Just be aware that if you do use more than one full size horn, you are going to have lobing issues (depending on how directional the horns are at the top of the passband). Your horns (however many you have) should all be within 1/4 wavelength at the top of the passband, that's center of mouth to center of mouth distance. Assuming you use the horns up to 100 hz, a quarter wavelength of 100 hz is 2.8 feet. That means the centers of your horn mouths should ideally be no more than 2.8 feet apart, to ensure full mutual coupling and to eliminate lobing issues.

Since your horn mouth is several times larger than 2.8 feet, putting these together so the horn mouth center to center distance is 2.8 feet is obviously physically impossible.

Now this all depends on how directional the horn is at higher frequencies, how high you intend to use it, where the "audience" will be located, how much destructive interference is considered acceptable and a few other things, but it's definitely something to consider.

On the other hand, if they are extremely directional and you put them far apart, they might not interfere destructively at all, but they won't constructively sum to their full potential over the full passband either.

This center to center issue also applies to where you put the mains as well, I suppose ideally they should be located right in the horn mouth for best results, like a big coaxial speaker.

Since your horn mouth is several times larger than 2.8 feet, putting these together so the horn mouth center to center distance is 2.8 feet is obviously physically impossible.

Now this all depends on how directional the horn is at higher frequencies, how high you intend to use it, where the "audience" will be located, how much destructive interference is considered acceptable and a few other things, but it's definitely something to consider.

On the other hand, if they are extremely directional and you put them far apart, they might not interfere destructively at all, but they won't constructively sum to their full potential over the full passband either.

This center to center issue also applies to where you put the mains as well, I suppose ideally they should be located right in the horn mouth for best results, like a big coaxial speaker.

Last edited:

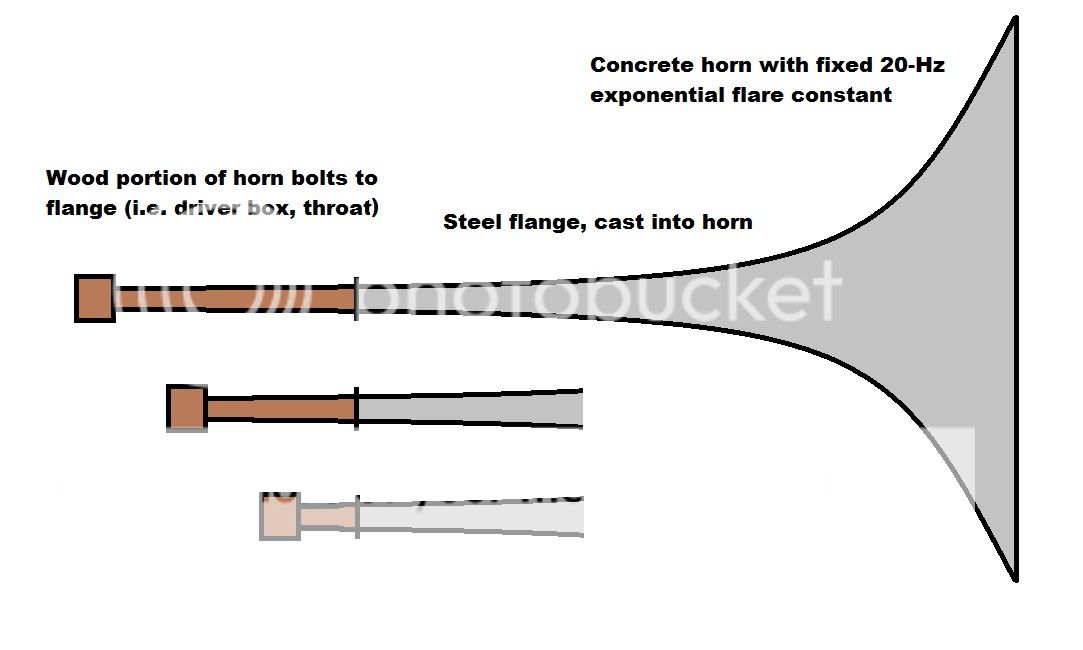

I'm pretty set on building a pair outdoor full-size, no-compromise, 20 Hz concrete horns.

That being said - I'm not sure that I need the ability to knock birds from the sky while playing Primus. i.e. twenty 18s per horn "might" be a little over-the-top, even for me just-a-guy - which is saying a lot (trust me) . . . I'm more interested in achieving high-fidelity with this project, than I am achieving punishing levels of SPL. Thus if a single 12" driver is expected to sound best within a 120,000 pound, 20 foot diameter mouth, straight exponential concrete horn, then that's exactly what I intend to build - two of them. . . . And think of how much money I'll save on drivers. . . .

I have another question that I'm pondering - which I'll ask in a few hours. . . .

That being said - I'm not sure that I need the ability to knock birds from the sky while playing Primus. i.e. twenty 18s per horn "might" be a little over-the-top, even for me just-a-guy - which is saying a lot (trust me) . . . I'm more interested in achieving high-fidelity with this project, than I am achieving punishing levels of SPL. Thus if a single 12" driver is expected to sound best within a 120,000 pound, 20 foot diameter mouth, straight exponential concrete horn, then that's exactly what I intend to build - two of them. . . . And think of how much money I'll save on drivers. . . .

