QUESTION:

As I'm going though this receiver, I want to replace

all the old 51 year old ceramic caps with either new

films, or Micas, or new C0Gs.

I haven't done anything with the AM or FM boards, yet

and probably don't want to replace those tuning ceramics.

However for the other boards, like tone amp, etc, is there a

reason to keep the old ceramics in there? They get noisy with age,

they become micophonic etc. I assume even the 51 year old NP0s

on the phono board get that way also.

I'm upgrading Transistors, diodes (and caps) as I come across them

board by board for new modern replacements.

This receiver is for my little girl who loves music.

Cheers,

As I'm going though this receiver, I want to replace

all the old 51 year old ceramic caps with either new

films, or Micas, or new C0Gs.

I haven't done anything with the AM or FM boards, yet

and probably don't want to replace those tuning ceramics.

However for the other boards, like tone amp, etc, is there a

reason to keep the old ceramics in there? They get noisy with age,

they become micophonic etc. I assume even the 51 year old NP0s

on the phono board get that way also.

I'm upgrading Transistors, diodes (and caps) as I come across them

board by board for new modern replacements.

This receiver is for my little girl who loves music.

Cheers,

Last edited:

I don't see a "question" in those comments.

However, I think you might be a bit critical about ceramic capacitors.

Unless they're obviously causing a noticeable issue, I'd leave them alone.

This "recapping" idea has spread like a desease over the internet, and in many cases is not warrented.

However, I think you might be a bit critical about ceramic capacitors.

Unless they're obviously causing a noticeable issue, I'd leave them alone.

This "recapping" idea has spread like a desease over the internet, and in many cases is not warrented.

QUESTION:

As I'm going though this receiver, I want to replace

all the old 51 year old ceramic caps with either new

films, or Micas, or new C0Gs.

I haven't done anything with the AM or FM boards, yet

and probably don't want to replace those tuning ceramics.

However for the other boards, like tone amp, etc, is there a

reason to keep the old ceramics in there? They get noisy with age,

they become micophonic etc. I assume even the 51 year old NP0s

on the phono board get that way also.

I'm upgrading Transistors, diodes (and caps) as I come across them

board by board for new modern replacements.

This receiver is for my little girl who loves music.

Cheers,

Leave the transistors unless they're a problem. Subbing transistors is a massive PITA, and 95% of the time they never go bad.

I'm fairly certain that C0G/NP0 capacitors didn't exist when this receiver was built. What's there doesn't get noisy with age- they're pretty much going to behave the same as they did in when they were new.

You may consider replacing the existing caps with C0G/NP0 ceramics or polypropylene film, but look on the schematic and see what they're doing. If they're just bypass caps, then leave them be. You won't see a performance improvement. Nobody uses C0G / NP0 caps for bypass caps- they're expensive and there's no advantage to doing so.

On the other hand, if they're part of a filter (like in an EQ circuit) or being used as a coupling cap, then there may be a worthwhile improvement in distortion and / or microphonics when replaced by C0G/NP0 caps. Polypropylene film capacitors are acceptable for larger values common in parts of the EQ. I would be surprised if Marantz used ceramic caps in the audio path, however.

Mica capacitors, while excellent for RF usage, are expensive and do not perform as well as C0G/NP0 caps in filter circuits.

Unless you really know what you're doing, leave the tuner alone. Do an alignment if you know how (and have the tools), but don't go nuts replacing everything.

If the receiver is from 1972, then it's worth doing all of the small (PCB-mount) electrolytics, just because they're going to cause an issue sooner or later. Any electrolytics near a heat source are particularly suspect.

Big can caps for power supply filtering, if they measure okay for ESR and leakage current, can be left. They're expensive to replace and aren't as common of a failure.

Its first and foremost a Receiver not an amplifier and must be treated differently so "first principals " in audio amplifiers don't directly apply to a piece of electronic equipment designed to receive radio transmissions .

Its so ingrained here to---change all the capacitors etc that it seems to be a "Rule of Audio Law " , well it could be in an old audio amplifier but certainly NOT in a receiver.

Its "insanity " to change small value ceramics /silver mica /small value polystyrene which help TUNE--yes TUNE the receiver , there are plenty of radio basic books available to teach you about the RF section and IF section.

I have those types of capacitors in equipment older than me and they are still working okay .

Unless somebody who knows nothing of radio transmissions "plays around " with his dads old equipment causing it to cease functioning then leave the "Front End " alone .

