Anyone reading your thread can, and possibly will, issue random sound nuisance complaints that will hobble your horn project from anywhere on the globe.Here's three reasons that this project will likely become a reality:

My labor costs are low, because I own the required construction equipment. The big unknown is the County permitting office.

They are the only folks with the power to shut down my horn project before it starts. I'm anticipating that the county will ultimately issue my construction permit - with a very firm warning not to draw any sound nuisance complaints. .

"Google maps" is really a fun diversion, you can see where your Mini Nuke project (oops, that was the project you were designing for free for me) will be built.

With the generous information you have shared, the GPS positions of your ultimate construction location are both "locked and loaded".

The term "locked and loaded" always seemed "goofy" to me, could you perhaps elucidate me as to their meaning when down in the "Yellow Submarine"?

Oh- I forgot to apologize again for my "shame-full" behavior. Sorry.

Good luck-

Have fun.

Cheers,

Art

Anyone reading your thread can, and possibly will, issue random sound nuisance complaints that will hobble your horn project from anywhere on the globe.

"Google maps" is really a fun diversion, you can see where your Mini Nuke project (oops, that was the project you were designing for free for me) will be built.

With the generous information you have shared, the GPS positions of your ultimate construction location are both "locked and loaded".

The term "locked and loaded" always seemed "goofy" to me, could you perhaps elucidate me as to their meaning when down in the "Yellow Submarine"?

Oh- I forgot to apologize again for my "shame-full" behavior. Sorry.

Good luck-

Have fun.

Cheers,

Art

And ... that's a really thinly veiled threat to very illegally file false police reports as payback for not getting paid.

I have no words. Except I'm out. I want no part of this anymore.

I'm available through PM and email but this thread has turned literally insane.

Dear JAT,1)You wanted OP to pay 20 billable hours for your advice and very likely a paid vacation to oversee the project (aka visit your girlfriend's daughter who you mentioned lives in the same area). I'm guessing you think your time is worth upwards of $100/hr, so roughly a bare minimum $2000 bill + expenses.

2) There's no shame in getting paid.

1) I don't give a flying eff through a rolling torus about the effing money.

I travel when and where I want with whomever I choose too.

Please give me your GPS coordinates so I can avoid any potential overlap in our location

In spite of plumbers, car repairman, and therapists extricating $60 to $200 per hour for "services rendered", I still bill at $35 USD per hour, regardless of race, political affiliation, or level of ignorance.

My most lucrative clients are the most ignorant of the advice they purchased, proof of a "rising economy".

2) No shame as long as you have provided a service.

Please share with us your outdoor stereo listening experiences that describe in detail the dozen or so scenarios I have iterated in this thread, which you have selectively ignored.

Cheers,

Art

I might even benefit from delaying the outer horns a few milliseconds from the inner – which has the pseudo-effect of positioning my horns on a convex wall – and specifically NOT a concave wall.

Two outer 15Hz horns delayed by 5 milliseconds, or 1.5 wavelengths at 300Hz.

Attachments

Anyone reading your thread can, and possibly will, issue random sound nuisance complaints that will hobble your horn project from anywhere on the globe.

"Google maps" is really a fun diversion, you can see where your Mini Nuke project (oops, that was the project you were designing for free for me) will be built.

With the generous information you have shared, the GPS positions of your ultimate construction location are both "locked and loaded".

The term "locked and loaded" always seemed "goofy" to me, could you perhaps elucidate me as to their meaning when down in the "Yellow Submarine"?

Oh- I forgot to apologize again for my "shame-full" behavior. Sorry.

Good luck-

Have fun.

Cheers,

Art

What aspect of my horn project has struck a nerve? You keep razzing me about nuclear power – why? Do you think I’m being untruthful about my profession? Do you suspect that I think less of your chosen profession? Now you are razzing me for being a Submarine veteran. Is it that you dislike veterans, or do you simply dislike me? You don’t even know me??? I find it hard to believe that all your negativity on this thread is simply because I will not PAY you for design input on a “DYI website” - but maybe it really is that simple. . .

