Thinner MDF sheets are denser than thicker MDF sheets due to the way the particles are compressed together in manufacture. See attached pdf from a certain manufacturer. One could glue thin sheets together if you were so inclined.

With the furniture MDF from the wood work workshop I have found it’s not necessary. You can even see the difference in the two types of products. So maybe looking for a better quality is the way to go. At least I have found it worthwhile. 😉

Regarding the MDF, there are also different quality MDF. The one used at “my” wood work workshop are quite different from the one that can be bought in the hardware store. More stiff and dense. Can’t prove it, but knocking on it get the feeling of less ringing.

I would agree. The MDF kit material I get from GSG and PE are a better quality of MDF.

Good point about MDF not being the same quality and weight per liter volume. It is definitely something I am going to keep in mind. I still think that the heavier, more mass, is a good thing all round. But even standard density MDF, if that is what is available to you, my only assurance is that you will still get a good result.

PS: I know that some have used 18mm hardwood with 25mm MDF to make up the rest of the front panel, and that certainly has my thumbs up!

PS: I know that some have used 18mm hardwood with 25mm MDF to make up the rest of the front panel, and that certainly has my thumbs up!

JarBar,

Thank you for sharing some details about your listening spaces in post #4349 of this thread.

It's good to see that you have the drivers in hand - good luck with your build!

And of course we look forward to your comments on the Elsinore ULD once you have them built and done some listening. 🙂

Joe,

Things are moving quickly it seems!

Thank you for sharing some details about your listening spaces in post #4349 of this thread.

It's good to see that you have the drivers in hand - good luck with your build!

And of course we look forward to your comments on the Elsinore ULD once you have them built and done some listening. 🙂

Joe,

Things are moving quickly it seems!

In the past I've used some good MDF manufactured on the GC and it was closer to 0.8kg/litre. Sheets were 32mm thick.

This getting cabinets built in Australia/ NSW isn't easy and perhaps for others who haven't a full wood shop .

What about getting cabinet plans CAD files to these guys and they can have an option or 2 ready Baltic Birch plywood sounds good to me ....

Sorry guys, i'm not building this speaker, but saw this link and its pretty awesome IMO. Please do let me know if any more Aussies make an order with them. the enclosures are fairly reasonably priced for the apparent quality, but the shipping is OTT!! I was looking at the 2 way monitor chassis and they will sell a pair for around $300AUD, but the shipping is $320AUD. still not a bad value, but it would be awesome if a few of us could split up a shipment and save a bit on shipping.

You are soo right about the lack of choices for enclosure machining here in OZ. any CNC quote I have gotten has been crazy expensive. I could buy a half decent CNC machine and do it myself for the same price.

@Jarbar: Wow!! now that's a nice picture!! 6 of those in the one room!!. I'm jelly 😱

while i'm here. does anyone have any tips on where to get the black core HDF in australia? I found one place in Melbourne , but they have not replied to my enquiry and i'm uncertain if it is HDF. they call it MDF, but the only black MDF i've seen before was at troelsgraven, but he called it HDF. it apparently machines even better than MDF and I love the idea of it being solid black and not needing further finishing, other than perhaps a hard clear coat.

I count 8 😉.

Ha!! so do I. as I was typing it I questioned myself. I should have checked. Thats crazy!! that like $3500AUD just in mid-woofers!! before tax and shipping. I have to wonder, given purifi are soon to release some larger drivers, would it not be prudent to wait and see what those are about? Don't mind me, like I said, i'm well jelly.

The Chinese tend to charge a lot for shipping as a way to make money as the items are usually very cheap. It can be difficult to get them to move on the shipping unless you buy 10 or more of the same item.I was looking at the 2 way monitor chassis and they will sell a pair for around $300AUD, but the shipping is $320AUD. still not a bad value, but it would be awesome if a few of us could split up a shipment and save a bit on shipping.

The costs and time of building a CNC for this purpose add up quickly.I could buy a half decent CNC machine and do it myself for the same price.

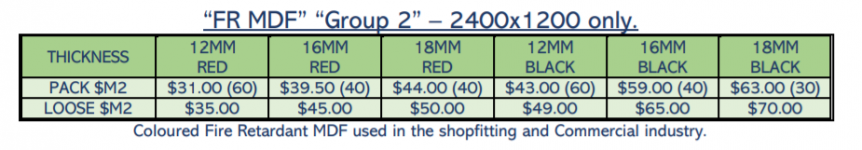

Valchromat or DMK does a Coloured Fire resistant MDFwhile i'm here. does anyone have any tips on where to get the black core HDF in australia?

Attachments

Oh I know, just as anything DIY costs time, but at the end, I would have a CNC machine, as well as my cabinets. There is all manner of things I want a CNC for and I nearly ordered an Axiom i2r 6, from the guys at BGPRECISION in Melbourne. I even flew down to check them out in late 2019, but then both my parents passed away and the pandemic hit; putting the brakes on those plans. I had gone down to look at the i2r 4, but walked away wanting the 6 ...

I've already got the baffles modelled up. I had decided at that time that I would just buy a CNC, fully made and more importantly, fully supported. I was just using it as an example, because the quotes I got, I could have gotten a half decent kit machine.

Thanks @fluid. re DMK, aha, right, I didn't realize they had it. love those guys. I was planning to go visit them next time i'm in Brisbane, as I planned to get some ply and veneer from them as well. I wonder if it's the same product they have at bord. I think their main showroom is at the GC though. maybe a trip is in order. Gotta go down for XMAS shopping anyway ... ugggh.