Its so ingrained here to---change all the capacitors etc that it seems to be a "Rule of Audio Law " , well it could be in an old audio amplifier but certainly NOT in a receiver.

Its "insanity " to change small value ceramics /silver mica /small value polystyrene which help TUNE--yes TUNE the receiver , there are plenty of radio basic books available to teach you about the RF section and IF section.

I have those types of capacitors in equipment older than me and they are still working okay .

Unless somebody who knows nothing of radio transmissions "plays around " with his dads old equipment causing it to cease functioning then leave the "Front End " alone .

The future for parts for DIY people

I am a old guy so I can remember being able to buy RCA tubes of any kind.

I have watched over the years parts for tube electronics become more and more problematic.

I am just now trying to learn solid state stuff and seeing thru hole components starting to be replaced with surface mount stuff.

I don't understand how one would use SMD without building PCBs. PCBs seem like a PITA for prototyping.

Should I be stocking up on discreet components?

Are there any cost effective ways to get custom one off PCBs?

At least my DIY tube radios will survive a nuclear electromagnetic pulse...lol

Even if I am dead...lol

Cheers,

Billy

I am a old guy so I can remember being able to buy RCA tubes of any kind.

I have watched over the years parts for tube electronics become more and more problematic.

I am just now trying to learn solid state stuff and seeing thru hole components starting to be replaced with surface mount stuff.

I don't understand how one would use SMD without building PCBs. PCBs seem like a PITA for prototyping.

Should I be stocking up on discreet components?

Are there any cost effective ways to get custom one off PCBs?

At least my DIY tube radios will survive a nuclear electromagnetic pulse...lol

Even if I am dead...lol

Cheers,

Billy

Billy as you say tube technology was very hard to get parts for with the advent of solid state --but times have changed , if you check up new companies and parts you will find there is a revival in analog audio , even share prices of said companies are rising including LP,s & record decks.

Of course countries are cashing in on it all round the globe but the problem now is with old solid state early stuff with modern equivalents are getting harder to obtain unless you head East and there it is "built to a price " in other words the importers want a big profit so they order bulk supplies of low quality goods and yes Billy I spent months checking into it as well as "putting my money where my mouth is".

Manufacturers concentrate on SMD now as that's whats put into all sorts of 21century electronic goods so if you want reliable quality you go for reputable big spares companies but they sell many parts now in SMD so you must compromise .

Yes SMD PCB,s using the "flow " technique is how manufacturers install components but they can still be soldered into older equipment in a DIY case.

Expecting WW3 Billy ?

Of course countries are cashing in on it all round the globe but the problem now is with old solid state early stuff with modern equivalents are getting harder to obtain unless you head East and there it is "built to a price " in other words the importers want a big profit so they order bulk supplies of low quality goods and yes Billy I spent months checking into it as well as "putting my money where my mouth is".

Manufacturers concentrate on SMD now as that's whats put into all sorts of 21century electronic goods so if you want reliable quality you go for reputable big spares companies but they sell many parts now in SMD so you must compromise .

Yes SMD PCB,s using the "flow " technique is how manufacturers install components but they can still be soldered into older equipment in a DIY case.

Expecting WW3 Billy ?

...I'm fairly certain that C0G/NP0 capacitors didn't exist when this receiver was built. What's there doesn't get noisy with age....

I'm sure "NP0" dates to the early 1950s, in tandem with N1500 and P500- designed-in tempos really helped radio stability. (Coils have a mechanical tempco so you assort cap tempcos to compensate.)

I too never heard a ceramic cap get "a little noise". I have heard them go NOISY, dominating the output, but that seems rare. And there is far too much to go wrong in wholesale re-capping.

Yes the tubular ceramic capacitors with the numerical value in colored paint on them as per the resistor color code were in production in the 50,s , silver mica was very popular in RF sections of receivers previously and I have many dating right into the 60,s .

In large quantities Germany produced ceramic capacitors in disc form in the 40,s and I have a collection of them in "rutile " -titanium dioxide which had a linear temperature dependence .

As the small value RF capacitors held their values and stability I pulled them from uneconomic old tube radios + communications receivers . It paid off as polystyrene capacitors were only pennies back in those days now you are talking a $1+ for each one and the bigger values shoot up in price.

In large quantities Germany produced ceramic capacitors in disc form in the 40,s and I have a collection of them in "rutile " -titanium dioxide which had a linear temperature dependence .

