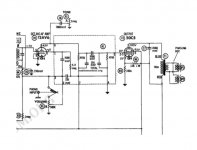

I am playing with an AA5 type radio - Sears Silvertone 7013, CH 132.40100.

I have downloaded the schematic and found in the AF section between the 12AV6 and 50C5, there is a module (like an earlier version of IC indicated as a rectangular dotted line). The module is a network of R/C. I opened the radio and confirmed there is indeed such as physical module.

There is nothing special about the components inside, only Rs and Cs. I have a few tube radios and this is the only one having such a module. I wonder what is the main purpose of using it instead of discrete components. I tried google but nothing come up, maybe I used the wrong term for searching. After all, I have no idea what it is called.....

I have downloaded the schematic and found in the AF section between the 12AV6 and 50C5, there is a module (like an earlier version of IC indicated as a rectangular dotted line). The module is a network of R/C. I opened the radio and confirmed there is indeed such as physical module.

There is nothing special about the components inside, only Rs and Cs. I have a few tube radios and this is the only one having such a module. I wonder what is the main purpose of using it instead of discrete components. I tried google but nothing come up, maybe I used the wrong term for searching. After all, I have no idea what it is called.....

Attachments

This is called a PEC (Printed Electronic Circuit) and was used in the 50s and 60s.

Some examples: http://www.dhtechservices.com/documents/PEC_centralab_schem.pdf

Some examples: http://www.dhtechservices.com/documents/PEC_centralab_schem.pdf

Thanks so much for your info ! I have identified the one inside my radio is PC-151 !

Audio companies used them also, like in the Dyna FM-3 tuner. If you are looking for performance over authenticity, replace it with a small pcb with good discrete components. By now those parts are likely

far out of whack.

Last edited:

There were several brands of radios, HiFi and even some TV sets that took some of their standard passive circuitry and made it into a custom circuit module. I always assumed the the true motive was to sell replacement parts, or insure that the unit would be brought to one of their authorized service centers for repair.

The early versions of these modules had small discrete components inside and the whole thing was coated in a brown resin or plastic case. Later on the resistors were screen printed on to the substrate, but the capacitors were discrete parts. By the late 60's all or most the passive components were screen printed on the substrate.

I started my 41 year engineering career at a Motorola plant in 1973. The plant would start a microelectronics operation in about 1975 manufacturing these modules for their two way radios. It would encompass about half the plant by the early 80's, and be completely gone by the 90's due to the advances in SMT (Surface Mount Technology).

The modules that were screen printed with conductive, resistive, or dielectric ink were called Thick Film Hybrids, or just Thick Film.

There were also some modules that used vapor deposition and electroplating to deposit the metals. These were used for high frequency RF circuitry where more precision was needed. These were Thin Film Hybrids or just Thin Film.

Different manufacturers often used different terminology for these devices, and their designs and manufacturing technology varied widely depending on the driving factors involved. We built "Mission Critical" (a person's life may depend on it working) two way radios for police fire and military applications.....cost was NOT a factor. Often cost is the primary factor in consumer grade electronics.

Before joining Motorola I was a service tech at an Olson's Electronics store. Those modules were the biggest failure in some products, and number two behind output transistors overall.

The early versions of these modules had small discrete components inside and the whole thing was coated in a brown resin or plastic case. Later on the resistors were screen printed on to the substrate, but the capacitors were discrete parts. By the late 60's all or most the passive components were screen printed on the substrate.

I started my 41 year engineering career at a Motorola plant in 1973. The plant would start a microelectronics operation in about 1975 manufacturing these modules for their two way radios. It would encompass about half the plant by the early 80's, and be completely gone by the 90's due to the advances in SMT (Surface Mount Technology).

The modules that were screen printed with conductive, resistive, or dielectric ink were called Thick Film Hybrids, or just Thick Film.

There were also some modules that used vapor deposition and electroplating to deposit the metals. These were used for high frequency RF circuitry where more precision was needed. These were Thin Film Hybrids or just Thin Film.

Different manufacturers often used different terminology for these devices, and their designs and manufacturing technology varied widely depending on the driving factors involved. We built "Mission Critical" (a person's life may depend on it working) two way radios for police fire and military applications.....cost was NOT a factor. Often cost is the primary factor in consumer grade electronics.

Before joining Motorola I was a service tech at an Olson's Electronics store. Those modules were the biggest failure in some products, and number two behind output transistors overall.

