I suppose, and I've seen photo of that - but it seems like an odd idea. A combination of diffusion and absorption is usually considered best. The nice thing about diffusion is that you don't lose the energy at those frequencies, it just gets spread around.What about covering up all of my side walls with those instead?

Here is a "room" that is all diffusion, and it works very well.

Caveman Speakers. The Troglodytes.

Hi Lasse,

Firstly, my appologeis for the late reply.

Unfortunately, I have no experience at acoustically treating rooms like you show in your first post. The room that I’m working on is a regular shaped room with a flat ceiling, but it is very small, measuring only 3.4m x 2.14m which makes the ratio of reflected to direct sound quite high and with annoying room modes and early reflections.

For your room you can be certain that it has the same kind of problems depending on its dimensions and the materials used in its construction.

As for the position of the diffusers, I would assume that if an acoustic absorption panel works on a sloped surface (and I’m sure they do) then a diffuser panel should work ok as well.

If after treatment you still have problems with early reflections, then you may want to consider the use of a waveguide or horn loaded loudspeaker with dispersion down to as low a frequency as practical.

In my room I’m using acoustic grade Rock Wool slabs as detailed in this link;

Rockwool RWA45 50mm Insulation 1200mm x 600mm (6.48m2/ Pack) | Builder's Emporium

and suspending the panels via keyhole hangers as shown in this link;

40Pcs 42mm x 16mm Silver Tone Metal Keyhole Hanger Fasteners For Picture Frames | eBay

To cover the front of the frames I’m using speaker grill cloth as detailed in this link;

Speaker Grill Cloth White Yard 70" Wide

For the back of the panels I’m covering them with 3mm HDF board. And for the ceiling panels only, I’ll spray the inside of the HDF board and the back of the Rock Wool with adhesive so the Rock Wool doesn’t droop down in the centre of the panel.

I intend to make a 650mm x 650mm jig out of 3mm thick hard board that allows me to precisely place the keyhole hangers on the panels and at many places on the walls and ceiling. I can then quickly and easily determine the best placement and how many panels I need for optimum results.

For behind the listening position, I’m lining the walls with diffusers (as detailed in my previous post) from floor to ceiling. IMO, I don’t think you can have too many diffusers placed a few feet behind the listening position.

Hope this helps.

Peter

Firstly, my appologeis for the late reply.

Unfortunately, I have no experience at acoustically treating rooms like you show in your first post. The room that I’m working on is a regular shaped room with a flat ceiling, but it is very small, measuring only 3.4m x 2.14m which makes the ratio of reflected to direct sound quite high and with annoying room modes and early reflections.

For your room you can be certain that it has the same kind of problems depending on its dimensions and the materials used in its construction.

As for the position of the diffusers, I would assume that if an acoustic absorption panel works on a sloped surface (and I’m sure they do) then a diffuser panel should work ok as well.

If after treatment you still have problems with early reflections, then you may want to consider the use of a waveguide or horn loaded loudspeaker with dispersion down to as low a frequency as practical.

In my room I’m using acoustic grade Rock Wool slabs as detailed in this link;

Rockwool RWA45 50mm Insulation 1200mm x 600mm (6.48m2/ Pack) | Builder's Emporium

and suspending the panels via keyhole hangers as shown in this link;

40Pcs 42mm x 16mm Silver Tone Metal Keyhole Hanger Fasteners For Picture Frames | eBay

To cover the front of the frames I’m using speaker grill cloth as detailed in this link;

Speaker Grill Cloth White Yard 70" Wide

For the back of the panels I’m covering them with 3mm HDF board. And for the ceiling panels only, I’ll spray the inside of the HDF board and the back of the Rock Wool with adhesive so the Rock Wool doesn’t droop down in the centre of the panel.

I intend to make a 650mm x 650mm jig out of 3mm thick hard board that allows me to precisely place the keyhole hangers on the panels and at many places on the walls and ceiling. I can then quickly and easily determine the best placement and how many panels I need for optimum results.

For behind the listening position, I’m lining the walls with diffusers (as detailed in my previous post) from floor to ceiling. IMO, I don’t think you can have too many diffusers placed a few feet behind the listening position.

Hope this helps.

Peter

The combo absorption/diffusion thing is a big aspect of Bogic Petrovic's designs. He's over on gearslutz and I'm a fan of his work. Here's another link for you to ponder over that (to me) looks more appealing and fairly cost effective to do, the wood slats over the insulation, if you need to add some diffusion back.