As the small value RF capacitors held their values and stability I pulled them from uneconomic old tube radios + communications receivers . It paid off as polystyrene capacitors were only pennies back in those days now you are talking a $1+ for each one and the bigger values shoot up in price.

Wiseoldtech, H713, Duncan2, Planobilly, PRR:

Points well taken. Two of the caps actually have NP0 printed on them.

I do have plenty of polystyrene caps and many silver micas.

I also have supply of films and some in smallish values.

The ceramics in question are in the phono section the section I'm working on.

We have 4pf 50v and 40pf 50V ceramics,

I was going to replace the 40pf with modern 47pF 50V C0Gs.

4pP 50V, I do have silver mica RF caps in that value, 4pF 275V,

These are the open frame RF caps, with one mica wafer in the middle

with the silver pressed fit to the mica. I was going to conformal coat these

caps before placing in service on the board.

My standard silver micas I have 10pf or 7 pf have to check.

I've replaced all six transistors with modern KSC1815.

They were the following:

2x 2SC458

4x 2SC1000

The only other thing left to do is installing the new electrolytics.

while ridding the board of the 22 uf solid tantalum caps.

The receiver is 51 years old, it worked when received.

Points well taken. Two of the caps actually have NP0 printed on them.

I do have plenty of polystyrene caps and many silver micas.

I also have supply of films and some in smallish values.

The ceramics in question are in the phono section the section I'm working on.

We have 4pf 50v and 40pf 50V ceramics,

I was going to replace the 40pf with modern 47pF 50V C0Gs.

4pP 50V, I do have silver mica RF caps in that value, 4pF 275V,

These are the open frame RF caps, with one mica wafer in the middle

with the silver pressed fit to the mica. I was going to conformal coat these

caps before placing in service on the board.

My standard silver micas I have 10pf or 7 pf have to check.

I've replaced all six transistors with modern KSC1815.

They were the following:

2x 2SC458

4x 2SC1000

The only other thing left to do is installing the new electrolytics.

while ridding the board of the 22 uf solid tantalum caps.

The receiver is 51 years old, it worked when received.

Attachments

Last edited:

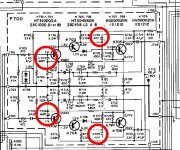

There are five other boards I'm concerned with:

P100 FM Front End Assy

P200 FM IF Amplifier Assy

P300 MPX Stereo Decoding Amplifier Assy

P550 Muting control Amplifier Assy

P150 AM Tuner Unit Assy

In these for longevity sake it was going to replace the electrolytics.

I won't be around to service this receiver 20 - 40 years from now and

I know I'll do it right. I was not going to replace any of the tuning ceramic

capacitors for the reasons cited by duncan2, PRR and others. Namely they compensate

for the tuning tempco's. Change them and the receiver will never function properly.

That I understand. I'm more concerned with the electrolytics, they've lived their

40 year life so far.

Finally there are two other boards:

P450 Tone Control Assy

P600 Loudness High and Lower Filter Switch Assy.

For the last two perhaps electrolytics, cleaning and

I'll check the ceramics.

Essentially I'm following the recommendation of Morgan Jones

in his Valve Amplifiers, 2nd ed text from Newnes, when he states,

"Ceramic capacitors, these have no place in analogue audio circuitry!"

He continues, "Ceramic capacitor excel as high frequency bypasses

in digital circuitry where there poor stability of value and low 'd' is not a problem."

Anything else I need to consider?

Or

am I going down the rabbit hole?

Cheers,

P100 FM Front End Assy

P200 FM IF Amplifier Assy

P300 MPX Stereo Decoding Amplifier Assy

P550 Muting control Amplifier Assy

P150 AM Tuner Unit Assy

In these for longevity sake it was going to replace the electrolytics.

I won't be around to service this receiver 20 - 40 years from now and

I know I'll do it right. I was not going to replace any of the tuning ceramic

capacitors for the reasons cited by duncan2, PRR and others. Namely they compensate

for the tuning tempco's. Change them and the receiver will never function properly.

That I understand. I'm more concerned with the electrolytics, they've lived their

40 year life so far.

Finally there are two other boards:

P450 Tone Control Assy

P600 Loudness High and Lower Filter Switch Assy.

For the last two perhaps electrolytics, cleaning and

I'll check the ceramics.

Essentially I'm following the recommendation of Morgan Jones

in his Valve Amplifiers, 2nd ed text from Newnes, when he states,

"Ceramic capacitors, these have no place in analogue audio circuitry!"