Centralab had the bright idea to reduce common networks to single many-leg parts. This was the end of the 1940s. It very likely came out of military micro-circuit thinking, but at commercial quality level. As George said, the earliest ones seem to be discrete on a board with glop; later ones were various inks on a slab under glop. Since individual Cs and Rs were a VERY competitive market, Centralab had to whomp these out cheap to get any sales at all.

PC-151 was $1.15 list. You could get Rs for 5 cents, small C for 10c, big C for 25c. 15+20+50 is 85 cents. Can your workers twist and solder these parts for 30 cents? What if your distributor dumps 470k resistors half-price? OTOH how much inventory overhead for 8 parts instead of one? (8 buckets, 8 stock numbers to check and re-order nightly...)

PC-151 was $1.15 list. You could get Rs for 5 cents, small C for 10c, big C for 25c. 15+20+50 is 85 cents. Can your workers twist and solder these parts for 30 cents? What if your distributor dumps 470k resistors half-price? OTOH how much inventory overhead for 8 parts instead of one? (8 buckets, 8 stock numbers to check and re-order nightly...)

Attachments

Last edited:

In the Musical Ibnstruments realm, Gibson amplifiers often used a mids-rejecting tee filter in the PEC form; Ampeg used a similar one including all resistors and capacitors in their James passive tone controls, just add two 1M Log pots.

I also suspect the idea was to have captive service networks, because time/size/cost savings were minimal.

Hey, last week I was just wondering about making a custom gain or EQ or compressor block for my own amps, go figure.

Basically by ordering a few hundred stamp sized PCBs with terminals on one side, preassembled with SMT parts, and potting them myself, then using them all over the place.

I also suspect the idea was to have captive service networks, because time/size/cost savings were minimal.

Hey, last week I was just wondering about making a custom gain or EQ or compressor block for my own amps, go figure.

Basically by ordering a few hundred stamp sized PCBs with terminals on one side, preassembled with SMT parts, and potting them myself, then using them all over the place.

Can your workers twist and solder these parts for 30 cents?

I was stuck on factory flow / product cost improvements on Motorola phone products in the late 90's.....modern version of the same question.....

In the late 1990's cell phones had a two resistor, one cap, and one zener diode network on each pin of the accessory connector to protect the phone from an ESD zap. Apple used 30 pin connector, we had 12.....that's still lots of parts.

Panasonic had a tiny little SMD gizmo that could protect 4 I/O lines per part, so 3 parts would replace 48. It cost more than the 16 parts it replaced, so that idea was squashed immediately.

So I had to ask the people running the line what I thought was a simple question......how much does it cost to place a part on a board? Nobody had a clue, or even knew how to answer......so I came back with how many phone boards flow through these machines in an hour? Then it was how many more could you run in an hour if I took 45 parts off the board, which would also remove 1 reel of SMD parts from the machine.........They are thinking now....

Next question, what is your pick and place defect rate, and how much would it improve if I took off 45 parts. The phone board had about 500 parts at the time, so 45 was a sizable dent, and once I could get the idiots running the show to think, we made some serious process improvements.

Parts reduction and consolidation / integration were the drivers that enabled the smart phone tech that we have now. I left Motorola in 2014, but the number of parts in a phone from the 90's to 2010 stayed in the 400 to 500 range most of that time. They just stuffed more goodies into each part, especially semiconductors.

I worked in a laboratory of thick ICs back in 1980 when I did my diploma project. The technology was used for specialized designs, not in mass production. We had case-less devices that glued and welded to ceramic substrates and baked on it conductors. Resistors were trimmed by lazer. Later application of this technology was SMD, when instead of ceramic substrate and baked paste resistors and conductors started using ordinary PCBs.

For mass production was thin film technology used. Resistors and conductors were made by spraying of metals. The process was automated. One fellow engineer who designed one such IC presented on the plant that made his ICs, when they prepared the manufacturing. The problem was, the robot was Japanese, but substrates were with lousy Soviet tolerances, so sometimes the robot put transistors near the substrate that was smaller than needed. 😀

For mass production was thin film technology used. Resistors and conductors were made by spraying of metals. The process was automated. One fellow engineer who designed one such IC presented on the plant that made his ICs, when they prepared the manufacturing. The problem was, the robot was Japanese, but substrates were with lousy Soviet tolerances, so sometimes the robot put transistors near the substrate that was smaller than needed. 😀

Last edited:

The problem was, the robot was Japanese, but substrates were with lousy Soviet tolerances

Our substrates were manufactured by Coors, the beer company.