I've already got the baffles modelled up. I had decided at that time that I would just buy a CNC, fully made and more importantly, fully supported. I was just using it as an example, because the quotes I got, I could have gotten a half decent kit machine.

Thanks @fluid. re DMK, aha, right, I didn't realize they had it. love those guys. I was planning to go visit them next time i'm in Brisbane, as I planned to get some ply and veneer from them as well. I wonder if it's the same product they have at bord. I think their main showroom is at the GC though. maybe a trip is in order. Gotta go down for XMAS shopping anyway ... ugggh.

Last edited:

[

You are soo right about the lack of choices for enclosure machining here in OZ. any CNC quote I have gotten has been crazy expensive. I could buy a half decent CNC machine and do it myself for the same price.

Hi Gadget I used to have 3 options in my country NSW area -but alas all gone 😡 I have faith in this store I linked - sadly freight to Australia is extortion it used to be half this before Covid. But the options in Australia -especially NSW! are a bloody joke - an elaborate speaker cabinet - is mega bucks. I am over doing it myself now - better leave it to the professionals 😀 Why waist all that time when you could be shagging super models (extreme daydreaming) sigh!

You are soo right about the lack of choices for enclosure machining here in OZ. any CNC quote I have gotten has been crazy expensive. I could buy a half decent CNC machine and do it myself for the same price.

Hi Gadget I used to have 3 options in my country NSW area -but alas all gone 😡 I have faith in this store I linked - sadly freight to Australia is extortion it used to be half this before Covid. But the options in Australia -especially NSW! are a bloody joke - an elaborate speaker cabinet - is mega bucks. I am over doing it myself now - better leave it to the professionals 😀 Why waist all that time when you could be shagging super models (extreme daydreaming) sigh!

Oh I know, just as anything DIY costs time, but at the end, I would have a CNC machine, as well as my cabinets. There is all manner of things I want a CNC for and I nearly ordered an Axiom i2r 6, from the guys at BGPRECISION in Melbourne. I even flew down to check them out in late 2019, but then both my parents passed away and the pandemic hit; putting the brakes on those plans. I had gone down to look at the i2r 4, but walked away wanting the 6 ...

Overview — Goliath CNC this seems to promise so much but how many more speakers am I going to build now?

I will see how this project progresses

Just FYI for everyone - my order is now finalized after payment clearance etc. Per our contact at Purify, Claus, my set are scheduled to be made and shipped by just before christmas as it stands, so about a 4 week lead time as all are made to order.

So if they arrive just after christmas perhaps Joe'll have the kinks out of the design by the time they show up 😀.

So if they arrive just after christmas perhaps Joe'll have the kinks out of the design by the time they show up 😀.

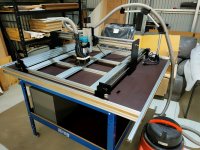

That is a nice looking machine and not an outrageous price for a completed unit. My own is somewhat similar with linear rails but still not running 🙄Oh I know, just as anything DIY costs time, but at the end, I would have a CNC machine, as well as my cabinets. There is all manner of things I want a CNC for and I nearly ordered an Axiom i2r 6, from the guys at BGPRECISION in Melbourne.

They moved to Molendinar but I would not call it a showroom. They have samples of most stuff to look at but it is basically a warehouse.I think their main showroom is at the GC though. maybe a trip is in order. Gotta go down for XMAS shopping anyway ... ugggh.

Attachments

Hmmm, Not really convinced by that audiogod66. They claim 0.1mm repeatability, but I cant see how that would be the case, given the mechanism. It also would appear it would struggle at (or just flat out not do) 3D contouring, being more of a '2 axis' machine in effect. the enormous work area possibilities are a bonus, but buying something like that direct from Italy, with no local support and nothing else like it around, seems like asking for trouble. Not cheap either and seems pretty slow. unless you absolutely need the huge work area, I would definitely buy something like the i2r range locally before that.

Last edited:

Gadget I cannot disagree but I am certain machines like this in 5 years will rule the roost - no need for a workshop just some space and away they go 🙂

That is a nice looking machine and not an outrageous price for a completed unit. My own is somewhat similar with linear rails but still not running 🙄

They moved to Molendinar but I would not call it a showroom. They have samples of most stuff to look at but it is basically a warehouse.

aha, ok, so just down the road from griffith uni, GC. Thats where they have their fabrication factory too isnt it? They will do CNC for you using their stock too on site IIRC, but i'm not sure of their capabilities.

Yes, very solid machines, trickle down tech from the more industrial axiom AR range really nice guys at BGPRECISION too. Yes. being me, I was convinced for a long time I would build a machine to get better value, but the more research I did and given my noob status in the field, the more convinced I was that for a change, I needed it fully built and locally supported.

Yours is a Great looking machine though mate! what's the problem? anything the brains trust can help with? issue with the electronics? That must be doing your head in, having that there, so close to functional 🙁

Last edited:

Available time and mission creep, if I just design this 3D printed part that will make this work better and be neater etc. etc. .... and yes having it sit in the shed so close to going but not is quite frustrating.Yours is a Great looking machine though mate! what's the problem? anything the brains trust can help with? issue with the electronics? That must be doing your head in, having that there, so close to functional 🙁

And yes not far from the Uni

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread