Woofer Tester 2

I assume you could run an impedance curve using it.

dirkwright, Hornresp appears to be good within its limitations, and those limitations are fairly well documented.

Can I ask what it is you are looking for when you decide what the rear volume should be?

You should probably ask JLH, since he believes he knows everything about this subject.

I designed a 70Hz hyp-ex (m=0.7) straight horn using the EVM15L driver back in 1992 using simple MathCAD and it appeared to work perfectly using the formulas I had at the time. The only thing unique about it was that the aspect ratio was constant throughout the length of the horn. Yes, the sealed rear chamber was from the known calculations. I was satisfied so did not build any more horns. I'm not in the horn building business.

So, I guess Bruce Edgar is nobody? You might want to brush up on your horn history.

I met Bruce in person in 1991 or so. I don't necessarily believe everything he says. He's a great guy and I like him a lot.

That is the difference between us, I'm not expressing an opinion, I'm presenting facts from actual builds. Not only from my own builds, but from other sources as well.

As far as I'm concerned, you have not presented any facts at all. You've only said that in yours and others experience, the Keele and Leach formulas for determining rear chamber volume are wrong. You've provided no mathematical proof that they are wrong. If you believe there is an error in their formulas, then you should come up with mathematical proof and then write a paper and submit it to the JAES for review. You should make a positive contribution to the engineering of acoustical horns instead of just sitting back and saying the existing formulas are wrong.

As far as I'm concerned, you have not presented any facts at all. You've only said that in yours and others experience, the Keele and Leach formulas for determining rear chamber volume are wrong. You've provided no mathematical proof that they are wrong. If you believe there is an error in their formulas, then you should come up with mathematical proof and then write a paper and submit it to the JAES for review. You should make a positive contribution to the engineering of acoustical horns instead of just sitting back and saying the existing formulas are wrong.

Ok this is just getting out of order .

(i) It's not up to John to put out a mathematical proof to please you . It's enough that he has build horns and gathered practical evidence of how they behave. Maybe John isn't a mathematician , most people are not .

(ii) Oh, John should 'make a positive contribution to the engineering of acoustical horns' - as opposed to what he's been doing for the last 15 years then , eh ?

Really ....

Resonance

Well JLH, I'm still struggling to get useful resonance data out of my system .

I fitted and sculpted some closed-cell polystyrene to my box ( 5.2L empty ) last night , reckon I got below 2L of free space with the driver fitted .

Testing with my solid-state Pass F4 amp , and a 270R series resistor , meter across the speaker , I could get some sort of minor 'blip' around 200Hz, then nothing until a broad impedance peak around 55Hz , well below the horn's range.

If I then try the Romy trick of opening up a gap on one side of the enclosure , I can see the impedance peak move slowly to 65Hz, 70Hz and then back to 80Hz with it completely taken off . Nowhere do I see a peak in the 100-150Hz range. It's most peculiar .

I'm expecting the peak to be reasonably obvious, if it's there, right ?

Maybe the polystyrene isn't dense enough ?

What I will do at the weekend is get some of that hard-setting spray foam and try to get a really small volume and work from there .

Well JLH, I'm still struggling to get useful resonance data out of my system .

I fitted and sculpted some closed-cell polystyrene to my box ( 5.2L empty ) last night , reckon I got below 2L of free space with the driver fitted .

Testing with my solid-state Pass F4 amp , and a 270R series resistor , meter across the speaker , I could get some sort of minor 'blip' around 200Hz, then nothing until a broad impedance peak around 55Hz , well below the horn's range.

If I then try the Romy trick of opening up a gap on one side of the enclosure , I can see the impedance peak move slowly to 65Hz, 70Hz and then back to 80Hz with it completely taken off . Nowhere do I see a peak in the 100-150Hz range. It's most peculiar .

I'm expecting the peak to be reasonably obvious, if it's there, right ?

Maybe the polystyrene isn't dense enough ?