Reflecting surfaces in control room not working as they should... - Gearslutz Pro Audio Community

Reflecting surfaces in control room not working as they should... - Gearslutz Pro Audio Community

Could you please elaborate on that? Does that mean that a diffuser must be effective down to 200Hz or lower to be of any benefit (in my case, that is), and thus a diffuser for, say, 600Hz and up would'nt be of any help? Somewhere else I've read that diffusion at such low frequencies doesn't make any sense in small rooms at all, so I'm a little confused now.

You've obviously done some homework on diffusion. Personally I like diffusion, but I've found it to be both expensive and extremely intrusive to do it well. By "doing it well", I mean that we're not only looking at the upper midrange frequencies, but those frequencies that give us some of the most trouble in room, because they're very difficult to control.

I'm speaking of the 100-500 Hz band. Not only is it difficult to control in terms of diffusion, but it also encompasses the beginning of the sparse mode region of the room and the inability to control directivity (keeping the early reflection SPL down via keeping the deposited acoustic energy off the walls, ceiling and floor) except by using absorption, bass traps, and arranging the listening position(s) to be in "just the right place". This is a "consolation prize of acoustic treatments", since this practice introduces a discontinuity in the acoustic characteristic of the room.

Diffusion that works down to 500 Hz, but then looks like a purely flat, reflective surface below that frequency brings in its own set of listening problems. Most hi-fi enthusiasts tend to ignore those subjects (and ensuing discussions of what to do about it). (I can say this by looking at the percentage of people using direct radiating woofers under midrange/high frequency horns, spacing their loudspeakers well away from the walls and living with the trades that result from that choice.) I've found that by doing something about it that actually works, the listening experience gets perhaps many times better, having dramatically more clarity. That's a portion of my "elaboration on that subject". I can be more verbose on that subject if needed.

Better loudspeaker directivity control in this band can also go a long way toward controlling these problems. [FYI...here is one solution to the problem: A K-402-Based Full-Range Multiple-Entry Horn - Technical/Modifications - The Klipsch Audio Community]. Unless you hear the difference, you might not be aware of the severity of the problem. This not only lessens the early reflection problems in this critical frequency band, it also seems to reduce the effects of absorption pads used in the near field to control imaging-destroying early reflections while retaining the sense of room size and presence that diffusion brings to those using loudspeakers that have directivity control in this band.

"The smaller the listening room, the better loudspeaker directivity that is needed." That means that the smaller the room, the bigger the horns that are needed to make it sound good.

Chris

That's the truth.Personally I like diffusion, but I've found it to be both expensive and extremely intrusive to do it well.

The store bought diffusers are $$$ and making your own can be time consuming. Plus the problem you mentioned in the 100-500Hz range. Too bad, as it does do wonders for the acoustics.

The store bought diffusers are $$$ and making your own can be time consuming. Plus the problem you mentioned in the 100-500Hz range. Too bad, as it does do wonders for the acoustics.But it looks odd.

It sure does, to some extend. But still somewhat 'better' than my untreated OSB walls, AFAIC.

As for the position of the diffusers, I would assume that if an acoustic absorption panel works on a sloped surface (and I’m sure they do) then a diffuser panel should work ok as well.

I've read that 1D diffusers only diffuse into one direction, so I'm not sure wether that's more of an advantage or disadvantage on a slanted wall. Maybe 2D diffusers (like the Skyline) would be more effective in my case? If they're effective at all, because there's just not enough room for diffusers effective below 600Hz or so.

Thanks for detailing your absorber construction. That's basically what I had intended in the first place, just without the backplate and the hangers. Maybe I'll just build and try some like yours though.

The combo absorption/diffusion thing is a big aspect of Bogic Petrovic's designs. He's over on gearslutz and I'm a fan of his work.

That looks quite nice indeed, thank you for that link. One more thing to consider trying out...

I'm speaking of the 100-500 Hz band. Not only is it difficult to control in terms of diffusion, but it also encompasses the beginning of the sparse mode region of the room and the inability to control directivity (...) except by using absorption, bass traps, and arranging the listening position(s) to be in "just the right place". This is a "consolation prize of acoustic treatments", since this practice introduces a discontinuity in the acoustic characteristic of the room.

Let's assume that diffusion in that range is not possible in my case. What would you advise me to do then? Start out with bass traps in the lower corners and some absorbers around the front end of the room, probably mounted up high so they reach (almost?) up to the 'ceiling'? I cannot hide the ridge purlin [or roof tree, dunno how you call it] altogether, because there's an expensive LED strip already that can't be moved anymore.