The good news - I have obtained a “basic” understanding of bass horn design. I’ve also identified additional engineering references on the subject of horn design, and outdoor sound reinforcement in general (I’ve got a lot more reading to do – as the data is coming in fast). I’ve also identified sources for purchasing required digital delays, and digital crossovers. I’m pretty happy with diyaudio thus far (and still actively trying to soak up the knowledge). Strike that - I'm VERY happy with diyaudio - this is a great website.

But one last thing weltersys - the chain reaction you posted on thread #934 is the natural decay of U235. You’ll be quite disappointed if you attempt to boil water and drive steam turbines with that process. You’d have much better results introducing a slow moving neutron, and actually splitting the atom. (I’m not sure if you were testing my knowledge, of if you just didn’t know? Like most of your jabs, I wasn’t going to respond - but for some reason this one was really eating at me. .. . )

Two outer 15Hz horns delayed by 5 milliseconds, or 1.5 wavelengths at 300Hz.

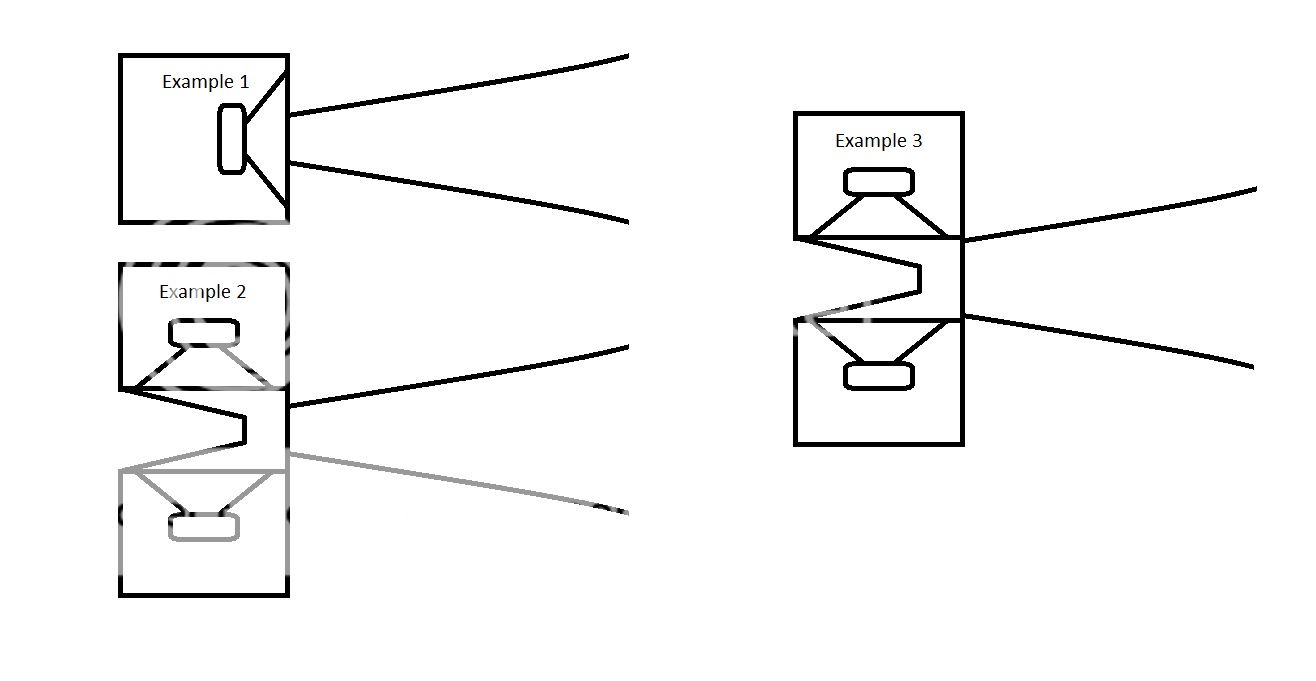

Dave, I am willing to accept some comb-filtering in exchange for obtaining four side-by-side bass horns. There will be significantly less driver clutter in the horn throats, and I’ll have my “true stereo” sound – even if I can’t hear stereo below 80 Hz. . . . And having the ability to introduce delay on the outer horns is simply icing on the cake. It will be a lot of fun to tinker with this system – to find the optimum crossover frequencies, the optimum delay settings, and the optimum main positions. (This will be an all horn system).

As others have pointed out, I do have neighbors to the South (we live in a neighborhood of 5-acre lots, surrounded by state land.) I like the idea of obtaining chest-pounding bass for throwing the occasional party, however the reality is that my system will very rarely operate at chest-pounding levels - so rarely in fact, that it's not a design requirement.

This is why my first driver iteration will be a traditional horn approach – to install a single 12” accordion surround driver into each horn throat (high BL, low Qts, low MMS, and high Xmax), and see how they sound. The plan is to turn phase plugs on the lathe (for various compression ratios), to see what combination sounds best. If I find that I need more drivers, then so be it. But if just (qty 4) 12” drivers sound simply fabulous, and go loud enough for backyard listening (which they very well might) – then that’s all I’m going to run . . .

Again, I really appreciate the hornresp software. It has been an invaluable tool in my learning process.

Last edited:

I still wish you would stop calling them that. Not that it matters, everyone knows what you are talking about at this point, but nothing about these horns is 1/4 space.

What you are thinking about building is a lot more like a single horn subdivided into 4 modular units and used in half space. Or if you want you could call it two horns subdivided into four modular units used in half space. Or you could even call it four horns used in half space.

But nowhere does 1/4 space enter the description of these horns. You are not designing them for use in 1/4 space and you are not going to use them in 1/4 space.

Each horn has a cutoff frequency of 15Hz and a mouth area of 8' x 14' or 104051.4 sq cm, meaning that Cir = 1 if the horn was to radiate into 1/4 space. It is therefore probably not unreasonable to describe the modules as "1/4-space full size 15 Hz exponential horns" since they comply with the rules generally applied when designing a full size exponential horn for use in quarter space.

The four exponential horns combined will have a cutoff frequency of 15Hz, and the overall mouth size will be such that Cir = 1 if the horn was to radiate into free space. For this reason it is therefore probably not unreasonable to describe the four-horn array as "essentially ... a single full-space 15 Hz horn".

The proposed design is "no-compromise" in that radiation into free space is assumed. Because in reality the horn array is not going to be suspended high above an open field facing skywards, I suspect that the mouth areas could be safely halved without unduly affecting bass response. The mouth size would still be such that Cir = 1 for half space radiation, which is a reasonable assumption to make given that the horns will actually be sitting on a ground plane.

Attachments

The proposed design is "no-compromise" in that radiation into free space is assumed. Because in reality the horn array is not going to be suspended high above an open field facing skywards, I suspect that the mouth areas could be safely halved without unduly affecting bass response. The mouth size would still be such that Cir = 1 for half space radiation, which is a reasonable assumption to make given that the horns will actually be sitting on a ground plane.

I actually put some thought into this, and I managed to convince myself that I needed a half-space horn for each stereo channel. . . .

My thinking was that if I built (qty 4) 1/8 space horns, that the individual stereo channels would be too small - where only mono signals would be properly loaded into half-space.

Last edited:

Some Considerations

Sub-Base Horn

To marry structural and acoustical requirement of a horn with a decade pass-band of 15-150 Hz. would be best served by an arch form cross-section for the reasons stated in [1]. In this frequency region, issues of directionally and pattern control are negligible. Longitudinally horn flare should follow Salmon's formula with a shape factor [M]<1.0 set to match the drivers selected, with an [Fc] and overall dimensions set to match 15 Hz high pass point.

Due to the wide expanse of this unit, recommend use of three drivers radially dispersed at the throat in the horizontal plane. At the upper bound these will be driven by left, right and center channel signals. A short feed horn for each driver will be used for reasons to be addressed in a later post.

