While I am waiting for the epoxy to arrive I fiddle my thumbs...

Last nite I spent a little time with my mk1´s and enjoying them, couldnt pass by the chance to set mk1 and mk2 side-by-side.

Less is more, unless you stand next to one with more - then less just look stupid

BTW - the epoxy should arrive some time mid-week so I hope I manage a pour before I leave for the weekend

Last nite I spent a little time with my mk1´s and enjoying them, couldnt pass by the chance to set mk1 and mk2 side-by-side.

Less is more, unless you stand next to one with more - then less just look stupid

BTW - the epoxy should arrive some time mid-week so I hope I manage a pour before I leave for the weekend

Attachments

First cabinet is cast, it took 45kg of EG (Sand and 12% epoxy) and 6hrs in total. My rig for vibration wasnt powerful enough to make the EG mix "liquify" so I had to manually compact the mix. A 12% EG mix appear quite dry, like moist sand.

Weight of one cabinet is now 70kg. Weight / moving mass ratio is already past 1200:1

So now I hope it all cures good, the oval piping will be removed on Monday if it does. If it doesnt.....

Weight of one cabinet is now 70kg. Weight / moving mass ratio is already past 1200:1

So now I hope it all cures good, the oval piping will be removed on Monday if it does. If it doesnt.....

Attachments

Last edited:

From yesterday to this morning the mix has firmed up a fair bit so its curing along - so it should be alright. Curing is stated to need 24-72hrs depending on temperature and extent of exothermal reaction. But with sand in the mix there wont be much help from the exotermal reaction (heat build-up during curing).

I am travelling away for the weekend so the cabinet is left alone, with heater on, untill Sunday and should be rock hard by then.

Obvously I did a "knock-test" on it, its like knocking a rock (with wood exteriour)

With epoxy, as long as the epoxy and hardener is good and mixed to right proportions (by weight) and stirred apropriately, curing will be fine - eventually

I am travelling away for the weekend so the cabinet is left alone, with heater on, untill Sunday and should be rock hard by then.

Obvously I did a "knock-test" on it, its like knocking a rock (with wood exteriour)

With epoxy, as long as the epoxy and hardener is good and mixed to right proportions (by weight) and stirred apropriately, curing will be fine - eventually

Last edited:

Yeah, its pretty decent - there are a few holes in thin internal thin walls of the EG, areas where I didnt manage to compact it good enough (or too much too fast) but those are easy to seal.

Here is an informal "tap test" between mk1 and mk2, mk1 is all sealed up and stuffed, mk2 is open on both ends.

You can hear the "tap" is higher in pitch and not as loud.

Video: Mk1 and Mk2 tap test

Here is an informal "tap test" between mk1 and mk2, mk1 is all sealed up and stuffed, mk2 is open on both ends.

You can hear the "tap" is higher in pitch and not as loud.

Video: Mk1 and Mk2 tap test

Just minor progress over the weekend, I have filled the interal wall holes that were present due to insufficient packing of the EG-matrix.

Plans for the coming week:

Plans for the coming week:

- Cast the chamber rear wall - aka an "EG-puck" for each chamber

- In this puck there will be a straw where the speaker wires can pass through

- Prepare the felt and start lining the chamber walls

"A single image is worth a 1000 words..."

The stages I am currently at dont give much visual update, it just looks like the cabinet thats been done for a while now (just heavier,much heavier..)

Hence not much imagery posted...

So plans for today is to make the final cast of EG on the first cabinet, sealing of the rear wall. Then I will quickly start lining the chambers and install all the wiring

If all goes well this first speaker might produce sound this weekend...

Then I can start lining up and casting the 2nd cabinet

The stages I am currently at dont give much visual update, it just looks like the cabinet thats been done for a while now (just heavier,much heavier..)

Hence not much imagery posted...

So plans for today is to make the final cast of EG on the first cabinet, sealing of the rear wall. Then I will quickly start lining the chambers and install all the wiring

If all goes well this first speaker might produce sound this weekend...

Then I can start lining up and casting the 2nd cabinet

I have a group of 3-4 chambers that sound "hollow" when I tap their back wall (EG puck). It appear that the plate used to line the rear openings, have bent away a few mm for some reason, allowing more of the EG-mass to flow out/up against the side walls. This leave less EG-mass for thickness and apparently didnt seat it fully.

For the time being I will not do anything about this but will see on the impedance sweeps if further action is required. The fix should be straight forward, simply hammer the weak ones out and re-cast. Will investigate.

All chambers are now lined with felt and filled with 10g each with stuffing.

So next job is to temporarely mount the drivers and hook it the first line up

For the time being I will not do anything about this but will see on the impedance sweeps if further action is required. The fix should be straight forward, simply hammer the weak ones out and re-cast. Will investigate.

All chambers are now lined with felt and filled with 10g each with stuffing.

So next job is to temporarely mount the drivers and hook it the first line up

I think you are on to something with these cabinets. But maybe you should have made them with a roundover - at least on the front. Diffraction is a bi**h.

This way is definitely inspiration for my next build. Think I will try the new SB 3". Maybe skip the glue and go all in fiber concrete...

//

This way is definitely inspiration for my next build. Think I will try the new SB 3". Maybe skip the glue and go all in fiber concrete...

//

Last edited:

But maybe you should have made them with a roundover - at least on the front. Diffraction is a bi**h.

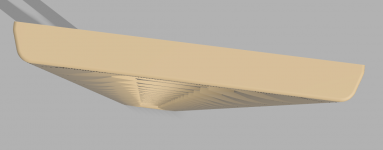

You mean like this? (see pic, front baffle top with bevelled and rounded edges)

Thank you for the kind words, I hope my project will be worth it i

One note against concrete - it never stop to cure and it will shrink during this process. Fiber reinforcement or aggregate will reduce this.

Its said that concrete shrink about 12mm over a 9m span and it dont take much to split/release from a weak surface.

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- HalAir Aeralis - Fullrange Line Array (Vifa TC9-18-08)