Morgan is not a materials guy and was wrong about that.

Maybe you must go to University of Bolton and teach professor Elias Siores about polymers

Professor Elias Siores | University of Bolton

http://www.google.com.ar/url?sa=t&r...xQ0KulLLu2246OA&bvm=bv.71198958,d.cWc&cad=rja

Attachments

I never figured it out entirely about this breaking of component. I found that new tubes and new capacitors sound better after 100-200 hours of playing music. I am conscious that there is just so many variables and so many parts that it is a miracle to hear the difference of one capacitors when there is 5 or more blocking the DC of your audio, and all the caps in the non regulated power supply and speaker crossovers.

Hifi capacitors take more than a week to sound good. Play more music than just one week.

Hifi capacitors take more than a week to sound good. Play more music than just one week.

Everything is made of materials, which have plenty of properties which intrude into the electrical space. The physical fiddling with bits of audio components, parts, etc, when putting them in place, tweaking, etc, leaves residual pressures which have to stabilise in their new environment, settle in. I see it like inserting a piece of timber into position, it takes some time for the timber to internally "warp", to take to their "new orientation".I never figured it out entirely about this breaking of component. I found that new tubes and new capacitors sound better after 100-200 hours of playing music. I am conscious that there is just so many variables and so many parts that it is a miracle to hear the difference of one capacitors when there is 5 or more blocking the DC of your audio, and all the caps in the non regulated power supply and speaker crossovers.

Hifi capacitors take more than a week to sound good. Play more music than just one week.

All very subtle of course, but just enough to be audible, if one is sensitive to such ...

I had a bad experience with teflon insulated wires, I don't know if it was piezoelectric or triboelectric or whatever, or the fact that the thing is such a good insulator that static charges can stay on it like forever, but if the preamp input wires rubbed together, I could hear it in the speakers, quite loud.

Same thing also happens with a lot of my 50 ohm coaxes, if you want to see what I mean, just stick a coax on your scope input and wiggle it.

Medical electronics like ECG use low-noise cables which have an antistatic layer at the interface between copper and insulator. I'd like to find some of this stuff without having to buy 100m reels...

What do you mean by "digital" ?

1) It could be a purely digital chip processing digital signals, like a CPU, or maybe a MOSFET driver. In this case you want to have the supply voltage within spec, noise can be very high, the chips don't care.

However, since we're probably speaking about mixed signal, you really want the HF noise from the digital supplies to stay far away from sensitive stuff like your analog signals, analog supplies, and especially your analog ground !... So you'd want to keep the noise currents in tight loops (to avoid emissions), avoid these currents going in your analog ground, etc.

This means a good layout, physically small decoupling caps close to the chips, knowing where the return currents flow, etc. On 2-layer boards this also means local power zones and ferrite beads.

Also a shunt regulator for powering your CPU (or DAC DVCC) is a very good thing. This might seem counter-intuitive, but if you got a load that draws a random noisy current with fast variations, it makes sense to put a shunt reg on it, to make the current draw from the main supply constant. For example a TL431. Of course, efficiency is awful, it only works for low power stuff.

2) Or it could be a digital chip that processes an analog signal (like a clock). Now you need all of the above, plus low noise and good stability.

> the greater capacitance in digital power decoupling give

> me each time the best sonic result.

Probably because it makes more of the current flow in a tight local loop, and less HF current pulled from the main supply (and returning through the GND)... if you push the idea even more, you get a shunt reg.

As for the "sound" of digital decoupling caps, well, if the layout is crap (which is usually the case), the results are random, so changing one cap will completely change the power supply impedance, resonances, emissions, etc, so why wouldn'it change the sound ? This doesn't say anything about one cap or the other being "better"...

Example :

Say you got a board with a DAC on it, and two PSU boards (Dig and Analog), each with its transformer, regulator, etc, connected with wires or long traces.

Best case :

- Both PSUs are current sources, High-Z output

- Local shunt reg at load, local caps, ferrite to keep noise from escaping

- Current in wires is constant, AC noise current stays in 1cm tight loop

- No problems.