What I will do at the weekend is get some of that hard-setting spray foam and try to get a really small volume and work from there .

Ok this is just getting out of order .

(i) It's not up to John to put out a mathematical proof to please you . It's enough that he has build horns and gathered practical evidence of how they behave. Maybe John isn't a mathematician , most people are not .

(ii) Oh, John should 'make a positive contribution to the engineering of acoustical horns' - as opposed to what he's been doing for the last 15 years then , eh ?

Really ....

I'm not asking him to please me. I'm saying that if he has proof that the equations do not work, then he could make a positive contribution to the professional engineering world with an article about it. If he's provided a formula for determining the rear chamber volume that works, then I've missed it. I apologize if that is the case.

Fireside Chat

DW,

If you are an AES member, you may post comments on papers published there directly at the website.

Do not feel alone, unsolicited negatives and other forms of offensive nonsense are to be found on any forum. However, participation does not require that you tolerate it at all. Most of the time, such discourse is an easy target to shoot at without missing. I particularly “love the smell of napalm in the morning”.

Regards,

WHG

As far as I'm concerned, you have not presented any facts at all. You've only said that in yours and others experience, the Keele and Leach formulas for determining rear chamber volume are wrong. You've provided no mathematical proof that they are wrong. If you believe there is an error in their formulas, then you should come up with mathematical proof and then write a paper and submit it to the JAES for review. You should make a positive contribution to the engineering of acoustical horns instead of just sitting back and saying the existing formulas are wrong.

DW,

If you are an AES member, you may post comments on papers published there directly at the website.

Do not feel alone, unsolicited negatives and other forms of offensive nonsense are to be found on any forum. However, participation does not require that you tolerate it at all. Most of the time, such discourse is an easy target to shoot at without missing. I particularly “love the smell of napalm in the morning”.

Regards,

WHG

DW,

If you are an AES member, you may post comments on papers published there directly at the website.

Do not feel alone, unsolicited negatives and other forms of offensive nonsense are to be found on any forum. However, participation does not require that you tolerate it at all. Most of the time, such discourse is an easy target to shoot at without missing. I particularly “love the smell of napalm in the morning”.

Regards,

WHG

No, I am not a member. I do not feel qualified to join. I'm a mechanical engineer, not a PhD in EE. I'm just pointing out that there is an opportunity here for JLH to make a positive difference if in fact he's found an error in the rear chamber calculations.

My off hand, top of the head, back of the envelope idea is that the equations only apply to straight horns that are radiating into precisely the space for which they were designed. The equations may also only be appropriate to full size horns as well, I don't know. There could be many reasons why the equations do not "work" in the real world.

Well JLH, I'm still struggling to get useful resonance data out of my system .

I fitted and sculpted some closed-cell polystyrene to my box ( 5.2L empty ) last night , reckon I got below 2L of free space with the driver fitted .

Testing with my solid-state Pass F4 amp , and a 270R series resistor , meter across the speaker , I could get some sort of minor 'blip' around 200Hz, then nothing until a broad impedance peak around 55Hz , well below the horn's range.

If I then try the Romy trick of opening up a gap on one side of the enclosure , I can see the impedance peak move slowly to 65Hz, 70Hz and then back to 80Hz with it completely taken off . Nowhere do I see a peak in the 100-150Hz range. It's most peculiar .

I'm expecting the peak to be reasonably obvious, if it's there, right ?

Maybe the polystyrene isn't dense enough ?

What I will do at the weekend is get some of that hard-setting spray foam and try to get a really small volume and work from there .

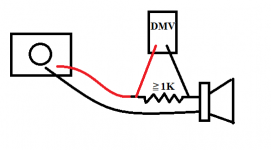

The peak should be very obvious. Try using a 1K series resistor and place your voltmeter across the resistor. Slowly sweep up in frequency starting at something like 30Hz. Also, you don't need much voltage, something like 150mV AC will work just fine. If you are doing this with your tube amp, then I'd suggest just trying with your function generator directly or get a small solid state amp.