I have another question that I'm pondering - which I'll ask in a few hours. . . .

Wreckingball,

"Barn doors", regardless of the material the OP ultimately decides to go with, could reduce his capital expenditures and work by 50% for the same output level in front of the system, while reducing unwanted rear radiation.

Art

That's one of the reasons I think shipping containers would make good shells to build horns into. Doors = horn extensions.

Your idea of shipping containers is a good one, however I live just a little too close to the prissy Seattle folks - where shipping containers have been deemed an eyesore (even for guys like me living way out in the woods, where the containers would only be visible from above. . . .)

How unfortunate. If you have to consider aesthetics / zoning, would a concrete horn also be considered an eyesore? Would you simply use your excavator to build a hill over the finished horns (like a hobbit house)? What hoops will you have to jump through, with respect to permits and such?

I have an acreage myself (Victoria, Australia) and want to get a container delivered next summer. It would initially be for storage / workshop use, but I was - of course - also considering how I might use it to house a music source. In my case (agricultural zoning), having a container is OK, but it requires what seems like a retarded amount of red tape. It:

- should be for agricultural use (which seems legit)

- needs a building permit (despite being a preconstructed monocoque, not a building, and most aspects of the permit being irrelevant)

- must be on secure footings (because, uh, it might blow away in strong winds? ...but the same container in a freight yard will not?)

Attachments

1) As JAG points out with a 100Hz crossover, since the horn mouth is several times larger than 2.8 feet, putting these together so the horn mouth center to center distance is 2.8 feet is obviously physically impossible.1)I'm pretty set on building a pair outdoor full-size, no-compromise, 20 Hz concrete horns.

2)That being said - I'm not sure that I need the ability to knock birds from the sky while playing Primus. i.e. twenty 18s per horn "might" be a little over-the-top, even for me just-a-guy - which is saying a lot (trust me) . . .

3)I'm more interested in achieving high-fidelity with this project, than I am achieving punishing levels of SPL. Thus if a single 12" driver is expected to sound best within a 120,000 pound, 20 foot diameter mouth, straight exponential concrete horn, then that's exactly what I intend to build - two of them. . . .

4)And think of how much money I'll save on drivers. . . .

A 20Hz horn will be nearly omni directional at the lower portion of it's pass band, but fairly directional at the top- probably less than 90 degree 6 dB down points, even if folded.

As JAG also mentioned, the pair of horns won't constructively sum over the full passband either, other than down the center, AKA "power alley". Other than the fairly narrow "power alley", all other listening areas will have a series of peaks and nulls dependent on the distance you choose to separate your pair of sixty ton horns.

Elevating 120 tons of horns will prove to be difficult even if you can afford the structure and the permits.

Putting the horns on the ground insures they will be too loud compared to the top cabinets when in the near field, unless you also put the top cabinets near ground level, in which case their sound will also be too loud in the near field compared to at distance, and ground bounce will make their frequency response uneven with distance.

2) Mike Justin, the original owner of Eclipse Concert Systems, one of my business partners 1977-78, was stationed on an island where the military tested a re-entrant (folded) horn over 20 foot long, the path length would be near 60 foot. The exit was around 8 feet (or whatever width military trucks were in the 1950s) in diameter, and the truck was so heavy it left permanent indentations in the asphalt road. The truck carried what looked to Mike to be tons of tube amplifiers, though probably far less output power than the 12.4 pound 6000 watt amps I now use.

Before the test, Mike and his platoon were instructed to go into an underground concrete bomb shelter until some designated time. The sound of the tests, with fingers in their ears, well below the surface, in an A-Bomb proof structure, was nearly unbearable to guys used to pumping off rounds from 45 pistols and heavy armament.

At the designated time, they came out to an eery silence, after a bit of scouting, the reason for the silence was obvious, all the birds lay dead on the ground.

I have looked for any documentation of the horn weapon, but have not found any. Obviously, friendly troops could not be in the vicinity without being deafened, and though deaf enemies are less effective fighters, they can still kill. The military probably just scrapped the project, and locked up the documentation in some long- forgotten file wasteland.

3) To help, you need to define what you mean by "sounds best", as there are many that would argue the merits of infinite baffle over horns, and there are many metrics in "high-fidelity" that you need to decide what weighting to give each.

In my opinion, the even distribution of accurate sound reproduction over the entire designated listening area is of prime importance, but would be incredibly expensive using 120 tons of horns. Since you don't desire punishing SPL, a system of far less weight could be built and elevated, using ferro-cement boat technology, if you are insistent on that material.

Aesthetically, I understand why you would want to use a material that can be easily surpassed for a fraction of the cost and build difficulty by an off-the-shelf weatherproof product, but from a "high-fidelity" standpoint you have little to gain, and eliminate any options for different configurations- a dance party could be served by subs around the perimeter, certain genres would be best served by a mono sub location, stereo and surround sound better served by 2 or 3, etc.

