Hi everyone,

I need to find replacements for some green mylar polyester caps and some voltage regulators.

The Caps

The caps are read 2A104J which I deduced as 100nF (0.1uF) 100V. However I can't seem to find these on the normal places I get components from. I don't' want to buy thorough eBay or Alibaba.

Are green mylar polyester caps no longer used? Is that why I can't find them? If so, what is a suitable replacement?

The Voltage Regulators

There are 2 I am replacing. 1 looks like it was running very hot which is what cause one of the caps to go black (I think).

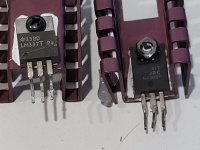

1 is clearly a a LM337T.

Is the other one an LM317T? It has 317 printed on it. I just want to double check before reaplacing.

Thanks

I need to find replacements for some green mylar polyester caps and some voltage regulators.

The Caps

The caps are read 2A104J which I deduced as 100nF (0.1uF) 100V. However I can't seem to find these on the normal places I get components from. I don't' want to buy thorough eBay or Alibaba.

Are green mylar polyester caps no longer used? Is that why I can't find them? If so, what is a suitable replacement?

The Voltage Regulators

There are 2 I am replacing. 1 looks like it was running very hot which is what cause one of the caps to go black (I think).

1 is clearly a a LM337T.

Is the other one an LM317T? It has 317 printed on it. I just want to double check before reaplacing.

Thanks

Attachments

The replies to your two specific questions are :

Yes, it is quite clearly an LM317 regulator.

Yes, those are 100nF film caps.

The replacement caps should be easy to find (eg. on the usual reputable online sources) and don't have to be green. Any film cap of the same ratings will do, you just have to check pin spacing and dimensions so that it fits properly.

(I can send you some green ones, almost identical to these, pulled from broken circuits, if you wish. Or I have the equivalent orange ones too )

)

On the other hand, it could be wise to check what happened to the circuit that you are repairing and why it failed.

If you post a picture of the circuit you are repairing, some here may suggest additional investigations.

Did you confirm that the two regulators are broken? both?

If heat caused it, then the heatsinks may be too small or incorrect mounting has caused insufficient heat dissipation. Does this need to be addressed?

Did you confirm that the caps are broken?

_

Yes, it is quite clearly an LM317 regulator.

Yes, those are 100nF film caps.

The replacement caps should be easy to find (eg. on the usual reputable online sources) and don't have to be green. Any film cap of the same ratings will do, you just have to check pin spacing and dimensions so that it fits properly.

(I can send you some green ones, almost identical to these, pulled from broken circuits, if you wish. Or I have the equivalent orange ones too

On the other hand, it could be wise to check what happened to the circuit that you are repairing and why it failed.

If you post a picture of the circuit you are repairing, some here may suggest additional investigations.

Did you confirm that the two regulators are broken? both?

If heat caused it, then the heatsinks may be too small or incorrect mounting has caused insufficient heat dissipation. Does this need to be addressed?

Did you confirm that the caps are broken?

_

Last edited:

My tip is to replace both LM317 and LM337 for new ones both of the same brand. Also buy two larger heatsinks with longer vertical fins, they seem underrated as they've changed colour. Please use metal tab regs as they are better with transferring the heat and mount them with isolation kits and larger washers at both sides. Maybe the PCB allows for drilling of 6 mm ventilation holes left and right of the regs UNDER the fins to improve air flow? If that is possible the situation may improve significantly.

You can use any Wima MKS type with the same ratings and the same pitch for the 100 nF.

Sometimes devices have design imperfections/errors that can be solved but then we need a name/type/pictures/schematic. Just like you need when you want something solved.

You can use any Wima MKS type with the same ratings and the same pitch for the 100 nF.

Sometimes devices have design imperfections/errors that can be solved but then we need a name/type/pictures/schematic. Just like you need when you want something solved.

Last edited:

RandomAudioGuy,

we can also notice that the LM337 has an isolated package (the tab is plastic) whereas the LM317 has a metal tab : as you probably know, the tab is in continuity with the center pin, and needs to be isolated from the heatsink.

Sorry if you already knew all this, it's just in case you didn't ...

If you order replacements for the regulators, make sure you select the appropriate package.

_

we can also notice that the LM337 has an isolated package (the tab is plastic) whereas the LM317 has a metal tab : as you probably know, the tab is in continuity with the center pin, and needs to be isolated from the heatsink.

Sorry if you already knew all this, it's just in case you didn't ...

If you order replacements for the regulators, make sure you select the appropriate package.

