Hi ! i have a maybe weird question.

The cabinet construction for a very powerful woofer is a very tough tech challenge.

In order to tame vibes is better to use bracing or load cabinet panels ? or both ? which technique do you prefer of the two and why ?

my guess is a cabinet good for a sub would be just fantastic for anything else

The best possible

The cabinet construction for a very powerful woofer is a very tough tech challenge.

In order to tame vibes is better to use bracing or load cabinet panels ? or both ? which technique do you prefer of the two and why ?

my guess is a cabinet good for a sub would be just fantastic for anything else

The best possible

Hi ! thanks a lot ! yes great advice indeed. But looking at some pictures it looks very very complex.Matrix cabinet

This design should increase stiffness ? and what about damping ?

To be honest my biggest curiosity is about sub cabinets ... they have a very tough job to do. But i cannot find pictures of the big names ...

Depends how high you need to cross it. Adequate bracing and some sound absorbtion material to take care of harmonics/mechanical/air noise is all you need for under 100hz.

Above that a combination of both might be needed.

If possible, mount the woofers on opposing sides.

Hi thanks ! to be more clear and risking to go OT i would like to adopt a sub cabinet for a monitor i have in mind. My thinking is that a cabinet good for a sub should be just phenomenal for a 8-10" Tannoy coaxial.

I have already two pairs of 8" to try out ... but i am looking to 10" units

I am involved in nearfield listening and have read great things about coaxials. But cabinet is very critical. A friend of mine took some drivers from a very old Grunding 2 ways and put them in a cabinet very stiff and heavy taken by an old KRK monitor. The result has been very good indeed. Much better than the original speakers.

I think a cabinet for sub should be even better ... it must be steady even when shaken very badly.

The driver will be just one. I understand perfecty that in a two woofers back to back arrangement the push and pull forces null themselves.

This is not feasible for me ... i will have just one driver.

I am sure something can be done anyway because there are TOTL subwoofers with just one woofer. More difficult for sure.

What ErnieM said.

Well-braced 18mm Baltic Birch is very much stiff enough to make sub 100hz cabinet resonances inaudible.

Hi ! thanks a lot for the very valuable advice. I will look for this wood for sure.

Yes i agree ... but i really have to stick with just one woofer. And by the way i see many sub using just one woofer ... even if this is not the ideal design.Dual woofers, mounted and braced magnet-to-magnet, is the way to keep your subs from dancing around the room.

I wonder how they have built the cabinet in order to stop the loudspeaker from dancing in the room.

Maybe the secret is mass loading ? i cannot find pics of the internals.

>>but i really have to stick with just one woofer. And by the way i see many >>sub using just one woofer ... even if this is not the ideal design.

>>I wonder how they have built the cabinet in order to stop the loudspeaker >>from dancing in the room.

>>Maybe the secret is mass loading ? i cannot find pics of the internals.

One woofer is fine. If you build it to fire down at the floor the forces are better distributed to discourage walking. Some people put weights on top of their sub cabinet. You could just build the walls extra heavy. You can build a plywood cabinet, then skin it with say 1/2" or 3/4" MDF, using construction adhesive in between. It's overkill acoustically but it will be heavier!

One more thing, when I build cabinets I like to put a brace on edge right behind the woofer magnet that extends to the back of the cabinet. Fit it with a small gap (1mm?) and glue a thin piece of rubber sheet on the edge. When you install the driver it will make solid contact and distribute the forces around the box, also insulate the driver from its own parasitic resonances as it hangs from the baffle. I do this for subs, woofers and mids.

>>I wonder how they have built the cabinet in order to stop the loudspeaker >>from dancing in the room.

>>Maybe the secret is mass loading ? i cannot find pics of the internals.

One woofer is fine. If you build it to fire down at the floor the forces are better distributed to discourage walking. Some people put weights on top of their sub cabinet. You could just build the walls extra heavy. You can build a plywood cabinet, then skin it with say 1/2" or 3/4" MDF, using construction adhesive in between. It's overkill acoustically but it will be heavier!

One more thing, when I build cabinets I like to put a brace on edge right behind the woofer magnet that extends to the back of the cabinet. Fit it with a small gap (1mm?) and glue a thin piece of rubber sheet on the edge. When you install the driver it will make solid contact and distribute the forces around the box, also insulate the driver from its own parasitic resonances as it hangs from the baffle. I do this for subs, woofers and mids.

>>but i really have to stick with just one woofer. And by the way i see many >>sub using just one woofer ... even if this is not the ideal design.

>>I wonder how they have built the cabinet in order to stop the loudspeaker >>from dancing in the room.

>>Maybe the secret is mass loading ? i cannot find pics of the internals.

