was very curious to listen to the stereo sound.

After one minute IRF's burned. Even now I do not know what the problem was.

I found that the resistance of 10 R on positive rail and 4r7 in Zobbel was brown. I think I had the sea oscillations at the exit, but I did not have time to test with the oscilloscope.

For the third time I replaced all the transistors, I checked the other components and the spaces between the PCB routes and the success ..... I lost two battles but I won the war

I am thinking of building A9 with two pairs of IRFs

Regard

Cornel

Attachments

Hello Cornel,

Congratulations on the success and that you were able to solve the problem and enjoying the sound.

So which one you used finally irf540 or irfp240?

For the fan noise, you could use an appropriate value power resistor to slow it down to the desired level so that there is enough cooling at the same time lower noise.

regards

Prasi

Hi Prasi,

Thanks for your appreciation, suggestions and help,

Regards

Cornel

Hi to All

Finally my A9 working.

I used my old Sony TA-F261RI and I replaced PSU, protector and STK 4182 with two A9.

It remains to build the fan controller, at the low volume of the amplifier, the fan is noisy.

I usually use the Sony TA-FE330 and compared to A9, the sound of A9 is better. For almost the same sound, Sony use bass and treble to maximum, to A9 is not needed. Sony has a flat sound compared to A9 in all frequencies: low, medium and high. A9 also has a better voice stamp and stereo effects have higher amplitude. The comparison is made with the same speakers and signal source.

Rail is +/- 35.6 V dc stabilized, offset 1.3 mV, 48 mA bias. I'm attaching a couple of photos during the tests. On the oscilloscope the signal source is directly connected to the A9 input. For input I have 0.5 V pp (0.5 V / division) and output about 50 V pp (10 V / division) and perfect sinus forms at 1 kHz, 20 Hz and 21 kHz.

Thanks to Mr. Miles for this great amplifier. Now I'm listening to my favorite music on the Sony A9which offers a higher quality audition than the other Sony. The sound space and the stereo effects are excellent.

Regards

Cornel

Nice work,

Regards

Nice work,

Regards

Thanks Mr. Mile.

The bass of A9 is special. Please post a schema for a 2.1 system. Sure it will be an excellent system. Thank you again.

Regard

Cornel

I would suggest to use a thermistor or a diode to detect temperature. Then use that signal to control the motor's speed.

Hi edbarx

Thanks for your suggestions and help.

I have schematic for fan control (see post 10449). I have some audio experience but I do not know how to design scematics like Mr. Mile. For speed control I do not have a schematic.

Regards

Cornel

What you really need is patience. Connect a small power transistor in common emitter configuration, that is, with the emitter connected to ground. Connect the fan motor to its collector with the other terminal connected to the appropriate supply terminal. As a control sensor use a thermistor with a negative coefficient. Use another fixed resistor in series with the thermistor. The thermistor-resistor chain should be connected between base and power supply terminal. Experiment with some resistor values so that the fan runs slowly when the temperature is low and increases speed as temperature rises. (Place a reverse biased diode across the transistor to prevent back emfs from the motor from destroying it.)Hi edbarx

Thanks for your suggestions and help.

I have schematic for fan control (see post 10449). I have some audio experience but I do not know how to design scematics like Mr. Mile. For speed control I do not have a schematic.

Regards

Cornel

Alternatively, you can use a diode as a sensor for temperature. At constant current the voltage across a diode drops by about 2mV/K (K = Kelvin or Celcius). If you use a diode as a sensor you need a different circuit.

What you really need is patience. Connect a small power transistor in common emitter configuration, that is, with the emitter connected to ground. Connect the fan motor to its collector with the other terminal connected to the appropriate supply terminal. As a control sensor use a thermistor with a negative coefficient. Use another fixed resistor in series with the thermistor. The thermistor-resistor chain should be connected between base and power supply terminal. Experiment with some resistor values so that the fan runs slowly when the temperature is low and increases speed as temperature rises. (Place a reverse biased diode across the transistor to prevent back emfs from the motor from destroying it.)

Alternatively, you can use a diode as a sensor for temperature. At constant current the voltage across a diode drops by about 2mV/K (K = Kelvin or Celcius). If you use a diode as a sensor you need a different circuit.

Hi edbarx

The ingenious solution for speed control and is not complicated. I'll test it on a test board and add it to the fan. Thank you again.

Regards

Cornel

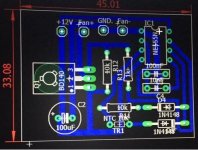

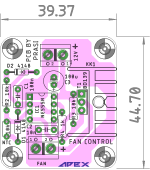

Use this PWM fan speed control

Hi Mr. Mile

Nice schematic as usual. Variable pulses at output 555 dependent on NTC resistance and variable fan speed. Elegant solution. Thanks!

Regards

Cornel

Use this PWM fan speed control

Another option for fan control. Could be useful for my AX-14 2 pair.

Attachments

- Home

- Amplifiers

- Solid State

- 100W Ultimate Fidelity Amplifier