If I'm tracking, he just wants a half-wave resonator wtih the slider -- no Vrc no Vtc just dbl-ended open pipe with the driver on the side (not inline). No, we can't do those 🙂 Er, at least we couldn't when I wanted to. I used the Akabak export and edited-in a "mirrored" end and another radiator. If you just do it in math like xrk does everything (positions as functions of L), you can manually "slide" and iterate driver positions. Er, if you just want to find the happy spot, it's half-way. As always, asymmetry and taper will vary results and be touchy beyond comprehension.

How could I convert the Hornresp sim attached that represents the top image to the stubbed horn illustrated in the bottom image?

I'm trying to do so because it doesn't look like Hornresp allows for the simming of a lined or stuffed Vtc. However, if I swap the section S1S2 with Vtc, then I can include the impact of lining or stuffing that section.

I'm trying to do so because it doesn't look like Hornresp allows for the simming of a lined or stuffed Vtc. However, if I swap the section S1S2 with Vtc, then I can include the impact of lining or stuffing that section.

How could I convert the Hornresp sim attached

As shown below (the results will be identical if no filling material and chamber resonances not masked):

In the u-frame open baffle simulation can baffle dimensions (width, height, sides' length) be entered ?

How ?

Thanks

How ?

Thanks

Thanks David!As shown below (the results will be identical if no filling material and chamber resonances not masked):

In the u-frame open baffle simulation can baffle dimensions (width, height, sides' length) be entered ?

The U-frame baffle is modelled as a cylindrical segment with the driver at one end, and the other end open.

S1 = baffle width x height

L12 (Con) = side length or depth

The example below assumes baffle width = 25 cm, height = 20 cm and depth = 20 cm.

The U-frame baffle is modelled as a cylindrical segment with the driver at one end, and the other end open.

S1 = baffle width x height

L12 (Con) = side length or depth

Perfect, thank you very much.

Hi there.

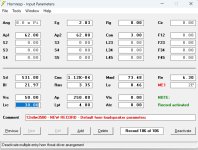

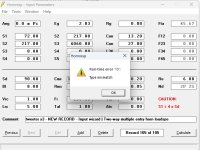

Im getting a run time error - 13 "type mismatch when using the Multiple entry horn simulation. Is it clear form my screen shots why this might be?

Im also having trouble moving back to the ND window after activating ME1.

Could someone explain in a very simple (click by click ) way how to navigate from completing my active me1 record to the ND window and set it to edit mode.

I have a feeling my error is based on this transitional step.

once I have the wizard i'll be all set to complete my sim

all the best

B

Im getting a run time error - 13 "type mismatch when using the Multiple entry horn simulation. Is it clear form my screen shots why this might be?

Im also having trouble moving back to the ND window after activating ME1.

Could someone explain in a very simple (click by click ) way how to navigate from completing my active me1 record to the ND window and set it to edit mode.

I have a feeling my error is based on this transitional step.

once I have the wizard i'll be all set to complete my sim

all the best

B

Attachments

Hi there,

My system is running Windows 11. The version is 24h2 (OS build 261004061)

Thanks David for this excellent program. lots of fun over the years!

B

My system is running Windows 11. The version is 24h2 (OS build 261004061)

Thanks David for this excellent program. lots of fun over the years!

B

Thanks for confirming that you are using Microsoft Windows - that eliminates one possible cause of the problem.

Everything works fine for me however, using the input data from the screen prints you posted.

Q1. Does the error occur when the Edit button is clicked on the Nd record, or afterwards when trying to open the Multiple Entry Horn Wizard?

Q2. Does the Nd record work okay if the ME1 record is not activated?

Q3. Would it be possible to export the ME1 and Nd records and post the files here as attachments, so that I can check to see if the contents are corrupted in any way?

After activating the ME1 record it should only be necessary to click either the Previous or Next button to move to the Nd record, click the Edit button and then select the Tools > Multiple Entry Horn Wizard menu commands.

Everything works fine for me however, using the input data from the screen prints you posted.

Q1. Does the error occur when the Edit button is clicked on the Nd record, or afterwards when trying to open the Multiple Entry Horn Wizard?