_

Last edited:

There are 2 I am replacing. 1 looks like it was running very hot which is what cause one of the caps to go black (I think)

Probably to exclude failure for about 1 Euro and to solve the overheating at the same time. That bloody "repair as cheap as possible"' is very annoying. Do stuff right at once.

Last edited:

Plain BS as the regs are already removed. THE chance to mount larger heatsinks and new regs "just in case". Resoldering old overheated desoldered parts so adding a new shot of heat twice and what then? Failure a few months from now? What is then exactly gained? That one is kept busy? The idea that one "saved money"?

Last edited:

Thanks for your comments so far everyone.

There is a longer story to this amp, but the short version is.

Is it a very big and powerful amp which runs very hot (by design). It's 20 years old. I was told the best way to ensure it running is to recap the power supply caps, which is what I was doing.

When I opened it to replace the power supply caps, I noticed that 1 of the voltage regulators had darker coloured caps and darker coloured solder joints under the board. This indicated to me it was running hotter than the other one. So I decided since I've got it opened that I will replace those. Then I thought since I was at it, I might as well replace all the caps while I'm at it - There's about 7 caps to replace.

I am good with a soldering iron, but not good at electronic repairs, so I can't check what is broken and what is not.

If it's not necessary to replace the caps, then I won't replace them, but I have no way of checking.

I will replace the main power supply caps, and I will replace the 2 voltage regulators and the green mylar caps since some of them have turned black from the heat.

I did find a place which stocks the green caps and have ordered them.

I don't understand this part sorry. I do see that 1 reg has a metal back and the other one has a black back. Do you mean I need to buy exactly the same? If so, how can I tell which one is which?

There is a longer story to this amp, but the short version is.

Is it a very big and powerful amp which runs very hot (by design). It's 20 years old. I was told the best way to ensure it running is to recap the power supply caps, which is what I was doing.

When I opened it to replace the power supply caps, I noticed that 1 of the voltage regulators had darker coloured caps and darker coloured solder joints under the board. This indicated to me it was running hotter than the other one. So I decided since I've got it opened that I will replace those. Then I thought since I was at it, I might as well replace all the caps while I'm at it - There's about 7 caps to replace.

I am good with a soldering iron, but not good at electronic repairs, so I can't check what is broken and what is not.

If it's not necessary to replace the caps, then I won't replace them, but I have no way of checking.

I will replace the main power supply caps, and I will replace the 2 voltage regulators and the green mylar caps since some of them have turned black from the heat.

I did find a place which stocks the green caps and have ordered them.

RandomAudioGuy,

we can also notice that the LM337 has an isolated package (the tab is plastic) whereas the LM317 has a metal tab : as you probably know, the tab is in continuity with the center pin, and needs to be isolated from the heatsink.

Sorry if you already knew all this, it's just in case you didn't ...

If you order replacements for the regulators, make sure you select the appropriate package.

_

I don't understand this part sorry. I do see that 1 reg has a metal back and the other one has a black back. Do you mean I need to buy exactly the same? If so, how can I tell which one is which?

The black back or tab is for the isolated package. The part number suffix usually contains the package code, something like lm337pf, but every mfg has there own package codes. Always refer to the mfg data sheet but you have to figure out who the mfg is, for that there is the logo

In your case you have an old national semi lm337t in a regular dual gauge To-220 and a JRC 317 in a isolated to-220 package

In your case you have an old national semi lm337t in a regular dual gauge To-220 and a JRC 317 in a isolated to-220 package

Last edited:

I don't understand this part sorry. I do see that 1 reg has a metal back and the other one has a black back. Do you mean I need to buy exactly the same? If so, how can I tell which one is which?

Besides rsavas indications :

You don't necessarily need to have the same versions as the current ones.

Insulated and non-insulated package are functionally the same.

Pros an cons:

The insulated version (package entirely plastic, black "tab") dissipates heat less efficiently, but makes mounting to the heatsink easier.

The non-insulated version (package with "metal tab" - I call "tab" the flat part where the screw to the heatsink goes...) requires an "insulator" between package and heatsink.

In a TO-220 package, the tab is connected to the middle pin.

For LM317 this is the Out voltage.

For LM337 this is the In voltage.

If it is in contact with a conductive heatsink, then the heatsink is at that voltage, and this is not safe.

Look up "TO-220 insulator" or "TO-220 mounting" for instructions.

Your regulator may have gotten "too hot" for these reasons :

- Excessive current pulled by the the circuit, due to some malfunctioning;

- Small heatsink, marginally sufficient to dissipate the heat;

- Oscillation, possibly because of a burned stabilizing cap (might be the purpose of those film caps);

(- other possible reasons may exist).