It seems that they had started their own ceramics division because nobody would make the ceramics they needed for brewing beer in non metallic vats.

Our substrates were manufactured by Coors, the beer company.

It seems that they had started their own ceramics division because nobody would make the ceramics they needed for brewing beer in non metallic vats.

We baked potatoes in muffin ovens. And kept beer in precision testing thermo chambers with Peltier control.

I guess you were all EEs in that floor 🙂 .So I had to ask the people running the line what I thought was a simple question......how much does it cost to place a part on a board? Nobody had a clue, or even knew how to answer......

Like most of Engineering branches, focusing on the specific Tech side, either designing (which can get distanced from the practical side) or manufacturing, by necessity with firmer feet on the ground, but still focused.

You should have called an Industrial Engineer 😎 , who specializes in "doing for 10 cents what others do for 1 Dollar" , machine or technology choice based on efficiency which in due time is heavily influenced by production scale, worker output, task analysis and assigning, quality control, parts ordering, plus related tasks such as worker compensation, storage/warehouse design, production line balancing and task scheduling.

All that not varying a single resistor value.

Our specialty was called "Engineer Designer and Technologist of Radio and Electronics Equipment", the faculty was "Design and Manufacturing of Radio and Electronics Equipment". I.e. in USSR we had to optimize the end result starting from the first phase, designing schematic and selecting components for the given environment conditions and other criteria like max possible price.

For example, my diploma project was a microwave alarm system based on Doppler effect. It supposed to be made around a thick film hybrid IC, and cost less than 70 rubles, work in usual home conditions indoors, work on 10.7 GHz. Solving this equation with multiple variables I designed an IC with only 2 external capacitors absolutely needed, the IC was used also as a rear lid for a waveguide-antenna, and the waveguide acted as a heatsink.

For example, my diploma project was a microwave alarm system based on Doppler effect. It supposed to be made around a thick film hybrid IC, and cost less than 70 rubles, work in usual home conditions indoors, work on 10.7 GHz. Solving this equation with multiple variables I designed an IC with only 2 external capacitors absolutely needed, the IC was used also as a rear lid for a waveguide-antenna, and the waveguide acted as a heatsink.

Last edited:

I guess you were all EEs in that floor...... designing (which can get distanced from the practical side.....Industrial Engineer , who specializes in "doing for 10 cents

As you stated engineering can become quite specialized, layered, and compartmentalized. In our facility which employed over 5000 people at the time, there were over 1000 people called "engineers" including industrial engineers. Many had only been out of school for a year or two and had never been near a manufacturing plant. SMD manufacturing was improving overnight at the time and we were adding new stuff, and entire production lines constantly.

The EE's often became so specialized that they worked on one small section of a radio product for their entire career. We didn't have radio engineers, or even transmitter engineers, we had VCO or RF power amp engineers. We had research engineers, product development engineers, product manufacturing engineers, factory process control engineers....and many more layers. Despite being a "communications company," communication between the layers was less than optimal.

This worked OK when were making police walkie talkies that sold for thousands of dollars each but cost a few hundred to make. Product volume was in the 10K to 25K units a year range.

I worked there for 41 years (about 25 at the time) and knew a lot of the other long time employees, so I knew who to ask, and how to bypass the red tape BS.

That factory and it's engineering staff created a hybrid device that was both a cell phone and a walkie talkie, the Nextel walkie talkie phone. It launched at 25,000 units a year, and was at 1 MILLION units a year in less than two years.....of course nobody expected that, or was prepared to handle it.

I had been making electronics in side businesses ever since I was a teenage kid, including a little PIC chip gizmo that sold 250K units, so I had some insight as to what questions to ask.....including the biggie...

How much does it cost your factory to pack and ship an EMPTY BOX. The answer.....nearly $50!

When you have only two customers in the US and a couple more internationally it doesn't make sense to make large boxes with multiple inserts for each phone, then crate them all....BULK PACK.

There's a Centralab catalog here that has several starting on page 40.

Untitled Normal Page

You might have a PC-150 Audet (R) Output Stage couplate.

http://bunkerofdoom.com/xfm/centralab/042.jpg

Untitled Normal Page

You might have a PC-150 Audet (R) Output Stage couplate.

http://bunkerofdoom.com/xfm/centralab/042.jpg

Last edited:

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- What is the main purpose of this module?