In this video they are talking about transformers and Jim White said that transformers with low flux are better than high flux transformers. I have not tried both, has anyone tried a low flux transformer?

Transformers | Pints with Ayre - YouTube

Transformers | Pints with Ayre - YouTube

Last edited:

I have, because I design and wind my own and experiment.

Any design is a compromise, you improve something at the cost of another factor.

It´s a good goal in OTs, because they are directly in the signal path, and lowering distortion is a good thing.

On a PT?

Not necessarily and I doubt you can "hear" it.

Any design is a compromise, you improve something at the cost of another factor.

It´s a good goal in OTs, because they are directly in the signal path, and lowering distortion is a good thing.

On a PT?

Not necessarily and I doubt you can "hear" it.

I can double that it is always a compromise, so I think there isn't 'a better' transformer. It can be better for some circumstances and may seriously depend on subjective intention of a designer.

One day I may want a low flux transformer, but the other day in other design I may want a high flux transformer, for example, to get maximum possible output power.

One day I may want a low flux transformer, but the other day in other design I may want a high flux transformer, for example, to get maximum possible output power.

In this video they are talking about transformers and Jim White said that transformers with low flux are better than high flux transformers. I have not tried both, has anyone tried a low flux transformer?

Transformers | Pints with Ayre - YouTube

So do you use flux capacitors in the power supply? Sorry.

G²

Maybe also flux compensators  ?

?

Hoping that JMFahey won't disagree, a PT should be designed in a way that the core just doesn't saturate neither when idling (enough turns per volt) nor with full load (enough iron) at the maximum allowed mains voltage. This yields to a transformer with stiff output voltages.

Arc welders or charging stations demand for something other, I know…

Best regards!

Hoping that JMFahey won't disagree, a PT should be designed in a way that the core just doesn't saturate neither when idling (enough turns per volt) nor with full load (enough iron) at the maximum allowed mains voltage. This yields to a transformer with stiff output voltages.

Arc welders or charging stations demand for something other, I know…

Best regards!

High flux, low flux transformers is BS to me.

I only know right flux and rating.

Same for O, R, C claimed to be THE best.

Whatever technology, toroids, EI and more;

There is only, the right flux for the core material with various quality and cost in steel and manufacturing.

I only know right flux and rating.

Same for O, R, C claimed to be THE best.

Whatever technology, toroids, EI and more;

There is only, the right flux for the core material with various quality and cost in steel and manufacturing.

High flux, low flux transformers is BS to me.

I only know right flux and rating.

Same for O, R, C claimed to be THE best.

Whatever technology, toroids, EI and more;

There is only, the right flux for the core material with various quality and cost in steel and manufacturing.

Of course there is an ideal flux transformer, in a idealized PC simulation where outlet voltage doesnt vary and where there isnt any DC present, when designing transformers you cant cut corners and expect "One size fits all" also the meaning of "low flux" is anything but an overall idea, there is nothing to "BS" here.

And what is the "right" flux for you?High flux, low flux transformers is BS to me.

I only know right flux and rating.

........

There is only, the right flux for the core material with various quality and cost in steel and manufacturing.

Not such a thing, design *is* a compromise, you pick the workpoint depending on your goals, which may vary *a lot*.

Have you designed, calculated power transformers ?

You bet.

Designed, built, made, sold and delivered some 20.000 by now, for own use and for third parties.

Most PT for SS and Tube musical instrument amps, which are *routinely* abused as part of their normal life, a few hundred OTs, for Tube amps and a few for SS ones too.

All very robust, not a dozen burnt ones in that full production, do the Math.

Using Class F and Class H "electric motor" rated (150/180C at high rotational force and high G ) , high insulation and thick wire for effective current all help achieve that.

OTs very robust too: high layer to layer and winding to winding Mylar insulation and impregnation with good high dielectric varnish all help them stand full power drive with disconnected speakers, worst combination possible.

Argentine Marshall representative "Import Music" routinely replaces original British made Drake or Dagnall transformers with my own when some problematic customer is careless and burns them twice in a row.

And then they never come back.

For Power Transformers the right flux is based on the power VA rating, depending on core material with tables considering safety ratings and local practices. Then calculations follow to define core sections and windings diameters and turns, the underlying rule being equal loss between copper and iron.And what is the "right" flux for you?

It is a balance between cost and losses. When cost is the ONLY object, you jam the iron with flux until it runs hot, and damm the waste heat. (This may include "safety ratings" but they are not so restrictive.) "Low flux" is inevitably high iron cost, but it may throw less crap around and that may reduce cooling or audio shielding costs.

High flux, low flux transformers is BS to me.

I only know right flux and rating.

Same for O, R, C claimed to be THE best.

Whatever technology, toroids, EI and more;

There is only, the right flux for the core material with various quality and cost in steel and manufacturing.

It may be stupid to complicate things unnecessarily. By the way, what does "flux" refer to?

But "A power tranformer" still is a quite wide area of different applications.For Power Transformers the right flux is based on ....

BTW, high or low flux is a misnomer: a 1MVA xformer might have 700,000 times the flux of 1VA one, but it will operate at a lower induction (B) which is what matters for losses, magnetic leaks, etc

This touches upon the essence of the subject matter. I am impressed.

machambin, I don't get that. Does it read Tesla times square meter and B times S?

Yes, it's B, the induction, that really counts in transformer design. Not to be confused with inductance, btw. It's unit is Tesla and formerly was Gauss. 1 T = 10 kG.

Best regards!

Yes, it's B, the induction, that really counts in transformer design. Not to be confused with inductance, btw. It's unit is Tesla and formerly was Gauss. 1 T = 10 kG.

Best regards!

Last edited:

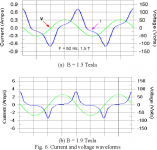

[PDF] Magnetizing Current, Harmonic Content and Power Factor as the Indicators of Transformer Core Saturation | Semantic Scholar

[PDF] Magnetizing Current, Harmonic Content and Power Factor as the Indicators of Transformer Core Saturation | Semantic ScholarIn saturation, a transformer core act as a source of current generating harmonics, some of which will flow directly toward the primary and secondary windings.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Power Supplies

- Low Flux transformers