One woofer is fine. If you build it to fire down at the floor the forces are better distributed to discourage walking

Hi thanks a lot for the kind reply and advice.

I think i should move the question in another section of the forum because i am only interested to the cabinet construction. In order to understand how to build it i have immediately thought to the most demanding task for a cabinet ... to house a subwoofer.

Maybe i am wrong thinking that a cabinet very good for a sub should be just exceptional for an almost full range monitor (down to about 40-50 Hz not much more).

Once the bass is kept under control the rest of the range will not be a problem.

Some people put weights on top of their sub cabinet. You could just build the walls extra heavy. You can build a plywood cabinet, then skin it with say 1/2" or 3/4" MDF, using construction adhesive in between. It's overkill acoustically but it will be heavier!

i see ... like the laminated construction used for security glass ? I think that it will add complexity to the build. But it sounds brilliant.

this sounds very good and effective. What kind of test do you carry out to check if the cabinet is well done ? test tones ? particular tracks ? some kind of measurements ? i have seen test to measure vibes but strangely they are carried out on side panels when the very critical one is the front one.One more thing, when I build cabinets I like to put a brace on edge right behind the woofer magnet that extends to the back of the cabinet.

Fit it with a small gap (1mm?) and glue a thin piece of rubber sheet on the edge. When you install the driver it will make solid contact and distribute the forces around the box, also insulate the driver from its own parasitic resonances as it hangs from the baffle. I do this for subs, woofers and mids.

If i am not wrong in the ideal situation with high SPLs at low Hz the front panel should stay completely steady ? not vibrating back and forth i mean.

If it's well braced it will also be heavy. I always use AR least 22 mm Mdf of plywood, and bracing. Well I used to, I have converted to I baffle subs, but Im not sure if you care to try this.

The Kjeldsen OB build thread

But, a subwoofer should not move too much. I would rather go for 15 inch with low cone movements than a 10 inch with lots of cone movements

The Kjeldsen OB build thread

But, a subwoofer should not move too much. I would rather go for 15 inch with low cone movements than a 10 inch with lots of cone movements

The cabinet construction for a very powerful woofer is a very tough tech challenge.

A subwoofer cabinet is actually one of the easiest. If you can move the box panel resonances above the bandwidth of the woofer the box becomes essentially inert.

Well braced plywood makes that easy.

Another trick, that really makes a huge difference to the box load, is push-push mounting of a pair of woofers where the resulting active reaction force cancelation dramatically resuces the amount of available energy to excite any box wall resonances from being excited. My extimate of this reduction is something like 90%.

We built an experiemental dual 10” box with 15mm BB and (relatively minimal bracing). It works REALLY well. without the drivers one could pick up the box with a couple fingers in the driver cutout. With wooofers 2 people are suggested.

dave

?.. to be more clear and risking to go OT i would like to adopt a sub cabinet for a monitor i have in mind. My thinking is that a cabinet good for a sub should be just phenomenal for a 8-10" Tannoy coaxial.

I have already two pairs of 8" to try out ... but i am looking to 10" units

I am involved in nearfield listening and have read great things about coaxials. But cabinet is very critical. A friend of mine took some drivers from a very old Grunding 2 ways and put them in a cabinet very stiff and heavy taken by an old KRK monitor. The result has been very good indeed. Much better than the original speakers.

I think a cabinet for sub should be even better ... it must be steady even when shaken very badly....

I think the basic misconception here is that a cabinet designed for a subwoofer will also make an excellent cabinet for a coaxial full range driver, i don't believe that's necessarily true because a stiff, thick wall with bracing and stuffing will still resonate at higher frequencies than a subwoofer is expected to reach, and just adapting the subwoofer box design for a wider frequency range might result in a cabinet that resonates at 2,500 hz instead of 250 hz, which would not be desirable for a full range driver. Hope that makes sense, Six.

I think the basic misconception here is that a cabinet designed for a subwoofer will also make an excellent cabinet for a coaxial full range driver, i don't believe that's necessarily true because a stiff, thick wall with bracing and stuffing will still resonate at higher frequencies than a subwoofer is expected to reach, and just adapting the subwoofer box design for a wider frequency range might result in a cabinet that resonates at 2,500 hz instead of 250 hz, which would not be desirable for a full range driver. Hope that makes sense, Six.

Agree 100%. The requirements for a sub, and what amounts to a full range enclosure are entirely different.

If it's well braced it will also be heavy.

I always use AR least 22 mm Mdf of plywood, and bracing. Well I used to, I have converted to I baffle subs, but Im not sure if you care to try this.

The Kjeldsen OB build thread

Hi your words confirm my feeling ... the only thing that has to move is the driver cone. I think there is a very telling test beyond the reach of the hobbyist ... i think it is called laser interferometry ?