4) At least your sense of humor is intact!

Cheers,

Art

I'm pretty set on building a pair outdoor full-size, no-compromise, 20 Hz concrete horns.

This I know, from both threads you started.

That being said - I'm not sure that I need the ability to knock birds from the sky while playing Primus.

At this point, before hearing your horn(s), I don't think you can make that statement - at least I would advise against it.

Why does bass usually sound loud? Usually it's because it's chock full of distortion and the room wreaks havoc with the frequency response so you have an incredible boom at some frequencies.

So is your horn going to sound loud? I would think not. Extraordinarily low distortion, no room boom, nothing but pure bass. Even if you can muster up 120 db at your listening position, I think you will want a lot more than that. 120 db won't sound loud if it's clean. You won't even notice that it is loud until you try to talk to the guy next to you and realize you can't even hear the words coming out of your own mouth.

I think your favorite listening position is going to end up being standing right inside the horn mouth, with full power applied.

Last edited:

I have an acreage myself (Victoria, Australia) and want to get a container delivered next summer. It would initially be for storage / workshop use, but I was - of course - also considering how I might use it to house a music source. In my case (agricultural zoning), having a container is OK, but it requires what seems like a retarded amount of red tape.

I'm zoned agricultural as well, and we have two full size shipping containers on two different properties. I don't think anyone even thought to check the bylaws. Nobody has complained yet. Neither are visible from the road though, so it's unlikely there will be complaints.

I've daydreamed about turning one of them into a sub, but I would never do it. Metal rots, so there's a very short shelf life on a used shipping container if you want it to stay airtight. Maintenance would require lifting it and all kinds of metal work. No thanks. Modular wood cabs are the ticket as far as I'm concerned. At this stage in my life anyway.

Elevating 120 tons of horns will prove to be difficult even if you can afford the structure and the permits.

I love a challenge. If elevating the horns is what’s required, then I’ll simply install footers, and support the horns on a few pairs of reinforced concrete columns (similar bridge supports).

Question: if I elevate the horns, am I still considered half-space, or is it considered a full-space loading application??? The difference between full-space and half-space horns will have a significant impact in the overall weight of the structure being elevated. And how high are we talking??? I might be able to simply move earth, build a tall retaining wall, then build my horns on the ground above & behind the wall (providing the elevation effect).

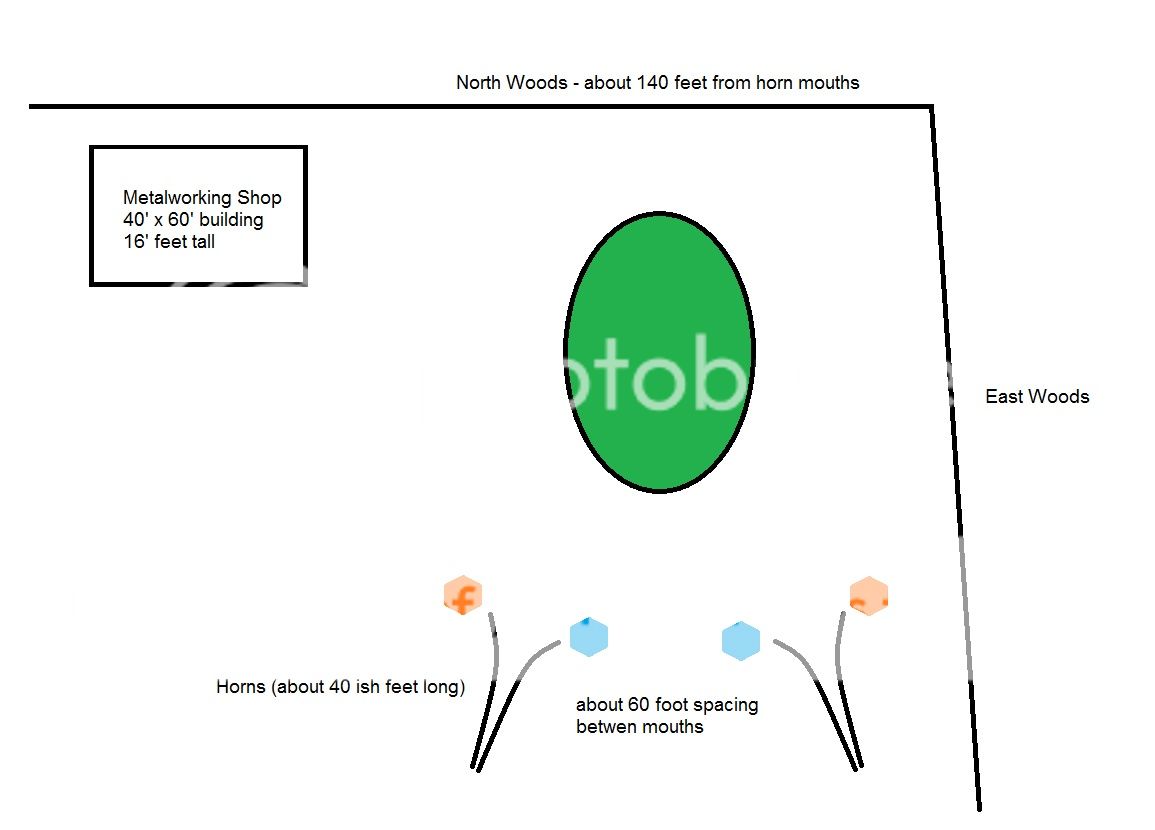

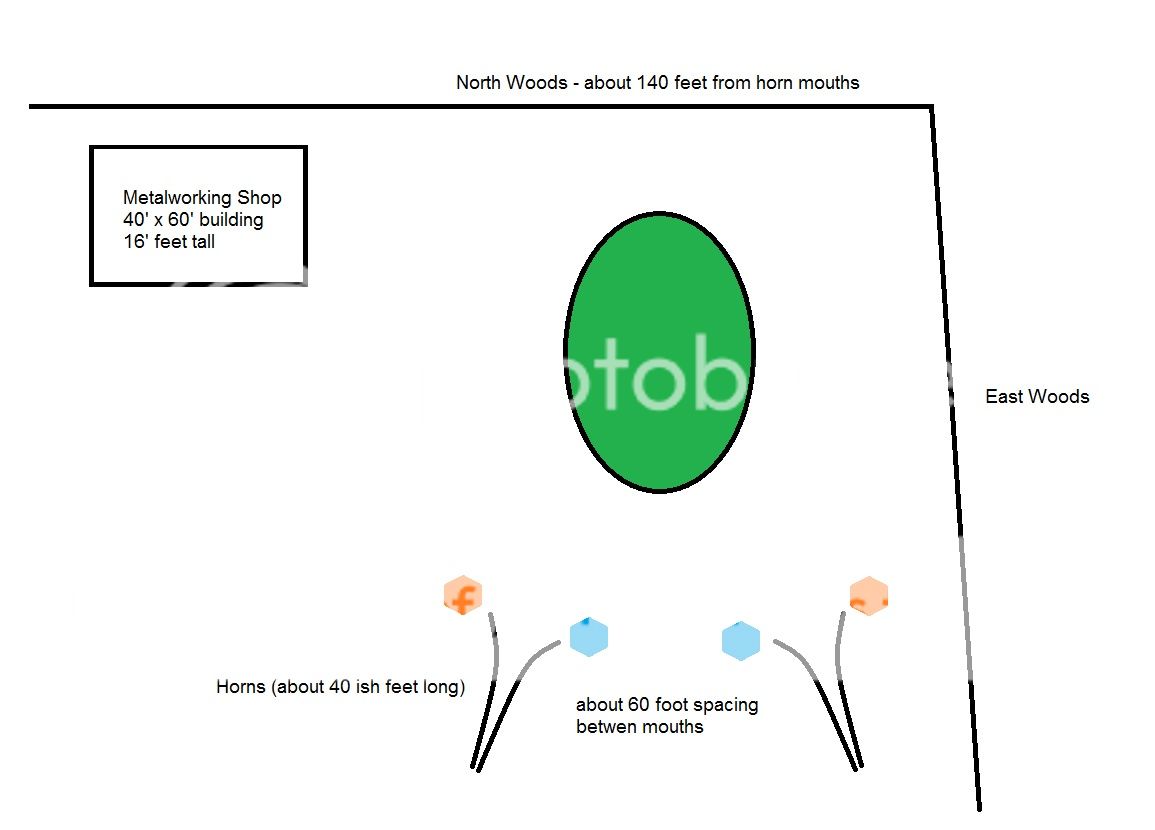

Below is my proposed horn layout (remember that nothing is finalized). The ground is generally flat, with a slight decrease in elevation towards the eastern tree line. My presumed listening area would be somewhere in green. I’m not sure where to put the mid & high horns. I’m thinking either at the locations marked in orange, or at locations marked in blue. Using simple vectors, I’m thinking the orange location would push the ideal listening area to the north side of the green circle. And the blue would shift it to the south side.

I’m hoping that my shop building is far enough away, and oriented in such a fashion, so that it does not acoustically interfere with my listening environment.

I’ve got a 20 ton dozer, so moving Earth his not a problem. However the county will get upset if I move more than 150 cubic yards without a permit. . . Note that a permit is on the table if needed. I could also theoretically build the horns and burry everything south of the mouths under dirt. . . It would remove much of the eyesore. We are technically not permitted to construct underground dwellings. However seeing as these horns are not dwellings (or even intended to be occupied) I’m sure the county would permit me to bury them – if I so desired.

Even if you can muster up 120 db at your listening position, I think you will want a lot more than that.

Yet again, I'm in full agreement. I'm still leaning towards (qty 5) 12" drivers per horn. If I build my horns with wooden rears, I can run a single 12 (extend the length & reduce the throat), or I can run a single 18, or I can make the throat large, and run several drivers. I want to be able to try different driver configurations - to see what sounds best - without having to take a jackhammer to my concrete. . . .

I’ve accepted the whole half-space loading phenomena (thank you for being patient with me during my painful learning process).