Worst case :

- Both PSU linear series regulator with low-ESR cap on the regulator output

- Local decoupling on DAC board

- No ferrites

DAC draws HF current on DVCC. Some of it goes through the local cap. The rest of AC current is provided by regulator. If the regulator is fast, problem is worse, you get more HF AC current in your wires/long traces/nice antennas. Also the GND of your DAC board is now at a different potential than the GND of your power supply board. If there is a ground loop somewhere, oops. If there are low-ESR caps at both ends of the long trace or wire, you get CLC resonant circuit. Changing any component (or wire) could change the EMI spectrum. Everything becomes a random mess.

Same thing also happens with a lot of my 50 ohm coaxes, if you want to see what I mean, just stick a coax on your scope input and wiggle it.

Medical electronics like ECG use low-noise cables which have an antistatic layer at the interface between copper and insulator. I'd like to find some of this stuff without having to buy 100m reels...

My short experience is I can't hear in digital decoupling difference with inductance but the greater capacitance in digital power decoupling give me each time the best sonic result.

My understanding is just 0.1 Cog/NPO should be used to // this bigger cap.

But some here says that a 1 Uf 0805 X7R is good enough ! But the scope, is someone able to hear the difference or is it just advised to put Cog to avoid worser piezo the pcb get older like in the same time the piezzo effect involved even with new solderrings ?

What is the best trade off between inductance, dielectric & piezzo ?

In digital design some tends to prefer for sound: smd PPS, acrylic in 1210 case, at least Tantalum for its particular damping aspect in some place.

What do you mean by "digital" ?

1) It could be a purely digital chip processing digital signals, like a CPU, or maybe a MOSFET driver. In this case you want to have the supply voltage within spec, noise can be very high, the chips don't care.

However, since we're probably speaking about mixed signal, you really want the HF noise from the digital supplies to stay far away from sensitive stuff like your analog signals, analog supplies, and especially your analog ground !... So you'd want to keep the noise currents in tight loops (to avoid emissions), avoid these currents going in your analog ground, etc.

This means a good layout, physically small decoupling caps close to the chips, knowing where the return currents flow, etc. On 2-layer boards this also means local power zones and ferrite beads.

Also a shunt regulator for powering your CPU (or DAC DVCC) is a very good thing. This might seem counter-intuitive, but if you got a load that draws a random noisy current with fast variations, it makes sense to put a shunt reg on it, to make the current draw from the main supply constant. For example a TL431. Of course, efficiency is awful, it only works for low power stuff.

2) Or it could be a digital chip that processes an analog signal (like a clock). Now you need all of the above, plus low noise and good stability.

> the greater capacitance in digital power decoupling give

> me each time the best sonic result.

Probably because it makes more of the current flow in a tight local loop, and less HF current pulled from the main supply (and returning through the GND)... if you push the idea even more, you get a shunt reg.

As for the "sound" of digital decoupling caps, well, if the layout is crap (which is usually the case), the results are random, so changing one cap will completely change the power supply impedance, resonances, emissions, etc, so why wouldn'it change the sound ? This doesn't say anything about one cap or the other being "better"...

Example :

Say you got a board with a DAC on it, and two PSU boards (Dig and Analog), each with its transformer, regulator, etc, connected with wires or long traces.

Best case :

- Both PSUs are current sources, High-Z output

- Local shunt reg at load, local caps, ferrite to keep noise from escaping

- Current in wires is constant, AC noise current stays in 1cm tight loop

- No problems.

Worst case :

- Both PSU linear series regulator with low-ESR cap on the regulator output

- Local decoupling on DAC board

- No ferrites

DAC draws HF current on DVCC. Some of it goes through the local cap. The rest of AC current is provided by regulator. If the regulator is fast, problem is worse, you get more HF AC current in your wires/long traces/nice antennas. Also the GND of your DAC board is now at a different potential than the GND of your power supply board. If there is a ground loop somewhere, oops. If there are low-ESR caps at both ends of the long trace or wire, you get CLC resonant circuit. Changing any component (or wire) could change the EMI spectrum. Everything becomes a random mess.

Last edited:

Well, I will answer my own question...if something sounds too good to be true, it is! Went ahead and purchased some of these caps (not a lot of money) to use on the signal path of a couple of my preamps and right away the difference was noticeable, the highs and the mids became attenuated, almost like if a blanket was covering my speakers. Break in time? Well, a week after using them still sounds the same, somewhat dull. I would not recommend these caps.

Most caps are snake oil.