What about the LEDE approach? I'm not sure if I got that right, but from what I understood of your last post the use of 'standard' diffusers not reaching as deep down in frequency would impose additional problems?

You can also reduce the early reflections by using dipoles

For now I'd prefer to keep my trusty speakers and not change them for dipoles or horns. Thanks for the tip though; I'll keep that in mind in case there comes a good opportunity for me to test that one out.

If there is an LED strip running along the top, then I wonder if you could use plastic baffles or attic vent chutes running vertically along the slanted ceiling to space out fiberglass equivalent insulation (or some folks on the Gearslutz forum seem to like Caruso Isobond or sometimes Basotect in some applications) a little from the OSB. These could potentially allow ventilation of moisture but would need to be relatively unobstructed at the top and bottom. You could then cover these with acoustically translucent cloth as originally intended, though it might be desirable to also install wooden strips running vertically at intervals of every 2 or 4 feet in case of sagging, also so that if and as desired, you could also later cover them further with binary amplitude diffusion panels or grating, which require little depth and could be done on one's own with a little homework if inclined and not inept like me.

"True" diffusion (amplitude and phase) likely more depth than you have available, also can become very expensive very quickly. You might think of this diffusion as scattering in direction and time, and because of the time element, the diffusion should be positioned at least several wavelengths of the lowest frequencies effectively diffused from the listening position.

"True" diffusion (amplitude and phase) likely more depth than you have available, also can become very expensive very quickly. You might think of this diffusion as scattering in direction and time, and because of the time element, the diffusion should be positioned at least several wavelengths of the lowest frequencies effectively diffused from the listening position.

Let's assume that diffusion in that range is not possible in my case. What would you advise me to do then? Start out with bass traps in the lower corners and some absorbers around the front end of the room, probably mounted up high so they reach (almost?) up to the 'ceiling'? I cannot hide the ridge purlin [or roof tree, dunno how you call it] altogether, because there's an expensive LED strip already that can't be moved anymore.

What about the LEDE approach? I'm not sure if I got that right, but from what I understood of your last post the use of 'standard' diffusers not reaching as deep down in frequency would impose additional problems?

Let me clarify what I was saying about diffusion: it is good to have it but it needs to be effective for your particular room because you need to put it where absorption panels would otherwise go--which we know would be effective if diffusion was not used. So the issue is having the right stuff in the right places, and all of it works as advertised. Having something that stops working at 500 Hz and starts behaving like a flat/hard surface (which is the acoustic problem to begin with) isn't my first choice, especially in small listening rooms that need every inch of room boundaries accounted for in the reflections/absorption/diffusion. In larger rooms, you can get away with alternating absorption and diffusion panels, but in very small rooms--now you've got a problem.

As far as "LEDE"--I believe in a reflection-free zone (RFZ...read your D'Antonio). But I'm using loudspeakers like these that control their polars very well:

My loudspeakers are in the room corners with an RFZ-type concept used with absorption pads around the extreme nearfield of the loudspeakers. This works well. I really don't need a lot of absorption, and the spaciousness of the room's sound is not affected by the relatively small amount of absorption surrounding the acoustic radiators, mostly in the horizontal axis direction. My room dimensions: 12 (l) x 4.7 (w) x 2.7 (h) metres (~152 cubic metres total volume with three open doorways).

If you're using loudspeakers that splash acoustic energy around in changing polar patterns vs. frequency (i.e., anything with direct-radiating cone loudspeakers...especially bass), you've got a much larger issue to deal with--especially in a room with low ceiling and low overall volume. Bass traps, i.e., modified Helmholtz resonators/absorbers, are used to control modal behavior, and can be placed almost anywhere. Placing flat fiberglass panels across a boundary between two orthogonal room surfaces is a convenient place to automatically form the enclosed volume. So you're pretty much free to find places to put them. If you can't find a place, then round Helmholtz absorbers can be placed almost anywhere.

For higher frequencies, the ray tracing thing becomes important, so you have to put them where the major reflections are going to occur--usually within 2-3 metres of the front of the room (depending on where you place the loudspeakers).

The problem gets a little more complicated in that you need to be aware of the room's transition frequency...the hand-calculated Schroeder frequency...between modal low frequency behavior, and higher frequencies where sound control behaves more like optics or ray-tracing. For your triangular prism-shaped room, you're probably going to have to measure the room mode response/vs. frequency, since the Schroeder formula is really good only for shoe-box shaped rooms.