He continues, "Ceramic capacitor excel as high frequency bypasses

in digital circuitry where there poor stability of value and low 'd' is not a problem."

Anything else I need to consider?

Or

am I going down the rabbit hole?

Cheers,

Last edited:

Hi, I agree that the re-cap concept for older gear has gone wild. I have two Marantz receivers from that vintage and a console amp from 1969. None have experienced any sort of capacitor issue and all are in use constantly. The only things that have ever caused trouble were a failed power switch on the amp, panel lights burning out on one receiver and a speaker relay that had some oxidation on the contacts. All three units still work like original. Marantz up to about 1978 or so was a rather conservative company and expected their gear to last forever. I recall an add from some years back where a receiver was in a house fire and had smoke and water damage. They dried it out and it worked fine. A few other brands (that I won't name here) are not so good and can require selective capacitor replacement of their electrolytics. The other capacitors should only be replaced if there is a clear indication of an issue.

I'll echo gofar99's comments.

And I also remember that Marantz receiver advertisement that survived a house fire.

Even if it was a true story, I'm sure Marantz used it for boosting sales purposes.

In most Marantz equipment, receivers that I've had in the shop, the only ones needing caps were those that used small yellow cloaked electrolyics on the amp boards. - they all were bad.

They definitely need to be yanked out and replaced.

This "recap" craze really needs to be rationalized, and worriers need to understand that just because the internet says something, it's not always needed to be followed.

In fact, in my experience, most cap failures seem to be found in recent manufacture products.

Go figure.

And I also remember that Marantz receiver advertisement that survived a house fire.

Even if it was a true story, I'm sure Marantz used it for boosting sales purposes.

In most Marantz equipment, receivers that I've had in the shop, the only ones needing caps were those that used small yellow cloaked electrolyics on the amp boards. - they all were bad.

They definitely need to be yanked out and replaced.

This "recap" craze really needs to be rationalized, and worriers need to understand that just because the internet says something, it's not always needed to be followed.

In fact, in my experience, most cap failures seem to be found in recent manufacture products.

Go figure.

gofar99, wiseoldtech,

Well just to satisfy myself, I pulled the 40pf caps and tested them

compared to to sets of 47pf C0G caps. The 51 year old NP0s test

better than the new one's from Vishay or Kemet.

Farard value within 0.1pF vs new 2-3pF variation

& d where Marantz d = 0.000 or 0.001 vs new 0.007,0.006.

So, okay I'm glad I asked, and that I confirmed.

I guess I'm just a doubting Thomas, go figure.

I'm still working on replacing the electrolytics...regardless

and out of spec resistors when I find them.

I'm thinking use full life has long expired. Yes?

So am I out of my mind replacing the 1uf Caps in those various stages

with low leakage Nichicon 105*C caps? Or should I use the 1uf Wima's

that I bought to do the job also?

As I said I won't be around to replace them down the road in another

40 or 50 years. I did find that house fire ad and included it here.

Cheers,

Well just to satisfy myself, I pulled the 40pf caps and tested them

compared to to sets of 47pf C0G caps. The 51 year old NP0s test

better than the new one's from Vishay or Kemet.

Farard value within 0.1pF vs new 2-3pF variation

& d where Marantz d = 0.000 or 0.001 vs new 0.007,0.006.

So, okay I'm glad I asked, and that I confirmed.

I guess I'm just a doubting Thomas, go figure.

I'm still working on replacing the electrolytics...regardless

and out of spec resistors when I find them.

I'm thinking use full life has long expired. Yes?

So am I out of my mind replacing the 1uf Caps in those various stages

with low leakage Nichicon 105*C caps? Or should I use the 1uf Wima's

that I bought to do the job also?

As I said I won't be around to replace them down the road in another

40 or 50 years. I did find that house fire ad and included it here.

Cheers,

Attachments

Last edited:

When there is space, I like to replace 1 uF electrolytic coupling caps with film, mostly because they last longer.

I've got mixed feelings on the whole recapping thing. I agree that people often go crazy with it, but at the same time I've also seen a lot of equipment with bad electrolytic capacitors. The biggest determining factor in the lifespan of electrolytic caps is heat, so I'm more likely to recap hot-running equipment as a form of "preventative maintenance" than equipment that barely gets warm.