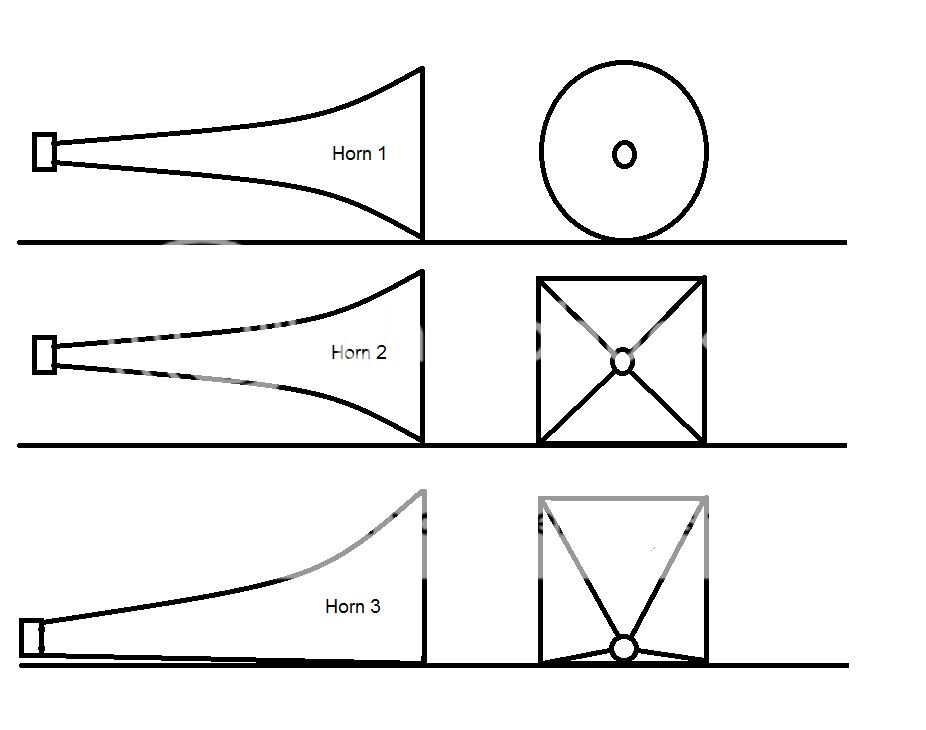

Question: how does one maximize the effects of half-space loading with their bass horn? Which horn above is most effective at half-space loading? Is there a significant difference between the three?

Note: my plan is to construct octagon bass-horns, oriented similar to the Horn 1 configuration (unless weltersys talks me into elevating my horns. . .)

Question: if I elevate the horns, am I still considered half-space, or is it considered a full-space loading application???

Depends how high you elevate and the wavelength of the frequency you are talking about.

I wouldn't entertain the notion of lifting the horn though - assuming you are bound to make it out of concrete, I would make it hemispherical (half a round axisymmetric horn) placed flat on the ground.

Your audience position in green isn't that large, it's well under 100 feet from front to back of the audience, so you won't have near field vs far field problems, everyone is standing in a relative small spot in the field.

Also, since your entire green audience position is only a few degrees wide relative to the horns, you probably won't have a lot of problems with lobing inside the audience area. Outside the audience area though, will be a nightmare, as you have the horns 60 feet apart center to center.

If you point the horns directly at the middle of the green patch and nobody wanders too far from center in the green patch, you will probably be ok as far as lobing even at higher frequencies.

Lobing issues are related to the triangulated distances from two sound sources playing the same frequency and a listener. As long as the two sound sources are an equal distance from the listener you are good. As soon as the triangulation gets lopsided you have problems. Higher frequencies are much more problematic than lower frequencies because you want any two sound sources that play the same frequencies within 1/4 wavelength of each other center to center.

Here's the problem though. If you expect to play music on this system and enjoy it while working near the barn, it's likely going to be a wildly erratic frequency response over there.

And with the two horns 60 feet apart, they are not going to fully mutually couple (constructively sum) at any frequency in the passband. Even at 20 hz the wavelength is 56.5 feet long and your horns are further than a full wavelength apart.

Honestly, if this is for looks and status (like an expensive watch) do what you need to do. But if this is about sound quality including in areas outside the green audience position at times, this is a terrible, horrible, inexcusably wasteful idea.

Now about reflections off the barn. Imagine the barn wall are made of mirrors. If you stand in the green audience position and look at your mirror barn, can you see the horns? if not, there won't be any direct (line of sight) reflections. But since the sound source is close to omni at low frequencies, some sound might bounce off the barn, hit something else, and bounce back at you. But it appears that the bulk of the soundwaves (if not the entirely of the sound) will reflect off the barn in directions away from the audience position.

Last edited:

I’ve accepted the whole half-space loading phenomena (thank you for being patient with me during my painful learning process).

Question: how does one maximize the effects of half-space loading with their bass horn? Which horn above is most effective at half-space loading? Is there a significant difference between the three?

Note: my plan is to construct octagon bass-horns, oriented similar to the Horn 1 configuration (unless weltersys talks me into elevating my horns. . .)