Q2. Does the Nd record work okay if the ME1 record is not activated?

Q3. Would it be possible to export the ME1 and Nd records and post the files here as attachments, so that I can check to see if the contents are corrupted in any way?

After activating the ME1 record it should only be necessary to click either the Previous or Next button to move to the Nd record, click the Edit button and then select the Tools > Multiple Entry Horn Wizard menu commands.

Hornresp Update 5800-250528

Hi Everyone,

CHANGE 1

The Frequency-Dependent Damping or FFD model Rms and Ams input values can now be entered directly in scientific format, if so desired.

Previously the E, e, + and - input characters were not recognised, meaning that a value of 1.23E-04 for example, had to be entered as 0.000123 or .000123.

The value can now be entered directly as 1.23E-04 or simply as 1.23E-4 as shown for Ams in the image below. If a lower case e is entered it will be automatically changed to upper case and if E-4 is entered it will change to E-04.

CHANGE 2

The main calculate driver parameters tool has been changed. The old and new input forms are shown below.

Sliders rather than text boxes are now used for inputting data. Data values can still be directly entered if so desired by selecting the relevant slider, keying in the required value and pressing Enter.

Electro-mechanical (E-M) parameters and their Thiele-Small (T-S) equivalents are now given. The value of Mms is also shown.

Changing an E-M value automatically adjusts the related T-S values. The name labels on the input E-M slider and associated T-S sliders are shown in bold green. The black >>>>>> pointer at the top of the form indicates that the T-S values are being calculated from the E-M values.

Changing a T-S value automatically adjusts the related E-M values. The name labels on the input T-S slider and associated E-M sliders are shown in bold green. The black <<<<<< pointer at the top of the form indicates that the E-M values are being calculated from the T-S values.

Old input form:

New input form:

Kind regards,

David

Hi Everyone,

CHANGE 1

The Frequency-Dependent Damping or FFD model Rms and Ams input values can now be entered directly in scientific format, if so desired.

Previously the E, e, + and - input characters were not recognised, meaning that a value of 1.23E-04 for example, had to be entered as 0.000123 or .000123.

The value can now be entered directly as 1.23E-04 or simply as 1.23E-4 as shown for Ams in the image below. If a lower case e is entered it will be automatically changed to upper case and if E-4 is entered it will change to E-04.

CHANGE 2

The main calculate driver parameters tool has been changed. The old and new input forms are shown below.

Sliders rather than text boxes are now used for inputting data. Data values can still be directly entered if so desired by selecting the relevant slider, keying in the required value and pressing Enter.

Electro-mechanical (E-M) parameters and their Thiele-Small (T-S) equivalents are now given. The value of Mms is also shown.

Changing an E-M value automatically adjusts the related T-S values. The name labels on the input E-M slider and associated T-S sliders are shown in bold green. The black >>>>>> pointer at the top of the form indicates that the T-S values are being calculated from the E-M values.

Changing a T-S value automatically adjusts the related E-M values. The name labels on the input T-S slider and associated E-M sliders are shown in bold green. The black <<<<<< pointer at the top of the form indicates that the E-M values are being calculated from the T-S values.

Old input form:

New input form:

Kind regards,

David

This will make some driver simulations easier for me! Help me sleuth out the important parameters to chase in design.

Much appreciated Master McBean.

Much appreciated Master McBean.

Previously the E, e, + and - input characters were not recognised, meaning that a value of 1.23E-04 for example, had to be entered as 0.000123 or .000123.

Kind regards,

David

NICE update!

With version 50.70, I've always been able to enter 1.23e-04 when I duplicate a posted HR input screen.

With version 50.70, I've always been able to enter 1.23e-04

For Cms and Cmp yes, but not for Rms or Ams until the latest update.

Hello! I would like to know which quality factors related to absorption and leakage are used in the 8th-order band-pass (parallel tuning) models in Hornresp. Could someone please let me know?

Also, is there any field where I could change these values?

Thank you for your attention.

Also, is there any field where I could change these values?

Thank you for your attention.

- Home

- Loudspeakers

- Subwoofers

- Hornresp