Satellite Horns

Due to anechoic character of the listening space (outdoors), recommend five satellite horn units be placed, unanchored on concrete pads so that unit position and toe-in may be adjusted. See reference [2] for an example of these. The extra two units will be used for ambiance simulation of performances recorded in enclosed spaces.

Site Plan

If there is a further interest, recommend a site plan for the listening space be addressed first, so that system throw and coverage requirements can be determined and quantified.

Regards,

WHG

References:

[2] retro vintage modern hi-fi: Ton And A AQuarter Of Sound - Audio 1964

I’m going to build (qty 4) 1/4-space full size 15 Hz exponential horns – each with an 8 foot wide & 14 foot tall mouth. The left two horns will combine as a half-space stereo channel, and the right two horns for the right. Assuming most bass is recorded mono, I will essentially have a single full-space 15 Hz horn (with the ability to reproduce stereo, if needed – depending on my final crossover point. . .. )

If I cast my horns 10” thick on all sides, I’ll need roughly 17 yards of concrete per horn (not including the foundation abutments). Concrete is about 150 pounds per cubic foot, making my horns weigh 68,850 pounds each (just in concrete). Assuming I’ll use a moderate level of steel reinforcement, add 6 pounds per cubic foot for the rebar, or 2750 pounds per horn. All four horns combined will weigh about 286,420 pounds, or 143 tons (less the foundation abutment). This will cost about 8 grand in concrete (assuming around 110 bucks/yard), and 3.3 grand in rebar. The wall, and the horn foundation abutments will easily increase the amount of concrete & rebar by 50%. . . The big unknown is the forms. To be cost effective, I need to build just one set of forms, and use them four times. . . .

Some unresolved design issues are: mid-bass/mid-range horn design, and more importantly mid-bass/mid-range horn placement - i.e. place them to the sides of the bass horns, above the horns, or inside the horns. . . .

Sub-Base Horn

To marry structural and acoustical requirement of a horn with a decade pass-band of 15-150 Hz. would be best served by an arch form cross-section for the reasons stated in [1]. In this frequency region, issues of directionally and pattern control are negligible. Longitudinally horn flare should follow Salmon's formula with a shape factor [M]<1.0 set to match the drivers selected, with an [Fc] and overall dimensions set to match 15 Hz high pass point.

Due to the wide expanse of this unit, recommend use of three drivers radially dispersed at the throat in the horizontal plane. At the upper bound these will be driven by left, right and center channel signals. A short feed horn for each driver will be used for reasons to be addressed in a later post.

Satellite Horns

Due to anechoic character of the listening space (outdoors), recommend five satellite horn units be placed, unanchored on concrete pads so that unit position and toe-in may be adjusted. See reference [2] for an example of these. The extra two units will be used for ambiance simulation of performances recorded in enclosed spaces.

Site Plan

If there is a further interest, recommend a site plan for the listening space be addressed first, so that system throw and coverage requirements can be determined and quantified.

Regards,

WHG

References:

[2] retro vintage modern hi-fi: Ton And A AQuarter Of Sound - Audio 1964

Attachments

Last edited:

The big unknown is the County permitting office. They are the only folks with the power to shut down my horn project before it starts. I'm anticipating that the county will ultimately issue my construction permit - with a very firm warning not to draw any sound nuisance complaints. . . .

Best of luck here.

My experience is you invariably run into more process /departments than anticipated, when a project doesn't fit neatly into what's allowed in the Municipal Code.

And the day a single neighbor goes in to the County to "express concern", I'd brace for special-use public hearings....at least that's how it went in rural VA..

The County's permit/approval problem is that they don't really have the authority to make a deal, as in "we'll give you the permit if you promise to keep it down".

They can't really make any kind of legitimate warning....they can only point to regs on the books.

So I'd expect a boatload of CYA and stalling from them...