I had a bad experience with teflon insulated wires, I don't know if it was piezoelectric or triboelectric or whatever, or the fact that the thing is such a good insulator that static charges can stay on it like forever, but if the preamp input wires rubbed together, I could hear it in the speakers, quite loud.

You nailed it- tribo. PTFE/silver is a particularly bad combination. I learned this the hard way.

Yeah, the noisy wires were classic silver plated copper, teflon insulated.

I'd like to find this kind of cable without having to buy $$$$$ reels :

Low Triboelectric Noise Wire and Cable manufacturing services, lead wires that are certified to AAMI standards for medical applications

Low Noise Cables & Wires for Measuring Vibration & Weak Signals

Balanced microphone cables also try to minize this effect.

I'd like to find this kind of cable without having to buy $$$$$ reels :

Low Triboelectric Noise Wire and Cable manufacturing services, lead wires that are certified to AAMI standards for medical applications

Low Noise Cables & Wires for Measuring Vibration & Weak Signals

Balanced microphone cables also try to minize this effect.

Balanced mike cables work really well- that's what I use for my turntable-to-preamp runs. Relatively inexpensive as well.

As you've indirectly pointed out, the place to look is industrial/metrology suppliers for mission-critical applications. No puffy claims, just engineering and performance.

As you've indirectly pointed out, the place to look is industrial/metrology suppliers for mission-critical applications. No puffy claims, just engineering and performance.

.

Thermionic design cannot proceed in a vacuum...

.

Thermionic design cannot proceed without a vacuum.

You nailed it- tribo. PTFE/silver is a particularly bad combination. I learned this the hard way.

I thought I was crazy and taking risks of confusing wires by using cotton insulation. Cant believe how crazy sensitive a circuit can be...

Do you have oscilloscope screen shots of the static noise?

It wasn't static, it was a distinct rubbing sound when the cables were moved or tapped, like the output of a mike or vibration sensor (which in essence it was).

No scope shots, this was a long, long time ago, before both digital cameras and any realization on my part that there would one day be Internet forums.

No scope shots, this was a long, long time ago, before both digital cameras and any realization on my part that there would one day be Internet forums.

Thermionic design cannot proceed without a vacuum.

If you take the trouble to read, in the book, at page xiii, textually says (well, Acknowledgements is at the right side)

So, I think that Morgan Jones want mean that SY is a bit annoying, and I fully agree with him on that.Acknowledgements

.

.

.

Thermionic design cannot proceed in a vacuum, so the author is grateful

for the perceptive insights and insults freely offered by Stuart Yaniger over

the recent years.

.

.

.

Then would teflon caps display the same by-products or such ?It wasn't static, it was a distinct rubbing sound when the cables were moved or tapped, like the output of a mike or vibration sensor (which in essence it was).

No scope shots, this was a long, long time ago, before both digital cameras and any realization on my part that there would one day be Internet forums.

Last edited:

Metalized (teflon) ptfe is rare most are foil . But I was thinking a long the lines of a mic rather than a rubbing voltage production . Large polyprop as well to the mic effect. Much of the view that cap sound different may fall to microphonics rather than easily tested df ,da, etc . That case it test well with little artifacts but is in fact acting like a mic picking up the vibrations from the air but delayed from the original signal . I can thump a cap and see the artifact on the scope but lack a uniform repeatable test . Should build a shaker table I guess.metal foil on ptfe could allow this "rubbing".

Metalised coating on the ptfe will not allow rubbing.

I had a bad experience with teflon insulated wires, I don't know if it was piezoelectric or triboelectric or whatever…

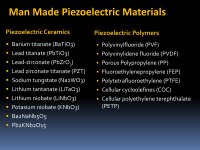

As Morgan Jones correctly pointed out, PTFE is both, piezoelectric and triboelectric.

When a cable is mechanically stressed through twisting, compression, or flexion, the cable itself generates noise, referred to as microphonics.

This noise is due mostly to piezoelectric effect, triboelectric effect and capacitance changes.

Other irrelevant links

http://www.google.com.ar/url?sa=t&r...gsRBPBU7DrxlyV2mpEddEDg&bvm=bv.71198958,d.cWc

Capgo - Understanding Noise

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Member Areas

- The Lounge

- Audiophiler capacitors on ebay