To experiment with FIR filters, get the software:

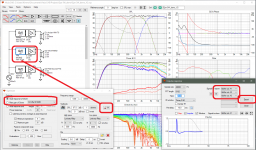

Rephase

JRiver Media Center (use inbuilt DSP with option to use the convolver). Other VST plugin can be oploaded to this.

Cheap laptop (Most older Lenovo Thinkpad do great in regards to low internal latencys)

Jriver is free for 30 days. Maybe consider buying it, because that solution is still the most easy way to trial.

You also need a soundcard. For trial, you can try a 2 way, so you only need a simple USB to stereo DAC (In Jriver you can route channel how you want)

With this setup and a cheap laptop, you can easy test FIR filters with length of ie. 60.000 tabs. And huge magnitude more than any commercial DSP in this world. You need way less, for anything above 500 hz .

.

It is very simple to achieve ruler perfect textbook stepresponse. But what about how it sounds?

In my experience, FIR-filters suck the life out of music. This conclusion was the same no matter what steepness of the filters I used. I remember one of few articles actually using blindtesting, that steepness above 48 pr. octave, is not prefered by listeners. With rephase you can acchieve ANY response you like to test. Remember that textbook filter and accoustic response must be the same. So in practice, you export filters from rephase, using them for reference. Also rephase is used to export the filters used for the convolution. Not that difficult after getting all things set up.

Above was from making all digital filters. The situation might chance if for instance correction a passive loudspeakers. Say a random B&W speakers (most of them measure VERY bad and sound equally weird) However, most of the time, this could be done with simple IRR filter (ie. simple EQ correction), maybe except from odd phase odities around the crossover of the driver.

This was my conclusion: It is easy to achieve PERFECT textbook phase/stepresponse, but it sounds no better than IRR filters.

Not many commercial speakers use FIR filters today. Some of the newer Dynaudio does (there is a review stating the that old one with only IRR filters sounded better).

Have heard Beolab 90 only once, and I think I could hear the same tendency (For this one, doing all what is does, is not possible without FIR-filters).

Im not saying that FIR filters are bad, I have just not been able to achieve a better sound with them.

Rephase

JRiver Media Center (use inbuilt DSP with option to use the convolver). Other VST plugin can be oploaded to this.

Cheap laptop (Most older Lenovo Thinkpad do great in regards to low internal latencys)

Jriver is free for 30 days. Maybe consider buying it, because that solution is still the most easy way to trial.

You also need a soundcard. For trial, you can try a 2 way, so you only need a simple USB to stereo DAC (In Jriver you can route channel how you want)

With this setup and a cheap laptop, you can easy test FIR filters with length of ie. 60.000 tabs. And huge magnitude more than any commercial DSP in this world. You need way less, for anything above 500 hz

It is very simple to achieve ruler perfect textbook stepresponse. But what about how it sounds?

In my experience, FIR-filters suck the life out of music. This conclusion was the same no matter what steepness of the filters I used. I remember one of few articles actually using blindtesting, that steepness above 48 pr. octave, is not prefered by listeners. With rephase you can acchieve ANY response you like to test. Remember that textbook filter and accoustic response must be the same. So in practice, you export filters from rephase, using them for reference. Also rephase is used to export the filters used for the convolution. Not that difficult after getting all things set up.

Above was from making all digital filters. The situation might chance if for instance correction a passive loudspeakers. Say a random B&W speakers (most of them measure VERY bad and sound equally weird) However, most of the time, this could be done with simple IRR filter (ie. simple EQ correction), maybe except from odd phase odities around the crossover of the driver.

This was my conclusion: It is easy to achieve PERFECT textbook phase/stepresponse, but it sounds no better than IRR filters.

Not many commercial speakers use FIR filters today. Some of the newer Dynaudio does (there is a review stating the that old one with only IRR filters sounded better).

Have heard Beolab 90 only once, and I think I could hear the same tendency (For this one, doing all what is does, is not possible without FIR-filters).

Im not saying that FIR filters are bad, I have just not been able to achieve a better sound with them.

Last edited:

Hi mark100:

Forgot to mention that. It was separate filters for every channel.

Forgot also to mention, that the impulse measurement, put into in rephase, I never found a good toturial how to do this the correct way. It bugged me how or rather IF this step made would do any major difference. However, my measurements confirmed, that I got perfect textbook stepresponse, and I always was sure, that the measurement gave me good phase when importing.

Forgot to mention that. It was separate filters for every channel.

Forgot also to mention, that the impulse measurement, put into in rephase, I never found a good toturial how to do this the correct way. It bugged me how or rather IF this step made would do any major difference. However, my measurements confirmed, that I got perfect textbook stepresponse, and I always was sure, that the measurement gave me good phase when importing.

Last edited:

Thanks

Yep, I've found getting perfect measurements with FIR is far too easy.