IMO, if reliability is a big concern, it's worthwhile to replace the smaller value electrolytics in a receiver, particularly if it has a lot of hours on it. In a lot of cases, it isn't obvious that they've failed, but their leakage current has started to get excessively high. This can make the whole issue with pots and switches worse. For a cheap receiver, it may not be worth it, but for a high-end piece of gear I think it's a good idea. It usually doesn't cost that much.

I've got mixed feelings on the whole recapping thing. I agree that people often go crazy with it, but at the same time I've also seen a lot of equipment with bad electrolytic capacitors. The biggest determining factor in the lifespan of electrolytic caps is heat, so I'm more likely to recap hot-running equipment as a form of "preventative maintenance" than equipment that barely gets warm.

IMO, if reliability is a big concern, it's worthwhile to replace the smaller value electrolytics in a receiver, particularly if it has a lot of hours on it. In a lot of cases, it isn't obvious that they've failed, but their leakage current has started to get excessively high. This can make the whole issue with pots and switches worse. For a cheap receiver, it may not be worth it, but for a high-end piece of gear I think it's a good idea. It usually doesn't cost that much.

QUESTION:

As I'm going though this receiver, I want to replace

all the old 51 year old ceramic caps with either new

films, or Micas, or new C0Gs.

I haven't done anything with the AM or FM boards, yet

and probably don't want to replace those tuning ceramics.

However for the other boards, like tone amp, etc, is there a

reason to keep the old ceramics in there? They get noisy with age,

they become micophonic etc. I assume even the 51 year old NP0s

on the phono board get that way also.

I'm upgrading Transistors, diodes (and caps) as I come across them

board by board for new modern replacements.

This receiver is for my little girl who loves music.

Cheers,

I've been repairing electronics at the consumer and broadcast level for almost 50 years. The number

of ceramic caps I've replaced can be counted on 1 hand. Does the unit have any noise issues? I'm betting

most everything is fine and the best thing you can do for it is to enjoy it until something actually fails. I've

had to repair units that somebody wanted to 'improve' by replacing parts that did not need replacing. It is a

PITA to restore things that have no business being worked on. Save your efforts for something actually

broken. if you DO choose to change all those parts, it will no longer be a Marantz.

G²

I don't agree that replacing capacitors is madness. I routinely replace capacitors for clients who send me their treasured Marantz, Luxman, NAD, etc for restoration. I test all of the capacitors pulled for value, leakage, Vlos, D and ESR and while some capacitors are like new, many are not. I can't predict if the good ones will last another decade or another year, so just replace the lot.

I tend to replace them with Tonerex, Fine Gold or Cerafine, or where possible Wima film which can be got in very compact packages up to a few µF. I check all capacitors for microphonics, including existing non-electrolytic ones and replace as necessary. I replace caps as required for stability.

The best capacitor is no capacitor, and often interstage capacitors can be removed or shunted; it depends on the circuit.

Manufacturers may also skimp on component values. By the time there are ½ dozen high pass coupling caps in a row (don't forget the coupling caps in source devices too) all picked for a 20Hz corner frequency, things will be rolling off from 50Hz and audible phase effects will run into 100s of Hz. I calculate an appropriate value for the coupling caps for ƒc of 0.2 - 2 Hz or so depending on the intrinsic value of the amplifier in question.

I've just done a Marantz PM-64 II that was completely underwhelming as it came to me. Funnily enough the critical caps that made all the difference were three small electrolytics in each channel used for tone control and coupling. The values were something like 0.47µf and 1.0µf. Films would have been stupidly cheap for such small values so the only reason I can think that type of capacitor was chosen in those position was to stop the amplifier sounding as good as its bigger, more expensive brethren.

Go mad, SyncTronX. There is magic to be had, plus the joy of giving an old treasure another few decades of life most likely sounding even better than new.

I tend to replace them with Tonerex, Fine Gold or Cerafine, or where possible Wima film which can be got in very compact packages up to a few µF. I check all capacitors for microphonics, including existing non-electrolytic ones and replace as necessary. I replace caps as required for stability.

The best capacitor is no capacitor, and often interstage capacitors can be removed or shunted; it depends on the circuit.

Manufacturers may also skimp on component values. By the time there are ½ dozen high pass coupling caps in a row (don't forget the coupling caps in source devices too) all picked for a 20Hz corner frequency, things will be rolling off from 50Hz and audible phase effects will run into 100s of Hz. I calculate an appropriate value for the coupling caps for ƒc of 0.2 - 2 Hz or so depending on the intrinsic value of the amplifier in question.

