Hi gino,

separating the enclosures has advantages.

Now talking about the main speakers instead of the sub:

However in the "main speaker" e.g. from 80 Hz upwards, one cannot use that "just stiffness" strategy in the cabinet, because the woofer driver (maybe midrange driver too) will ineviteably excite some "eigenfrequencies"/ resonances anywhere between 80 ... 500Hz (and possibly much higher) in a typical "MDF like" cabinet (*).

Here a "mixed" strategy including damping of the walls (bring down the Q of wall resonances) and also mass hampering (to decrease vibration with frequency, as higher frequencies are radiated more efficiently in structure born sound like from vibrating panels ...) is worth thinking about.

Maybe you should have a look at the "classic" paper from BBC by Harwood and Matthews:

"Factors in the design of loudspeaker cabinets"

H.D. Harwood, B.Sc. R. Mathews

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

That 1977 paper is "old but important" IMO. Many Speaker Builders - even in the industry - didn't "get the hang of it" until today, sorry to say this ...

Also decoupling of the woofer - using rubber grommets e.g. - and also "magnet mounting" are techniques worth thinking about in "wideband" used cabinets (bass to midrange).

"Just stiffness" is IMO only possible to be applied to (compact) subwoofers.

Sketch from Siegfried Linkwitz as an example for grommets and/or magnet mounting:

http://www.linkwitzlab.com/images/photos/driver-mountg1.gif

____________

(*) Just talking about resonances of the walls/structure here, not about resonances due to standing waves of the enclosed volume of air.

separating the enclosures has advantages.

Now talking about the main speakers instead of the sub:

However in the "main speaker" e.g. from 80 Hz upwards, one cannot use that "just stiffness" strategy in the cabinet, because the woofer driver (maybe midrange driver too) will ineviteably excite some "eigenfrequencies"/ resonances anywhere between 80 ... 500Hz (and possibly much higher) in a typical "MDF like" cabinet (*).

Here a "mixed" strategy including damping of the walls (bring down the Q of wall resonances) and also mass hampering (to decrease vibration with frequency, as higher frequencies are radiated more efficiently in structure born sound like from vibrating panels ...) is worth thinking about.

Maybe you should have a look at the "classic" paper from BBC by Harwood and Matthews:

"Factors in the design of loudspeaker cabinets"

H.D. Harwood, B.Sc. R. Mathews

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

That 1977 paper is "old but important" IMO. Many Speaker Builders - even in the industry - didn't "get the hang of it" until today, sorry to say this ...

Also decoupling of the woofer - using rubber grommets e.g. - and also "magnet mounting" are techniques worth thinking about in "wideband" used cabinets (bass to midrange).

"Just stiffness" is IMO only possible to be applied to (compact) subwoofers.

Sketch from Siegfried Linkwitz as an example for grommets and/or magnet mounting:

http://www.linkwitzlab.com/images/photos/driver-mountg1.gif

____________

(*) Just talking about resonances of the walls/structure here, not about resonances due to standing waves of the enclosed volume of air.

Last edited:

Hi gino, separating the enclosures has advantages.

Now talking about the main speakers instead of the sub:

However in the "main speaker" e.g. from 80 Hz upwards, one cannot use that "just stiffness" strategy in the cabinet, because the woofer driver (maybe midrange driver too) will ineviteably excite some "eigenfrequencies"/ resonances anywhere between 80 ... 500Hz (and possibly much higher) in a typical "MDF like" cabinet (*).

Hi and thanks a lot again for the very helpful advice.

If i understand well all the resonances in the end will translate in a vibration of the speakers panels, am i right ?

I also guess that the "displacement" of the panels caused by these resonances will be max just in the middle of the panel.

Then just a lead weight glued and rigidly applied to the panel will almost completely absorb those vibrations.

I know that the lead is toxic but nothing beats the lead as a vibes absorber.

The panels will become completely "dead".

I am telling this because i did it on a larger scale on a pair of old Dynaudio speakers.

We played some double bass tracks before and after the mods. The difference was astonishing with the instrument finally coming out of the speaker. We were shocked.

We exaggerate with the lead and with the risk. But small lead plates/disks place strategically in the center of the panels will cancel any medium-low level vibes especially for Hz >100 ... the double bass can go much lower than that. But for me the low bass is a sub-woofer duty. I do not like speakers with big woofers in them.

Here a "mixed" strategy including damping of the walls (bring down the Q of wall resonances) and also mass hampering (to decrease vibration with frequency, as higher frequencies are radiated more efficiently in structure born sound like from vibrating panels ...) is worth thinking about.