I've made many mistakes in either correcting to too narrow a spot, or overcorrecting in general. And have experinced the music-life suckout you mentioned.

When I've used rephase to build the FIR files, I always imported the frequency response (mag and phase) and worked with that ...never tried to import an impulse response...

POS showed a method for flattening drivers' in-band and out-of-band response and then applying linear phase xovers.

I've always used that with great results, (when i don't overcorrect, or to a spot etc....haha)

Steep xovers have worked extremely well for me, improving polars i make outdoors.

I think because: a. they are lin phase (steep IIR clearly doesn't work ime), and b. they are not as fully steep as they would appear, because a hunk of their steepness goes to offset the out-of-band flattening I use. Hope that made sense.

On axis though, steep vs shallow doesn't seem to matter much.

A great way to "automate" FIR file generation might be using REW to simply invert the impulse response and then multiply by a xover imported from rephase.... like the thread linked earlier. (I think VituixCAD can do this too, not sure.)

I keep meaning to play with that technique some more, but life has been too easy using commercial FirDesigner, and I'm not sure how to apply smoothing to correction made like that.

Anyway, for me the real trick in using FIR has been to figure out what measurement or average of measurements to correct, and then how much correction....something i expect to keep learning for a while..

Yep, I've found getting perfect measurements with FIR is far too easy.

I've made many mistakes in either correcting to too narrow a spot, or overcorrecting in general. And have experinced the music-life suckout you mentioned.

When I've used rephase to build the FIR files, I always imported the frequency response (mag and phase) and worked with that ...never tried to import an impulse response...

POS showed a method for flattening drivers' in-band and out-of-band response and then applying linear phase xovers.

I've always used that with great results, (when i don't overcorrect, or to a spot etc....haha)

Steep xovers have worked extremely well for me, improving polars i make outdoors.

I think because: a. they are lin phase (steep IIR clearly doesn't work ime), and b. they are not as fully steep as they would appear, because a hunk of their steepness goes to offset the out-of-band flattening I use. Hope that made sense.

On axis though, steep vs shallow doesn't seem to matter much.

A great way to "automate" FIR file generation might be using REW to simply invert the impulse response and then multiply by a xover imported from rephase.... like the thread linked earlier. (I think VituixCAD can do this too, not sure.)

I keep meaning to play with that technique some more, but life has been too easy using commercial FirDesigner, and I'm not sure how to apply smoothing to correction made like that.

Anyway, for me the real trick in using FIR has been to figure out what measurement or average of measurements to correct, and then how much correction....something i expect to keep learning for a while..

I think VituixCAD can do this too, not sure.

Some tips how to do it.

Nice thing is that you can monitor off-axis/directivity and power and other CTA-2034-A to help shaping of target responses so that too optimized by axial does not ruin the sound (which is the weakness of blind/deaf design by axial only).

Attachments

Great input, mark100  !

!

Totally agree with your point about what to actually correct.

Interesting point about your experience with steep XO. I seem almost never to prefer steep XO of the tweeter. Think there is nothing wrong with that, because I think preference in sound vary more than one would think.

Totally agree with your point about what to actually correct.

Interesting point about your experience with steep XO. I seem almost never to prefer steep XO of the tweeter. Think there is nothing wrong with that, because I think preference in sound vary more than one would think.

Looks like QSC does the same thing with their products. Here's a basic white paper from 2007 explaining what it does.

"Intrinsic Correction"

https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiOycPYs7bvAhVrJjQIHdyKDisQFjABegQIAhAD&url=https%3A%2F%2Fwww.qsc.com%2Fresource-files%2Fwhitepapers%2Fq_wp_sys_spk_intrinsiccorrection.pdf&usg=AOvVaw1VbkprJ5EknBM_bxlF2bko

Doesn't seem any different than what the enlightened diy'er can do with widely available software.

"Intrinsic Correction"

https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiOycPYs7bvAhVrJjQIHdyKDisQFjABegQIAhAD&url=https%3A%2F%2Fwww.qsc.com%2Fresource-files%2Fwhitepapers%2Fq_wp_sys_spk_intrinsiccorrection.pdf&usg=AOvVaw1VbkprJ5EknBM_bxlF2bko

Doesn't seem any different than what the enlightened diy'er can do with widely available software.

An overlooked low-tech method?

I'm one of those people who got "Cs" in calculus so please be gentle with me for not following the propeller head stuff.

You probably are (or should be) familiar with the "low tech" ways to reduce waveguide resonances or the more elusive Geddes HOMs? To the layman like me, these make sense intuitively, in that they do some combination of break up or inhibit the membrane at the mouth (towel cowl) and/or absorb stray reflections (Geddes foam plug), fully or partially lining the waveguide to absorb ricchochets.