I’ll renege on my non-reply statement this one time only. There is no opportunity for some new miraculous formula for back chamber volumes. While Leach’s formula is mathematically correct for its intended purpose, it cannot address all the other variables that would otherwise alter the real world results. In addition, it does not apply to the tractrix, but more suitably to the hyperbolic-exponential horn. I have a fifth order polynomial that when solved simultaneously with 6 horn variables predicted the tractrix back chamber volume within a +/- 12% error. However, it was very limited because it fell apart once the horn was outside a 105Hz to 160Hz flare rate. It also fell apart if the room volume or boundaries changed. I derived it from the multiple tractrix horns I built and tested in this size range. While it was somewhat interesting, for all practical purposes it was useless and a tremendous waste of time. The type of detail and the number of variables required to address all horns would be so complex it would be too monotonous to use.

Is there an opinion on the throat entry angle?

The design I'm beginning to settle on has a 6 degree half angle. I would assume it should be 0 degrees but I don't see why I should assume anything. Without treating the throat area (such as a phase plug) I don't want to guess.

Edit: Is a flat baffle with a hole (that has sharp edges) good in this range? Is there some simple throat chamber treatment that is worth the effort?

The design I'm beginning to settle on has a 6 degree half angle. I would assume it should be 0 degrees but I don't see why I should assume anything. Without treating the throat area (such as a phase plug) I don't want to guess.

Edit: Is a flat baffle with a hole (that has sharp edges) good in this range? Is there some simple throat chamber treatment that is worth the effort?

Last edited:

Is there an opinion on the throat entry angle?

The design I'm beginning to settle on has a 6 degree half angle. I would assume it should be 0 degrees but I don't see why I should assume anything. Without treating the throat area (such as a phase plug) I don't want to guess.

Edit: Is a flat baffle with a hole (that has sharp edges) good in this range? Is there some simple throat chamber treatment that is worth the effort?

If we are still talking about cone loaded horns, then the throat angle is not all that critical. Generally you would allow the throat angle to be whatever the horn expansion dictates at the throat. Now, if you are dealing with compression drivers that have a machined throat built into them, then you want to match this angle and then transition as smoothly into your horn expansion. Really large changes in angles near the throat are the primary cause of higher order modes (HOM). Earl Geddes has studied this and is probably the most qualified to comment on it.

In addition, if you are designing a phase plug yourself, then you can make the throat angle whatever you like. If you design it such that your horn mates directly to the output of the phase plug, the throat can be any reasonable angle. This is because a phase plug doesn't really have its own angle.

I normally do not leave the sharp edge on the baffle piece. I would knock it down with some sandpaper, or give it a small roundover with my router.

Last edited:

No luck

Tried everything I can think of so far.

Built a bigger back chamber ( 7L ) then filled it to create a really small back-chamber .

Cannot get a resonance peak to appear . Only way I've seen one so far is without a back-chamber .

see :

audio-talk :: View topic - Something stirs in the Undergrowth

Given up & waiting for the Fane drivers now. Hopefully with them something will start to make sense.

Tried everything I can think of so far.

Built a bigger back chamber ( 7L ) then filled it to create a really small back-chamber .

Cannot get a resonance peak to appear . Only way I've seen one so far is without a back-chamber .

see :

audio-talk :: View topic - Something stirs in the Undergrowth

Given up & waiting for the Fane drivers now. Hopefully with them something will start to make sense.

Hey Mark,

Haven´t followed this thread all the way. But I guess you measure the resonant peak without horn, only with box?

Haven´t followed this thread all the way. But I guess you measure the resonant peak without horn, only with box?

Lars

How am I going to measure the resonant peak without the horn ?

The box fits over the back of the driver, attaching to the horn rear flange.

We're looking for the resonance of the system, surely ?

How am I going to measure the resonant peak without the horn ?