Thanks for the link. When you say arch form, do you literally mean a horn mouth similar in shape to the St. Louis Gateway Arch - where the ground-plane itself would be an integral surface of the horn? This idea was mentioned before in this thread.Sub-Base Horn

To marry structural and acoustical requirement of a horn with a decade pass-band of 15-150 Hz. would be best served by an arch form cross-section for the reasons stated in [1]. In this frequency region, issues of directionally and pattern control are negligible. Longitudinally horn flare should follow Salmon's formula with a shape factor [M]<1.0 set to match the drivers selected, with an [Fc] and overall dimensions set to match 15 Hz high pass point.

Due to the wide expanse of this unit, recommend use of three drivers radially dispersed at the throat in the horizontal plane. At the upper bound these will be driven by left, right and center channel signals. A short feed horn for each driver will be used for reasons to be addressed in a later post.

There's a significant problem in making an arch shaped exponential horn (a construction limitation of mine). The concrete forms are going to be primarily plywood construction (with steel snap-ties, and external wooden reinforcement bracing). And here's the problem: I can only "shape" my plywood forms by bending the wood about a single axis. I.E. I could achieve a bend in the X-Y plane to form the arch, but if I attempted to achieve a bend in the X-Z plane also - to form the exponential expansion profile - my plywood would undergo excessive deformation & fail (i.e. bending a sold surface in two planes requires planar plastic-deformation of the surface). If I had a steam oven, some large steel dies, and an industrial press, I could form the plywood into complex shapes required for casing an exponential arch horn - but I do not. I chose the rectangle horn shape for several reasons - but mainly because I can easily achieve the exponential curvature along all four horn walls, by simply bending the plywood about a single axis, then trimming the edges to achieve the desired cross-sectional width. Vertical horn walls (although curved about the horn’s center axis) are easily tied into the foundation abutment (footer), and are therefore are well suited for supporting the top wall of the horn - which is essentially a reinforced load-bearing slab (in bending-tension) simply supported on ends. The horns are large enough for kids to enter and play inside, thus a formal engineering analysis of the structure per ACI-318, will likely be required by the county.