The brilliant flash of inspiration occurred to me (ok more like lighting a candle ): why couldn't these same methods work inside the compression driver? Now, granted there isn't much space to work with, but in principle, why couldn't one stuff fiberglass, chinchilla fur, the ubiquitous 30 ppi foam, or the sound absorbing material of your choice, inside the CD cavity prone to undesired paths? Wouldn't it achieve some reduction of the "riccochets", the unwanted sound paths? Sure, you lose perhaps 3 dB of the direct sound path, but you'd get better attenuation of unwanted reflections? And no preringing, I'd guess.

): why couldn't these same methods work inside the compression driver? Now, granted there isn't much space to work with, but in principle, why couldn't one stuff fiberglass, chinchilla fur, the ubiquitous 30 ppi foam, or the sound absorbing material of your choice, inside the CD cavity prone to undesired paths? Wouldn't it achieve some reduction of the "riccochets", the unwanted sound paths? Sure, you lose perhaps 3 dB of the direct sound path, but you'd get better attenuation of unwanted reflections? And no preringing, I'd guess.

I'm one of those people who got "Cs" in calculus so please be gentle with me for not following the propeller head stuff.

You probably are (or should be) familiar with the "low tech" ways to reduce waveguide resonances or the more elusive Geddes HOMs? To the layman like me, these make sense intuitively, in that they do some combination of break up or inhibit the membrane at the mouth (towel cowl) and/or absorb stray reflections (Geddes foam plug), fully or partially lining the waveguide to absorb ricchochets.

The brilliant flash of inspiration occurred to me (ok more like lighting a candle

Last edited:

Bateman beat me to it.

Of course, someone has done it all before. Our resident mad scientist, Patrick Bateman, did back in 2014:

Cheap / Free Ways to Improve Your Horn

Drat, apparently some commercial products already use foam inside the CD. Now, Celestion is a quality brand, but even inept dabbler I may be, 15 watts and a 2000 Hz crossover are scarcely world-class compression driver figures �� but they admit it's "entry level".

New Entry-Level Compression Driver From Celestion

To answer Pano's question, I propose trying damping material anywhere in the sound path inside the CD proper. Based on Bateman's post, damping material is standard practice in the rear chamber of some CD.

Nagging doubts dept: It occurs to me that the argument I sometimes use when debating renewable energy with people also applies here: "If X is such a good idea, why aren't manufacturers already doing X?" In the Celestion case, perhaps they in fact are.

Of course, someone has done it all before. Our resident mad scientist, Patrick Bateman, did back in 2014:

Cheap / Free Ways to Improve Your Horn

Drat, apparently some commercial products already use foam inside the CD. Now, Celestion is a quality brand, but even inept dabbler I may be, 15 watts and a 2000 Hz crossover are scarcely world-class compression driver figures �� but they admit it's "entry level".

New Entry-Level Compression Driver From Celestion

To answer Pano's question, I propose trying damping material anywhere in the sound path inside the CD proper. Based on Bateman's post, damping material is standard practice in the rear chamber of some CD.

Nagging doubts dept: It occurs to me that the argument I sometimes use when debating renewable energy with people also applies here: "If X is such a good idea, why aren't manufacturers already doing X?" In the Celestion case, perhaps they in fact are.

Last edited:

Yep, i believe in applying/exhausting every available common sense, low-tech tuning technique, during the prototype building stage.

Getting the best acoustical design possible, before applying electrical correction pays big dividends ime/imo.

The biggest trick there though, seems to be finding when the S/N ratio from such acoustic gains begins to pale vs gains from electrical tuning. Finding when to let go....when to quit focusing on trying to acoustically solve diffraction, or horn reflections for example.

That let-go point for me comes down to what is legitimately electrically correctable. Which seems to distill down to drivers' minimum phase response variations that occur all across the desired beamwidth.

I've tried a towel (and many other materials) around horn mouths with limited success.

I've also tried the special foam that is supposed to reduce HOMs when placed in the throat. Again, not much success.

My success with horns (and cones in cabinets) has mainly come from the idea of preconditioning, which i think is simply a marketing term for applying appropriate impulse inversion ala FIR.

Getting the best acoustical design possible, before applying electrical correction pays big dividends ime/imo.

The biggest trick there though, seems to be finding when the S/N ratio from such acoustic gains begins to pale vs gains from electrical tuning. Finding when to let go....when to quit focusing on trying to acoustically solve diffraction, or horn reflections for example.

That let-go point for me comes down to what is legitimately electrically correctable. Which seems to distill down to drivers' minimum phase response variations that occur all across the desired beamwidth.

I've tried a towel (and many other materials) around horn mouths with limited success.

I've also tried the special foam that is supposed to reduce HOMs when placed in the throat. Again, not much success.

My success with horns (and cones in cabinets) has mainly come from the idea of preconditioning, which i think is simply a marketing term for applying appropriate impulse inversion ala FIR.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Preconditioning FIR filters, how do you make them?