Maybe you should have a look at the "classic" paper from BBC by Harwood and Matthews:

"Factors in the design of loudspeaker cabinets"

H.D. Harwood, B.Sc. R. Mathews

http://downloads.bbc.co.uk/rd/pubs/reports/1977-03.pdf

That 1977 paper is "old but important" IMO. Many Speaker Builders - even in the industry - didn't "get the hang of it" until today, sorry to say this ...

Also decoupling of the woofer - using rubber grommets e.g. - and also "magnet mounting" are techniques worth thinking about in "wideband" used cabinets (bass to midrange).

"Just stiffness" is IMO only possible to be applied to (compact) subwoofers.

Sketch from Siegfried Linkwitz as an example for grommets and/or magnet mounting:

http://www.linkwitzlab.com/images/photos/driver-mountg1.gif

____________

(*) Just talking about resonances of the walls/structure here, not about resonances due to standing waves of the enclosed volume of air.

thanks a lot for the very interesting link. I will study before saying more silly things.

However i am a firm believer in measurements with accelerometers like some magazines like Stereophile do.

I would build a very stiff cabinet. Then i glued and fastened those lead plates in the center of all the side panels and then check with the accelerometers for any vibes.

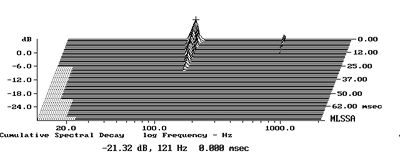

I am pretty sure i will get a result like this (depending on the amount of lead used of course). All the panel vibes will be absorbed completely by the lead plate. There is nothing like the lead. No rubber mat can even compare.

Just hit a lead panel with a hammer ... you will hear almost nothing.

http://www.stereophile.com/images/archivesart/bwll801fig03.jpg

And the sound would be spectacular. Completely free of boxiness.

I think we here a box when it vibrates. Like we hear a wall when it reflects sound.

Thanks a lot again.

gino

Last edited:

Hi gino,

(i am a fan of Norway due to the landscapes - and the people - btw. I nearly drowned in Geirangerfjord when i was 16 ... then some fishermen pulled me out of the water ... 😉 )

but "acceleration" or amplitude of vibration of the cabinet's walls does not tell everything.

Imagine a cab. made of "rubber walls". The walls might vibrate significantly at low frequencies. But the propagation speed of the bending waves in the rubber will be low, because "structure born sound" in rubber is typically slow (because of low stiffness).

Wavelengths of the bending waves (in our example "rubber cabinet") will typilcally be much smaller than wavelenths of sound in air:

And as long as this is the case, a modal "vibration" (of a panel) will not radiate sound efficiently, because zones of "positive" and "negative" pressure near the surface of a vibrating plate e.g. will cancel out, due to the "pressure gradients in air" moving faster.

But when you have a panel material with - depending from frequency due do "dispersion" - higher speed of bending waves than "sound in air", then there will be "efficient" radiation (which is unwanted in a loudspeaker cabinet).

So vibration or "acceleration" in a zone (or just a "point" ?) of the cabinet, does not tell the truth about "total sound radiated".

In fact an accelerometer does not tell anything about that:

I have to tell this, although i appreciate the "measurement sections" in Stereophile, as they tell a lot about e.g. speakers and amps ...

(i am a fan of Norway due to the landscapes - and the people - btw. I nearly drowned in Geirangerfjord when i was 16 ... then some fishermen pulled me out of the water ... 😉 )

but "acceleration" or amplitude of vibration of the cabinet's walls does not tell everything.

Imagine a cab. made of "rubber walls". The walls might vibrate significantly at low frequencies. But the propagation speed of the bending waves in the rubber will be low, because "structure born sound" in rubber is typically slow (because of low stiffness).

Wavelengths of the bending waves (in our example "rubber cabinet") will typilcally be much smaller than wavelenths of sound in air:

And as long as this is the case, a modal "vibration" (of a panel) will not radiate sound efficiently, because zones of "positive" and "negative" pressure near the surface of a vibrating plate e.g. will cancel out, due to the "pressure gradients in air" moving faster.

But when you have a panel material with - depending from frequency due do "dispersion" - higher speed of bending waves than "sound in air", then there will be "efficient" radiation (which is unwanted in a loudspeaker cabinet).

So vibration or "acceleration" in a zone (or just a "point" ?) of the cabinet, does not tell the truth about "total sound radiated".

In fact an accelerometer does not tell anything about that:

I have to tell this, although i appreciate the "measurement sections" in Stereophile, as they tell a lot about e.g. speakers and amps ...