The box fits over the back of the driver, attaching to the horn rear flange.

We're looking for the resonance of the system, surely ?

There has to be something wrong. I just setup a quick measurement check with one of my 8PE21 woofers and it worked fine. I tested it in free air and unmounted. I set my function generator to 500Hz and adjusted the voltage output so that 2 VAC was accross the 1K resistor. I then slowly turned the frequency down while watching the voltmeter. You are looking for the lowest dip accross the resistor. For me it dipped the lowest at 97Hz. If I continue to reduce the frequency the voltage accross the resistor comes back up. Make sure you are going VERY, VERY slowly. The dip is very narrow.

Attachments

You can do either. The goal is to get the resonance at the right place. But off course it must be the combined result that counts. The reactance annuling idea is to have the horn and driver-in-chamber resonace to coincidence. But I think JLH found the chamber should have a slightly lower resonance-point.

Yes

Yes, well I've measured as shown and with voltmeter across the driver. The dip becomes a peak when you measure across the driver, and is more obvious, as long as you feed enough volts into the combination. The high output impedance just means the voltage across the driver tracks the impedance - I understand this .

As I said earlier, I was able to easily measure the driver+horn resonance without the back-chamber - this was 80Hz . It was obvious and quite sharp . I can measure the driver alone at some stage just for completeness if you like . I can measure the other ( not run-in ) driver this evening .

Now the problem is that I lose any form of resonant peak in the expected area once a chamber of ANY size is attached over the driver. I've scanned widely and I've scanned slowly . It's not as if there's a 'bit of a ripple' or a small peak or dip or anything - there is NOTHING ...other than a broad peak lower down, around 50 or 60, which must be something else.

JLH - have you ever measured the 8PE21 on anything other than a full (90deg) mouth tractrix ? I wonder if there is some kind of non-theory deviation from the hornresp model in this case ?

Hopefully I will have the Fanes in a week or two and I can get more data .

Yes, well I've measured as shown and with voltmeter across the driver. The dip becomes a peak when you measure across the driver, and is more obvious, as long as you feed enough volts into the combination. The high output impedance just means the voltage across the driver tracks the impedance - I understand this .

As I said earlier, I was able to easily measure the driver+horn resonance without the back-chamber - this was 80Hz . It was obvious and quite sharp . I can measure the driver alone at some stage just for completeness if you like . I can measure the other ( not run-in ) driver this evening .

Now the problem is that I lose any form of resonant peak in the expected area once a chamber of ANY size is attached over the driver. I've scanned widely and I've scanned slowly . It's not as if there's a 'bit of a ripple' or a small peak or dip or anything - there is NOTHING ...other than a broad peak lower down, around 50 or 60, which must be something else.

JLH - have you ever measured the 8PE21 on anything other than a full (90deg) mouth tractrix ? I wonder if there is some kind of non-theory deviation from the hornresp model in this case ?

Hopefully I will have the Fanes in a week or two and I can get more data .

IslandPink,

Yes, I've measured them on a 85Hz exponential midbass horn. On this and all the other horns it has been just as obvious as it when you measure the woofer in free air. See how small the rear chamber is on the 142Hz tractrix loaded with the Fane 8M. I further reduced the chamber size with foam and then added a little bit of acoustic filling. The volume was under 1 liter and set the resonance to about 125Hz. I'm not sure what to advise at this point. This is very odd behavior I've never seen before. Something has to be wrong.

Yes, I've measured them on a 85Hz exponential midbass horn. On this and all the other horns it has been just as obvious as it when you measure the woofer in free air. See how small the rear chamber is on the 142Hz tractrix loaded with the Fane 8M. I further reduced the chamber size with foam and then added a little bit of acoustic filling. The volume was under 1 liter and set the resonance to about 125Hz. I'm not sure what to advise at this point. This is very odd behavior I've never seen before. Something has to be wrong.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Best 8" to 12" driver for 130hz tractrix horn