Remember, the concept is to create a half horn and the boundary creates a mirror image. Keeping that in mind, #3 is the best. The only way to make it better would be to make it round, hemispherical) all the way from the throat to the mouth. Basically like an ice cream cone cut in half and set down on a table.

Technically it probably doesn't matter all that much, but since #3 is also resting on the ground over it's entire length, it's also the easiest to build and the strongest (unless you backfill the entire area under your elevated horn body).

Last edited:

But if this is about sound quality including in areas outside the green audience position at times, this is a terrible, horrible, inexcusable idea.

The main purpose of this sound system, is for me to place a hot tub somewhere in the green area (above ground, or perhaps in-ground - haven't decided yet) - to relax in the tub and enjoy some music with my family (reasonable listening levels).

The second purpose of the system is to entertain guests (aka party) assume no more than 100 people (aka elevated listening levels). I have no idea if all 100 people will go out into the green area, and dance. Most of my friends are mechanical engineers, nuclear engineers, and physicists. I'm considered the grease-monkey of the group. Likely there will not be much dancing - unless people bring their teenage kids. . . . I may end up installing a few telephone poles - to hoist up DJ-style lights. The DJ-lights are NOT part of the initial design, and "might" come later.

If I'm anywhere near the shop, I'll be inside it - likely wearing hearing protection and grinding/machining steel. The house is several hundred feet to the South. So really, the only listening area is in the green. Please, feel free to make adjustment/recommendations for the horn layout. The 60 foot spacing was intended to get stereo separation down low. It is necessary, I don't know. . .

Not shown is a small shed that will be between the rear of the horns. The shed will receive a dedicated 240 volt, 200 amp service, and house the electronics (should be more than enough power).

Last edited:

Well... you have to get the power out to the horns... that's a challenge...

Anyhow, why not build with concrete block?

Much cheaper, easier, and faster. Remember you need to build very serious forms

to do standard concrete, plus reybar for reinforcement!

Again, before you commit the big $$ to a final project, best build up some prototypes out of ply, OSB or other serviceable cheap stuff, just to see the general trends of what does what. One could make a heavy throat and driver enclosure to mate up with the cheepo expansion...

A run of "speaker cable" the distance you propose is likely not a great idea, fwiw.

Consider a step up transformer at ur "shed" and a run of proper insulated heavy gauge wire out to the speakers with isolation/step down xfmrs out there to step down the voltage... getting the signal out there is also problematic... you might do well with a wireless link, or else low Z lines (600ohm being "normal" but maybe others have better experience with running signals 100 yards (or meters)?

Anyhow, why not build with concrete block?

Much cheaper, easier, and faster. Remember you need to build very serious forms

to do standard concrete, plus reybar for reinforcement!

Again, before you commit the big $$ to a final project, best build up some prototypes out of ply, OSB or other serviceable cheap stuff, just to see the general trends of what does what. One could make a heavy throat and driver enclosure to mate up with the cheepo expansion...

A run of "speaker cable" the distance you propose is likely not a great idea, fwiw.

Consider a step up transformer at ur "shed" and a run of proper insulated heavy gauge wire out to the speakers with isolation/step down xfmrs out there to step down the voltage... getting the signal out there is also problematic... you might do well with a wireless link, or else low Z lines (600ohm being "normal" but maybe others have better experience with running signals 100 yards (or meters)?

Last edited:

More pictures for chit-chat: above is the tree line directly to the north, taken while standing in the proposed green area. Note: I don't know why, but the trees in this picture look squished unless you click on the picture. I don't know why the formatting is screwed up? My other pictures look fine. Oh well. . . .The chicken-wire fence is to keep my beagles in. The fence will be going away (moving the dogs to the lower part of our property). This looks very pretty in the winter.

This is looking north-west at the shop.

The most important tool for this project - my excavator. It's a 30,000 pound earth mover. I recently reskinned & hard-faced the bucket. My army truck (American General M923) parked in the background (everyone should own a 22,500 pound 6-wheel drive army truck - to pull their cannon

inside the garage

more garage

more garage

I picked up a mill that was beyond the capacity of my forklift, so I designed and built this gantry crane to move it. The crane is point-loaded with over 8000 pounds in this picture!

Last but not least, is my dozer. Old but functional. It's 40,000 pounds of earth moving joy!

Please, feel free to make adjustment/recommendations for the horn layout.

Does that include eliminating one of the sub horns? If so that's my STRONG recommendation.

The 60 foot spacing was intended to get stereo separation down low. It is necessary, I don't know. . .

You don't need stereo separation down low. You don't even need stereo separation at the top of the sub's passband.

Ok, in this thread pics have worked wonders where words have failed. So let's try one more sim. It's been ages since I've used this spreadsheet, so I think I'm using it right but can't guarantee it.

Horn directivity doesn't come into play in this sim. I can only make the "speaker" 999 mm diameter anyway, so I didn't even bother filling in the diameter, not that it makes any difference at all in this sim anyway. But directivity doesn't matter, as long as your horn is making sound over at least 10 degrees horizontally, I don't think we need to worry about directivity too much at this point since the horns are aimed at the green audience position.