The challenge for you (assuming you own DR loudspeakers) is that you'll need to control the 100-500 Hz wide polars down to something like 50 x 50 degrees. A LEDE approach is just what is typically used for such an arrangement. That means a fair amount of absorption/diffusion in the front of the room around the loudspeakers. But note that the Schroeder frequency for your room is probably in the 250-300 Hz region, perhaps higher. So you're going to need absorption or sound reflectors/quasi-midbass waveguides for the 250-500 Hz band to narrow the polars significantly. How you do that is up to you, but you'll need to do some measurements I believe.

After that work is behind you, then adding absorption to control the higher frequency "slap" early reflections will be likely a cut-and-try approach, usually adding absorption in differing locations until you've got something that is a happy tradeoff point. Note that I stated that small rooms with sloping walls require a lot more absorption. Keep that in mind and do not be afraid to add a lot of absorption to control those slap reflections. It's going to be pretty obvious once you start to get close. You can add or subtract once you start to get everything dialed in and some listening time under your belt. You can use old blankets or quilts temporarily tacked up to approximate what you'll need in terms of full-time absorbers. If one of your family members is into quilt making, then all the better...

Chris

Last edited:

The problem is, you have created a new heated environment.That's true, under the attic floor there's a foil layer. According to the contractor this foil was not needed on the attic, because of the OSB. Was that wrong?

Vaulted ceiling attic venting 101:

Heat holds moisture

Heat and moisture pass through OSB. The perm rating is ok but it's not a vapour retarder

Air cools, condensation forms at the dew point, often on the underside of the decking (fiberboard)

With no air flow to dry the condensation, mold forms

Mold can be an irritant or worse depending on the person.

Rot OTOH takes years but can give you a heck of a headache if you're in the room when the roof collapses

Question is, why allow either to happen in the first place?

Again, if I am misreading you then disregard, but what you've said so far has me concerned.

Your Contractor may or may not be fully aware of these things but please don't trust the guy who's swinging the hammer as his primary interest is contracting, not design.

We moved from a regular rectangular listening room to a loft room for the HiFi.

Mine is a different kettle of fish system to yours.. horn system.

I had no problems with the upper channels.

No correction or any tricks there.

Just plonked down and all worked and measured well.

The mid bass, mid, upper mid and tweets sound just fine.

The below 90Hz bass however was like a rollercoaster. Suck outs and peaks.

I use DSP x/o (a DIY audio Najda set up) spent a good while working a solution that sounded good enough.

Got more powerful bass channel amps with higher damping factors.

That helped too.

I'm pretty happy with it.

Sounds a bit different and does something's better, some not quite so to my ears.

A few hifi visitors who have heard both have even commented that it sounds better than the previous room!

I would not know where to start with acoustic room correction stuff.

The tapped horns are lying down either side and point upwards. Worked best like that..

Pic of room.

Mine is a different kettle of fish system to yours.. horn system.

I had no problems with the upper channels.

No correction or any tricks there.

Just plonked down and all worked and measured well.

The mid bass, mid, upper mid and tweets sound just fine.

The below 90Hz bass however was like a rollercoaster. Suck outs and peaks.

I use DSP x/o (a DIY audio Najda set up) spent a good while working a solution that sounded good enough.

Got more powerful bass channel amps with higher damping factors.

That helped too.

I'm pretty happy with it.

Sounds a bit different and does something's better, some not quite so to my ears.

A few hifi visitors who have heard both have even commented that it sounds better than the previous room!

I would not know where to start with acoustic room correction stuff.

The tapped horns are lying down either side and point upwards. Worked best like that..

Pic of room.

Again, if I am misreading you then disregard, but what you've said so far has me concerned.

Not sure, but now you have me concerned that my roof might collapse anytime soon...

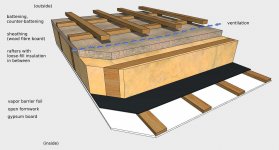

I've attached an image that pretty much resembles how my roof was built. The graphic comes from another contractor, who built several of my neighbor's homes. I tried to translate the descriptors as good as I can.

In my case (for the attic only) the foil, formwork and gypsum board were replaced by a single layer of OSB. Would you say that the missing foil (and probably the formwork) is a real problem? Should I do anything about it before it is too late?

Otherwise the construction is pretty similar to how the other walls of the house are built. The whole house, including the attic, is pretty much air tight to pass the blower door test, which it did. To counter the development of mould we have a whole-house ventilation system. The attic, as a heated room, is of course attached to the ventilation system, too.