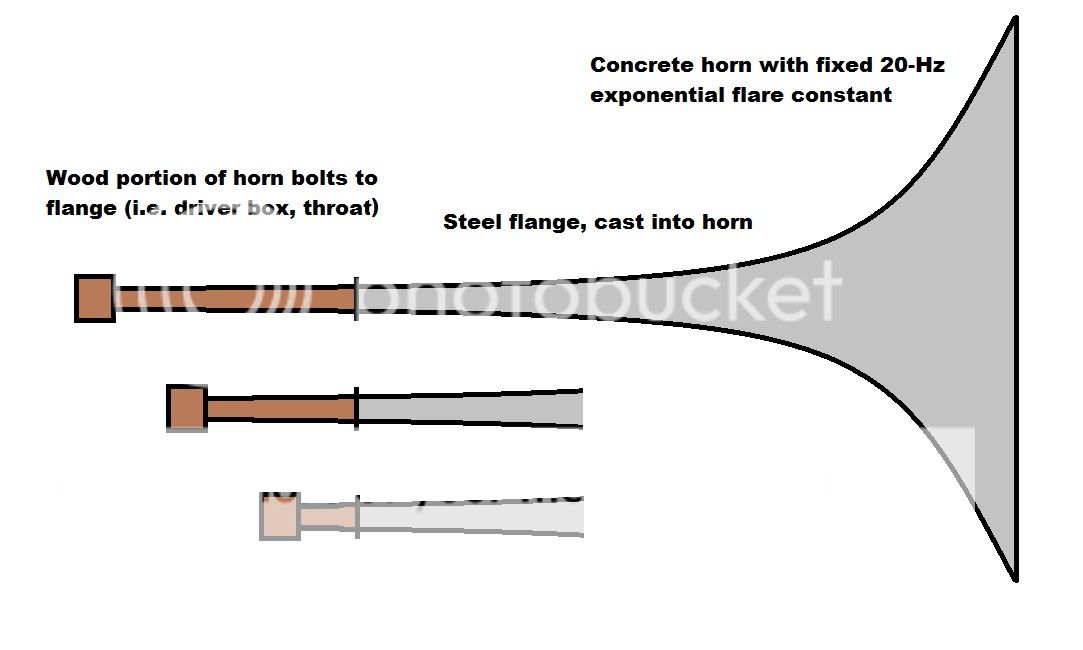

Can you please further explain your recommendation for three drivers, radially dispersed at the throat in the horizontal plane? Perhaps provide a sketch? And maybe a sketch for the arch horn too? Below is my current design plan (my sketch is not to scale). I am going to cast a 304L stainless steel flange into each horn, creating an oversized throat (or at least the largest throat I anticipate that I'd ever need). This way I can construct wooden enclosures to try various driver/design iterations - e.g. one driver with low compression ratio, one driver with high compression ratio, multiple drivers, big drivers, little drivers, etc. The steel flange will permit me to make design changes without taking a jackhammer to my horns, and recasting concrete. . . .

Below are some sketches for some early conceptual questions I had. This is where my idea for a steel flange joint originated. . . .

Hi Entropy.

I know you're kind of ignoring my posts but can you not form a 1/2 round horn by using a tube roller to form steel semi circles the required radius and mount them in the ground (I'd use the galvanised electric conduit tube here in the UK - 3/4" 1.2mm wall). Then cover with a fine steel mesh (small chicken wire fence material) and render with a thin concrete covering. Then add your rebar etc and the heavy duty concrete covering. I'm not really a concrete kind of guy but that's how I'd do it if I wanted round horns.

I know you're kind of ignoring my posts but can you not form a 1/2 round horn by using a tube roller to form steel semi circles the required radius and mount them in the ground (I'd use the galvanised electric conduit tube here in the UK - 3/4" 1.2mm wall). Then cover with a fine steel mesh (small chicken wire fence material) and render with a thin concrete covering. Then add your rebar etc and the heavy duty concrete covering. I'm not really a concrete kind of guy but that's how I'd do it if I wanted round horns.

Best of luck here.

My experience is you invariably run into more process /departments than anticipated, when a project doesn't fit neatly into what's allowed in the Municipal Code.

And the day a single neighbor goes in to the County to "express concern", I'd brace for special-use public hearings....at least that's how it went in rural VA..

The County's permit/approval problem is that they don't really have the authority to make a deal, as in "we'll give you the permit if you promise to keep it down".

They can't really make any kind of legitimate warning....they can only point to regs on the books.

So I'd expect a boatload of CYA and stalling from them...

I am miles from town, with hundreds of acres of state land in between. Nonetheless, I know exactly what you are talking about. When I pulled my garage permit (for my 40' x 60' shop, with 16' ceilings), the permit clerk was trying to strong-arm me into building a smaller shop - she literally said to me "why do you need such a big garage?" Wow did that spin me up. . . .

The county regulations are pretty clear. I will take the approach that my horns are inanimate objects - no different than artwork. The county will absolutely require they be structurally safe, and pass a site-specific design review (for storm water management, property setbacks, environmental impacts, etc). I will make the argument that just because I can play music through them, doesn't necessarily mean that the horns will be too loud. Every stereo has a volume control. We shall see what happens. I anticipate that the county permitting staff will have much difficulty in differentiating between large horns, and loud horns. But I am a patient person nonetheless - one who happens to be familiar with the County building codes also. Thus we shall see. . . .

I might be able to obtain a special-purpose permit, which is basically the county saying - we don't want to let you build your outdoor horns, but if you pay us a few thousand dollars for your permit, in lieu of a few hundred, we'll give your project "special" consideration. . . .

Hi Entropy.

I know you're kind of ignoring my posts but can you not form a 1/2 round horn by using a tube roller to form steel semi circles the required radius and mount them in the ground (I'd use the galvanised electric conduit tube here in the UK - 3/4" 1.2mm wall). Then cover with a fine steel mesh (small chicken wire fence material) and render with a thin concrete covering. Then add your rebar etc and the heavy duty concrete covering. I'm not really a concrete kind of guy but that's how I'd do it if I wanted round horns.