So the instructions refresher I did says to enter the listening/measuring position and driver offsets in meters. So I put the mic 20 meters from the "speakers" and put the "speakers" 18 meters apart (9 and -9 meters relative to the listening axis).

I just grabbed a random .frd file off the internet for this sim, and loaded the same .frd twice, once as a woofer and once as a tweeter, just to get two identical "speakers" input into the sim. I could have made a .frd file from your response and used it instead but that would take time I don't want to spend, so this .frd is fine for this purpose. The frequency response curve itself isn't important, what we are looking for is the onset and frequency of lobes.

So I've shown here the inputs I just described and the frequency response.

There are 3 frequency response charts.

Frequency response 1. Summed response at 0 degrees (directly on axis, this is what you hear if your hot tub is directly on axis with the horns, in other words draw an X starting at the horn throat and place your hot tub right where the lines meet - X marks the spot).

Frequency response 2 - Summed response when you move just 2.86 degrees off center in the horizontal plane.

Frequency response 3 - Summed response at 8,53 degrees off axis in the horizontal plane.

(In all cases the mic is assumed to be directly on axis in the vertical plane.)

So assuming I am using the spreadsheet right, response goes all to hell very quickly with each step away from the direct on axis response. I don't have a protractor and I'm not good with estimating angles, so in reference to your horn (either one of them) how horizontally wide would you estimate your green audience position is in degrees?

How much of this garbage do you want to put up with just to have dual horns instead of a single horn?

A single horn won't have any of these problems, the only problem will be lobing at the crossover frequency between the sub and the mains, and if you keep the mains very close and use steep crossovers it won't be bad. In fact if you put the mains inside the horn mouth like a big coaxial speaker a lot of these issues will completely disappear (for the most part).

Just in case it's not clear, the big dips in response are due to destructive interference aka lobing.

Last edited:

Why not build with concrete block?

Before you commit the big $$ to a final project, best build up some prototypes?

A run of "speaker cable" the distance you propose is likely not a great idea.

We live in a Class-II earthquake zone, where structures must be designed to withstand 1 G-force of lateral acceleration every 50 years (also known as a magnitude 7.0 earthquake). Concrete block construction is specifically not rated for this type of seismic loading - unless you also drop rebar down the center of the blocks, and fill them with concrete. The roof of the horn (particularly the mouth) is going to weigh a ton (probably several), and must be designed as a load-bearing slab, that's simply supported on ends (which means it must be cast in place with a whole bunch of rebar). At this point, its easier to cast the whole darn horn from reinforced concrete. ..

I'm going to get my feet wet in building my midrange horns first (this way it wont hurt bad if I screw up). For the bass horns however, I have no choice but to jump right off the high-dive - as there's no testing the waters here. A screw up is big-time. .. . .

I have two options for power. Option 1. Build a small shed, centrally located between the horn rears (about a 35 foot speaker wire run, in this configuration). Trust me - I will get the DCR down, even if I have to run copper 4/0 welding leads out to the horns .. .

Option 2. build a small shed over the rear of each bass horn. Advantage is that I can place amps directly over each horn throat. Another advantage is the rear of the horn stays dry. Disadvantage is that I've got pull a permit to bring power into two buildings, instead of just one. Note that the more permits I need to pull for this project, the more "attention" it will get from the county - which normally is a bad thing. . ..

Ok, lobing is pretty crappy. I've never actually seen it on a graph, but I'm well aware of the phenomena, and what causes it.Just in case it's not clear, the big dips in response are due to destructive interference aka lobing.

The few times I've visited the ultra-high-end stereo stores (with Helmholtz resonators on every wall, tube-traps in every corner, 1/4 wave filters draped over every wall), and a single chair - precisely positioned in the near center of the room. The system sounded absolutely amazing! Note: the reason I want an outdoor system, is that I don't want to deal with room nodes. Outside "should" be inherently better, right???

Nonetheless, what I think you are saying is that even outside, my system is only capable of sounding absolutely amazing, if I'm sitting smack dab in the sweet spot (i.e. the hot tub?). Honestly, I would rather have that, than build a mono system. . . .

What do the sound reinforcement guys do? I've heard some pretty good outdoor venues. I'm assuming they were loaded with lobing. Perhaps they had the volume up so high, I simply couldn't tell?

Last edited:

I'm not really all that certain about the validity of my lobing sim, this definitely isn't what that spreadsheet was meant to be used for. Anyone confirm or deny those results or know of a program that's specifically for this stuff that doesn't take an engineering degree to figure out?

You seriously want to trade stereo separation at subwoofer frequencies for lobing issues? Probably most media is mixed in mono at sub frequencies anyway, even if it wasn't you wouldn't notice the difference unless the bass was panned hard to one side which is hardly a useful effect and not something you need, so you are trading lobing issues for essentially no benefit whatsoever.

Weltersys is the pro on this but I'll take a stab at it. They calculate the dispersion angle (directivity) of the speakers and then set them up for full coverage of the audience with minimal overlap. Then they use different types of arrays to steer the sound and sometimes more speakers in discreet locations for coverage in places that are lacking.