Last edited:

Hi gino, (i am a fan of Norway due to the landscapes - and the people - btw. I nearly drowned in Geirangerfjord when i was 16 ... then some fishermen pulled me out of the water ... 😉 )

Hi ! i am expatriat here. I am italian. I do not like hot weather, but this is too cold for my taste. Yes the country is very beautiful and wild. But it is for tough people. And the water is very very cold all the year.

but "acceleration" or amplitude of vibration of the cabinet's walls does not tell everything.

my reasoning is very trivial and i am not sure that is right.

We hear a driver because it vibrates and the vibration moves air.

When the driver is still (no signal applied) we do not hear sounds.

The same for me applies to speakers panels. We hear them only if they move, vibrate.

Do you mean that an accelerometer has a limited bandwidth maybe ?

Actually i find this ... it seems that they have issues at higher Hz

An externally hosted image should be here but it was not working when we last tested it.

so it could be that high Hz vibes are not detected. This is a problem.

Imagine a cab. made of "rubber walls". The walls might vibrate significantly at low frequencies. But the propagation speed of the bending waves in the rubber will be low, because "structure born sound" in rubber is typically slow (because of low stiffness).

Wavelengths of the bending waves (in our example "rubber cabinet") will typilcally be much smaller than wavelenths of sound in air:

And as long as this is the case, a modal "vibration" (of a panel) will not radiate sound efficiently, because zones of "positive" and "negative" pressure near the surface of a vibrating plate e.g. will cancel out, due to the "pressure gradients in air" moving faster.

But when you have a panel material with - depending from frequency due do "dispersion" - higher speed of bending waves than "sound in air", then there will be "efficient" radiation (which is unwanted in a loudspeaker cabinet).

So vibration or "acceleration" in a zone (or just a "point" ?) of the cabinet, does not tell the truth about "total sound radiated".

In fact an accelerometer does not tell anything about that:

I have to tell this, although i appreciate the "measurement sections" in Stereophile, as they tell a lot about e.g. speakers and amps ...

It is difficult to understand for me but i trust you.

I wonder why they keep on doing this test that is flawed in the end.

I know that some big manufacturers used laser interferometry to measure panels vibrations

An externally hosted image should be here but it was not working when we last tested it.

I think B&W has used that. I am afraid not a system that the average hobbyist can afford. That should be the best i guess.

I remember some speakers made out of concrete or even marble.

Those would not vibrate for sure.

An externally hosted image should be here but it was not working when we last tested it.

Thanks again, gino

...

Those would not vibrate for sure.

Hi gino,

i fear in this world there is no "would not vibrate".

There is only the question "at which frequency(ies)".

Hey gino

interesting concept

Do you have more info?

Regards

Daniel

interesting concept

An externally hosted image should be here but it was not working when we last tested it.

Do you have more info?

Regards

Daniel

Hi gino,

i fear in this world there is no "would not vibrate".

There is only the question "at which frequency(ies)".

I find that when the rest of the furniture in the room vibrates the speakers do as well.

Not all vibration is internal.

Grant.

Hey gino

interesting concept

Those "threaded bars" used "hanging freely" in that cabinet e.g. are a catastrophe and will vibrate at frequencies depending on the length of the bars. If you don't use the cabinet up to that frequency you are lucky. But since this seems a 2-way i have my doubts ...

I have real experience with those bars and had them e.g. in sand filled tubes.

There is a big difference in constructions that really have "low vibration" and also "low radiation" (which is not the same), and those which are "just believed" to have that (because of just looking "solid" ) ...

Last edited:

Hi gino,

i fear in this world there is no "would not vibrate".

There is only the question "at which frequency(ies)".

Hi again. Yes i agree. But from what i understand the high Hz vibes have very little energy and can be tamed very easily. For instance just some additional rubber pad on the panels and they are gone.

I can tell you a story.

I had an electronic x-over and a pair of small 2-way speakers with not much emission below 100Hz.

A friend suggested me to cut the signal with the x-over below 100Hz, 24dB/octave.

The sound became immediately much cleaner. And also the image improved a lot. The box of the speaker was quite good but still taking away everything below 100Hz cleaned up the sound quite evidently.

The high Hz vibes are not that critical in my mind. Low Hz ones are.

For this i would decouple bass from mid high always. I like the bass cabinet + satellite concept a lot ... like the Wilson Audio Watt + Puppy as an example.

Thanks again, gino

Hi gino,

"freeing" a small satellite speaker - it works with many speakers indeed - from the "bass burden" say below 80Hz will reduce cone excursion very much.

Many speakers sound "cleaner" then in midrange and dynamic headroom is increased too ...

A common observation IMO, when the "low end" is being reproduced by a subwoofer and the satellite is high pass filtered.