I apologize for not responding to your post. We are almost up to 1000 posts on this thread, and if I responded to every one, we'd be nearing 2000.

I had considered using shotcrete (a sprayed on concrete). The problem is that shotcrete doesn't take well to overhead spraying - which means I'd need to spray the top of the horns from above - where I'm back to making forms.

Due to the size of my horns, and the fact I'm in a Class-II earthquake zone, I need thick concrete, that is well reinforced throughout with steel rebar. Fine steel mesh is not going to make the cut. I am going to backfill earth over my horns, which means someone might park a car on top of them.

Edit - - - scratch everting I just posted above. You are talking about making the forms. I need to give this idea some thought. The advantage is that I could obtain complex shapes. The disadvantage is that I'd need to make (qty 4) one-off forms, as the forms would become part of the horns. This is not a traditional way to make forms for casting concrete. I need to think about this. . . .

Last edited:

Eric,1)Some unresolved design issues are: mid-bass/mid-range horn design, and more importantly mid-bass/mid-range horn placement - i.e. place them to the sides of the bass horns, above the horns, or inside the horns. . . .

2)What aspect of my horn project has struck a nerve?

3)You keep razzing me about nuclear power – why? Do you think I’m being untruthful about my profession?

4)Do you suspect that I think less of your chosen profession? Now you are razzing me for being a Submarine veteran. Is it that you dislike veterans, or do you simply dislike me? You don’t even know me???

5)I find it hard to believe that all your negativity on this thread is simply because I will not PAY you for design input on a “DYI website” - but maybe it really is that simple. . .

6)The good news - I have obtained a “basic” understanding of bass horn design.

7)But one last thing weltersys - the chain reaction you posted on thread #934 is the natural decay of U235. (I’m not sure if you were testing my knowledge, of if you just didn’t know? Like most of your jabs, I wasn’t going to respond - but for some reason this one was really eating at me. .. . )

1) Your unresolved design issues encompass seven of the ten octaves of music, and are far more difficult to resolve than the bass portion of the system. For a sound system to work well, it needs to be designed as a system from the ground up, not a selection of parts.

2) Having started my audio career as a direct result of hearing a large bass horn playing live music from a distance where neither the stage nor the horn could be seen, your "horn project" struck a nerve in my memory banks, bringing back a time when I first started learning about bass and high frequency horns from Mike Justin that summer day in 1970. Watching your "progress" is like going back in time 46 years.

3) I have not "razzed" you about nuclear power, like you are doing here, I am simply looking for you to "bring me up to speed" on my backyard "project".

4) I don't know what you think of those of us that have been designing speaker systems and mixing live bands in concert venues and recording studios for more than four decades. I respect veterans of all wars, regardless of what branch of the service they chose. Of all the different branches, my gut feeling is the submariner has the most courage.

You are right, I don't know you, other than a few bits of "design work" you have come up with after a few hours with Hornresp and photos of you on the bridge.

5) My negativity has been focused on a troll. Your lack of attention to the details I have given you is an annoyance, but I don't post for the benefit of just one person.

As I have already spent around 40 hours answering your questions in great detail and defending myself against out of context trolling, it should be obvious to anyone with two firing synapses that I ain't in it for the money.

6) Your knowledge appears to be at the level mine was in 1970, after I spent hours carefully listening to the answers to my questions about horns and sound systems, and the blues. Mike Justin was able to answer all my questions that day. Later, he could no longer answer my more detailed questions, so I had to search out the answers from hundreds of often conflicting sources. I have continued to devote many hours a day pursuing the answers to questions you may never ask, because you think your “basic” understanding of bass horn design some how will make it possible for you to design a well-integrated sound system.

7) I assume by your resume your knowledge of nuclear reactors is far greater than mine, which is why I feel so fortunate that you will freely give it. I don't really want to spend all the time needed to learn how to design the Mini Nuke myself, which is why I hope you will do it for me.

