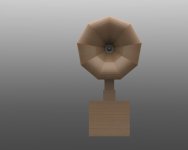

Intriguing...well done.Wow amazing stuff. I’m using the TPL-150H with the B&C 12PE32 as a 2-way in my smaller listening room. I’ve done a couple of different custom horns for this driver. One was a little bi-radial using the JMLC flare in both axis. The vanes kept the wavefront time aligned to reduce cancelation effects.

I've used the TPL150 in two previous projects.

1. Beyma Three-Way "World Beater", based on the Mark Levinson / Daniel Hertz $100,000 M1 system. I used curved birch ply, CNC'd...plus designed dedicated tweeter horn. 800 watt MiniDSP amp for the bass, and LR2 passive for the mid/tweeter. Good output.

2. Dual SB Acoustic 8 inch with TPL150...slim birch cabinet.

I also CNC the Yuichi 290S. (The big bass front loaded horn is also my design, using CNC CAD, for Altec 416/515 woofer.)

We're kindred spirits.

Kind regards.

Attachments

-

IMG_4075 v2.jpg80.8 KB · Views: 677

IMG_4075 v2.jpg80.8 KB · Views: 677 -

rear plates.png503 KB · Views: 281

rear plates.png503 KB · Views: 281 -

post-142611-0-17073000-1415444318.jpg151.5 KB · Views: 322

post-142611-0-17073000-1415444318.jpg151.5 KB · Views: 322 -

59242908d5c45_frontfinished2_jpg_24f2cc99a6a6b044a95fefc990e097ea.jpg59.3 KB · Views: 671

59242908d5c45_frontfinished2_jpg_24f2cc99a6a6b044a95fefc990e097ea.jpg59.3 KB · Views: 671 -

IMG_4071.JPG91 KB · Views: 667

IMG_4071.JPG91 KB · Views: 667 -

hi fi rack in home.jpg999.7 KB · Views: 669

hi fi rack in home.jpg999.7 KB · Views: 669 -

tweeter wood horn.jpg68.9 KB · Views: 710

tweeter wood horn.jpg68.9 KB · Views: 710

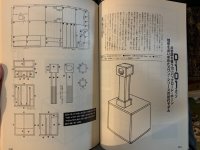

How is it coming along and what happened with your ES-300/FE108EZ? YouTubeI have plans for a 300Hz JMLC x9 pedal wood horn that can use 4”-5” fullrange drivers. I’m currently waiting for the FE126EN on back order from Solen.

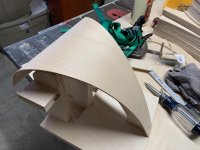

The outside diameter is 24”. It uses bent plywood by soaking in hot water for five minutes. Two layers of 3mm thick Baltic Birch Plywood for the Horn walls.

Flat packs will be available July timeframe. The plans are complete but I’m validating the design once the drivers arrive. It would ideally be suited to use a wood phase plug (see photo).

I purchased a RouterParts Pro Benchtop CNC router which arrives mid May. I’m very excited to start using this machine!

Do you still plan on offering flat packs, and if so, estimated ETA on them?

Also, and this may be nuts, but I can't help wonder about the possibility of mounting your ES-300/FE108EZ to a Nagaoka D-100 Swan Horn, altering the swan neck to slant backward thus for accommodating the ES-300 front horn closer in and over the lower horn chambers??? Untitled Document

Last edited:

How is it coming along and what happened with your ES-300/FE108EZ? YouTube

Do you still plan on offering flat packs, and if so, estimated ETA on them?

Also, and this may be nuts, but I can't help wonder about the possibility of mounting your ES-300/FE108EZ to a Nagaoka D-100 Swan Horn, altering the swan neck to slant backward thus for accommodating the ES-300 front horn closer in and over the lower horn chambers??? Untitled Document

Hi Mp9, actually I spent all day yesterday working on it. It's my number one priority since I'm so excited about it. The build is going slow since I'm doing a video at the same time to walk through each step. I'm also making minor changes and updating the drawings as I go. The bending fixture worked the first try, but the ratchet straps are a little unwieldy so I need to fasten the ratchet mechanisms directly to the fixture so they stay put. The Fostex FE126EN's arrive Monday. I'll be testing with these drivers and posting measurements, (coloured polar map, Frequency Response, Spectrogram/Waterfall Decay Response, impedance curve, sensitivity@1watt)....