The pretty good outdoor venues you have heard might have been engineered well using these tactics to get a nice even coverage with minimal lobing issues. But even if there were dramatic lobing issues, you would never know it unless you moved around in the crowd. At any given location the frequency response is fixed - so you might have been in a good spot. And if/when you do wander around you usually aren't paying full attention to the music anyway, so if you wandered through areas of ragged response you probably wouldn't have noticed, you would probably be too busy making sure you didn't bump into people or get your wallet pickpocketed.

Nonetheless, what I think you are saying is that even outside, my system is only capable of sounding absolutely amazing, if I'm sitting smack dab in the sweet spot (i.e. the hot tub?). Honestly, I would rather have that, than build a mono system. . . .

You seriously want to trade stereo separation at subwoofer frequencies for lobing issues? Probably most media is mixed in mono at sub frequencies anyway, even if it wasn't you wouldn't notice the difference unless the bass was panned hard to one side which is hardly a useful effect and not something you need, so you are trading lobing issues for essentially no benefit whatsoever.

What do the sound reinforcement guys do? I've heard some pretty good outdoor venues. I'm assuming they were loaded with lobing. Perhaps they had the volume up so high, I simply couldn't tell?

Weltersys is the pro on this but I'll take a stab at it. They calculate the dispersion angle (directivity) of the speakers and then set them up for full coverage of the audience with minimal overlap. Then they use different types of arrays to steer the sound and sometimes more speakers in discreet locations for coverage in places that are lacking.

The pretty good outdoor venues you have heard might have been engineered well using these tactics to get a nice even coverage with minimal lobing issues. But even if there were dramatic lobing issues, you would never know it unless you moved around in the crowd. At any given location the frequency response is fixed - so you might have been in a good spot. And if/when you do wander around you usually aren't paying full attention to the music anyway, so if you wandered through areas of ragged response you probably wouldn't have noticed, you would probably be too busy making sure you didn't bump into people or get your wallet pickpocketed.

I'm zoned agricultural as well, and we have two full size shipping containers on two different properties. I don't think anyone even thought to check the bylaws. Nobody has complained yet. Neither are visible from the road though, so it's unlikely there will be complaints.

Interesting. My situation may be similar.

I've daydreamed about turning one of them into a sub, but I would never do it. Metal rots, so there's a very short shelf life on a used shipping container if you want it to stay airtight. Maintenance would require lifting it and all kinds of metal work. No thanks. Modular wood cabs are the ticket as far as I'm concerned. At this stage in my life anyway.

How important is 'airtight'? It would depend on the build:

1) A horn constructed within the shell of a shipping container.

For this, it wouldn't matter at all - if the container had a rust hole, or the door seals were cracked, the horn would still be a horn.

2) Built as an IB (infinite baffle), with an array of woofers firing out of a manifold in the closed end of the container.

Again, it wouldn't matter. An extremely non 'airtight' scenario* here would be with the container in use, both doors wide open. The enclosure would effectively be a huge U-frame / open baffle.

...but it would take sound almost 1/10 of a second to traverse the ~25m (80') path length difference between front and back of the manifold, so the OB roll off would not be significant until <30Hz by the usual equation. I think the significance would be even less in practice.** That would be good enough for me, and a very simple build.

...but it would take sound almost 1/10 of a second to traverse the ~25m (80') path length difference between front and back of the manifold, so the OB roll off would not be significant until <30Hz by the usual equation. I think the significance would be even less in practice.** That would be good enough for me, and a very simple build.

3) Built as a 'normal' sealed box (relatively small compared to driver VAS).

This is where airtight would matter most, but the number of drivers required means it wouldn't happen. The smallest (20') container has 33 m^3 internal volume, enough for 64 of these drivers, with oodles of volume left for bracing:

Data-Bass

Nobody is going to use >$150,000 of subs (2 containers = 128 drivers for stereo) in a couple of shipping containers without modding and rustproofing them.

Data-Bass

Nobody is going to use >$150,000 of subs (2 containers = 128 drivers for stereo) in a couple of shipping containers without modding and rustproofing them.

Is the 'very short life' based on your own containers?

Since they are good for 10+ years of shipping use (a pretty rough and salty life), I had assumed that, if static, clean, well painted and well sited (that is: with no water allowed to pool on them, the base raised / not in contact with damp earth), they'd last a lifetime - particularly in a spot that's usually hot and dry and 200km from the sea.

Off topic but interesting (?) links. I was at the latter in 2015 and it still looks brand new, after several years of use.

https://en.wikipedia.org/wiki/Container_City

https://en.wikipedia.org/wiki/Re:START

*note that 'normal' IB builds are in houses, which are a long way from being airtight. They have a lot of leaks / a very short path length difference if you consider them as oddly folded open baffles. So I presume that leaks doesn't matter.

For example, check out this chap's IB:

William Cowan's Homepage

...when you consider that a 20Hz tone will go right through a glass window, the path length difference there is miniscule.

**for the reason above, and because you could be listening in the 'near field' - 10m would be 'near' relative to that 25m path length distance.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question