"freeing" a small satellite speaker - it works with many speakers indeed - from the "bass burden" say below 80Hz will reduce cone excursion very much.

Many speakers sound "cleaner" then in midrange and dynamic headroom is increased too ...

A common observation IMO, when the "low end" is being reproduced by a subwoofer and the satellite is high pass filtered.

Hey gino

interesting concept

Do you have more info?

Regards

Daniel

Hi ! some more info here

Cinder speakers turn concrete blocks into high fidelity | MNN - Mother Nature Network

problem is that the chamber for the bass is very small.

However, i am much much more fascinated by metals. Maybe with some additional strategic damping solution to tame any "ringing" or bell effect.

Metal especially aluminum is neverending. The speaker of the life. Also the drivers i would like in Al ... and concave. Like Revel ones. Same exact design for all the drivers with different sizes, of course.

This concept suggests perfection.

Regards, gino

Hi gino,

"freeing" a small satellite speaker - it works with many speakers indeed - from the "bass burden" say below 80Hz will reduce cone excursion very much.

Many speakers sound "cleaner" then in midrange and dynamic headroom is increased too ...

A common observation IMO, when the "low end" is being reproduced by a subwoofer and the satellite is high pass filtered.

Thanks a lot for the very important confirmation.

I wonder why the 2 box solution is not more popular when full range is wanted.

A friend of mine bought big JBL speakers i think it was 250 something.

He became mad for moving them around.

Instead a bass box with detachable handles would be much easier.

Then you select the 2 ways you like better, some x-over design and bam ... a very nice full range solution.

And it is my ultimate project actually.

But first the room. I am always on the move 🙁 what a life. 😱

Thanks a lot again, gino

A single bass box? Or multiples 😀

Hi ! for stereo both channels should be treated in the same way.

Same amplification (dual mono) and same bass solution for both.

Also i do not like very much when the speakers are not equal, for instance with the drivers not on the same vertical axis.

But for the satellite i have a coaxial solution in mind so ...

This thread has been fascinating and very informative. I'm currently building my first ever pair of speakers and chose the rigid hefty route with all panels made of 24mm BB ply and 3 shelf braces.The main speakers are just for 2 Dayton RS180 mids 80hz high pass with a separate open back top mounted enclosure for a AMT Pro 4 taking over at 1500hz. I have a 12" tapped horn sub for lows. I'm now considering attempting a CLD by lining the inner surfaces with a layer of 2mm butyl car deadening product then adding a layer of 2.24mm lead sheet. Does this sound worthwhile? I'm planning to add layers of 10mm wool carpet underlay to that lot and wool wadding in the remaining space.

Cheers!

Martin.

Cheers!

Martin.

This thread has been fascinating and very informative. I'm currently building my first ever pair of speakers and chose the rigid hefty route with all panels made of 24mm BB ply and 3 shelf braces.The main speakers are just for 2 Dayton RS180 mids 80hz high pass with a separate open back top mounted enclosure for a AMT Pro 4 taking over at 1500hz. I have a 12" tapped horn sub for lows. I'm now considering attempting a CLD by lining the inner surfaces with a layer of 2mm butyl car deadening product then adding a layer of 2.24mm lead sheet. Does this sound worthwhile? I'm planning to add layers of 10mm wool carpet underlay to that lot and wool wadding in the remaining space.

Cheers!

Martin.

I'd say you are approaching your system design correctly, in that, you are making it "modular" aka, addressing 3 different parts of the spectrum with 3 different enclosure types.

attempting a CLD by lining the inner surfaces with a layer of 2mm butyl car deadening product then adding a layer of 2.24mm lead sheet

lead is probably not the best idea

constrained layer damping doesn't rely on mass at all, most damping works better at higher frequency anyway

the added "constraining" layer only has to have in-plane stiffness higher than the damping layer material - even thin hardboard should be fine

I believe damping cross-bracing would be Geddes choice over CLD as likely more effective

and Geddes claims to use micro-ballon filled soft curing polyurethanes for his damping layers

car damping products are generally engineered to be applied to relatively thin formed metal sheet

Last edited:

This is a link to the best article I've found on cabinet bracing, it matches my experiences:

Bracing

For best imaging and clear sound a speaker should be built like a brick s%&* house. I don't care if some guru says you can't tell, because I can. The bracing stops movement from lower frequencies and stuffing or damping deals with the higher frequencies.

Bracing

For best imaging and clear sound a speaker should be built like a brick s%&* house. I don't care if some guru says you can't tell, because I can. The bracing stops movement from lower frequencies and stuffing or damping deals with the higher frequencies.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- how to brace a speaker cabinet?