If I have to learn on my own, you may finish your system design before mine will be "on line".

I guess my request for your knowledge of nuclear energy may have struck a similar nerve in your memory banks as your horn "beamed" in mine.

Cheers,

Art

Outside the Box

Yes! But more to the proportions shown in sketch posted earlier. Your first pour will be easy, it is nothing more than a monolithic slab. For the next of several see some options here: https://www.youtube.com/watch?v=z_eXVgiU6ws

I need to see a site plan. In any event more later.

Regards,

WHG

Thanks for the link. When you say arch form, do you literally mean a horn mouth similar in shape to the St. Louis Gateway Arch - where the ground-plane itself would be an integral surface of the horn? This idea was mentioned before in this thread.

>snip<

Yes! But more to the proportions shown in sketch posted earlier. Your first pour will be easy, it is nothing more than a monolithic slab. For the next of several see some options here: https://www.youtube.com/watch?v=z_eXVgiU6ws

I need to see a site plan. In any event more later.

Regards,

WHG

Last edited:

What "this" is remains an unanswered question.Only thing I have to add.

Given the property and the resources, I would have to do this.

I have little doubt Eric has the competence in his field to construct anything from "this" Mini Nuke or a sound system made from concrete, steel, aluminum paper, plastic and neodymium.

What is thus far completely lacking in this "project" is any semblance of an integrated sound system design. This project is unusual in that regard, as most would not consider spending the resources Entropy Eric plans to lavish about without a cogent plan.

Eventually, Eric may actually define the audio goals he desires to meet, so far he has only shared aesthetic considerations, and a few sketches with demonstrably negative implications in each, including the one he said I "inspired".

Takes all kinds to make the "world go round" to post 999

Cheers,

Art

Erratum:Eric,

2) Having started my audio career as a direct result of hearing a large bass horn playing live music from a distance where neither the stage nor the horn could be seen, your "horn project" struck a nerve in my memory banks, bringing back a time when I first started learning about bass and high frequency horns from Mike Justin that summer day in 1970. Watching your "progress" is like going back in time 46 years.

The above should have read:

Having started my audio career as a direct result of hearing a bi-amplified two-way stereo system with two 2x15" bass horns each with a vertically mounted EV 8HD diffraction horn with a phenolic diaphragm 1" screw on driver and a blown EV T-35 tweeter mounted on the bass horn's central stiffener brace. The system had a peak power of around 2000 watts of Phase Linear amplification. The "Cruncher" bass enclosures were a Steve Hall design commissioned for Mike Justin's sound company, then called Common Ground, also the name of Mike's record/Hi Fi/PA store. Mike had commissioned a young Mark "Wingo" Winger to design and build the sound system's 1kHz stereo active crossover and mixing console, which had no more than 12 channels.

The Common Ground system, placed directly on the grass either side of stage, "toed in" to the central mix location around 50' from stage could clearly be heard playing stereo recorded music of Hound Dog Taylor's fellow "Alligator Records" label playing on a Webcor Regent two track tape machine from approximately 1/2 mile (one kilometer) distance, where neither the stage nor the sound system could be seen. The sound just seemed to get a little bit louder as I made the walk across the Mississippi bridge to the river flat area where the live concert featuring Hound Dog Taylor took place.

Your (Entropy Eric's) "horn project" struck a nerve in my memory banks, bringing back a time when I first started learning about bass and high frequency horns from Mike Justin that summer day in 1970. Watching your "progress" is like going back in time 46 years.

Sorry for the omission of some information relevant to the OP's questions.

Astounding that at 1000 posts, the OP has not done a single measurement or listening test.

The Keystone Sub horn thread, with only 38 less posts dating from March of 2011 had links and more data in the first page than the OP has read in 1000 posts in this "Concrete Bass Horn Design Question" thread.

Nothing attracts a crowd like a crowd does ;^).

Cheers,

Art

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question