Please tell me that everything's fine...

Attachments

So the issue is having the right stuff in the right places, and all of it works as advertised.

I see. The more often I re-read your posts, the better I think I understand them now. Many thanks again for your thorough explanations!

But note that the Schroeder frequency for your room is probably in the 250-300 Hz region, perhaps higher. So you're going to need absorption or sound reflectors/quasi-midbass waveguides for the 250-500 Hz band to narrow the polars significantly. How you do that is up to you, but you'll need to do some measurements I believe.

I can certainly provide you with some REW measurements. Would you help me with the interpretation? From what I can tell they don't look utterly crappy, but there're still some 20dB dips in the response. And I wouldn't know what to look out for to find the Schroeder frequency of my room...

Mine is a different kettle of fish system to yours.. horn system.

Looking good

I can certainly provide you with some REW measurements. Would you help me with the interpretation? From what I can tell they don't look utterly crappy, but there're still some 20dB dips in the response. And I wouldn't know what to look out for to find the Schroeder frequency of my room...

Certainly. I'll send my email address through a private message.

Chris

That won't happen but the roof does not meet building code standards where I live and I expect not where you live either. Moisture is moisture and it cares not where it livesNot sure, but now you have me concerned that my roof might collapse anytime soon...

There are some words being used that do not coincide with what we use here so I won't be using the term fiberboard (OSB here), open formwork (battens or purlins here), I will simply use terms like sheathing, etc.I've attached an image that pretty much resembles how my roof was built.

I see trouble on the horizon. The designer has taken certain ideas and implemented different materials that cannot do the job as intended. If the insulation fills the cavity to the top of the rafter, it must be air free. No air means no moisture. That's works fine but is difficult to implement. Batt insulation does not eliminate the air so you require a gap between it and the sheathing, with air the flow from the eaves right through to the ridge. You don't require ventilation above the sheathing, you usually have a breathable watershedding membrane on top of the sheathing to catch the small amount of moisture that get's by the tiles in really bad weather.

The correct way to build your roof with the materials at hand is as follows:

The insulation must be kept lower than the top of the rafters by 4 cm. Often some form of retainer is used like battens or WHY, that prevents it from billowing back up and blocking the air flow. At the eaves you must have air intake. The amount is determined by the total area. Around here it's a 300:1 ratio meaning 1 cm^2 of air flow for every 300 cm^2 of roof deck area. 50% of the ‘breathing’ is done at the eaves and 50% at or near the ridge. If that is done everything above that is fine the insulation is fine. The vertical battens allow for uninterrupted water flow during really bad weather and the cross strapping allows for the use of static breather vents rather than continuous ridge venting.

The easiest and least painful way of dealing with this is to pull down the OSB, remove the insulation, ensure there is a means for the air to flow at the eaves and at or near the ridge, add insulation retainers so when you reinstall the insulation it stops 4 cm short of the top of the rafters, then add a proper vapour retarder like polyethylene sheet making sure it is well sealed and reinstall the OSB. The OSB does not need the joints to be sealed, you can place the interior finish right over it or you can fill the holes and seams and do whatever you wish.

I will do a little chicken scratch drawing and post it a little later. It, along with this outline will give you trouble free construction. Otherwise mold will move in probably in a year and rot will be evident in less than 10.

There are some words being used that do not coincide with what we use here so I won't be using the term fiberboard (OSB here), open formwork (battens or purlins here), I will simply use terms like sheathing, etc.

The soft fiberboard is not OSB in this case, it's something like this stuff: http://www.steico.com/en/products/wood-fibre-insulation/. OSB is OSB here, too.

Open formwork was what the translator gave me for "Sparschalung". It's pretty much the same as your battens or purlins. We call them "Latten" or "Dachlatten", so it's "Lattung" and "Konterlattung" on the outside, and "Schalung" or "Sparschalung" on the inside.

I'm looking forward to your scratch. I've seen a lot of roofs already, because I sometimes have to add some cables there, and the way that I pictured them is certainly not uncommon around here...

If the insulation fills the cavity to the top of the rafter, it must be air free. No air means no moisture. That's works fine but is difficult to implement.

Since the insulation is a fluffy mess, it was blown into each of the cavities between the rafters through a hole. The holes were taped up afterwards. Like this stuff here: isofloc | Processing of injected insulation materials

The cavities are sealed air tight at the top and bottom ends with spray foam.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Room Acoustics & Mods

- Proposed acoustic treatment of attic room - overkill?