Fostex FE126EN

Fostex FE108EZ

MarkAudio Alpair7.3eN (with Planet 10 EnABL)

Your idea on the swan is a great one. I'll draw it up and see what it look like. I have all the Nagaoka books as well and I'll take a peruse and see if anything else jumps out at me.

Here is a picture of the pedal in the bending fixture to give you sense of what it will look like. The youtube video you linked to had me kerfing the backside to get the wood to bend. I didn't like the segments left by the kerfing so I continued to experiment. I found that 3mm plywood will bend to the desired radius. So I'm going to use two layers on each pedal...so 6mm thick total.

Attachments

Here is a video for the bending fixture.

http://https://www.instagram.com/p/BxB2ek8gshw/?utm_source=ig_share_sheet&igshid=2bs246ftbt7a

http://https://www.instagram.com/p/BxB2ek8gshw/?utm_source=ig_share_sheet&igshid=2bs246ftbt7a

Yes, actually was going to suggest just that, it's more like the way grand pianos are made.Here is a picture of the pedal in the bending fixture to give you sense of what it will look like. The youtube video you linked to had me kerfing the backside to get the wood to bend. I didn't like the segments left by the kerfing so I continued to experiment. I found that 3mm plywood will bend to the desired radius. So I'm going to use two layers on each pedal...so 6mm thick total.

Keep up the good work!

Hi Mp9, actually I spent all day yesterday working on it. It's my number one priority since I'm so excited about it. The build is going slow since I'm doing a video at the same time to walk through each step. I'm also making minor changes and updating the drawings as I go. The bending fixture worked the first try, but the ratchet straps are a little unwieldy so I need to fasten the ratchet mechanisms directly to the fixture so they stay put. The Fostex FE126EN's arrive Monday. I'll be testing with these drivers and posting measurements, (coloured polar map, Frequency Response, Spectrogram/Waterfall Decay Response, impedance curve, sensitivity@1watt)....

Fostex FE126EN

Fostex FE108EZ

MarkAudio Alpair7.3eN (with Planet 10 EnABL)

Your idea on the swan is a great one. I'll draw it up and see what it look like. I have all the Nagaoka books as well and I'll take a peruse and see if anything else jumps out at me.

@Joseph Crowe:

Very interested of the 300hz horn.

Any progress and how does the; ”(coloured polar map, Frequency Response, Spectrogram/Waterfall Decay Response, impedance curve, sensitivity@1watt)” look like?

/Pepe

@Joseph Crowe:

Very interested of the 300hz horn.

Any progress and how does the; ”(coloured polar map, Frequency Response, Spectrogram/Waterfall Decay Response, impedance curve, sensitivity@1watt)” look like?

/Pepe

The ES-300 petal horn is documented here...

Joseph Crowe's DIY Speaker Building Blog: ES300 Front Horn + Fostex FE126En

If you have access to a CNC then this would be the preferred construction method.

Troy Joseph Crowe on Instagram: “Conceptually an interesting new approach to machining large horns. Expect to see more of this in upcoming projects. Design Features:…”

I would suggest having the horn designed to suit your driver. I can offer this service as well as the CAM programming, and/or cutting.

Here is a video for the bending fixture.

http://https://www.instagram.com/p/BxB2ek8gshw/?utm_source=ig_share_sheet&igshid=2bs246ftbt7a

Nice jig for bending the curves. Do you cut the long axis edge bevels before you bend?

I'm building multi-cell horns from wood, Altec 1505, WE 26, etc. It's very easy to use a 90 degree pattern bit in the router table to cut the 45 degree bevels when there are only 4 'petals'

I've been enjoying your videos and posts on your site lately, keep it up!

Tried to contact

I tried contacting through your site. I need plans but cutsheet. I want to hand make. Please contact me. Summer rain looks pretty badass. Mike

This is a shameless plug but I can certainly help...I offer front horns plans on my website. I include the AutoCAD files as well.

I have a growing number of different designs, and I can customize to your needs since I’m an avid Solidworks user able to do flat shapes from bent wood designs.

Summer Rain Front Horn for BG Neo8, flat response from 180Hz -20kHz

Mini Version (25% smaller) 280Hz -20kHz

Or

Summer Rain Front Horn using 8” diameter driver...180Hz - 3kHz (driver dependant).

Summer Rain Front Horn Drawing Package – Joseph Crowe

What bandwidth of horn are you looking for? I recently built a small Yuichi biradial that uses the Beyma TPL-150.

I tried contacting through your site. I need plans but cutsheet. I want to hand make. Please contact me. Summer rain looks pretty badass. Mike

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Front loaded wood horn Plans