conical

Now there's a challenge. The low end has that droop, and the efficiency is reduced. I'm also needing a larger mouth to keep diffraction down. The polar plots also look troublesome. I may be able to model a conical horn in a different simulator.

Attachments

Looking at it this way, (the first has a 4000cm^2 mouth and the second 8000cm^2), the larger mouth does show some interference off axis, but the smaller mouth seems to cause the driver to behave more as a direct radiator in the passband. I'll play some more.

Attachments

Well, I've tried to make a conical expansion fit but if this is the way to get a little extension (below), then I'll probably have to say no. The ease in building it is tempting, but the greater excursion and the off axis issues are not.

The extension difference between exponential and tractrix doesn't show in hornresp the way others claim exp should go lower. I think I still want to build the tractrix. Maybe I'll make it just an inch or two longer.

The extension difference between exponential and tractrix doesn't show in hornresp the way others claim exp should go lower. I think I still want to build the tractrix. Maybe I'll make it just an inch or two longer.

Attachments

These are my two suggestions. One is with a phase plug, the other is without. Note that part of the length includes the phase plug. The best part about building your own phase plug is you can carry the correct flare rate all the way from the plug to the end of the horn.

Hello John, thanks for the suggestions! I have a couple of questions. 1) The model with phase plug is an exponential horn? Why didnt you suggest a tractrix flare? 2) Both models seem to roll off at 200hz, did u forget I was hoping to achieve a lower xover point or you know these horns will go lower in real life situations? Thanks a lot for your help, I just wanna make sure everything is okay before I start building the horns. 😱

Keith

Hello John, thanks for the suggestions! I have a couple of questions. 1) The model with phase plug is an exponential horn? Why didnt you suggest a tractrix flare? 2) Both models seem to roll off at 200hz, did u forget I was hoping to achieve a lower xover point or you know these horns will go lower in real life situations? Thanks a lot for your help, I just wanna make sure everything is okay before I start building the horns. 😱

Keith

I thought the goal was 200Hz? The exponential worked out better for the one with a phase plug. If we stuck with the tractrix, then the mouth would have to been larger.

Well, I've tried to make a conical expansion fit but if this is the way to get a little extension (below), then I'll probably have to say no. The ease in building it is tempting, but the greater excursion and the off axis issues are not.

The extension difference between exponential and tractrix doesn't show in hornresp the way others claim exp should go lower. I think I still want to build the tractrix. Maybe I'll make it just an inch or two longer.

The conical is no easy task. It requires the right woofer in the just right horn. I made one with an EVM12L that only had a 2dB dip near Fc. The dip was not audible and the directivity advantage sealed the deal. Its about balancing things that best meet your needs.

And you're lecturing me because why now? Are you violating the rules of this message board with this post?

Because you are misleading people by blindly restating things that are known to not be true. I have explained in great specificity with real world examples from multiple sources that the back chamber volume formulas do not work. However, you continue to drone on about how people’s back chambers are too small. Many inexperienced horn builders waste a lot of time and money by taking advice from those that have never actually built anything. Theory is fine if it is used as a guideline, but quoting it like it is fact is troublesome. What forum rules do you believe I've violated? IMO none. I've only challenged your statements and supported my position by giving real world examples. If you failed to back up your position it’s not my fault.

I thought the goal was 200Hz? The exponential worked out better for the one with a phase plug. If we stuck with the tractrix, then the mouth would have to been larger.

Hello John, my bad, perhaps I didn't make myself clear... please refer to the image below to see what I'm trying to do.

I would like to go as low as possible with the vertical "horn rack". One reason is I suspect the mid-bass horn isn't as good at 200hz as what the B&C 10MD26 can achieve in a 120-130hz round tractrix. Second reason would be trying to make the "horn rack" as wide band as possible for imaging. Keep in mind these are only my assumptions so if you have better ideas please chime in. And if you would, please help me design a horn model again, I feel much more confident building your design, thanks! 😱

Best regards,

Keith

Attachments

My 8PE21s arrived today and they're banged around a little on the edges. They look intact. First listening with them sitting on the shipping box with a little EQ, I think they sound OK (speakers never sound good like this, cone breakup seems obvious).

But maybe one has a slightly different tone than the other. They sound much more similar than different. I realise the cast baskets will take a lot without showing it and I just wonder whether these drivers are likely to suffer any damage without it being obvious?

But maybe one has a slightly different tone than the other. They sound much more similar than different. I realise the cast baskets will take a lot without showing it and I just wonder whether these drivers are likely to suffer any damage without it being obvious?

The magnet could have moved.

Check very carefully around the mag to basket interface to see any broken paint or slip marks etc that could give a clue.