I've just done a Marantz PM-64 II that was completely underwhelming as it came to me. Funnily enough the critical caps that made all the difference were three small electrolytics in each channel used for tone control and coupling. The values were something like 0.47µf and 1.0µf. Films would have been stupidly cheap for such small values so the only reason I can think that type of capacitor was chosen in those position was to stop the amplifier sounding as good as its bigger, more expensive brethren.

Go mad, SyncTronX. There is magic to be had, plus the joy of giving an old treasure another few decades of life most likely sounding even better than new.

In post ##10 its pointed out that the famed Morgen Freeman he of tube amplifiers doesn't like COG ceramics, that is not the view held by JLH and others including, if my memory is right D.Self .

Be that as it may I will repeat I do not agree with pulling very small value capacitors of the elements I posted as in HF your receiver has been TUNED using those capacitors and if as I think there are "radio types " here on DIY audio they must realize that the higher in frequency you go even short legs on those capacitors count for frequency check on the correct station positioning on your dial .

As a matter of fact in old TV tuners you were warned by the manufacturers that even doing small changes to the type/positioning or even interfering in the components would cause loss of TV channels.

To impress this on those doing their own repairs many articles were printed that if you insist on doing it even the solder flow contributed to DE-TUNING.

Those not up to receiver old school technology can easily destroy a receiver , take IF alignment --no NOT "peak it up " the skirts have to be broad enough for correct fidelity of operation and that requires specialized RF test equipment to show it on an oscilloscope screen.

Be that as it may I will repeat I do not agree with pulling very small value capacitors of the elements I posted as in HF your receiver has been TUNED using those capacitors and if as I think there are "radio types " here on DIY audio they must realize that the higher in frequency you go even short legs on those capacitors count for frequency check on the correct station positioning on your dial .

As a matter of fact in old TV tuners you were warned by the manufacturers that even doing small changes to the type/positioning or even interfering in the components would cause loss of TV channels.

To impress this on those doing their own repairs many articles were printed that if you insist on doing it even the solder flow contributed to DE-TUNING.

Those not up to receiver old school technology can easily destroy a receiver , take IF alignment --no NOT "peak it up " the skirts have to be broad enough for correct fidelity of operation and that requires specialized RF test equipment to show it on an oscilloscope screen.

I recently sold a Marantz 2230 that I bought new in early 1973. In 48 years of constant use the only repairs it needed were:

-a failed power switch that wouldn't latch (very common failure in these at about 10 years.)

-failed output transistors (one channel failed at about 40 years of age taken out by a failed resistor so I replaced these parts on both channels.)

-the light bulbs that illuminate the dial, STEREO light, tuning meter, etc. (I think I redid these twice over the years and they were due again when I decided to sell the unit.)

All of the caps in the unit were OEM factory units and when I replaced the power transistors an output test showed it meeting original factory specs.

-a failed power switch that wouldn't latch (very common failure in these at about 10 years.)

-failed output transistors (one channel failed at about 40 years of age taken out by a failed resistor so I replaced these parts on both channels.)

-the light bulbs that illuminate the dial, STEREO light, tuning meter, etc. (I think I redid these twice over the years and they were due again when I decided to sell the unit.)

All of the caps in the unit were OEM factory units and when I replaced the power transistors an output test showed it meeting original factory specs.

Last edited:

The fact a unit functions does not mean it is working or sounding as good as it should. I recently rebuilt a Marantz 2216. One problem was that the FM sounded bright; it had a broad hump to +3dB in the region from ~2kHz to ~13kHz. Yet it met factory specs because the factory spec was +/- 2dB 20 Hz to 15kHz on FM within which the 3dB lump fitted. Turns out that the deemphasis circuit was a cockup by Marantz with two ƒc, one at ~6kHz and another at ~10kHz, instead of a single ƒc at ~3.2kHz; so the filter starts too shallow and ends too steep. FM is perfect now the deemphasis is implemented correctly.

The same receiver responded amazingly to a capacitor refresh with carefully up-spec capacitors in appropriate places. That diminutive 2216 ended up being the greatest Cinderella to Princess transformation I have heard yet, an absolutely astounding improvement.

The same receiver responded amazingly to a capacitor refresh with carefully up-spec capacitors in appropriate places. That diminutive 2216 ended up being the greatest Cinderella to Princess transformation I have heard yet, an absolutely astounding improvement.

- Home

- Design & Build

- Parts

- Rebuilding 1972 Marantz Receiver