Would you like to learn how to test if the regulator functions properly?

You'll need _knowledge of the safety rules_ and a voltage meter.

_

Last edited:

Previous post is correct. The metal tab versions for both LM317 and LM337 are better with heat transfer and we know they get hot in this device. Less hot = good.

One of the most popular reasons in older devices was to drop the voltage to unrealistic low voltages, this only to prevent a more expensive transformer with separate windings. For instance dropping +/50V with resistors and regs to +/-15V for opamps. With for instance 100 mA load current the resistor and regulator then dissipate 3.5W (per side!). As you can see we drive in the dark without head lights when the requester does not mention brand/type and delivers no pictures or a schematic*. I have seen parts that became so hot hat they desoldered themselves and the owner only noticed when protection kicked in. From how it looks it seems at least one of the regs has already been replaced in the past.

In severe cases adding a 10 Euro small toroid is the best solution when the scenario is like indicated.

*My patience with helping out has reached the point that I no longer want to assist people delivering nothing only to want best advice. How can someone expect answers without telling what we are talking about?

Your regulator may have gotten "too hot" for these reasons :

- Excessive current pulled by the the circuit, due to some malfunctioning;

- Small heatsink, marginally sufficient to dissipate the heat;

- Oscillation, possibly because of a burned stabilizing cap (might be the purpose of those film caps);

(- other possible reasons may exist).

One of the most popular reasons in older devices was to drop the voltage to unrealistic low voltages, this only to prevent a more expensive transformer with separate windings. For instance dropping +/50V with resistors and regs to +/-15V for opamps. With for instance 100 mA load current the resistor and regulator then dissipate 3.5W (per side!). As you can see we drive in the dark without head lights when the requester does not mention brand/type and delivers no pictures or a schematic*. I have seen parts that became so hot hat they desoldered themselves and the owner only noticed when protection kicked in. From how it looks it seems at least one of the regs has already been replaced in the past.

In severe cases adding a 10 Euro small toroid is the best solution when the scenario is like indicated.

*My patience with helping out has reached the point that I no longer want to assist people delivering nothing only to want best advice. How can someone expect answers without telling what we are talking about?

Last edited:

.. I was told the best way to ensure it running is to recap the power supply caps ...

Who told you to do this and why didn't he offer you to perform the "repair"

(of a working item?) instead of leaving this to a newcomer ? Do you think

it was good advice ? How competent is he to lead you in this direction ?

The caps in first picture of post 1 have been black from he beginning and it

is quite normal that some semiconductors run hot. Owners did not care for

20 years. These components are fine.

i repeat post 5.

Oh oh the ever important tone. Should we be hypercorrect with tiny words that don't insult (A. no one. B: at all) and instead suggest below the belt remarks based on assumptions as a better way? The "plain B-word", man man man  ....

....

The regs have already been desoldered so the regs (either new or used) will need to be soldered again hence if there will be damage to the PCB that is unavoidable.

Now ask yourself what you have contributed and reread your own posts.

PS I was on topic. You started about feeling hurt (which is a choice).

The regs have already been desoldered so the regs (either new or used) will need to be soldered again hence if there will be damage to the PCB that is unavoidable.

Now ask yourself what you have contributed and reread your own posts.

PS I was on topic. You started about feeling hurt (which is a choice).

Last edited:

OP needs LM317 and LM337 in this version with 2x isolation kit with preferably larger M3 washers, heatsink paste of good quality and 2 larger heatsinks. If OP delivers info that we can calculate with there may be other solutions to reduce the heat.

Attachments

That they got too hot (I then conclude they are already broken) is comically one of the details the OP did give. So we get insufficient info and crawl over eachother to help out based on the limited details we got. You, I and others spend time to solve stuff and use our weapons to kill the duck. You with bow and arrow, I with a gun, some use hand grenades and we all shoot in various directions and at eachother but where is the duck?

Now, do we also have to ask if stuff is really broken? Next thing is we start a DIYAudio repair service receiving the devices with a ticket "repair, complaint unknown".

Disclaimer: no animals were hurt in the production of this post.

Now, do we also have to ask if stuff is really broken? Next thing is we start a DIYAudio repair service receiving the devices with a ticket "repair, complaint unknown".

Disclaimer: no animals were hurt in the production of this post.

Last edited:

- Home

- Amplifiers

- Power Supplies

- Help with replacing capacitors and voltage regulators