It is fundamental that in ANY situation the front baffle stays still.

How to achieve this ? adding mass to a stiffened front baffle for instance.

And if the cabinet is very stiff the entire mass of it contributes to keep the front baffle still of course.

I read a nice analogy somewhere ... they were comparing the front baffle to a newspaper ... it is very difficult to read when the newspaper moves back and forth ... a vibrating baffle acts as an "additional driver" around the actual driver.

Strange enough i have seen vibrations measurements of loudspeakers side and back panels but never of the most important one ... the front panel.

Ok laser interferometry devices are not cheap and not very available.

I guess B&W has used laser interferometry to check for the baffle movements in their speakers. That is what a really great company does.

With lasers even the smallest displacement can be detected ... if the baffle stands still even when the woofer fidgets like a possessed human being ... that is a very good baffle.

thanks a lot and i read this as well. I think that the popularity of smaller woofers maybe can be related to the requirement to keep subwoofer size small ? But clearly a limitation. For lower Hz the bigger the better.But, a subwoofer should not move too much. I would rather go for 15 inch with low cone movements than a 10 inch with lots of cone movements

Last edited:

A subwoofer cabinet is actually one of the easiest. If you can move the box panel resonances above the bandwidth of the woofer the box becomes essentially inert.

Well braced plywood makes that easy.

Another trick, that really makes a huge difference to the box load, is push-push mounting of a pair of woofers where the resulting active reaction force cancelation dramatically resuces the amount of available energy to excite any box wall resonances from being excited. My extimate of this reduction is something like 90%.

We built an experiemental dual 10” box with 15mm BB and (relatively minimal bracing). It works REALLY well. without the drivers one could pick up the box with a couple fingers in the driver cutout. With wooofers 2 people are suggested.

dave

Here i disagree. For me the design of a cabinet for a speaker that must reproduce the bass below 50Hz at high SPLs is a very tough challenge.

The midrange and treble generate very little mechanical energy that can be suppressed quite easily with some damping material (at my own risk i tried lead sheets and they were just superb ... by far the best damping material on earth. A very telling test is to hammers a lead slab ... you hear almost nothing. A very deaf sound. Actually i hoped for a long time that my church adopted lead bells ...

The BBC approach is not good for a subwoofer. The goal with that method is to push the resonances down in frequency. Not very easy to push them low enuff in a dub.

dave

I wonder what they use at BBC to check the sound of a pipe organ recording ... like the Toccata e fuga

the only BBC approved monitors i know do not go down that much

Google the BBC White Papers regarding enclosure design - some of the best methods proved to be most counter-intuitive! My experience is rigidity for subs, and damping for mids, and make subs non-cuboid to reduce panel size

Hi and thanks for the valuable advice. But i would read also papers from B&W I am more interested in the measurements ...

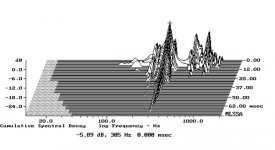

For instance i would like to see some tests results on baffle vibrations ... never seen one but i am sure there are some. I mean graph like this one here

https://www.stereophile.com/images/720P701fig2.jpg

cumulative spectral-decay plot calculated from output of accelerometer fastened to center of sidewall level with upper woofer

but relevant to the baffle and not side or back cabinet walls, very much less critical. If not of no use at all. If you think any noise emitted by the side and back walls has to reach room walls and then be reflected to the listening spot. They are already very low in level and if the reflection issues are taken care the listener hears nothing at all. Not so with the direct sound caused by the front baffle vibrations. That can increased distortion.

At the point that i am pretty sure that just a simple bracing opposing to the baffle vibrations would have a sensible effect ...

I think the basic misconception here is that a cabinet designed for a subwoofer will also make an excellent cabinet for a coaxial full range driver, i don't believe that's necessarily true because a stiff, thick wall with bracing and stuffing will still resonate at higher frequencies than a subwoofer is expected to reach, and just adapting the subwoofer box design for a wider frequency range might result in a cabinet that resonates at 2,500 hz instead of 250 hz, which would not be desirable for a full range driver. Hope that makes sense, Six

Hi thanks a lot for your very helpful reply. The verb believe tastes of religion. And even if higher Hz resonances can occur i am sure they can be dealt with very easily with some sheets of damping materials like those used in car doors for instance.

Instead i still believe

I can remember the boxy sound of an old Tannoy Eaton ... the driver was fantastic ... not so the box. Instead in the pro Tannoy DMT series

the cabinet was out of this world ... one of the best cabinet available. But many models were using a strange plastic materials for the cones ... i heard an heavy sound. Better the paper cones.

And of course i am sure that the DMT cabinet would be just exceptional for an high end subwoofer as well.

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Bracing or mass loading panels ?