Check the stroke of the cone in both directions. The "in" is easy, the "out" could be very difficult to achieve and even more difficult without accidentally throwing the cone off centre. Try pressing it in all four quadrants simultaneously, then in one quadrant in turn. Is there any Voice Coil rubbing?

Check very carefully around the mag to basket interface to see any broken paint or slip marks etc that could give a clue.

Check the stroke of the cone in both directions. The "in" is easy, the "out" could be very difficult to achieve and even more difficult without accidentally throwing the cone off centre. Try pressing it in all four quadrants simultaneously, then in one quadrant in turn. Is there any Voice Coil rubbing?

No, they seem OK that way Andrew. I may have a private chat with the seller and assess the attitude toward future customers. I may be able to let this slide.

Because you are misleading people by blindly restating things that are known to not be true. I have explained in great specificity with real world examples from multiple sources that the back chamber volume formulas do not work. However, you continue to drone on about how people’s back chambers are too small. Many inexperienced horn builders waste a lot of time and money by taking advice from those that have never actually built anything. Theory is fine if it is used as a guideline, but quoting it like it is fact is troublesome. What forum rules do you believe I've violated? IMO none. I've only challenged your statements and supported my position by giving real world examples. If you failed to back up your position it’s not my fault.

As far as I know, you're about the only one saying that the formulas do not work. Many people who use the Hornresp program appear to be satisfied with it's calculation of rear chamber volume. Many other people who, yes, actually build horns say that it is the most accurate simulation anywhere. So, I'm not sure where you are coming from and why you have to direct your frustration at me, and why you think I'm actually misleading people. Everything I say is my opinion only, don't you realize that? If I have a different opinion from yours, then who are you to tell me I'm wrong? I don't give a flip how many horns you've built. It's your attitude that I don't like.

No, they seem OK that way Andrew. I may have a private chat with the seller and assess the attitude toward future customers. I may be able to let this slide.

If you have WT2 or something similar, then if the impedance curves match pretty close to the published one, then I'd say they are OK. I think WT2 detects woofer defects as well.

As far as I know, you're about the only one saying that the formulas do not work

So, I guess Bruce Edgar is nobody? You might want to brush up on your horn history.

Everything I say is my opinion only, don't you realize that?

Yes I do, but others do not know and that is the problem. Less experienced folks may accept your opinion as fact when it is not.

If I have a different opinion from yours, then who are you to tell me I'm wrong?

That is the difference between us, I'm not expressing an opinion, I'm presenting facts from actual builds. Not only from my own builds, but from other sources as well.

I don't give a flip how many horns you've built. It's your attitude that I don't like.

The feeling is mutual. Typical move, you lose the intellectual and factual argument so you turn it to being personal. Bravo!

I’m sure the moderators have seen enough and will be here shortly to tell us to cool it. Therefore, I’m NOT going to be responding to anymore of your posts directed at me. I’ve made my point and feel satisfied that any interested parties can make their own mind up who to believe.

Woofer Tester 2

I assume you could run an impedance curve using it.

dirkwright, Hornresp appears to be good within its limitations, and those limitations are fairly well documented.

Can I ask what it is you are looking for when you decide what the rear volume should be?

I assume you could run an impedance curve using it.

dirkwright, Hornresp appears to be good within its limitations, and those limitations are fairly well documented.

Can I ask what it is you are looking for when you decide what the rear volume should be?

If you have WT2 or something similar,

wt2??

$159.95 to check if a driver might be damaged.Woofer Tester 2

I assume you could run an impedance curve using it.

Are you in their employ?

$159.95 to check if a driver might be damaged.

Are you in their employ?

No, of course not. I'm just suggesting something that may be helpful. There are many other things that WT2 can do, as well as other software packages, of course. Parts Express sells WT3, for example, and there are free ones also apparently.

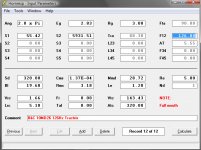

This is what I got with my limited skills and understanding of horns.

B&C 10MD26 in 126Hz Tractrix horn, it looks good down to about 150hz...

That looks fairly good. I guessing this is with a phase plug? If you choose not to use a phase plug than I'd suggest a throat diameter of 6.5 inches. However, this will make the horn too short to get much below 200Hz unless you go bigger. That's when the exponential starts to look like a better option. Go ahead and play with some of the numbers in Horn Response for both the Tractrix and Exponential, you'll see what I'm talking about.

You'll want to make Lrc a more realistic value; something like 15 cm. Change Fr to 40 and Tal to something like 2.54 cm. This will account for some acoustic stuffing in the rear chamber.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Best 8" to 12" driver for 130hz tractrix horn